Small load impact wear testing machine

A technology of wear test and load, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of low degree of automation, low measurement accuracy, large impact force, etc., and achieve high degree of automation and data repeatability High, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

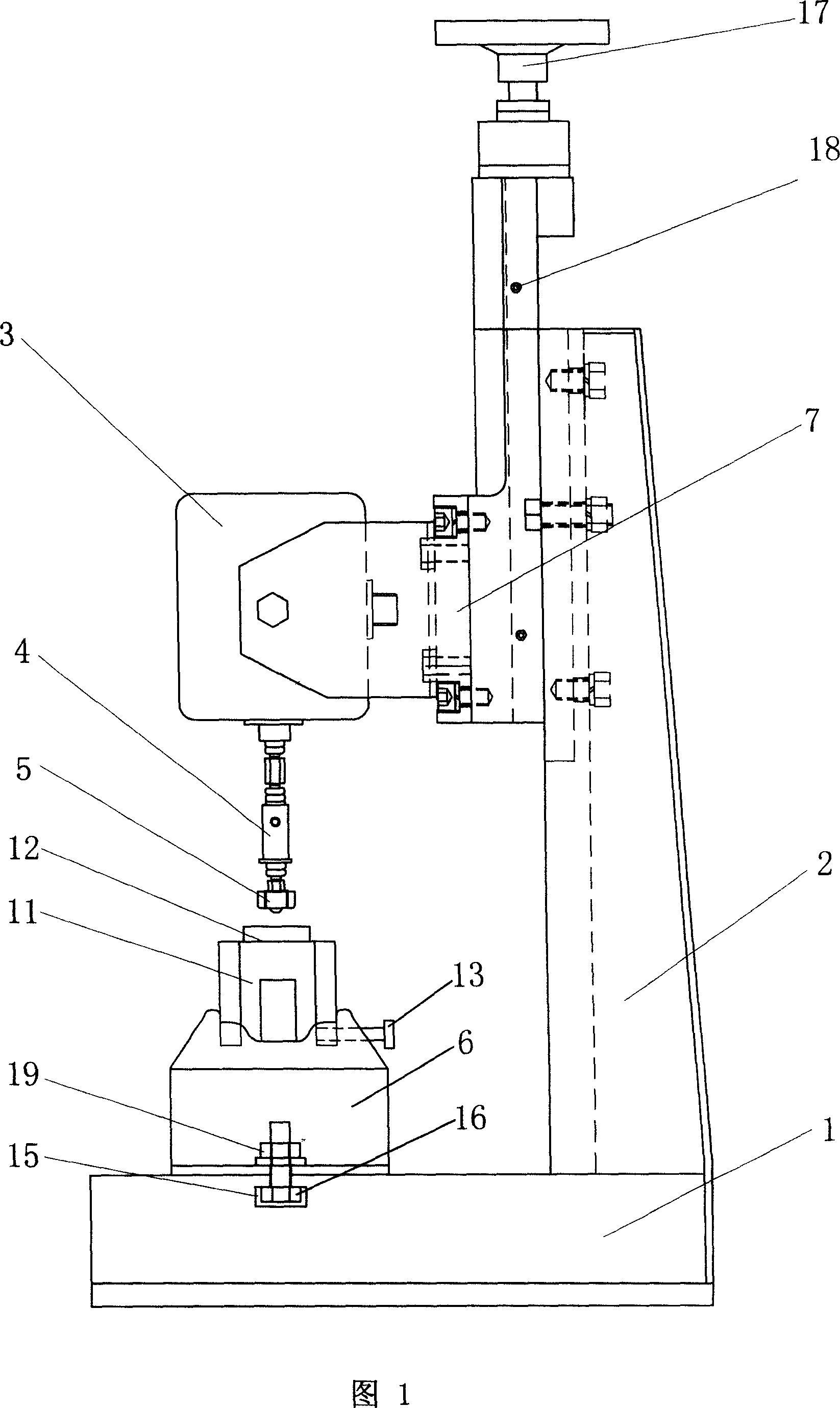

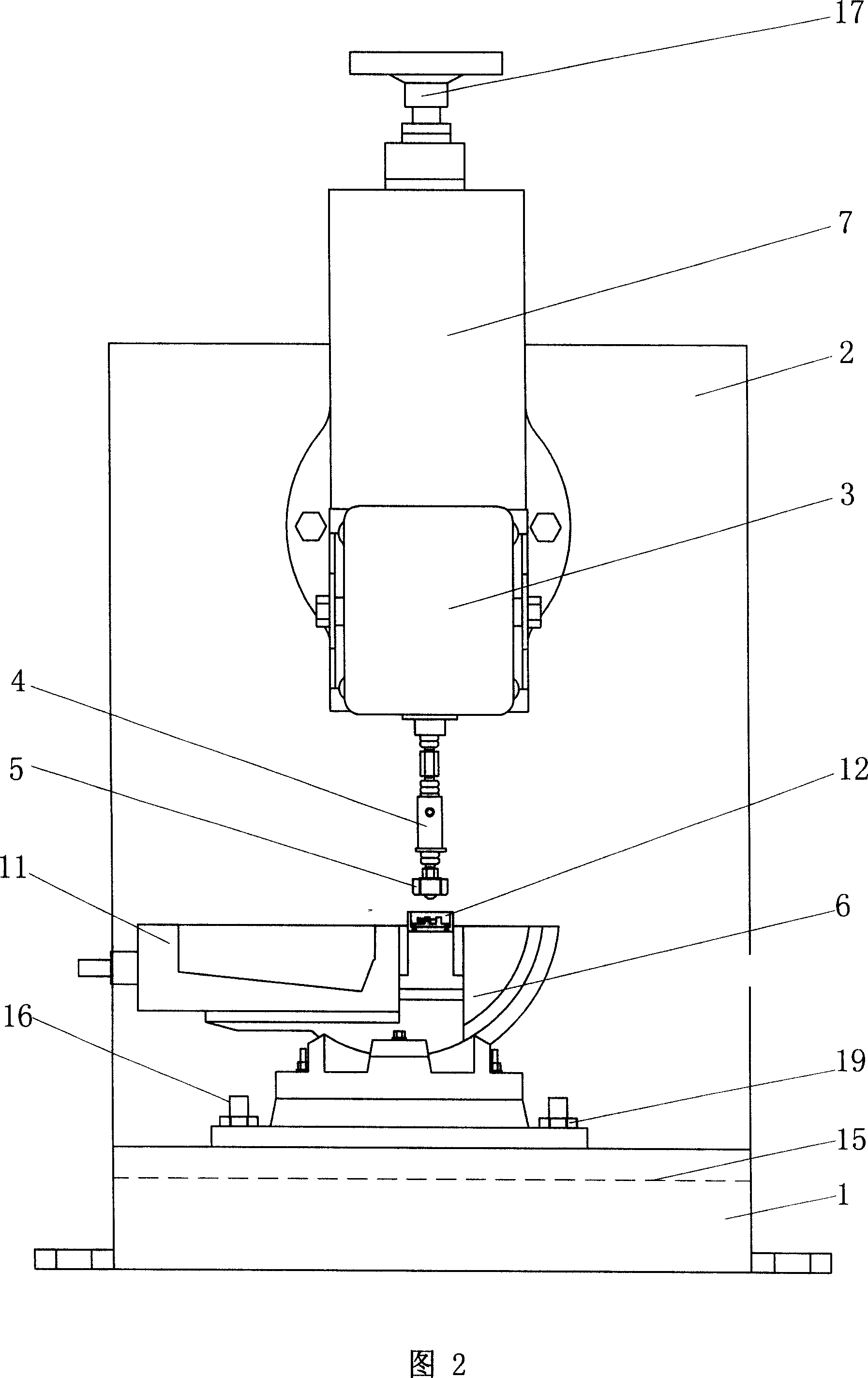

[0024] Figures 1 and 2 show that a specific embodiment of the present invention is: a small load impact wear tester, which is characterized in that: a vertical plate 2 is fixed at the rear of the base 1, and a vibrator 3 with the push rod downward Installed in front of the upper part of the vertical plate 2, the end of the ejector rod of the vibrator 3 is sequentially connected to the piezoelectric impedance sensor 4 and the upper sample holding device 5; the base 1 is located below the upper sample holding device 5, and is fixed with Lower sample holding device 6.

[0025] The specific structure of the vibrator 3 installed on the vertical plate 2 is as follows: the upper front of the vertical plate 2 is equipped with a goose tail groove slide plate 7 that can slide up and down, and the vibrator 3 is installed and fixed on the goose tail groove slide plate 7; 7 is provided with a spiral lifting mechanism 17 and a slide plate locking screw 18.

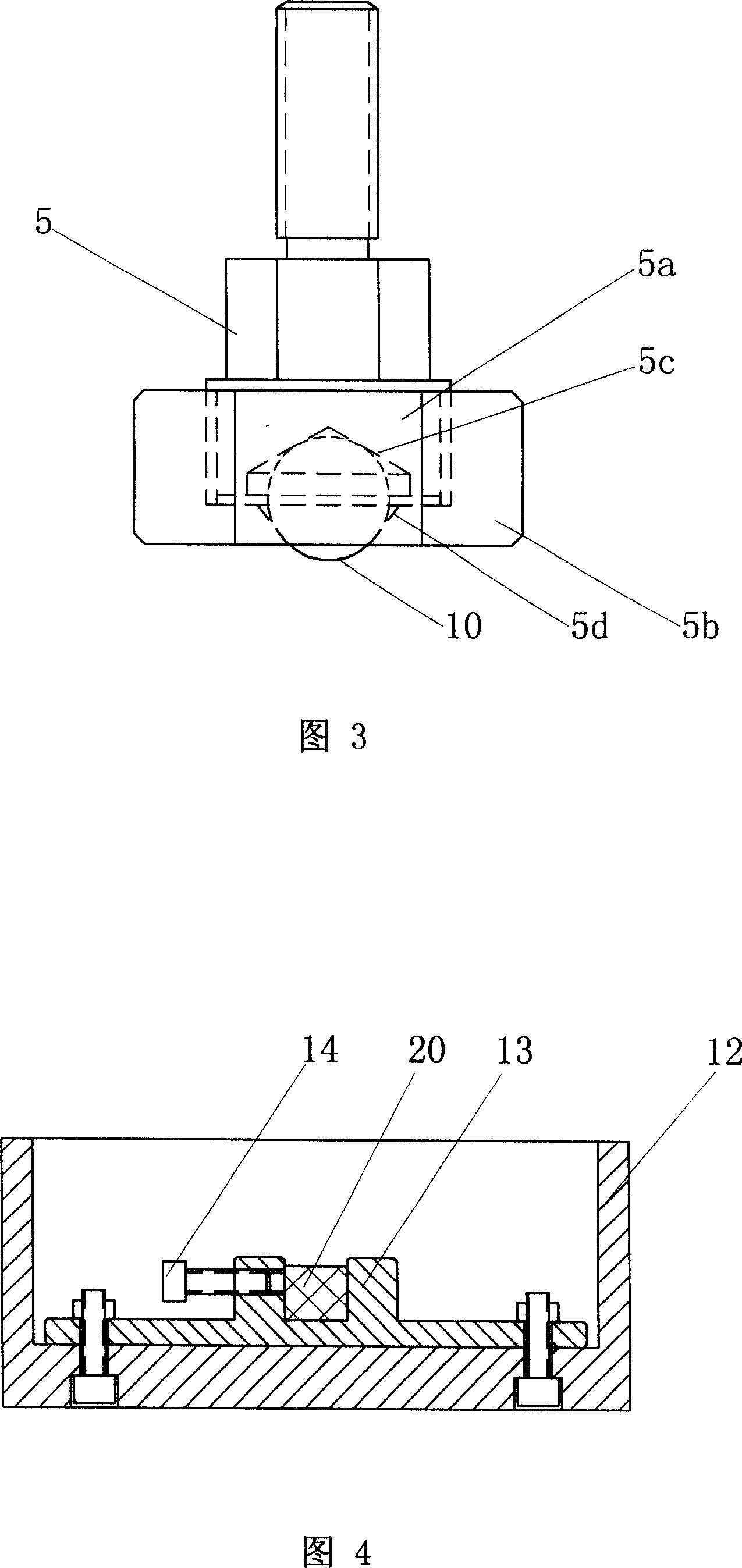

[0026] Figures 1-3 show that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com