Corrosion fatigue test apparatus with high temperature and high pressure circulating water

A high-temperature, high-pressure, corrosion-fatigue technology, applied in the field of material experiments, can solve problems such as complex structure, troublesome use and maintenance, and achieve the effects of simple operation, low cost and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

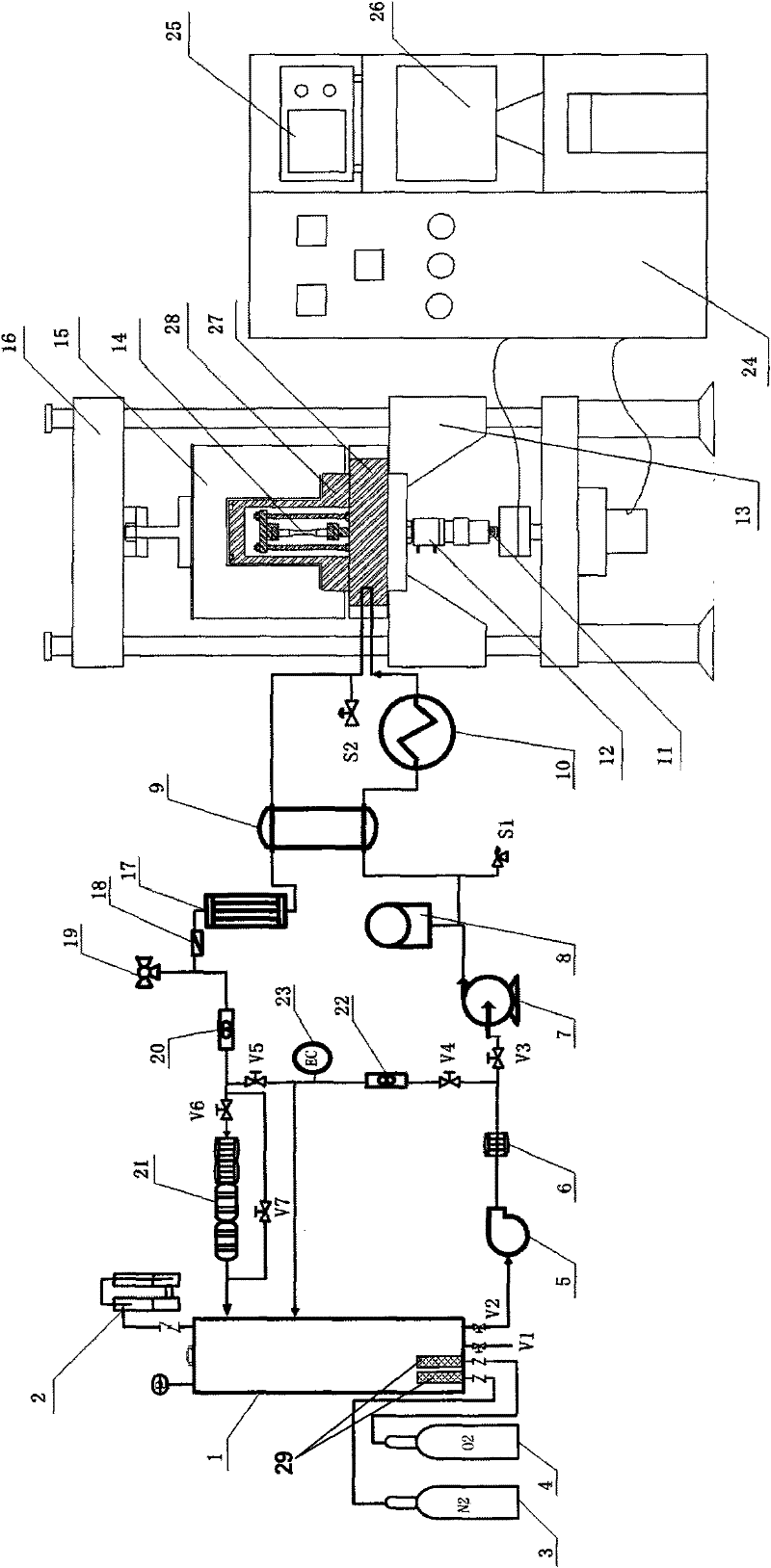

Method used

Image

Examples

Embodiment 1

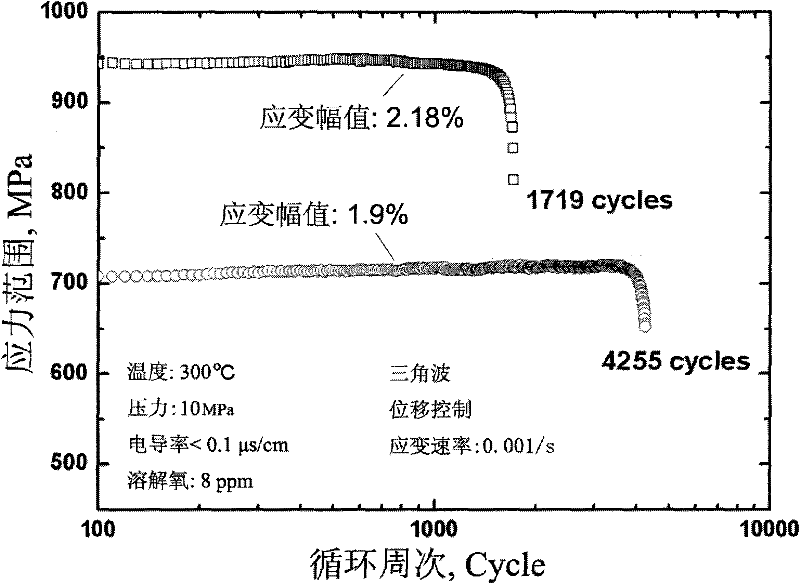

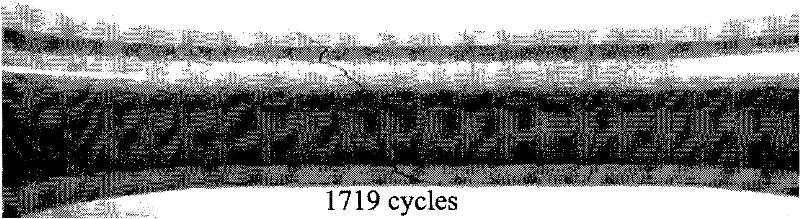

[0051] The corrosion fatigue test of SA508-3 low alloy steel for domestic pressure vessels in 300℃, 10MPa, DO dissolved oxygen saturated high temperature and high pressure circulating water, the strain amplitude is 2.18%.

[0052] The experimental sample material is SA508-3 low-alloy steel for domestic nuclear power plant pressure vessels, which is processed into a smooth round bar sample with a gauge length of 16mm and a diameter of 8mm. The fatigue sample is fixed on the fixture, the autoclave is tightened, and the water storage After the tank is filled with water, introduce oxygen to keep the oxygen pressure of 0.2-0.5MPa in the water storage tank for at least 12 hours, and the dissolved oxygen in the water reaches saturation (8ppm). Start the high-temperature and high-pressure circulating water control cabinet and the fatigue machine control cabinet. Start the circulation pump to filter all the water through the ion exchange resin. When the electrical resistivity of the out...

Embodiment 2

[0054] High temperature and high pressure corrosion fatigue test of SA508-3 low alloy steel for domestic pressure vessels at a strain amplitude of 1.9%.

[0055] The experimental sample material is SA508-3 low-alloy steel for domestic nuclear power plant pressure vessels, which is processed into a smooth round bar sample with a gauge length of 16mm and a diameter of 8mm. The fatigue sample is fixed on the fixture, the autoclave is tightened, and the water storage After the tank is filled with water, introduce oxygen to keep the oxygen pressure of 0.2-0.5MPa in the water storage tank for at least 12 hours, and the dissolved oxygen in the water reaches saturation (8ppm). Start the high-temperature and high-pressure circulating water control cabinet and the fatigue machine control cabinet. Start the circulation pump to filter all the water through the ion exchange resin. When the electrical resistivity of the outlet water is greater than 10MΩ.cm, turn on the high-pressure pump and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com