Reciprocal and rotary type incorporated frictional wear test machine

A friction and wear, testing machine technology, applied in the direction of testing wear resistance, etc., can solve the problems of increasing the space occupied by equipment, increasing equipment investment, increasing the workload of experimenters, etc., to achieve the effect of ensuring accuracy, stable and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

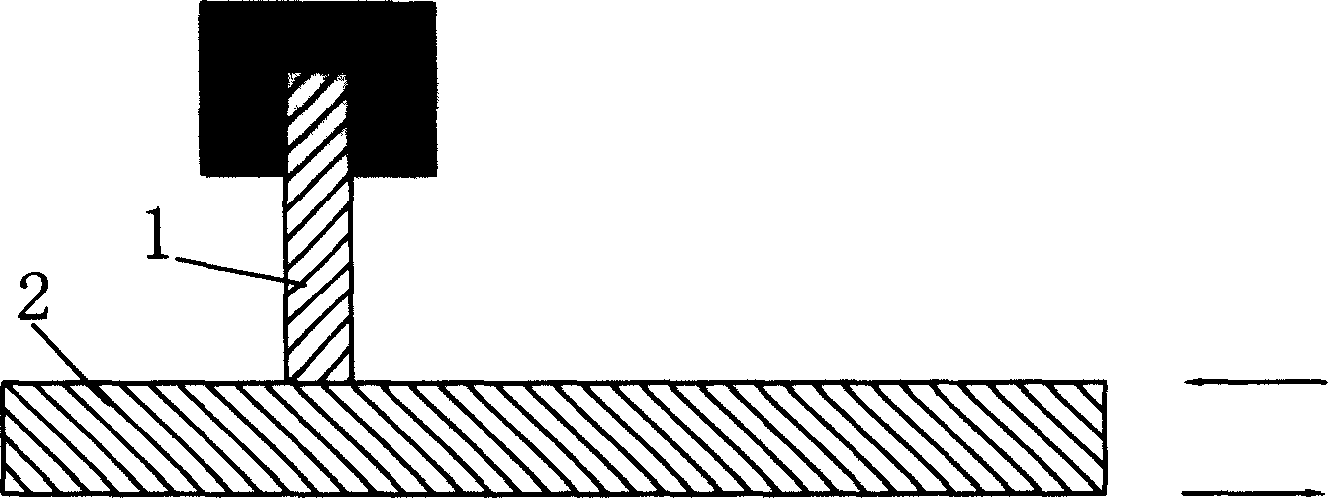

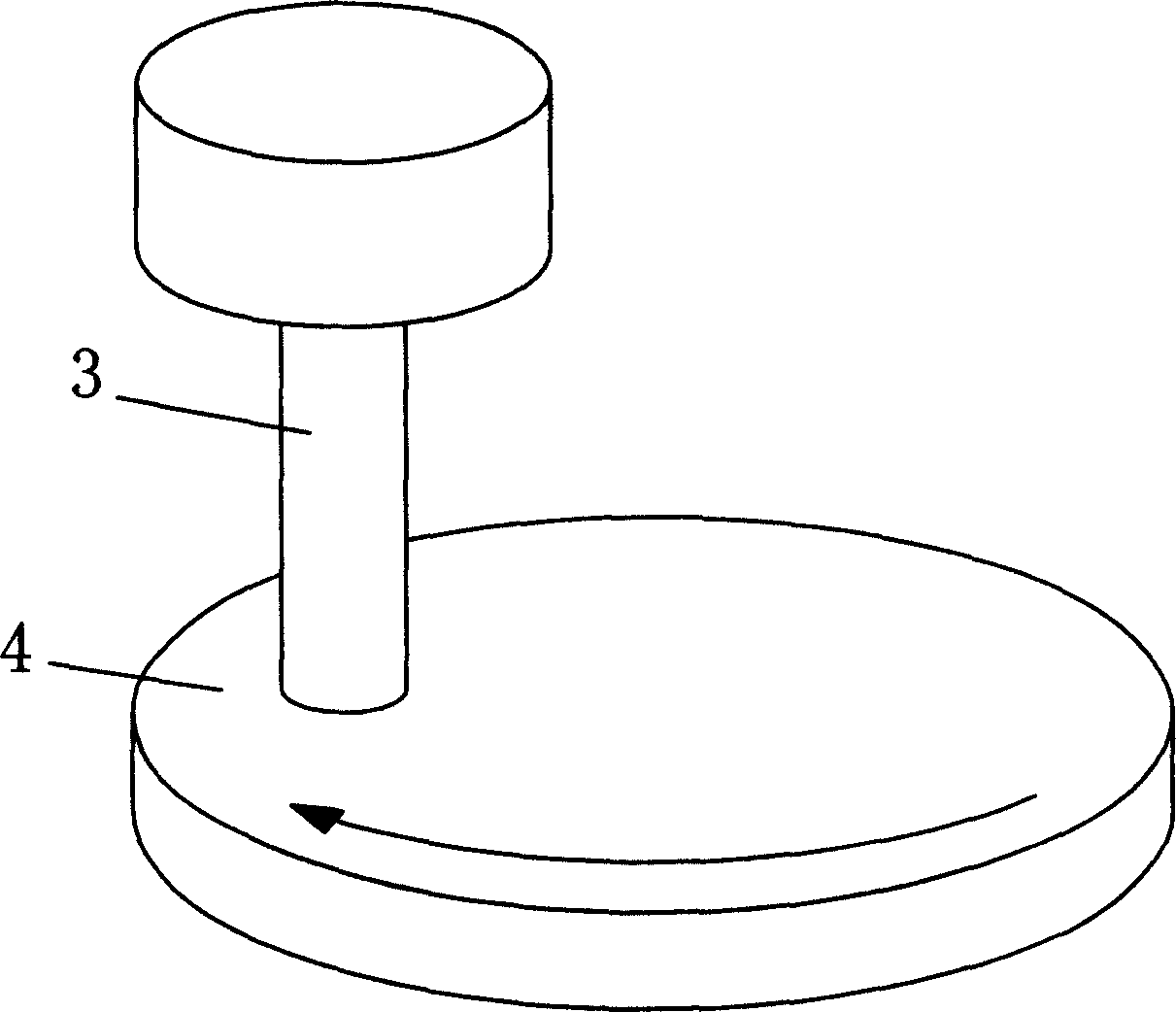

[0026] Such as figure 1 Shown is a schematic diagram of reciprocating friction, the upper sample 1 is fixed, and the lower sample 2 is reciprocating horizontally. figure 2 It is a schematic diagram of rotating friction. The upper sample 3 is fixed, and the lower sample 4 rotates. A certain normal load N is applied to the upper sample 1 and the upper sample 3. The friction force F is generated during friction, and its magnitude is determined by F =N*f, f is the friction coefficient. Under the same working condition, the measured results of different pairs of friction pairs are comparable. The so-called "same working condition" refers to the same friction mode, the same Normal load, same speed, same stroke, same lubrication conditions.

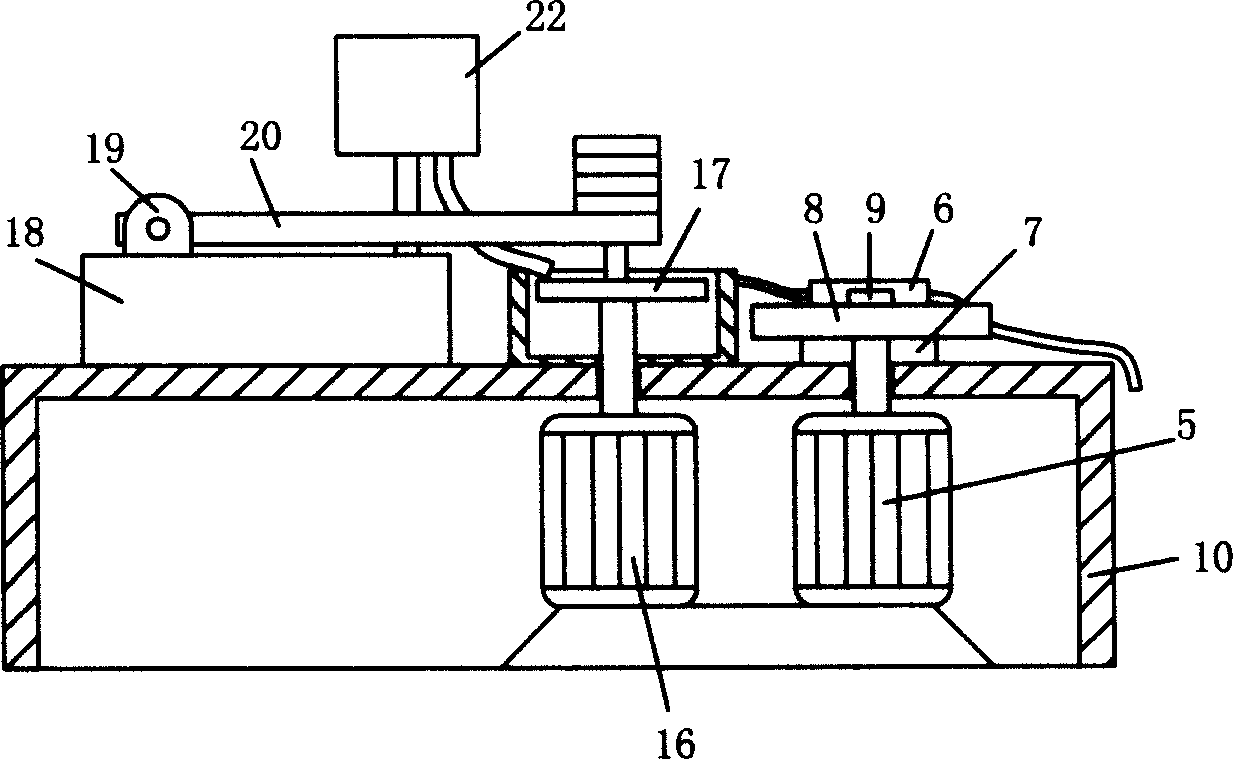

[0027] Such as image 3 , the first experimental machine shown in Fig. 4, the whole experimental machine is made up of base 10, reciprocating mechanism, rotary mechanism and upper sample control device, wherein reciprocating mechanism is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com