Expansion joint for conductive rail

A technology of expansion joints and conductor rails, applied in the direction of power rails, etc., can solve the problems of the guide plate design without considering the increase of joint stiffness requirements, poor anti-theft performance and anti-vibration performance, and reduced service life of expansion joints. risk, improve anti-theft performance, and debug the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

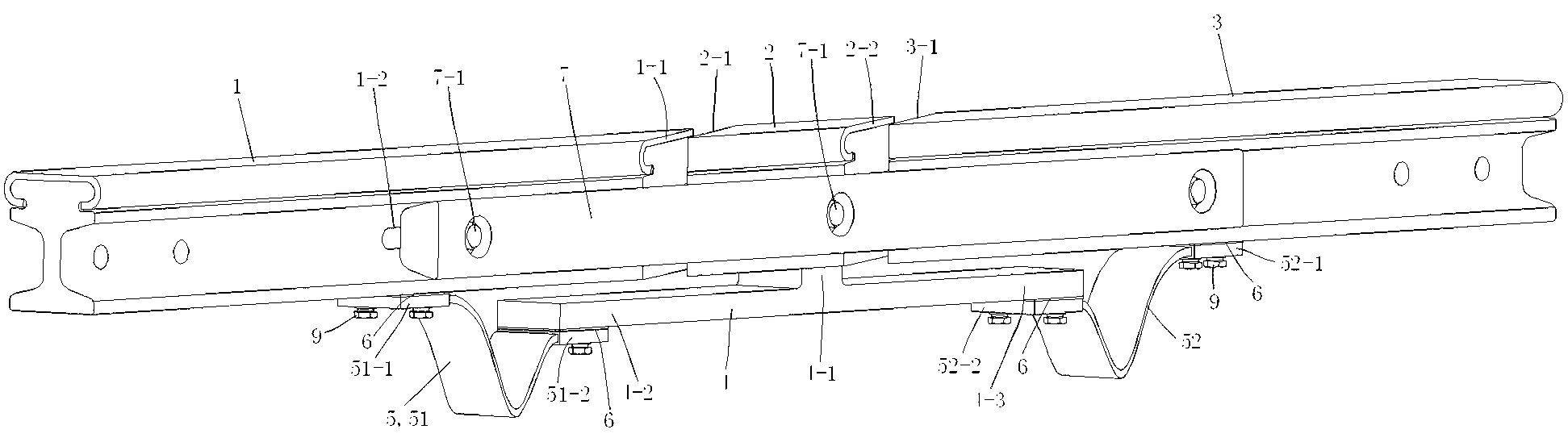

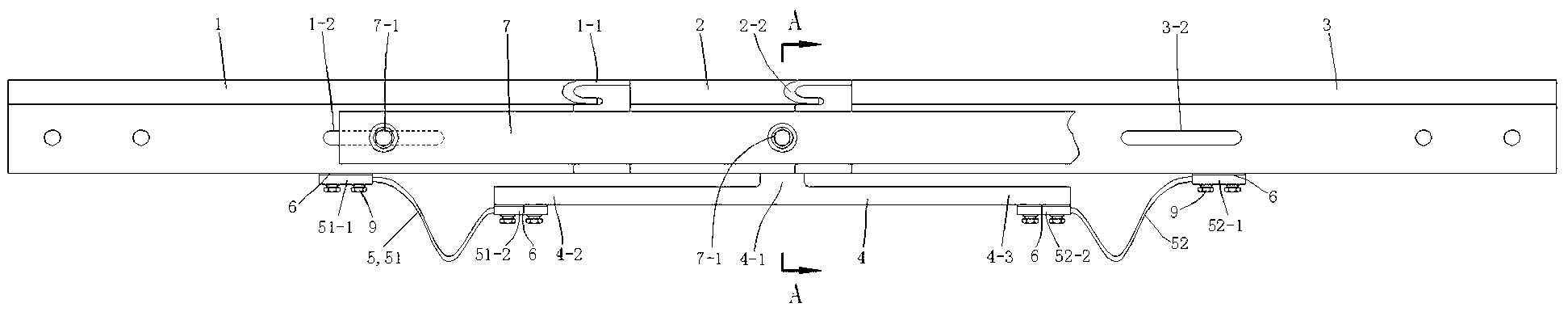

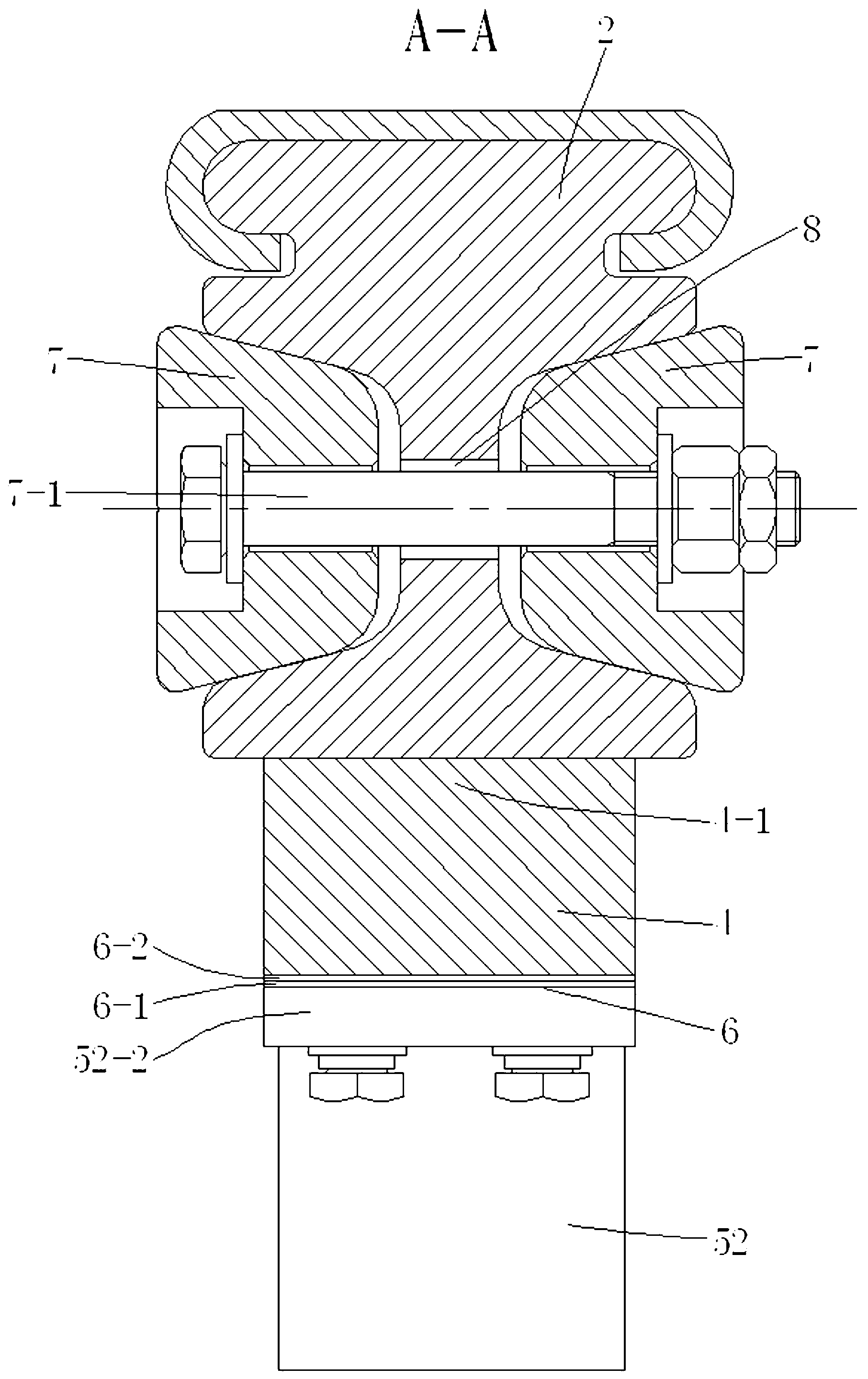

[0034] see Figure 1 to Figure 6 A conductive rail expansion joint shown includes a left conductive rail 1, a middle rail 2 and a right conductive rail 3; 2 and the left end surface 3-1 of the right conductive rail 3 are mutually parallel slopes, the expansion joint also includes a conductive plate 4 and a wire 5; the conductive plate 4 has a boss portion 4-1, and the convex portion of the conductive plate 4 The table portion 4-1 is fixedly connected to the bottom surface of the middle rail 2, and the left and right ends 4-2 and 4-3 of the conductive plate 4 are suspended; the wire 5 is divided into a left wire 51 and a right wire 52, and the left wire 5 One end 51-1 of the wire 51 is connected to the bottom surface of the left conductive rail 1, the other end 51-2 of the left wire 51 is connected to the left suspension end 4-2 of the conductive plate 4, and one end 52-2 of the right wire 52 1 is connected to the bottom surface of the right conductive rail 3, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com