Electrochemical in-situ measurement electrolytic cell device

An in-situ measurement and electrolytic cell technology, which is applied in measuring devices, scientific instruments, and testing wear resistance, can solve the problems of inability to perform electrochemical measurements and unsuitable three-point bending samples, etc., and achieve a simple and practical overall structure, Avoid galvanic corrosion and realize the effect of remaining life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

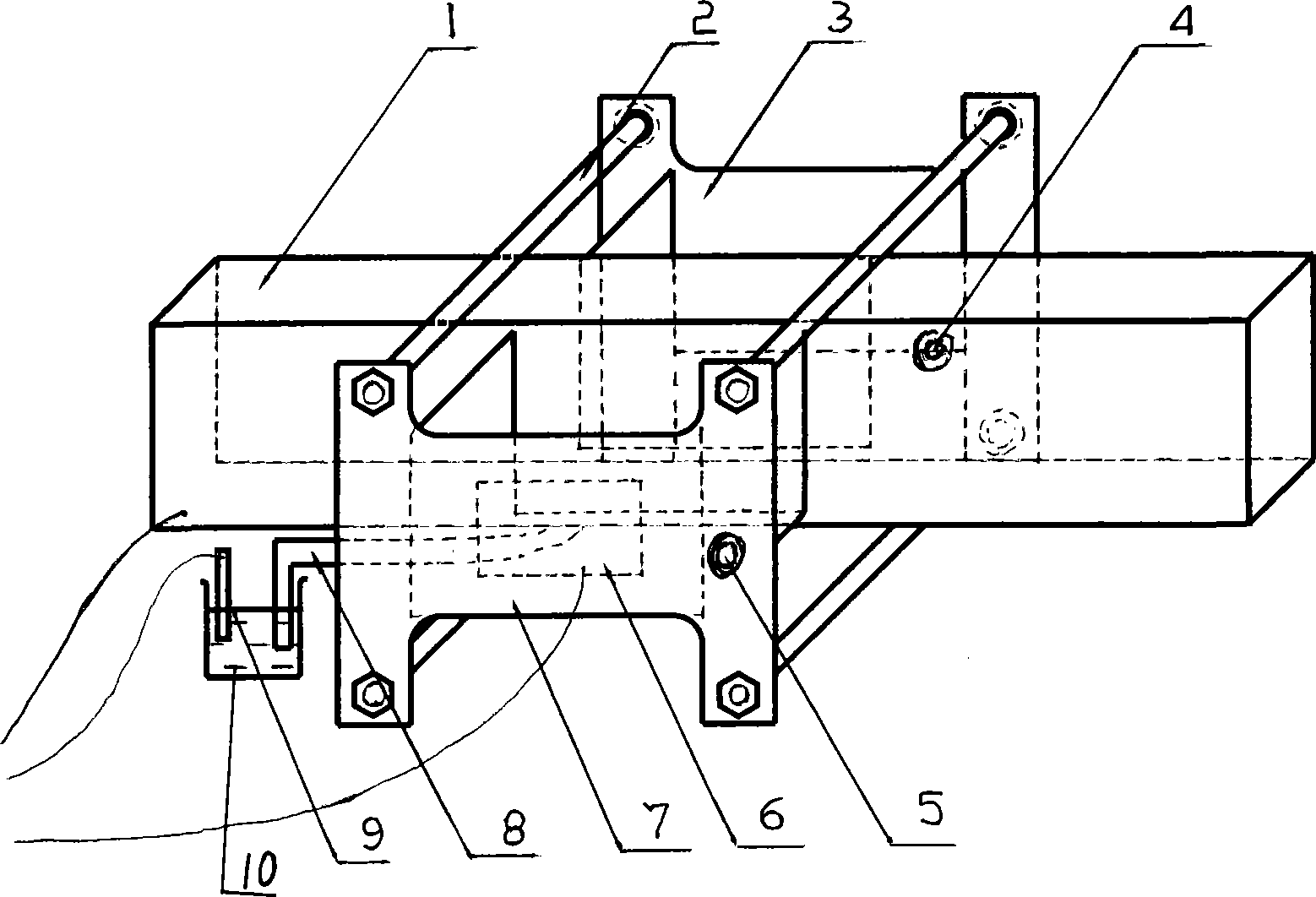

[0013] The main structure of this embodiment includes a front cell body 7, a rear cell body 3, a working electrode or a three-point bending sample 1, a bolt 2, a water outlet hole 4, a water inlet hole 5, an auxiliary electrode 6, a salt bridge 8, and a reference electrode 9 and Erlenmeyer flask 10; the front cell 7 and the rear cell 3 are symmetrical half-body structures, and the two are aligned to form the electrolytic cell box of the box-type structure, and the front and rear cells 7 and 3 are connected by long bolts 2 3. It is fixed on both sides of the three-point bending sample 1. There is a gasket at the connection between the two tanks and the sample. The gasket can prevent the leakage of the corrosive liquid; the front tank 7 is divided into a front plate and a left side plate. , the right side plate and the bottom plate, wherein the four top corners of the H-shaped front plate are respectively shaped with round holes for fixing the bolts 2, and the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com