Equipment for implementing synchronous dry-wet alternate accelerated corrosion in loading process and application thereof

A technology of alternating dry and wet to accelerate corrosion, applied in the field of metal material corrosion and corrosion fatigue, can solve the problem of lack of good experimental evaluation, and achieve the effect of convenient assembly and disassembly, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Economical MnCu weathering steel (Patent No.: 200510045624.6; Publication No.: CN1800428A) under simultaneous dry-wet alternating accelerated corrosion for 60 cycles

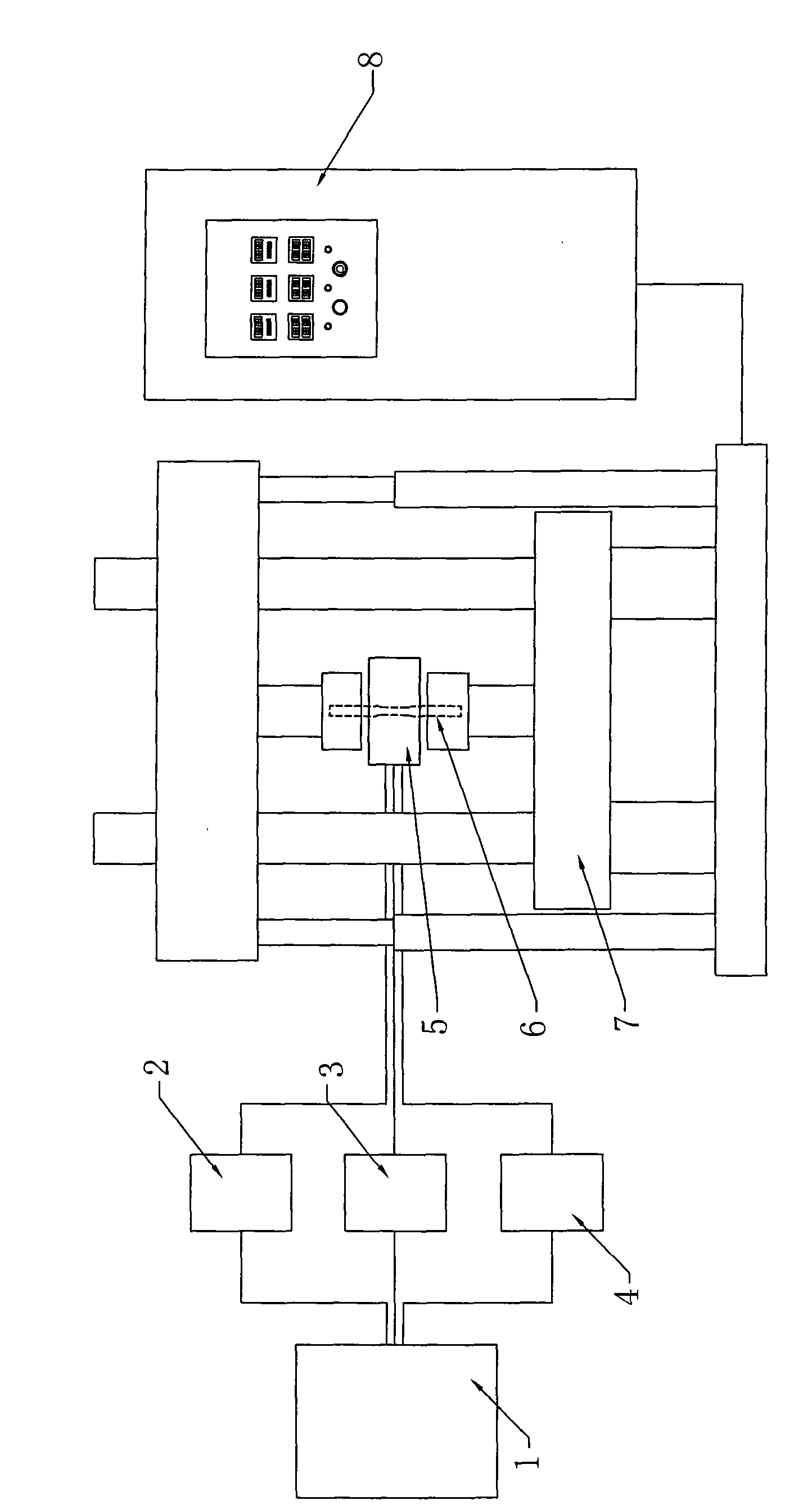

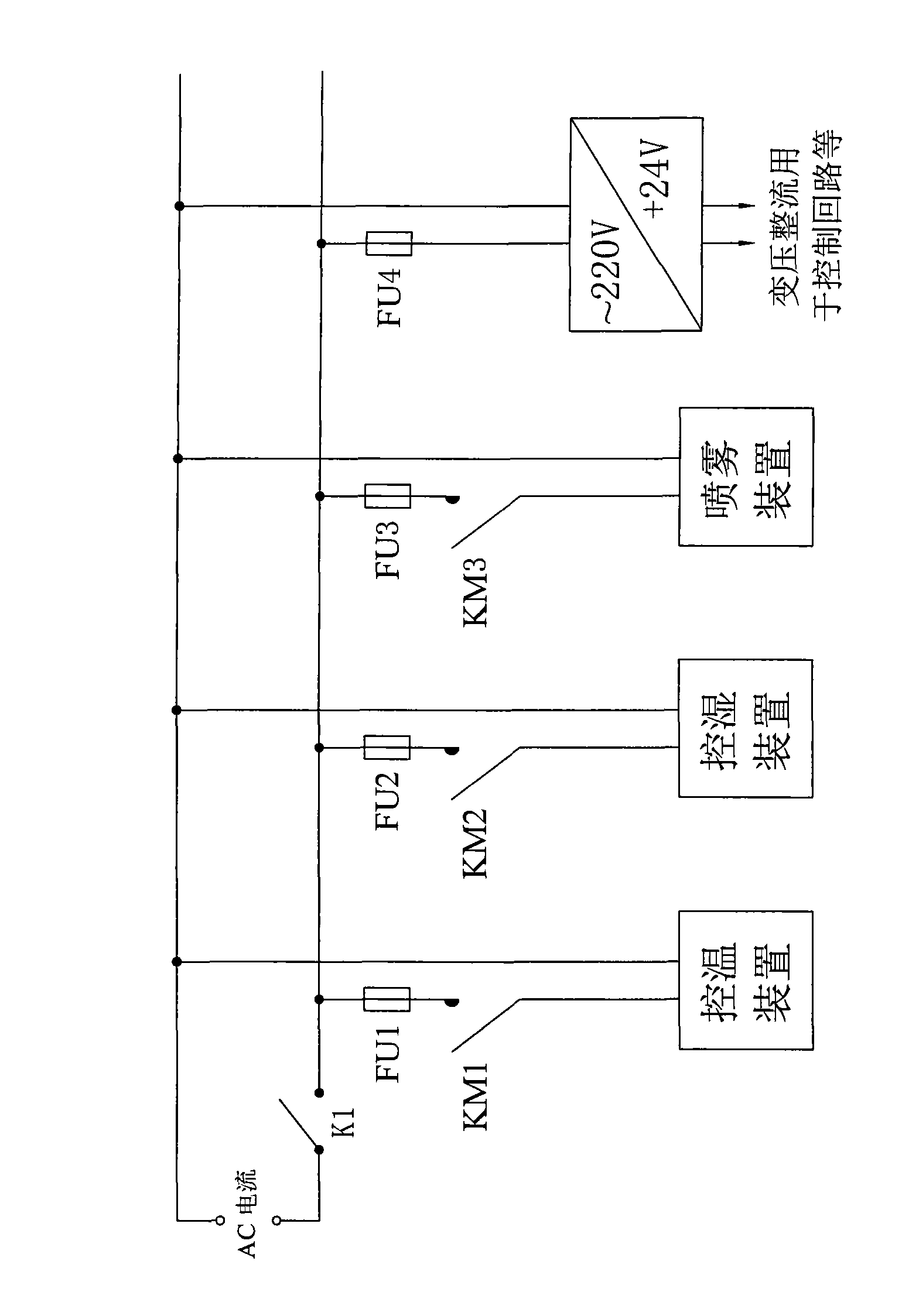

[0034] 1. If figure 1 As shown, the equipment of the present invention mainly includes: control system 1, temperature control device 2, humidity control device 3, spray device 4, corrosion fatigue box 5, fatigue machine loading system 7, fatigue machine control system 8, and the output terminals of control system 1 are respectively Connect the temperature control device 2, the humidity control device 3, and the spray device 4, the output ends of the temperature control device 2, the humidity control device 3, and the spray device 4 are respectively connected to the corrosion fatigue box 5, and the output end of the fatigue machine control system 8 is connected to the fatigue machine The loading system 7 and the fatigue machine control system 8 apply cyclic loads to the samples 6 in the corrosion...

Embodiment 2

[0043] Example 2 Economical MnCu weathering steel (Patent No.: 200510045624.6; Publication No.: CN1800428A) under simultaneous dry-wet alternating accelerated corrosion for 120 cycles

[0044] 1. If figure 1 As shown, the control system 1 uses the temperature control device 2, the humidity control device 3, and the spray device 4 to accelerate the corrosion of the sample 6 in the corrosion fatigue chamber 5 under temperature control and humidity control.

[0045] 2. If figure 1 As shown, the fatigue machine control system 8 synchronously applies a cyclic load to the sample 6 in the corrosion fatigue chamber 5 through the loading system 7 .

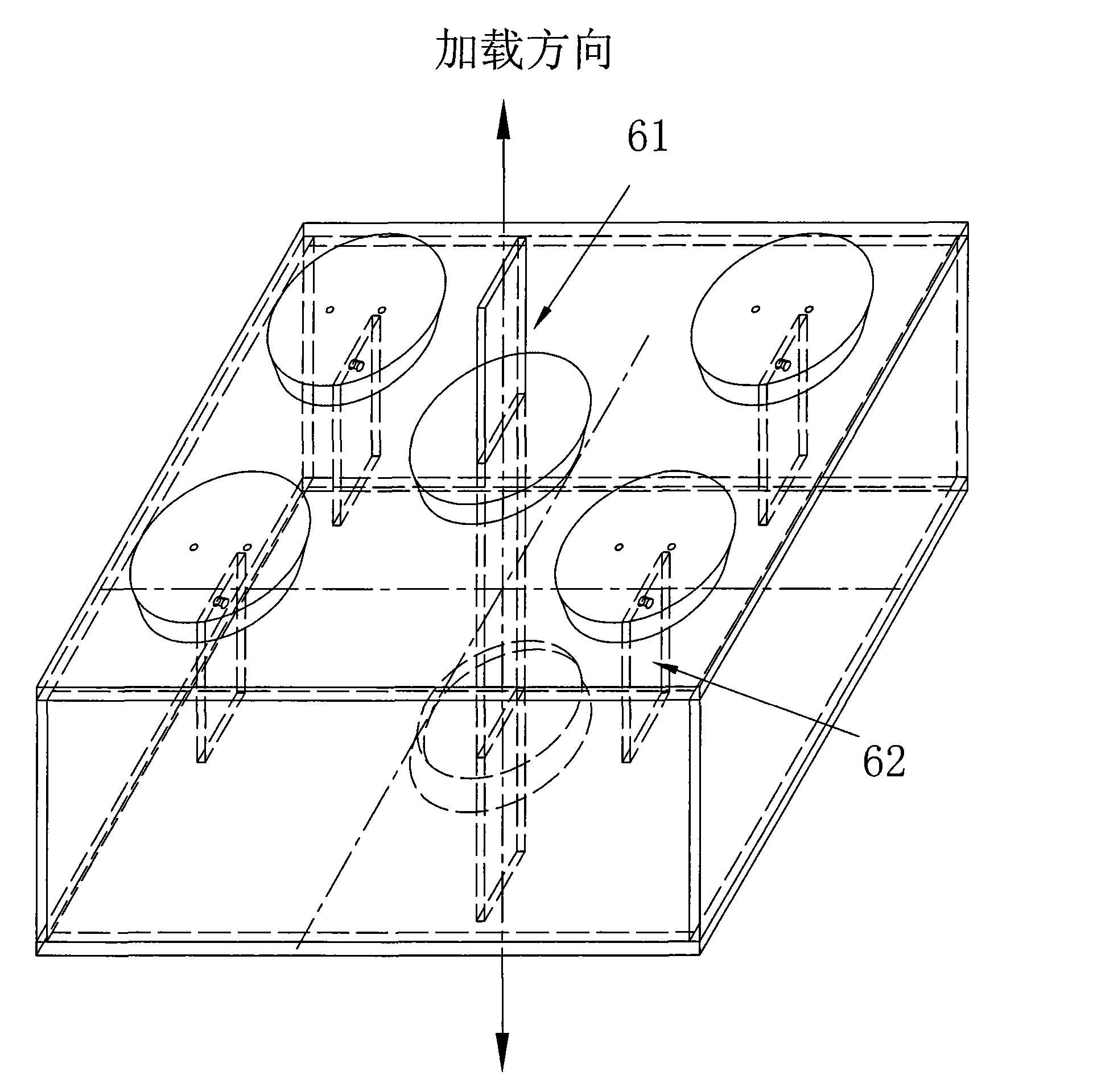

[0046] 3. If figure 2 As shown, the loaded sample 61 and the unloaded sample 62 in the corrosion fatigue chamber 5 are subjected to the accelerated corrosion action of alternating wet and dry at the same time.

[0047] 4. Use the equipment prepared to realize synchronous dry-wet alternating accelerated corrosion during the loading proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com