Graded aluminium alloy cylinder liner material and preparing method thereof

An aluminum alloy and cylinder liner technology, which is applied in the field of gradient aluminum alloy cylinder liner materials and its preparation, can solve problems such as insufficient high temperature resistance and tribological properties of alloys, insufficient feeding pressure, low metal yield, etc., to achieve quality Excellent use effect, improved tribological properties, and beneficial effects on tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

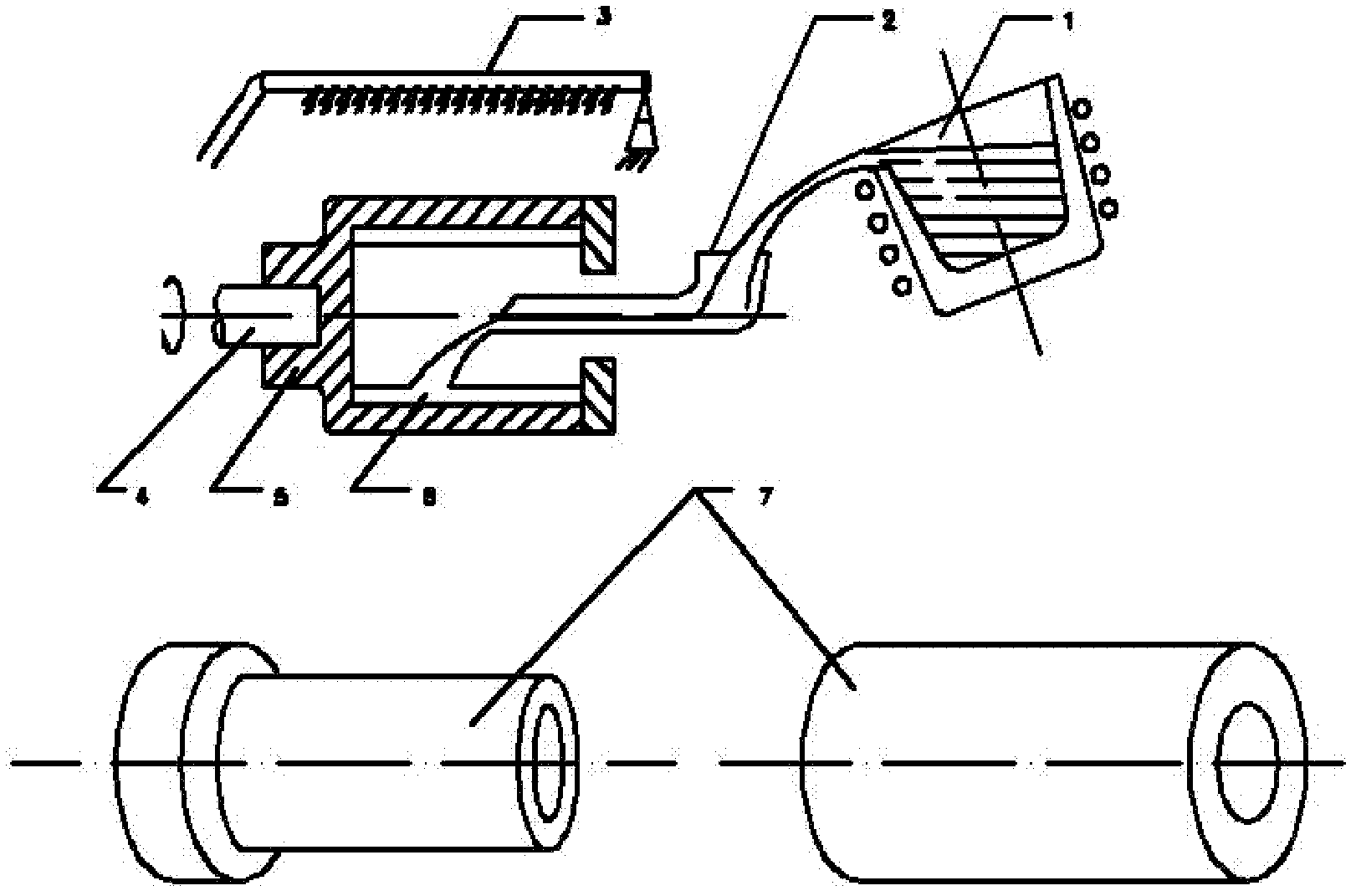

[0081] A preparation method of gradient aluminum alloy cylinder liner material:

[0082] ① Composition design and precise batching: carry out precise batching according to the composition formula of the alloy of the present invention. In the batching method, the alloy elements with high melting point such as silicon, nickel, manganese, copper, rare earth, etc., are prepared by the method of master alloy, so that these high melting point alloy elements can be added to the aluminum liquid, that is, Al-40 %Si, Al-20%Ni, Al-50%Cu, Al-15%Mn, Al-10%RE intermediate alloys are used for batching. The melting point of magnesium is close to the melting point of aluminum, and the batching is carried out in the form of pure metal charge. After batching with the charge of master alloy, if the amount of aluminum is insufficient, it will be supplemented with the charge of pure aluminum.

[0083] In order to avoid the volatilization and combustion of phosphorus, the method of master alloy is...

Embodiment 2

[0167] Table 5 Example 2 Tribological properties

[0168]

[0169] Note: 1) The loading load is 800N, the reciprocating speed is 1m / S, and the time is 180min; the tribological performance data on the reciprocating testing machine; 2) 42MnCr52 steel (surface high-frequency quenching treatment) (cylinder liner) and 65Mn chrome plating (piston ring ) is equipped with secondary condition materials for the current engine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com