Aluminum-coated steel curtain wall section structure

An aluminum-clad steel and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large horizontal divisions, large spans between floors, and uncoordinated visual effects of buildings, and achieve beautiful appearance and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

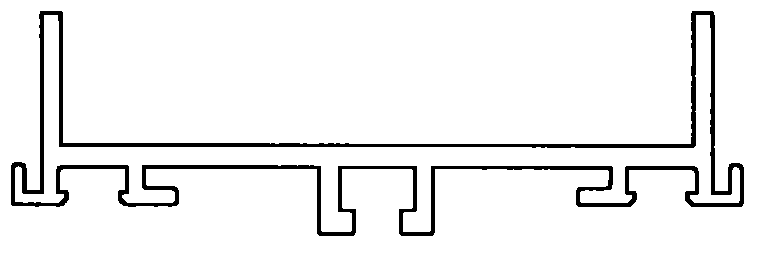

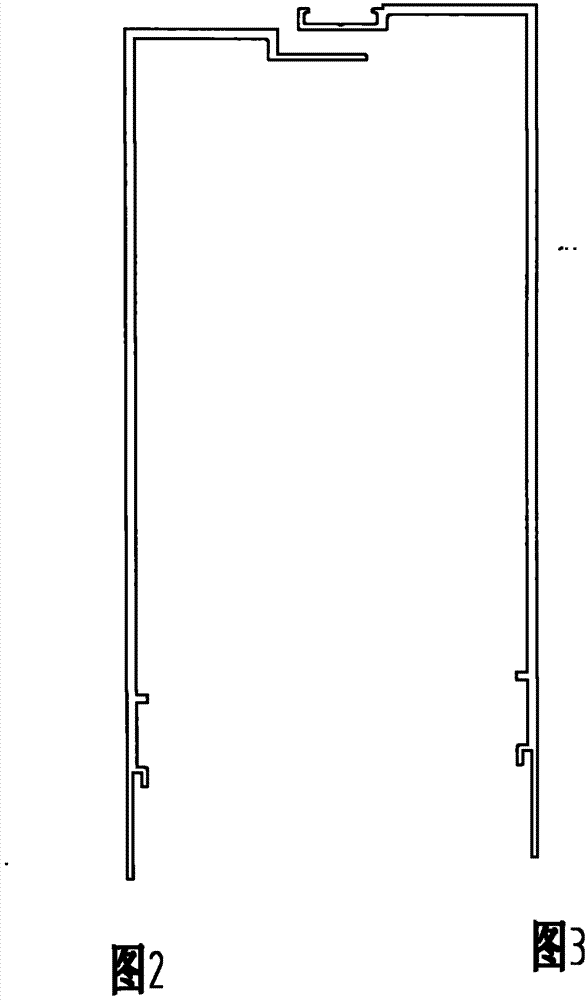

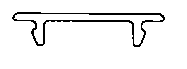

[0027] Example 1, such as Figure 1-6 As shown, this embodiment discloses an aluminum-clad steel curtain wall profile structure, which includes a steel keel column 1, a transverse limiting frame material 2, a longitudinal male frame material 3 and a longitudinal female frame material 4, One end of the male frame material 3 and the female frame material 4 are respectively inserted into the slots 11 of the limiting frame material, and the other end is overlapped on the upper surface of the steel keel, thereby forming a frame material combination, which covers the steel keel 1 overall. The overlap between the male frame material 3 and the female frame material 4 forms a groove 5, and a stainless steel self-tapping screw 51 is installed in the groove 5 to fix the male frame material 3, the female frame material 4 and the steel keel 1, and the limit The frame material 2 and the steel keel 1 are also fixedly connected by stainless steel self-tapping screws 51; rubber gaskets 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com