High silicon gradient composite aluminum alloy cylinder sleeve material and preparation method thereof

An aluminum alloy and gradient technology, which is applied in the field of high-silicon gradient composite aluminum alloy cylinder liner and or bushing material and its preparation, can solve the problem of insufficient high temperature resistance and tribological properties of the alloy, high temperature of the alloy, low mechanical properties at room temperature, and poor quality. Consistency and poor uniformity of mechanical properties, etc., to achieve the effect of superior cylinder liner processing surface quality and use effect, beneficial tribological properties, and superior product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

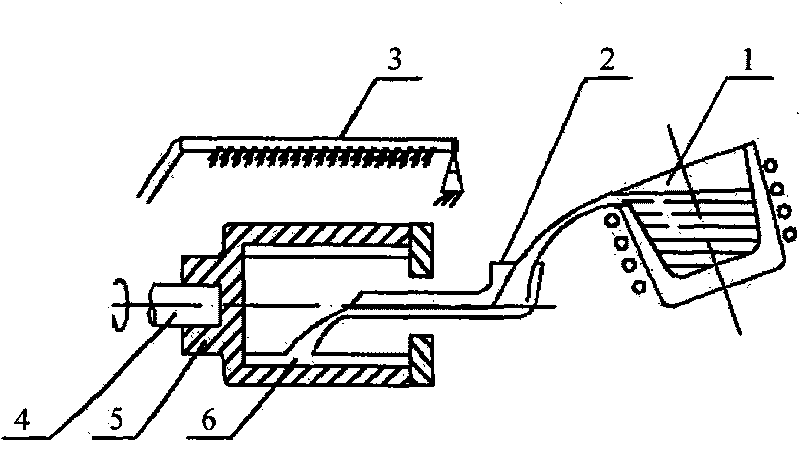

[0082] Preparation method of high-silicon gradient composite aluminum alloy cylinder liner:

[0083] Component design and precise batching: carry out precise batching according to the composition formula of the alloy of the present invention. In the batching method, the high melting point alloy elements such as silicon, iron, nickel, manganese, copper, vanadium, strontium, rare earth, etc., are prepared by the method of master alloy, so that these high melting point alloy elements can be added to the low melting point. In aluminum, namely Al-40% Si, Al-30% Fe, Al-20% Ni, Al-50% Cu, Al-15% Mn, Al-15% V, Al-10% Sr, Al-10 %RE, Cu-10%P intermediate alloy charge form for batching. The melting point of magnesium is similar to that of aluminum, and the ingredients are prepared in the form of pure metal charge. After batching with the charge of master alloy, if the amount of aluminum is insufficient, it will be supplemented with the charge of pure aluminum.

[0084] In the control ...

Embodiment 1、 Embodiment 2 and Embodiment 3

[0095] The material of the present invention and the product that adopt material of the present invention and above-mentioned preparation method to manufacture have the characteristics that:

[0096] Each embodiment chemical analysis of table 1 (wt %)

[0097] Example

[0098] Example

[0099] Take Example 2 as an example to do batching calculation:

[0100] 1) the chemical composition of embodiment 2 is as follows:

[0101] Si: 20.5%; Fe: 1.50%; Ni: 2.00%; Cu: 2.00%; Mg: 0.50%; Mn: 0.50%; V: 0.35%; Sr: 0.08%; RE: 0.08%; : The balance of the aluminum alloy.

[0102] 2) The amount of each alloy element required in the alloy is:

[0103] Calculate the ingredients according to 100 kg of furnace charge:

[0104] Si: 20.5 kg; Fe: 1.50 kg; Ni: 2.00 kg; Cu: 2.00 kg; Mg: 0.50 kg; Mn: 0.50 kg; V: 0.35 kg; Sr: 0.08 kg; RE: 0.08 kg; P: 0.07 kg. Al: The balance is 100 kg - the total algebraic sum (27.58 kg) of the above alloying elements is 72.42 kg.

[0105] 3) ...

Embodiment 4

[0143] The embodiment 2 material and cylinder liner sample pieces that adopt material of the present invention and preparation method to manufacture have the characteristics that:

[0144] Its physical performance characteristics:

[0145] 1) thermal conductivity

[0146] At room temperature of 25°C, 100W / m / k; at high temperature of 250°C, 120W / m / k.

[0147] 2) Expansion coefficient

[0148] At room temperature 25°C, 16.5×10 -6 1 / °C; at a high temperature of 300°C, 17.95×10 -6 / °C.

[0149] 3) Density

[0150] At room temperature 25°C, 2.80g / cm 3 .

[0151] The surface hardness characteristics of the cylinder liner:

[0152] 1) At room temperature 25°C, HB250≥160.

[0153] The processing surface characteristics of the cylinder liner:

[0154] 1) Surface roughness Ra 0.6-1.2μm;

[0155] It simulates the tribological performance characteristics of engine mating conditions:

[0156] Table 4 Tribological performance data of high-silicon gradient composite aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com