Bipolar plate for flow batteries

A flow battery and bipolar plate technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as corrosion of bipolar plates, damage to bipolar plates, etc., to extend service life, improve service life, and ensure stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

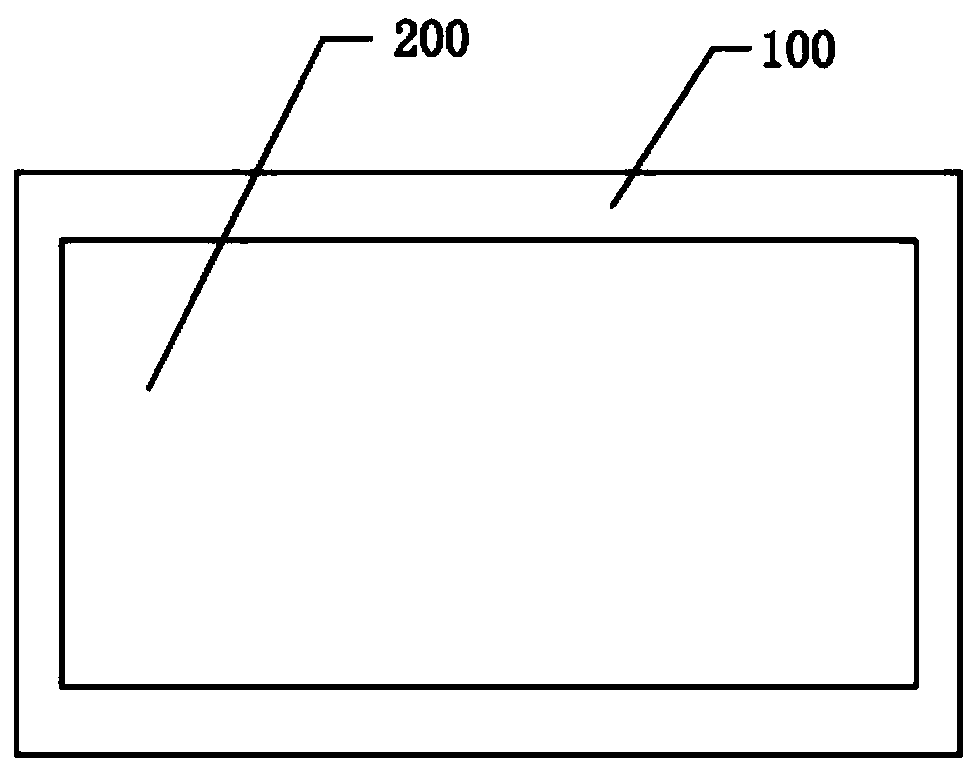

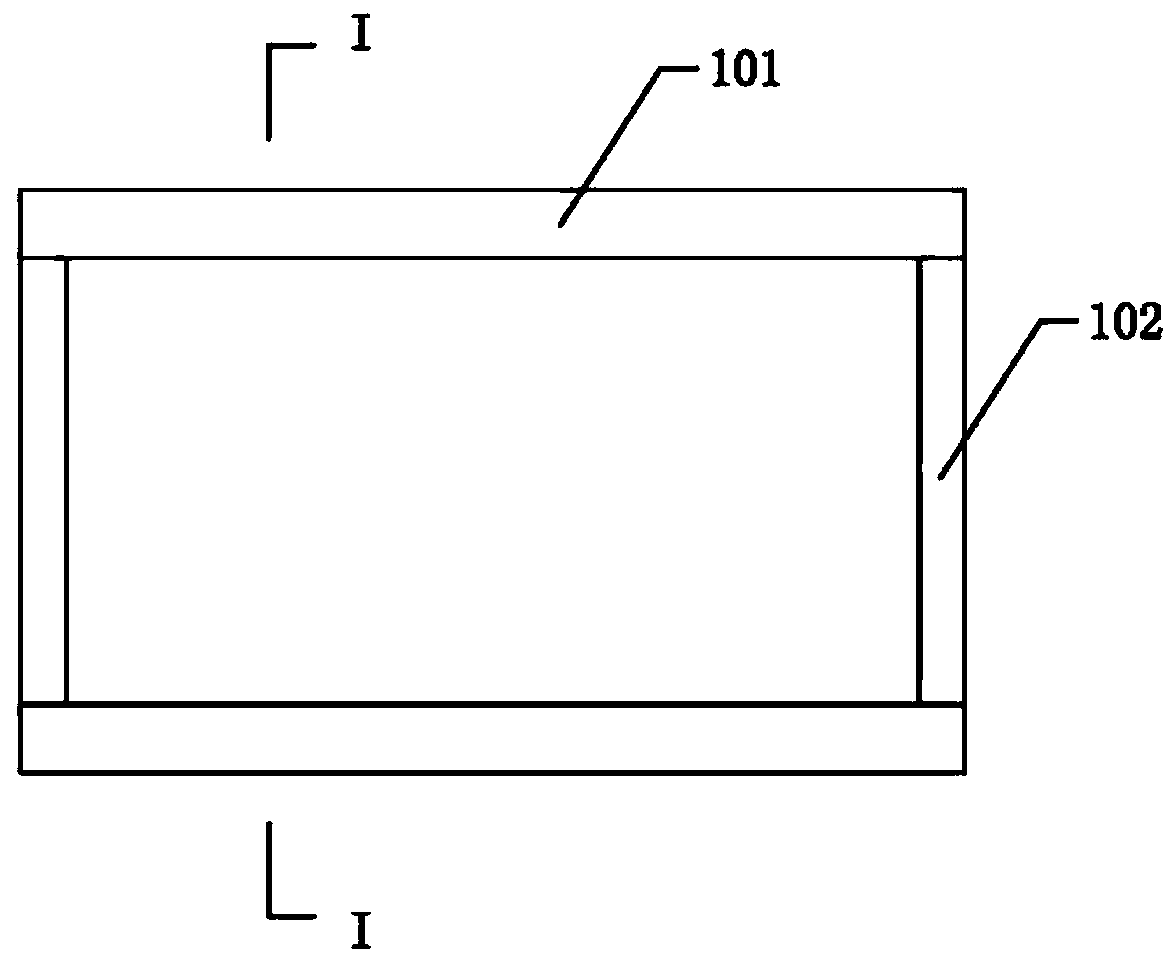

[0030] A bipolar plate for a liquid flow battery has a size of 500mm in length and 400mm in width. The bipolar plate is divided into an electrode area 200 and a non-electrode area 100, such as figure 1 As shown; the non-electrode area 100 is divided into a flow channel area 101 and a non-flow channel area 102, such as figure 2 shown.

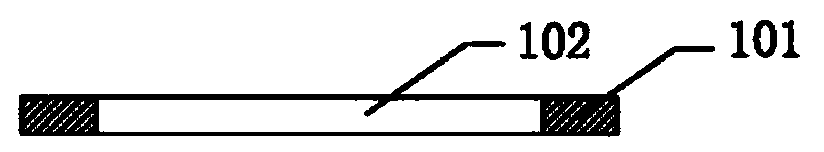

[0031] Such as figure 2 As shown, the flow channel area 101 of the bipolar plate is located on the long side of the bipolar plate, and the non-flow channel area 102 of the bipolar plate is located on the short side of the bipolar plate. The width of the flow channel area 101 of the bipolar plate is 20mm. The non-runner area 102 of the plate is 10 mm wide. Such as image 3 As shown, the thickness of the electrode region 200 of the bipolar plate is equal to the thickness of the non-electrode region 100, which is 2mm. The material of the non-runner area 102 of the bipolar plate and the material of the electrode area 200 are carbon-plastic co...

Embodiment 2

[0033] A bipolar plate for a liquid flow battery has a size of 1000 mm in length and 700 mm in width. The bipolar plate is divided into an electrode area 200 and a non-electrode area 100 ; the non-electrode area 100 is divided into a flow channel area 101 and a non-flow channel area 102 .

[0034] The flow channel area 101 of the bipolar plate is located on the long side of the bipolar plate, and the non-flow channel area 102 of the bipolar plate is located on the short side of the bipolar plate. The width of the track region 102 is 12 mm, and the thickness of the electrode region 200 of the bipolar plate is 2 mm. The non-electrode area 100 of the bipolar plate is covered with a layer of polyethylene insulating material with a thickness of 1 mm, so the thickness of the non-electrode area 100 of the bipolar plate is 4 mm, and the flow channel area 101 and the non-flow channel area 102 of the bipolar plate have the same thickness. The polyethylene insulating material is connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com