On-line measuring and testing machine for radial sliding bearing friction and wearing

A bearing friction and radial sliding technology, used in mechanical bearing testing, measuring devices, testing wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

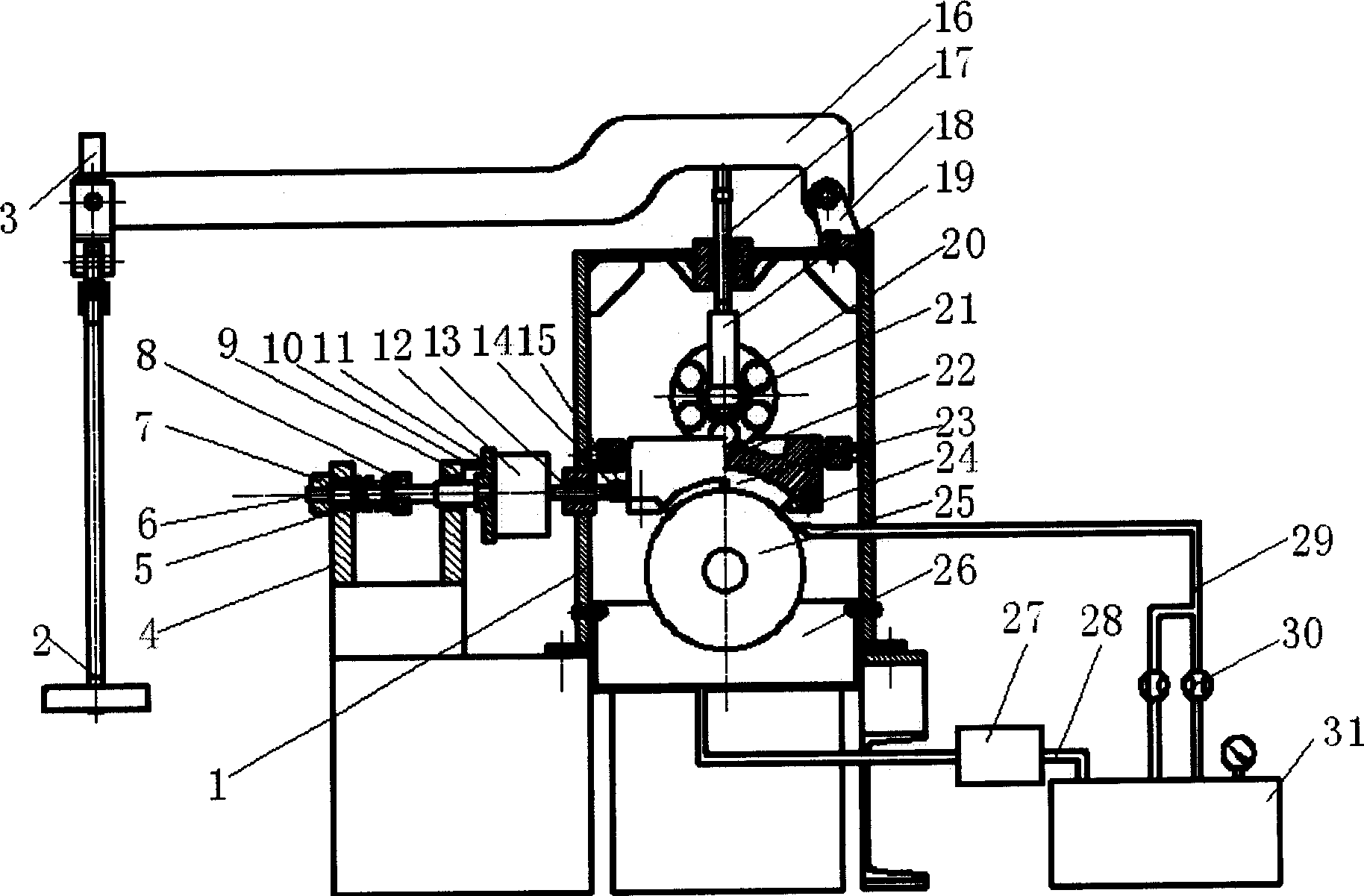

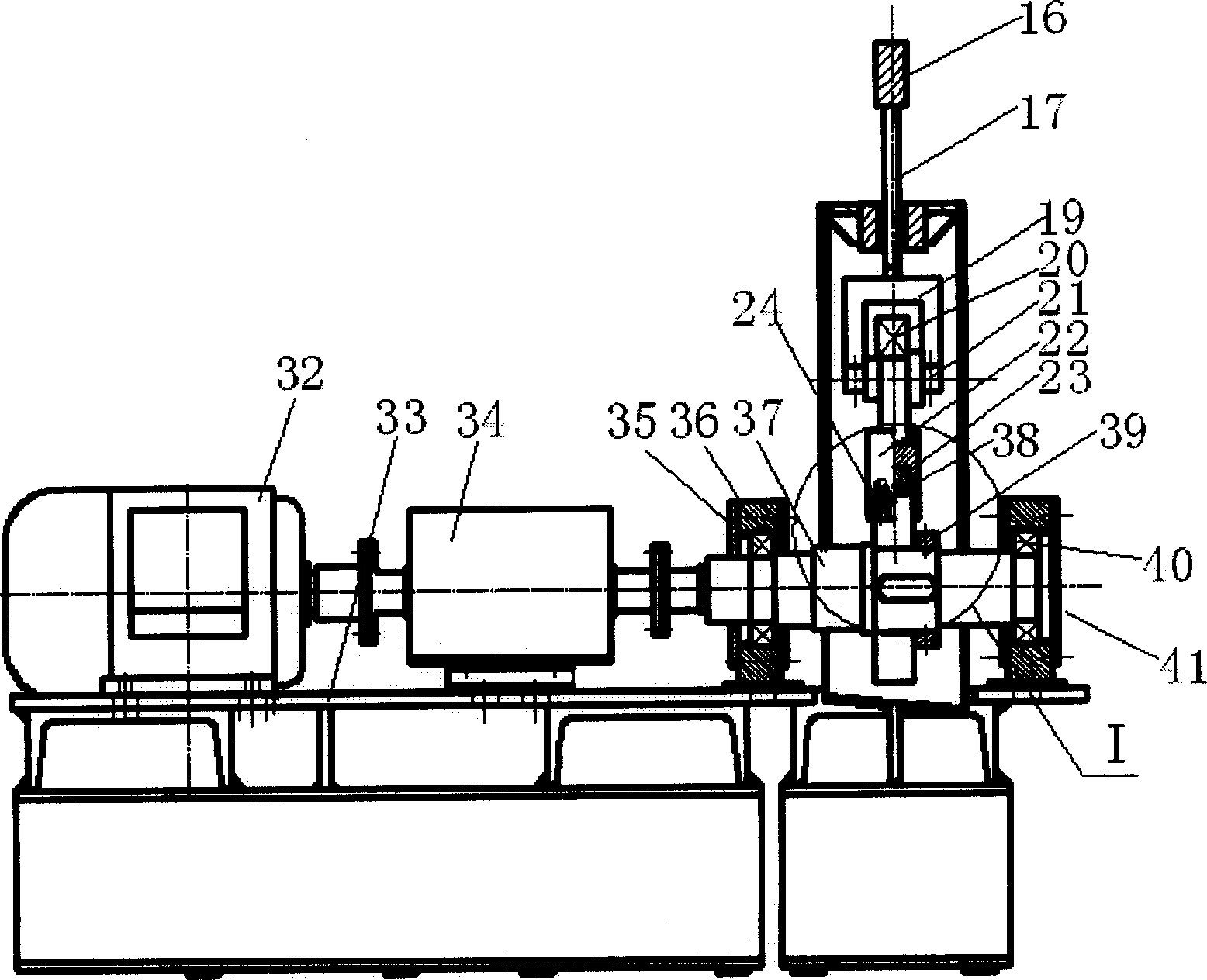

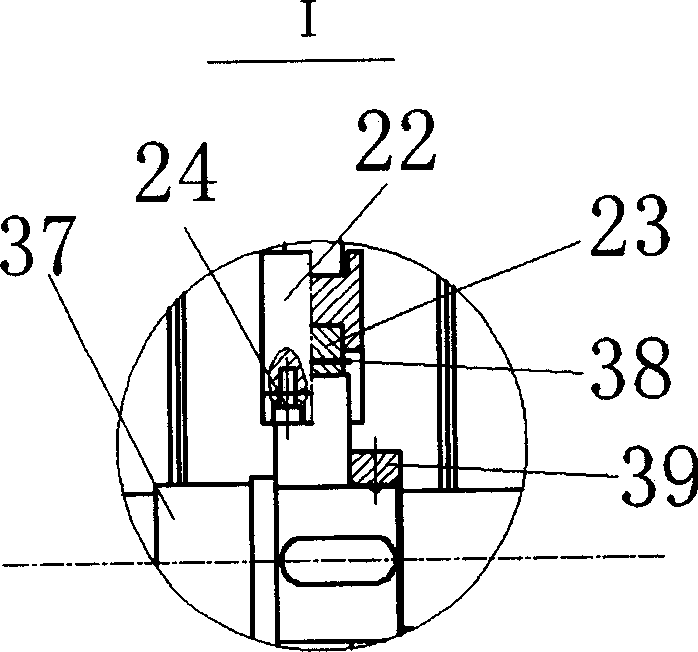

[0023] figure 1 It is an embodiment disclosed by the present invention (see figure 1 ), before the experiment, according to the test requirements, the lower surface of the upper sample 23 to be detected is processed into an inner arc (see Image 6 ), the lower sample 25 is processed into a disk. Install the radial ball bearing 35, the lower sample 25, the lower sample fixture 39 and the cylindrical roller bearing 40 on the support shaft 37, then install the shaft assembly on the bearing housing 36 and the bearing housing 41, and start the motor 32 Adjust the rotating speed, then load, start the lubricating device 31 and the signal collecting device. The frequency conversion motor 32 drives the support shaft 37 to rotate through the torque speed sensor 34, and the support shaft 37 drives the sample 25 to rotate together. According to the test requirements, the lubricating oil flows from the lubrication system 31 and the pipeline 29 to the outer surface of the lower sample 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com