Noodle high-temperature drying process

A high-temperature drying and dried noodle technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of high energy consumption, long drying time, high irregularity of dried noodles, bending and breaking rate and natural breaking rate, etc., to achieve good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

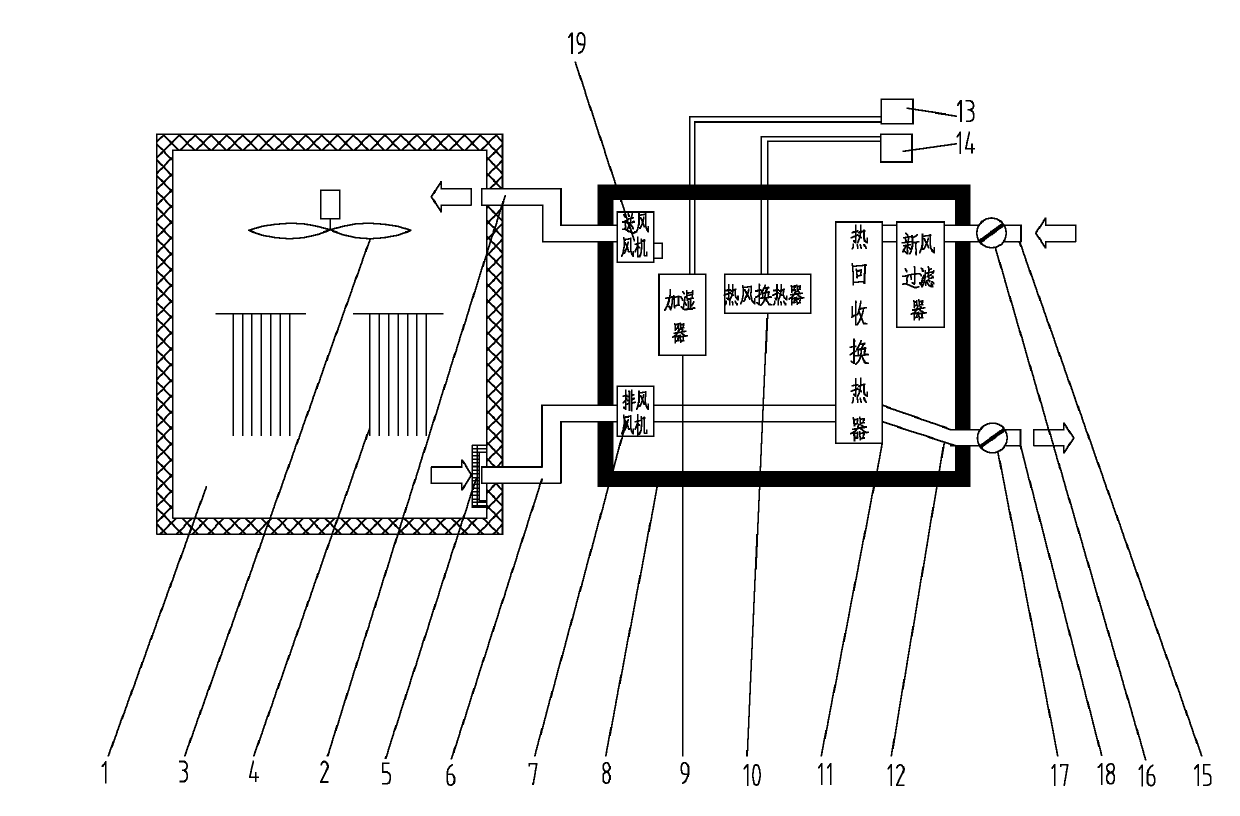

[0102] This embodiment is a six-stage drying method. Each drying section is fully enclosed, independent of each other, and does not interfere with each other. The dry hot air is processed by the hot air centralized processing system and distributed to six drying chambers through air ducts. After the air is mixed, it is in contact with the material, and the high-humidity air is returned to the centralized processing device through the air duct, and part of it is discharged to the outside. The indoor temperature, humidity, moisture removal and air intake of the six drying chambers are intelligently controlled in proportion and according to the heat demand, and the process steps are carried out in the drying chamber.

[0103] Among them, there are three fixed-strip drying chambers for constant-temperature and constant-humidity strip drying, which are respectively the first strip drying chamber, the second strip drying chamber and the third strip drying chamber.

[0104] The ambie...

Embodiment 2

[0120] The difference from Embodiment 1 is that this embodiment adopts seven-stage drying, and the indoor temperature, humidity, moisture removal, and air intake of the seven drying chambers are intelligently controlled in proportion and according to the heat demand, and the process steps are in the drying chamber. conduct.

[0121] Among them, there are three fixed-strip drying chambers for constant-temperature and constant-humidity strip drying, which are respectively the first strip drying chamber, the second strip drying chamber and the third strip drying chamber.

[0122] The ambient temperature of the first sizing drying room is 25°C-35°C, the ambient humidity is 68%-72%, the wind speed is 1.5m / s-2.5m / s, and the running time of dried noodles in this room is 4-10 minutes ;

[0123] Preferably, the ambient temperature used is 30°C, the ambient humidity is 70%, the wind speed is 2.5m / s, and the passing time of the dried noodles is 4.5 minutes.

[0124] The ambient tempera...

Embodiment 3

[0140] The difference from the above-mentioned embodiment is that this embodiment adopts eight-stage drying, and the indoor temperature, humidity, moisture removal, and air intake of the eight drying chambers are intelligently controlled in proportion and according to the heat demand, and the process steps are in the drying chamber. conduct.

[0141] Among them, there are four fixed-strip drying chambers for constant-temperature and constant-humidity strip drying, which are respectively the first strip drying chamber, the second strip drying chamber, the third strip drying chamber and the fourth strip drying chamber.

[0142] The ambient temperature of the first sizing drying room is 25°C-35°C, the ambient humidity is 68%-72%, the wind speed is 1.5m / s-2.5m / s, and the running time of dried noodles in this room is 4-8 minutes ;

[0143] Preferably, the ambient temperature used is 30°C, the ambient humidity is 70%, the wind speed is 2.5m / s, and the passing time of the dried nood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com