Determination method of cable steel wire corrosion fatigue damage law, application, device and fixture

A technology for corrosion fatigue and measurement methods, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of repeated force/pulsation force to test the strength of materials, etc., which can solve problems such as weak resistance loss, failure, and wear of insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for measuring the corrosion fatigue damage law of cable steel wire,

[0054] Step 1 Get relevant parameters

[0055] Extract the real bridge cable steel wire environmental spectrum, cable static stress value and stress time history spectrum including temperature, humidity and corrosive ion concentration parameters within a period of working time T under service conditions. Among them, corrosive ions mainly refer to The ions that can significantly promote the electrochemical reaction of corrosion are generally Cl - or SO 3 2- ; The extraction process of the steel wire environmental spectrum of the real bridge cable is as follows: the temperature and humidity during this period are obtained by setting a temperature and humidity sensor near the real bridge cable, and whether the corrosive ion concentration can be determined according to the water or rain in the sheath; the static stress of the cable The extraction process of the value is: according to the design ...

Embodiment 2

[0092] Application of a method for determining the corrosion fatigue damage law of cable steel wires in the estimation of the remaining service life of cable steel wires in real bridges. The remaining service life of cable steel wires in real bridges is N f,CFT -N CFT , N f,CFT is the number of cycles when the real bridge cable steel wire obtained in claim 1 breaks, N CFT is the current number of cycles, and the current resistance of the steel wire of the real bridge cable is measured by using a high-precision resistance measuring instrument, and the change value of the current resistance ΔR is calculated to determine the current number of cycles N CFT .

Embodiment 3

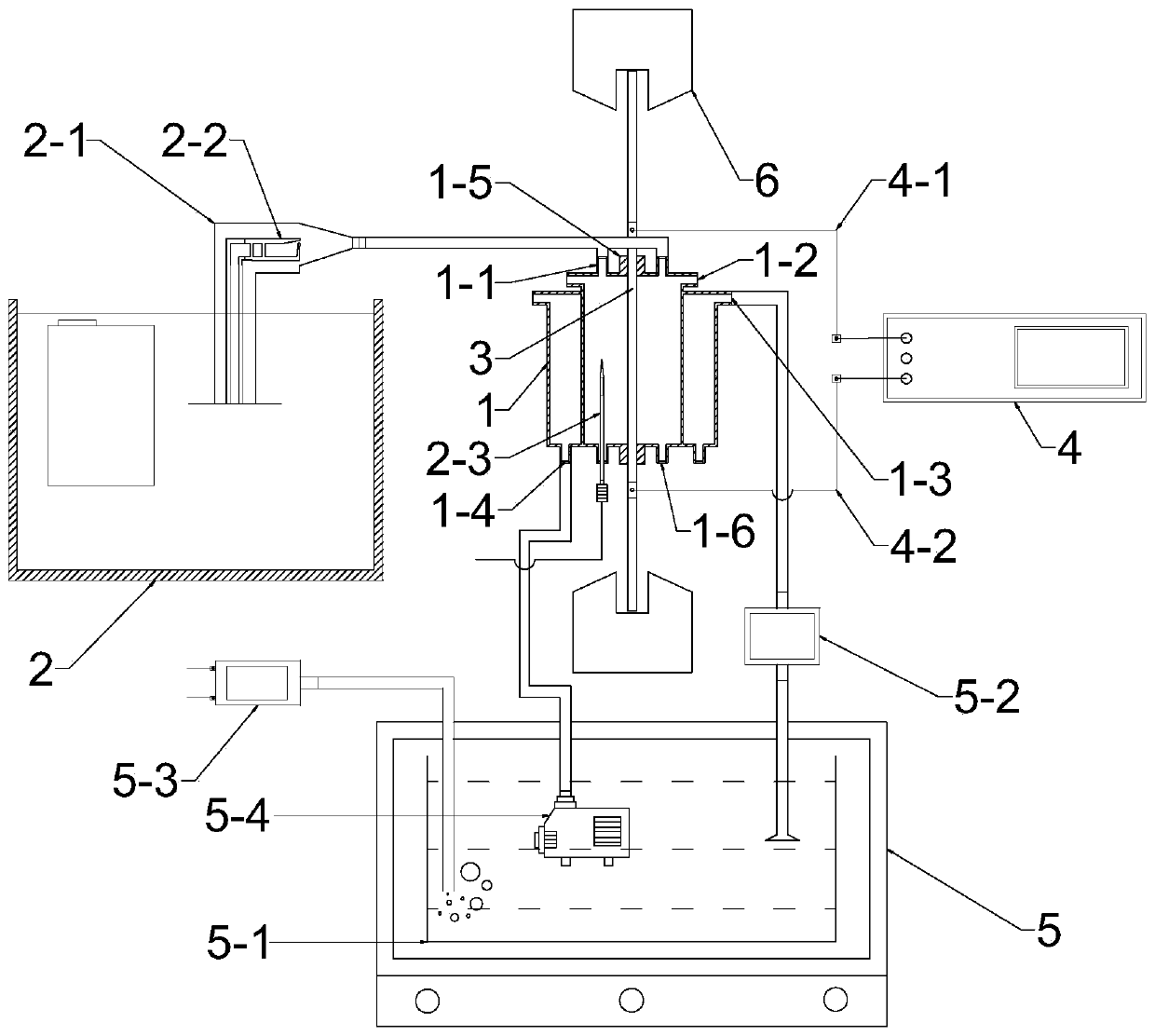

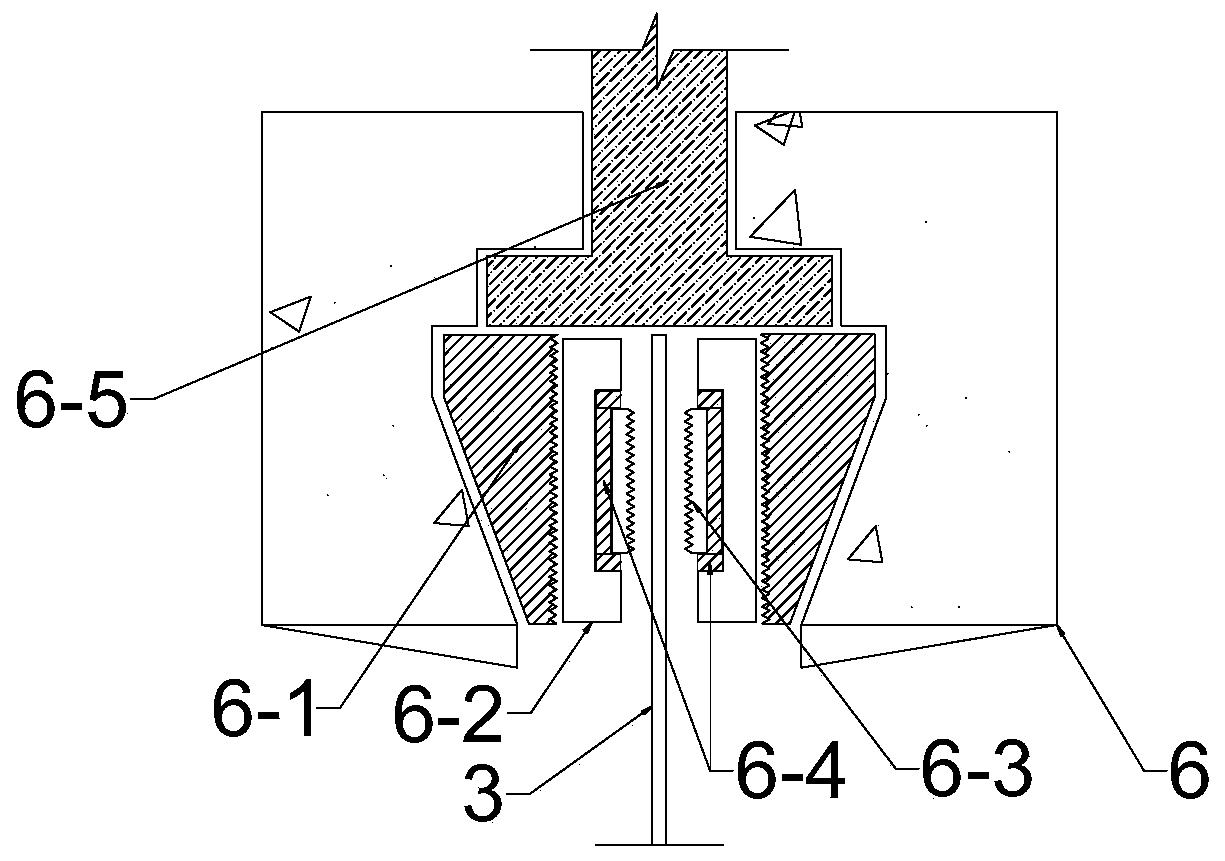

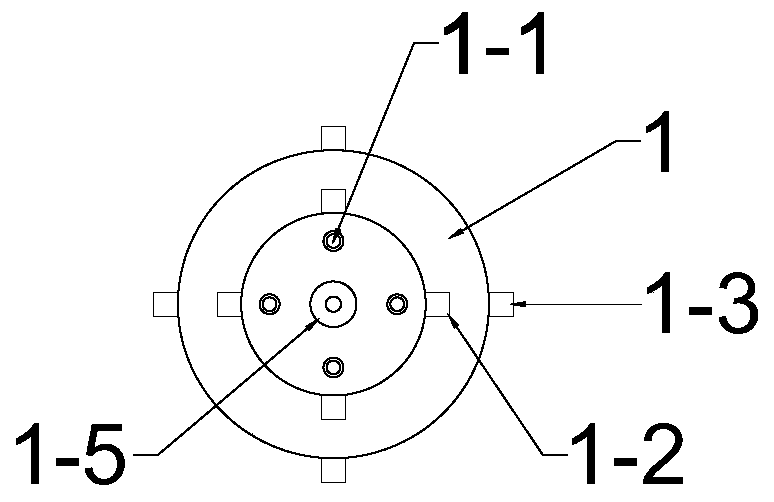

[0094] A device for measuring the fatigue damage law of cable steel wire corrosion, including a double-layer corrosion chamber 1, a salt spray chamber 2, a high-precision resistance tester 4, a constant temperature chamber 5, and a fatigue testing machine. The double-layer corrosion chamber 1 is composed of an inner chamber and a package The inner chamber is composed of an annular outer chamber, the upper and lower ends of the inner chamber are respectively provided with via holes for inserting the steel wire to be tested, and the upper part of the inner chamber is provided with an inner chamber salt spray inlet 1-1 and The overflow port 1-2 is provided with an inner chamber corrosive liquid inlet 1-6 which is also used for emptying the fluid in the inner chamber at the lower part of the inner chamber, and a plug-in temperature and humidity sensor 2-3 is arranged in the inner chamber. The upper part of the annular outer chamber is provided with an outer chamber overflow port 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com