High-speed high-temperature multifunctional friction and abrasion tester

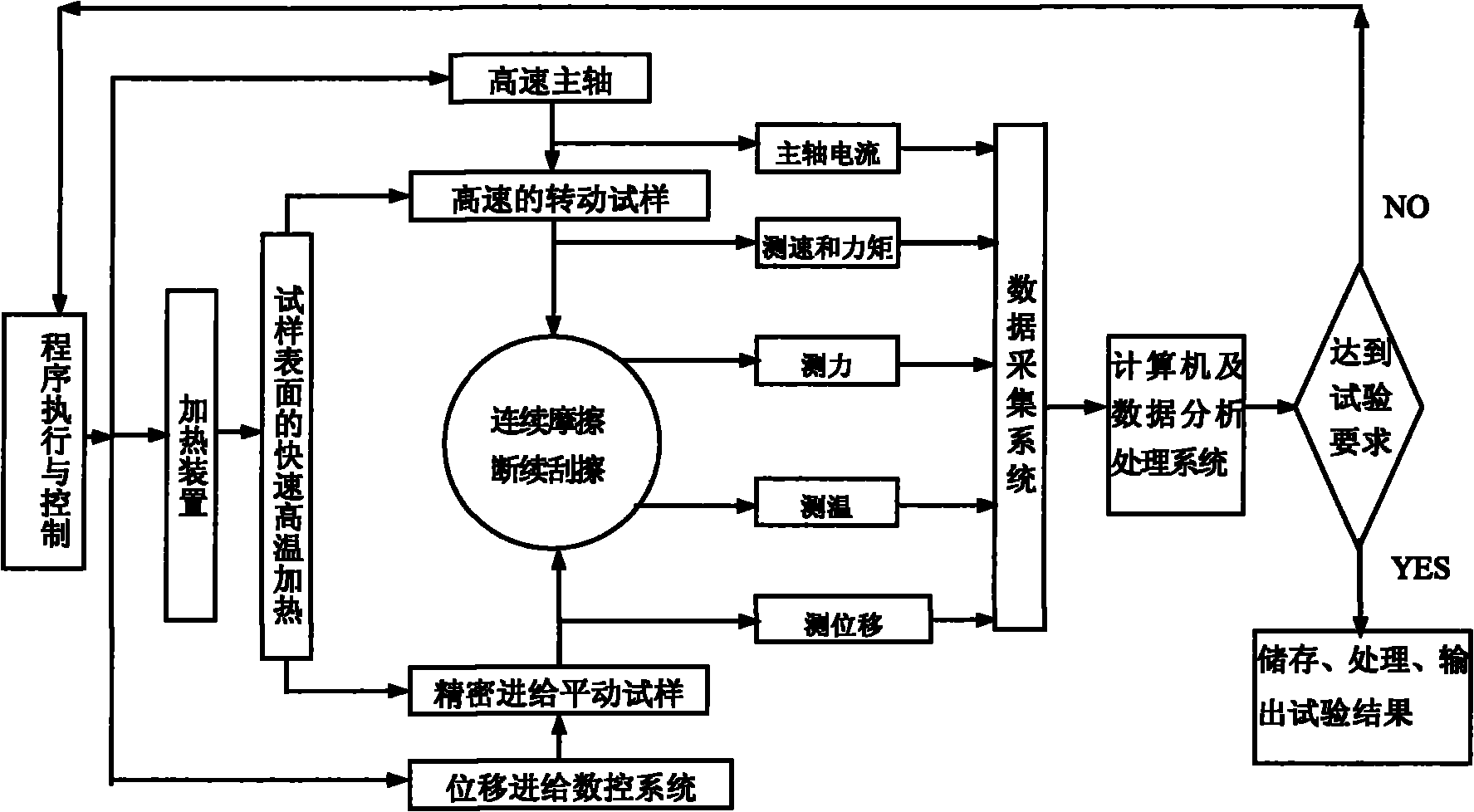

A friction and wear test, multi-functional technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problem that the linear velocity of the friction pair movement and the experimental temperature cannot reach high speed, and cannot simulate the high-speed and high-temperature scraping wear of a turbojet engine Working conditions and other issues, to achieve the effect of compact structure, low manufacturing cost, and avoid complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

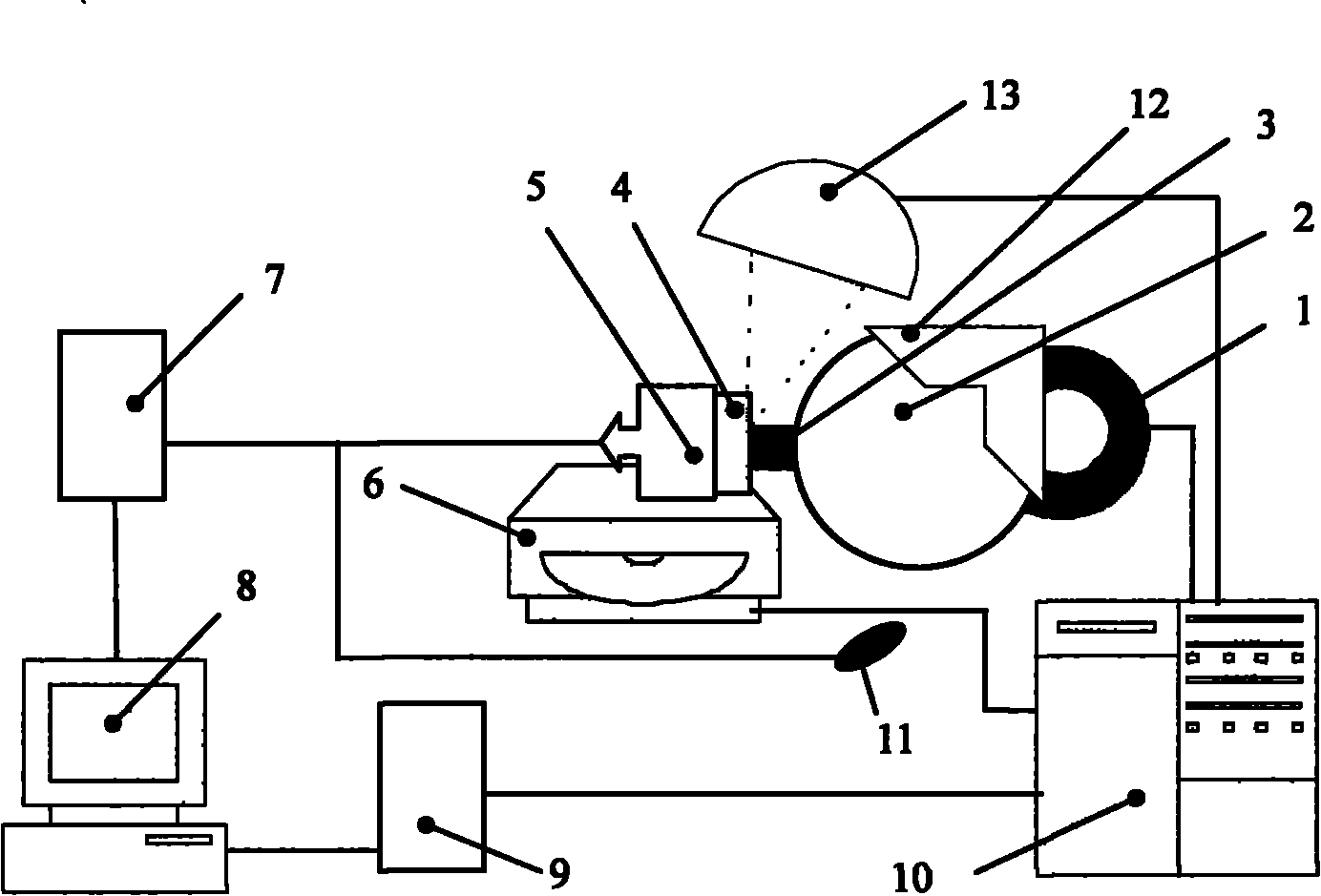

Embodiment 1

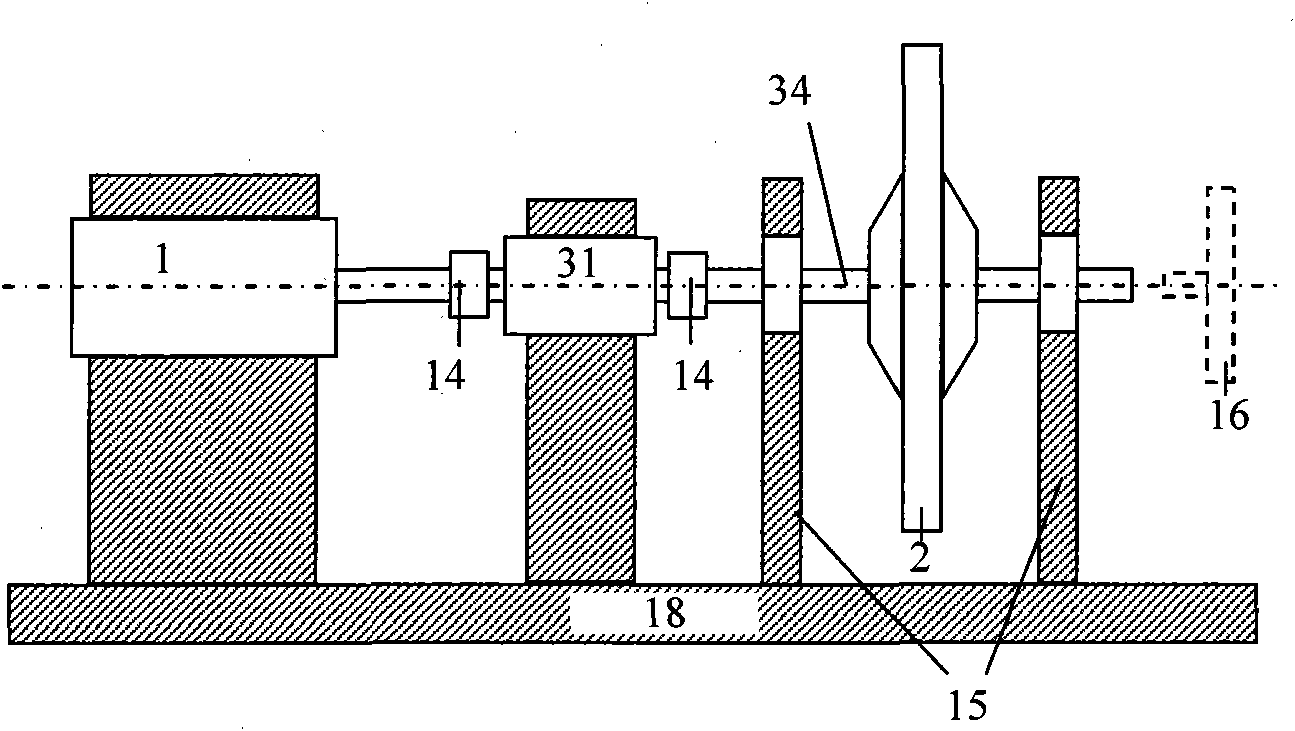

[0053] Such as Figure 5 As shown, when performing the scraping friction and wear experiment, firstly, the frequency conversion speed regulation parameters and acceleration curve of the electric spindle 1 are used to achieve and control the spindle speed required by the experiment. Then the torque meter 31 for speed measurement and torque measurement is zero-adjusted, so that the no-load speed of the rotating sample reaches the condition required by the stable test, and the torque value when not loaded is calibrated to zero. The rotating sample 3 is a single or multiple tooth-shaped scraping sample, which is installed on the rotating disk A2 on the rotating spindle 34, and its size and quality need to meet the static and dynamic balance conditions. The force measuring system 28 is arranged on one side of the longitudinal sliding table 27, and the other side of the longitudinal sliding table 27 is provided with a transverse sliding table 29. The translational sample 4 is instal...

Embodiment 2

[0056] The change compared with embodiment 1 is:

[0057] Such as Figure 6 As shown, the rotating sample 3 is installed on the outer circumference of the rotating disc B16 at one end of the high-speed rotating main shaft 34 , and the rotating disc A2 is separated from the rotating main shaft 34 and fixed on the base 18 . The rotating sample 3 is ring-shaped, and its outer diameter is smaller than the rotating diameter of the scraping test, which is beneficial to the preparation of the sample. Its outer circumference is the test surface, which forms a ring / block friction pair with the block-shaped translational sample 4, and performs continuous or intermittent friction motion.

[0058] The process of carrying out the ring block friction and wear test is as described in Example 1. In this embodiment, experimental parameters such as speed, temperature, feed depth and feed speed can also be actively changed to obtain a variety of experimental schemes, including: adjustment of m...

Embodiment 3

[0060] The change compared with embodiment 2 is:

[0061] Such as Figure 7As shown, the difference lies in the formation of the pin / disk friction pair. The translational sample 4 is pin-shaped and transformed into a feed motion in the X-axis direction. The annular rotating sample 3 is installed on the outer end surface of the rotating disc B16 at one end of the rotating spindle 34. The outer end surface of the annular rotating sample 3 is the test surface, forming a circumferential wear track. At this time, in order to ensure the force balance of the rotating main shaft 34, the position of the translational sample 4 must be symmetrical, so there is no movement in the Y-axis direction. The force-measuring system 28 is set on the top of the longitudinal slide 27, and the other side of the longitudinal slide 27 is provided with a transverse slide 29, and the translational sample 4 is installed on the sample fixing bracket 30 on one side of the force-measuring system 28. Becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com