Test method for acoustic emission detection cable coating corrosion fatigue crack initiation and growth

A technique for corrosion fatigue, test methods, applied in the direction of material analysis using sonic emission technology, testing material strength using applied stable tension/pressure, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings and specific preferred embodiments.

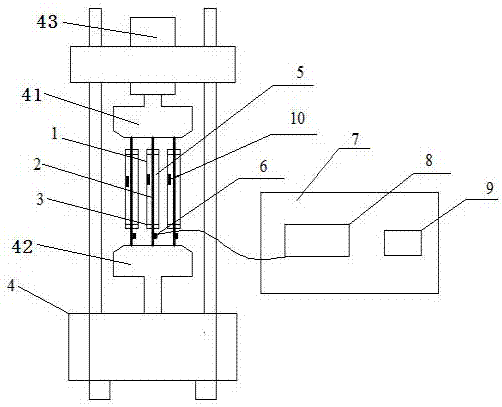

[0045] Such as figure 1 As shown, an acoustic emission test device for detecting the initiation and propagation of corrosion fatigue cracks in cable coatings includes a fatigue testing machine 4, a tensile fixture, a corrosion tank, a corrosive medium 5, an acoustic emission monitoring system, an electronic endoscope 10 and a computer 9 .

[0046] Among them, the acoustic emission monitoring system and the electronic endoscope are both connected to the computer.

[0047] The fatigue testing machine is an existing technology and is purchased on the market. The loading waveform of the fatigue testing machine includes a sine wave, and the stress ratio of the fatigue testing machine can be adjusted.

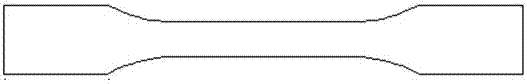

[0048] The cable is the load-bearing component of the bridge. All the dead weight and live load of the superstructure are borne by the cable, but the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com