Multifunctional tribology performance test system

An experimental system and tribological technology, applied in the field of comprehensive performance testing experimental system, can solve the problem that the bearing mechanism, lubrication mechanism and wear mechanism of sliding bearings and ring blocks cannot be truly grasped, and the comprehensive performance testing method is not perfect and cannot be accurately measured. Liquid film thickness and other issues, to achieve the effect of simple structure, easy replacement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

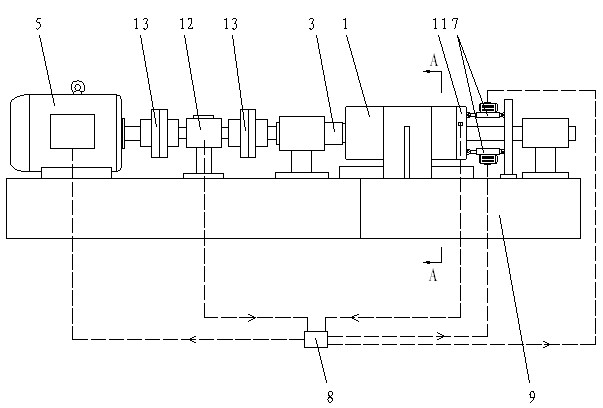

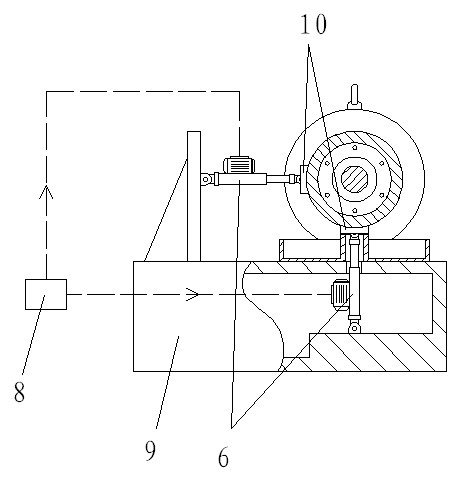

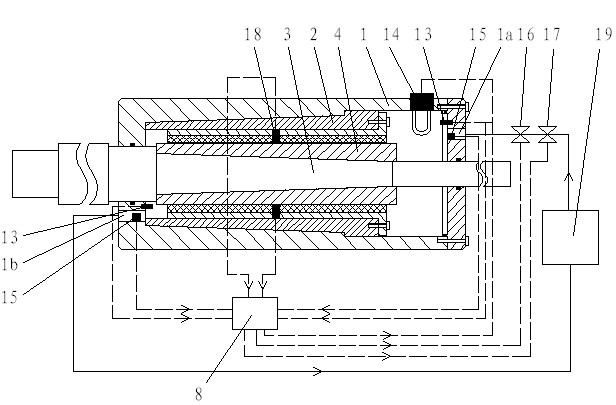

[0030] figure 1 It is the front view of the multifunctional tribological performance experimental system of the present invention; figure 2 for figure 1 Sectional view along A-A; image 3 It is an axial sectional view of the test chamber body. Line segments with arrows in each figure represent detection signal transmission or flow of lubricant.

[0031]The multifunctional tribological performance experimental system of this embodiment includes a test cabin 1, a bearing sleeve 2 fixedly arranged in the test cabin 1 in a detachable manner, a test shaft 3 arranged in the bearing sleeve 2 and coaxial with it, In a detachable manner, the shaft sleeve 4 that is overlaid on the test shaft 3, the driving device 5 for driving the test shaft 3 and the loading device for loading the test cabin body 1 are fixed, and the gap between the shaft sleeve 4 and the bearing sleeve 2 The space is the installation space of the tested piece, and the two ends of the test chamber 1 are in rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com