Service life test device and method of ball screw for parking clamp

A ball screw and life testing technology, applied in the field of ball screw, can solve the problems of complex structure, inconvenience of testing personnel, cumbersome testing process, etc., and achieve the effect of accurate service life, simple overall structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

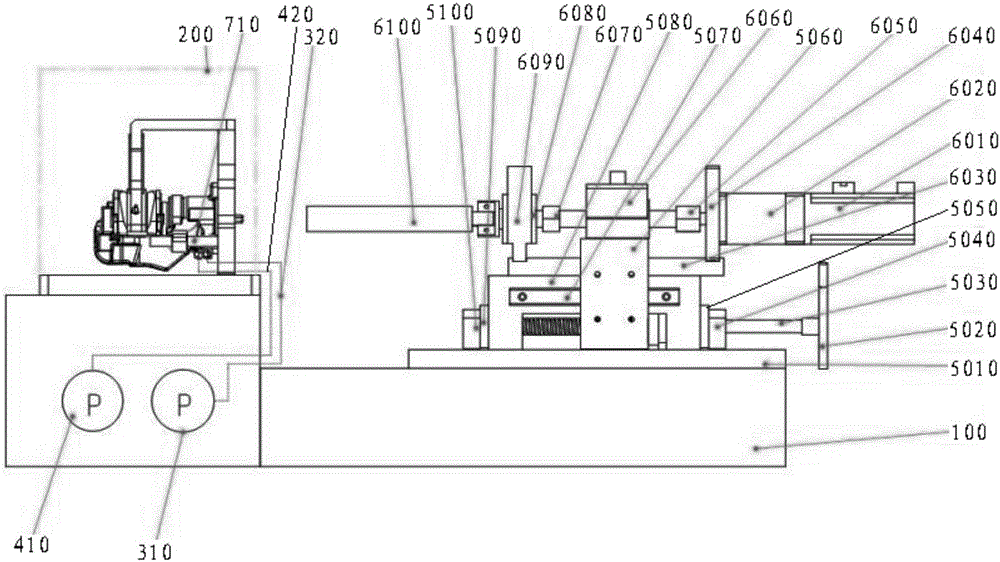

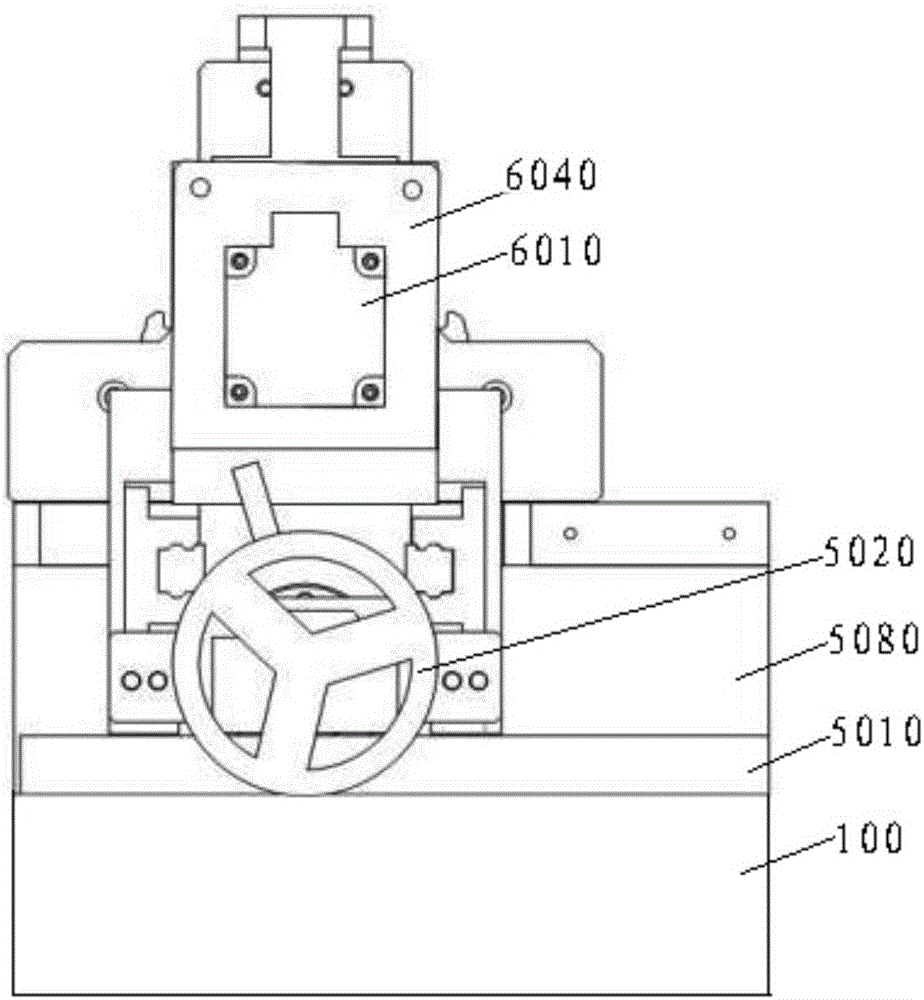

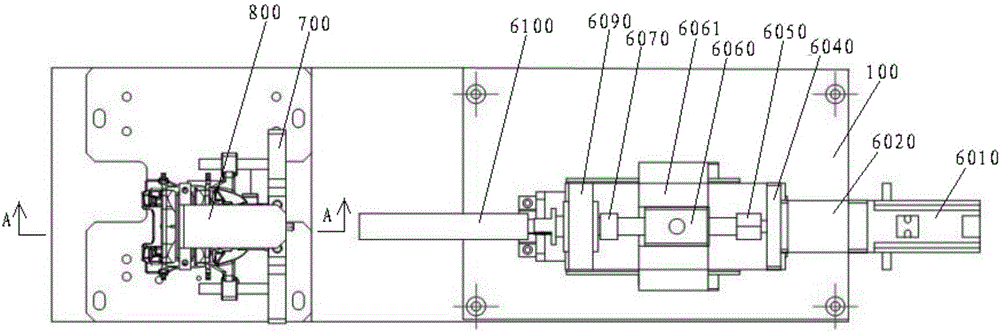

[0038] Reference Figure 1-Figure 5 As shown in the figure, a life test device for a ball screw for a parking caliper is shown, including a workbench 100, a high and low temperature box 200, a vacuum device, a hydraulic device, a torque device, a feed device and a PLC control system.

[0039] The high and low temperature box 200 is set on one side of the workbench 100 to control the test temperature of the ball screw 910 during the test. The high and low temperature box 200 is provided with a caliper 940 equipped with the ball screw 910. The caliper 940 passes through the upper part of the caliper. The guide sleeve is arranged on the guide post 710 of the caliper fixing plate 700, the caliper fixing plate 700 is installed on the workbench 100, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com