Oral environment simulation test machine

A technology of environmental simulation test and testing machine, which is applied in the direction of testing wear resistance, applying repeated force/pulsation force to test material strength, etc. It can solve the problems of high price, low degree of automation, and insufficient authenticity of occlusal motion simulation. , to achieve the effect of high degree of automation, simple operation, real and reasonable oral environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

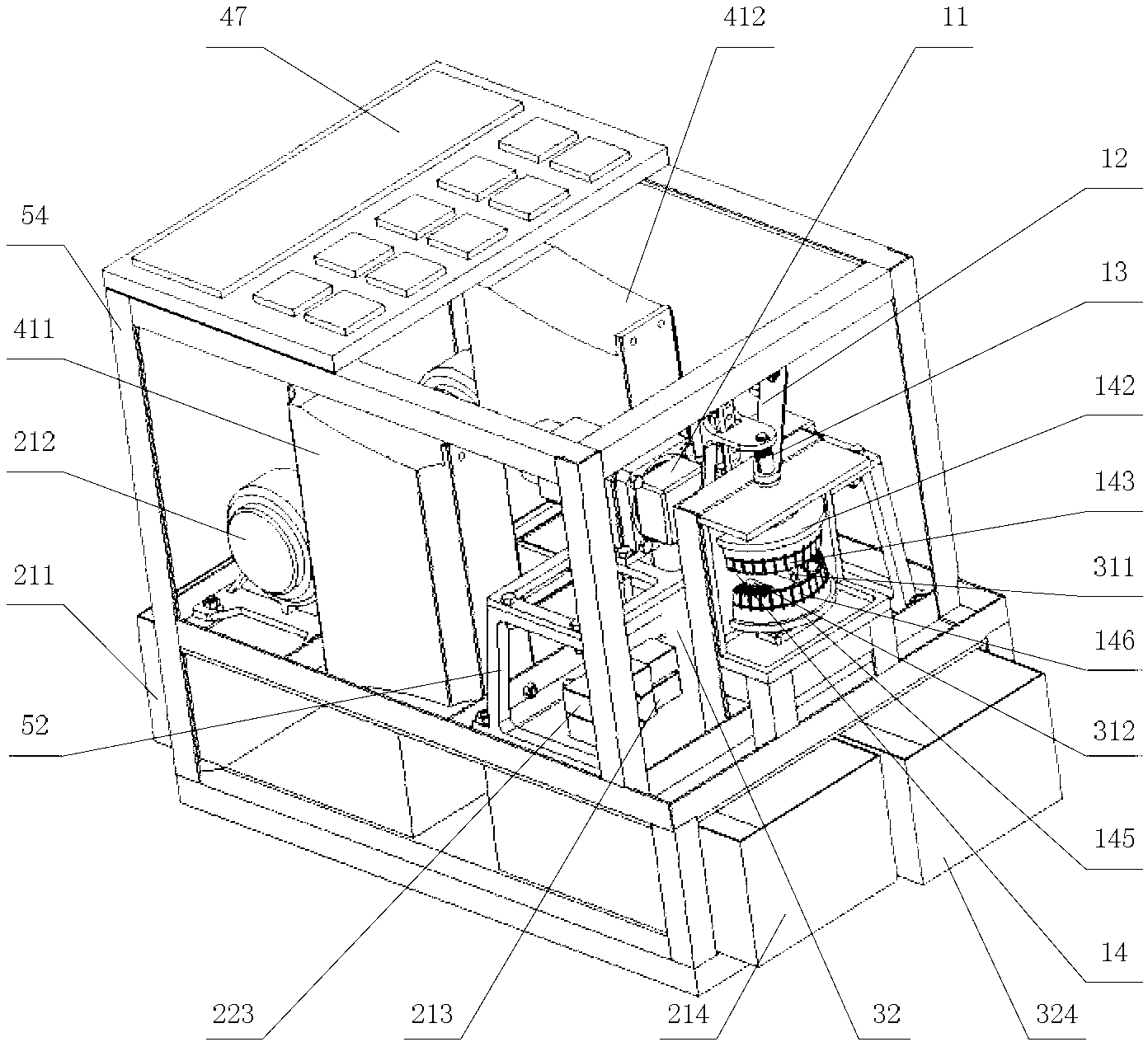

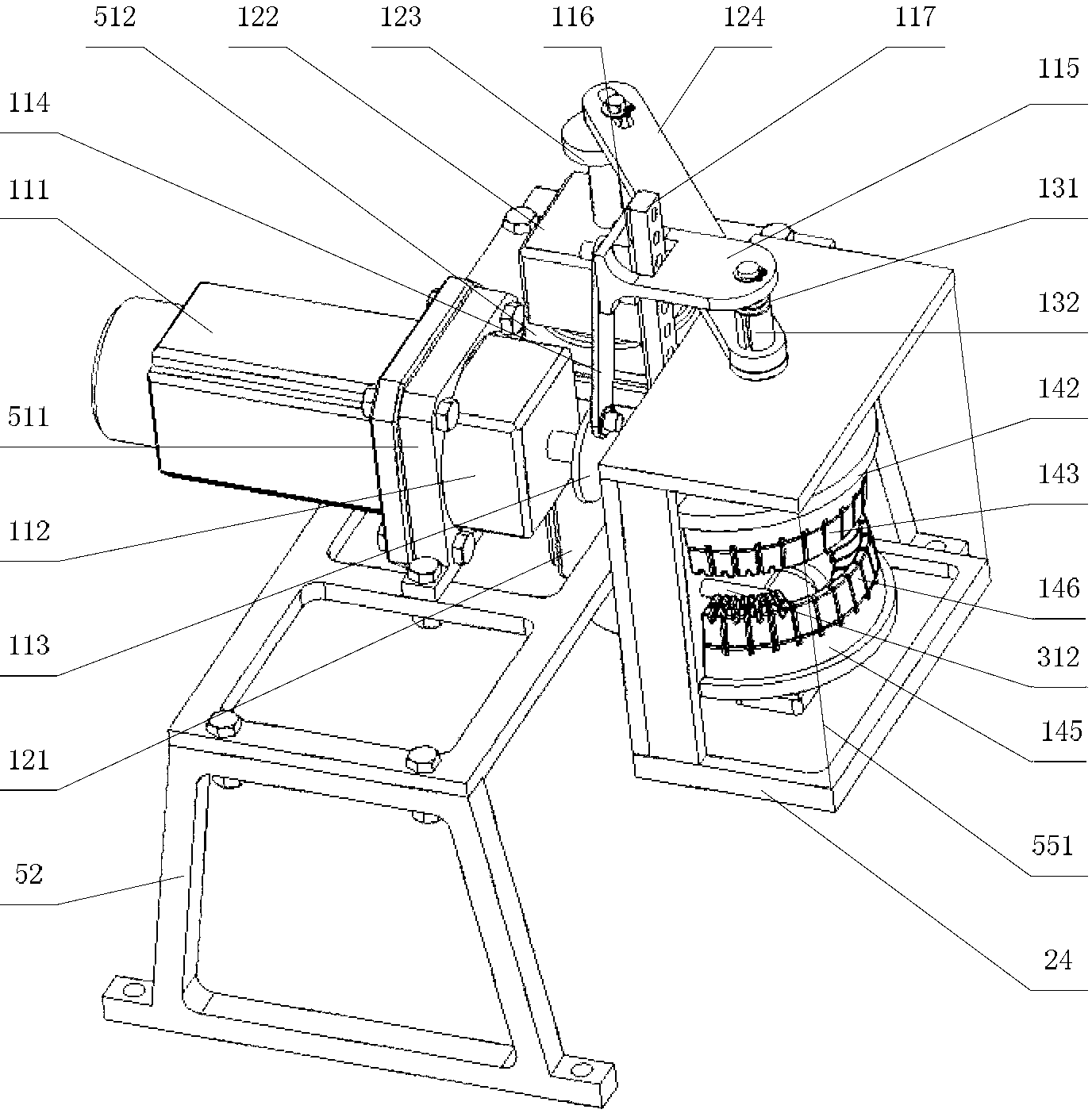

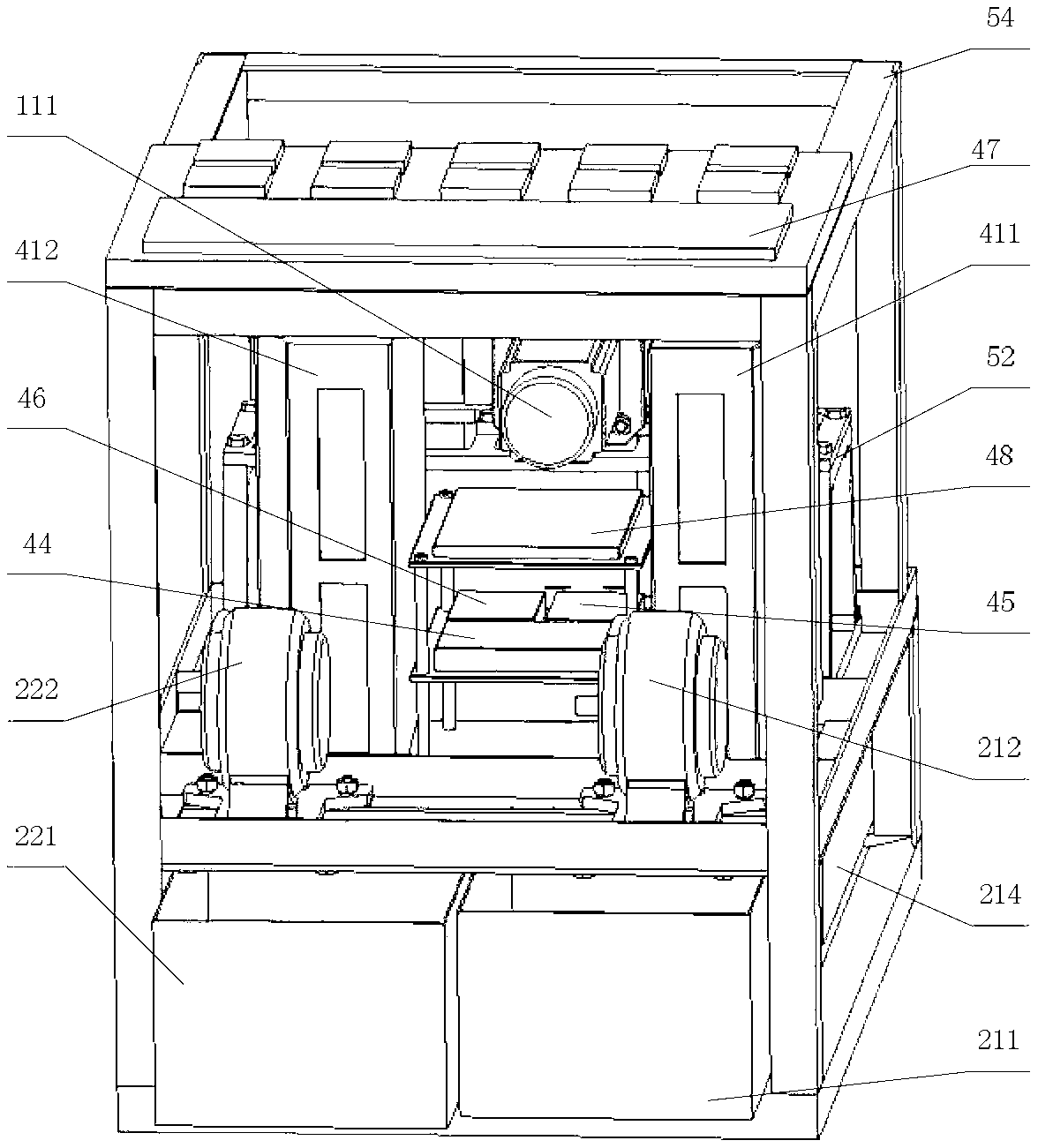

[0016] combine figure 1 , the oral environment simulation testing machine of the present invention is composed of an oral and jaw two-degree-of-freedom movement unit, an oral liquid (saliva, bacterial liquid, carbonated beverage, etc.) injection unit, an intraoral temperature adjustment unit and a control unit, and the oral and jaw two-degree-of-freedom The motion unit, the liquid injection unit in the mouth and the temperature adjustment unit in the mouth are respectively connected with the control unit, and are all installed in the overall frame 54 of the testing machine. The experimenter observes the simulation of the occlusal movement of the two degrees of freedom of the mouth and jaw. The saliva injection unit in the mouth is placed at the rear end and the lower end of the overall frame 54 of the testing machine; the temperature adjustment unit in the mouth is located at the front end of the overall frame 54 of the testing machine; Between the two-degree-of-freedom motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com