Heat sink insulated liquid refrigeration semiconductor laser and stack array thereof

A semiconductor and laser technology, used in the field of liquid refrigeration semiconductor lasers, can solve the problems of high water quality requirements for refrigeration liquids, blockage of microchannel heat sinks, and restrictions on heat dissipation efficiency, avoiding electrochemical corrosion, reducing chip stress, and eliminating processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

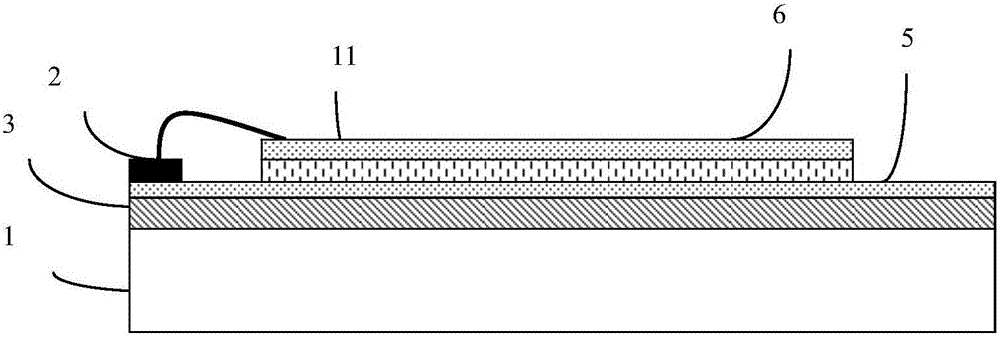

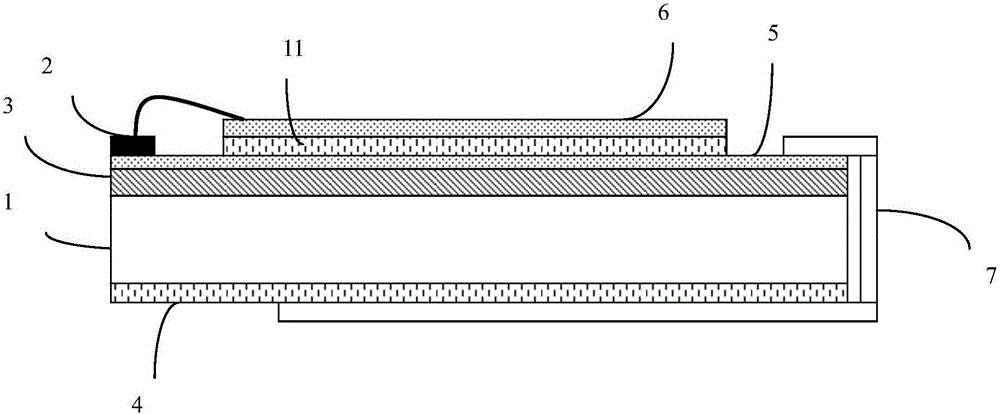

[0033] Such as figure 1 As shown, the heat sink-insulated liquid-cooled semiconductor laser of the present invention is mainly composed of a heat sink, a laser chip, a first insulating layer, a first conductive and heat-conducting layer, and a negative electrode copper sheet. The first insulating layer insulates the heat sink from the laser chip, and the first conductive and heat-conducting layer on the first insulating layer respectively arranges the laser chip and the negative electrode copper sheet at different positions, wherein the positive surface of the laser chip is directly bonded to the first conductive and heat-conducting layer. layer, an insulating interlayer exists between the negative electrode copper sheet and the surface of the first conductive and heat-conducting layer, and the negative electrode copper sheet is connected to the negative electrode surface of the laser chip through a gold wire.

[0034] The heat sink material is preferably copper, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com