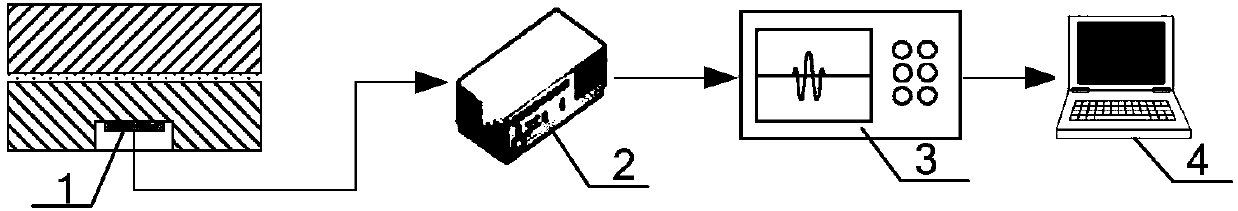

Total-range lubricating film thickness ultrasonic detection device and method

A technology of ultrasonic testing and lubricating film, applied in measuring devices, using ultrasonic/sonic/infrasonic, instruments, etc., can solve the problem of increasing the cost of film thickness testing equipment, introducing large deviations in lubricating film thickness of small tribological components, and measuring position Inconsistency and other problems, to achieve the effect of excellent detection means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

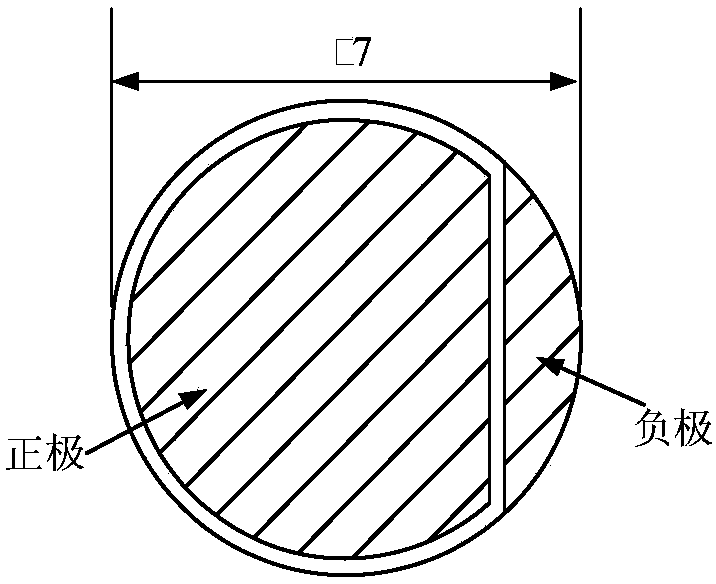

Method used

Image

Examples

Embodiment

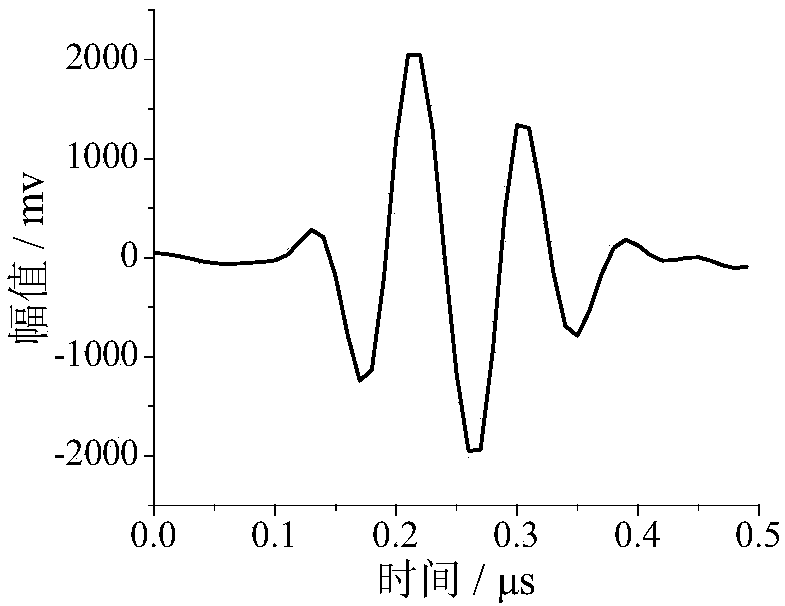

[0046] by Figure 5 The shown high-precision lubricating film thickness simulation test bench constructs a series of known lubricating film thicknesses for actual measurement as an example, illustrating the effectiveness of the testing method of the present invention. A high-precision lubrication film thickness simulation test bench is constructed by using a screw micrometer 6, a piezoelectric controller 5, a piezoelectric actuator 7, a clamping device 8, and a PC4, and a series of lubricating films of known thickness are constructed on this bench. film, through the film thickness detection device and method provided by the present invention, the lubricating film with a thickness from 0.1 μm to 200 μm has been measured, and the experimental measurement results are in good agreement with the set values. The comparison results are as follows Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com