Patents

Literature

42results about How to "Control resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

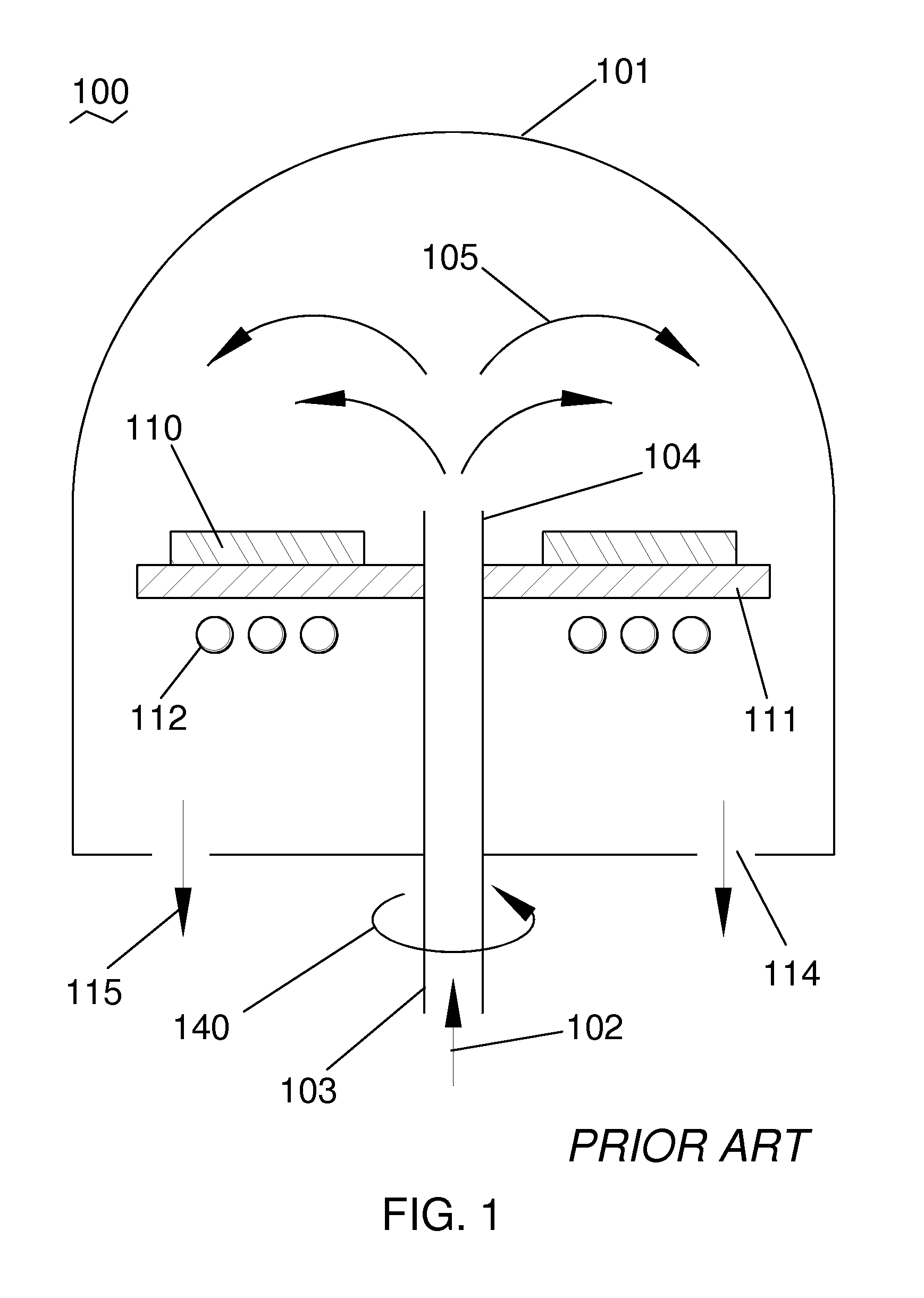

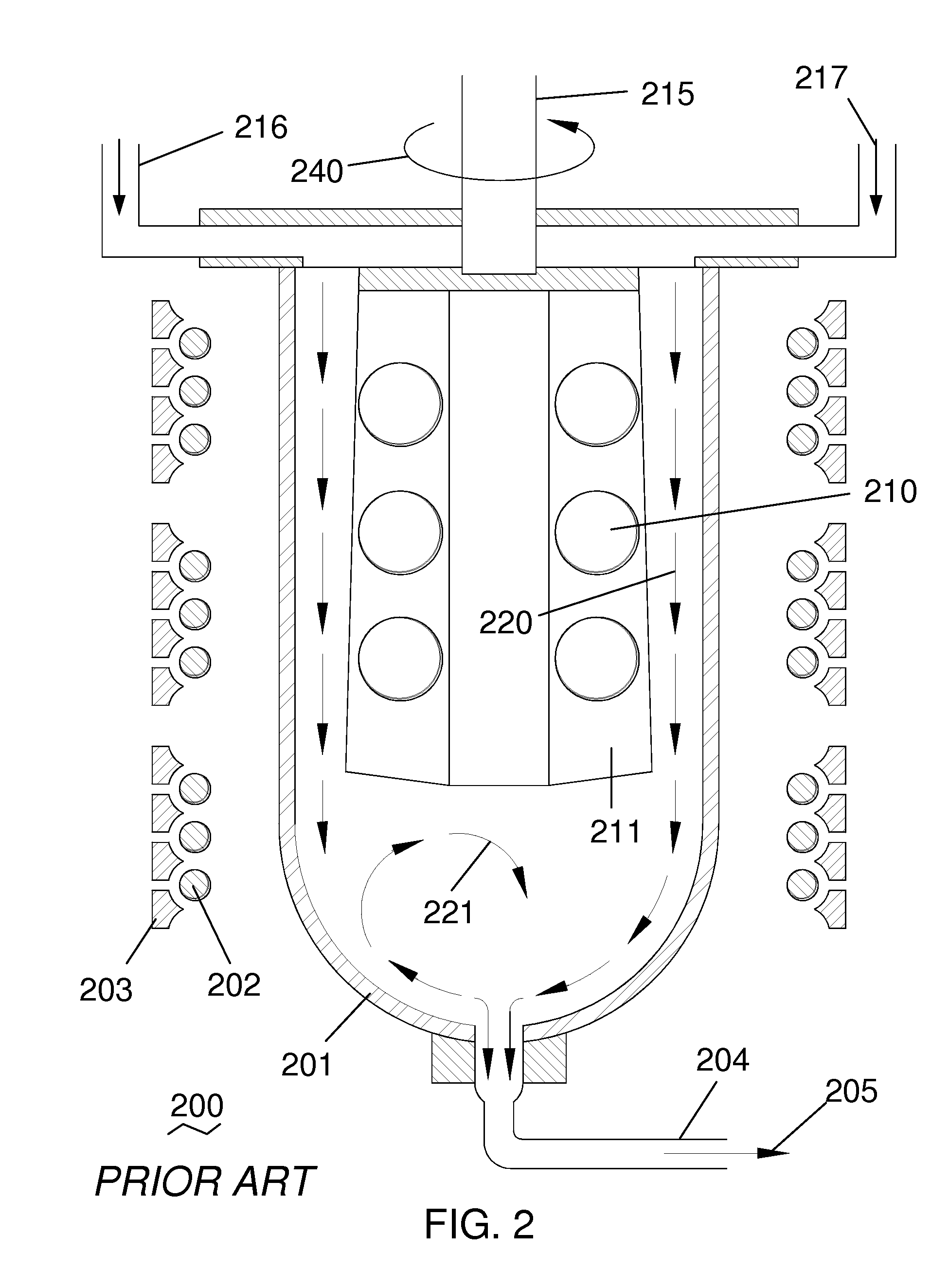

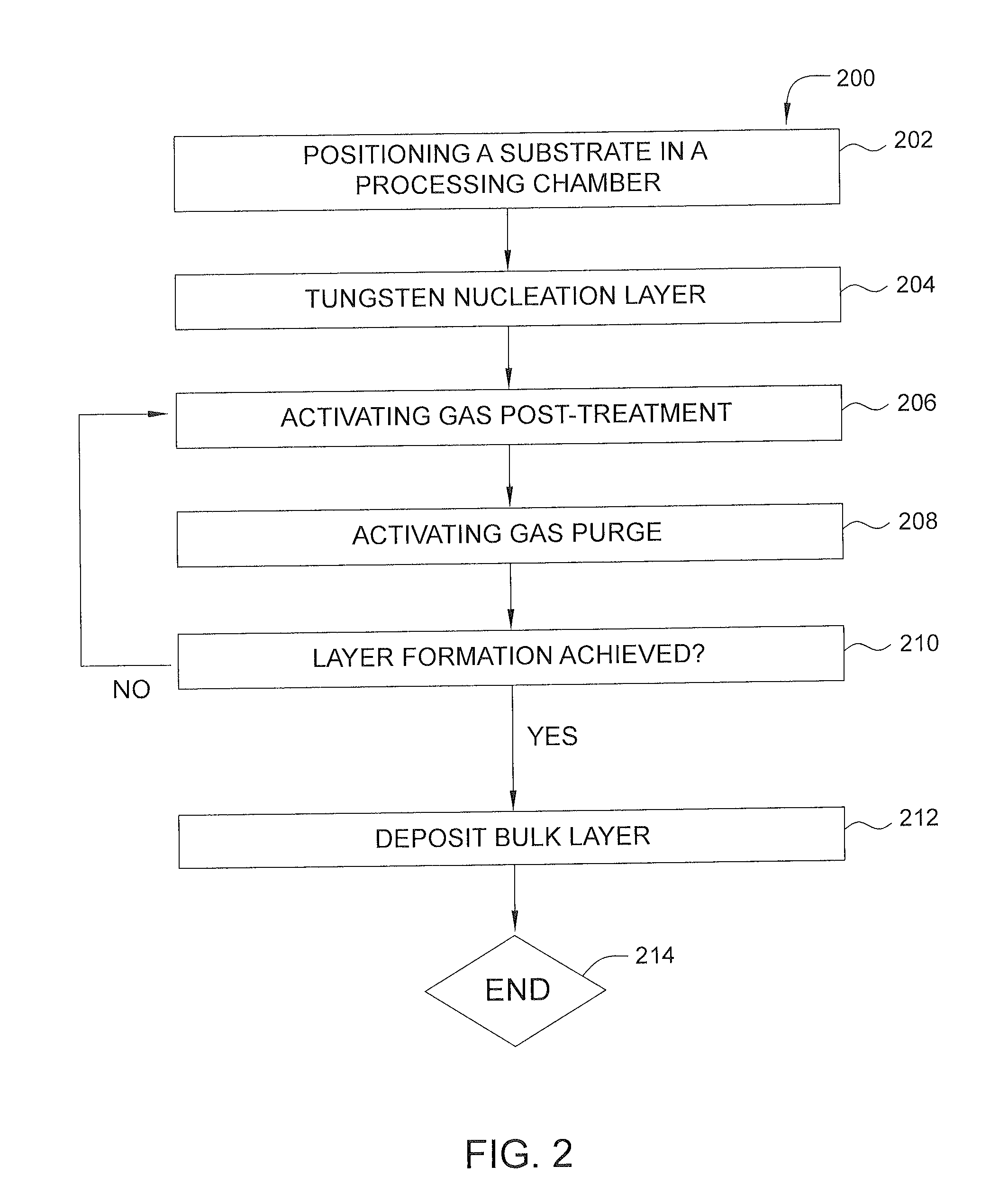

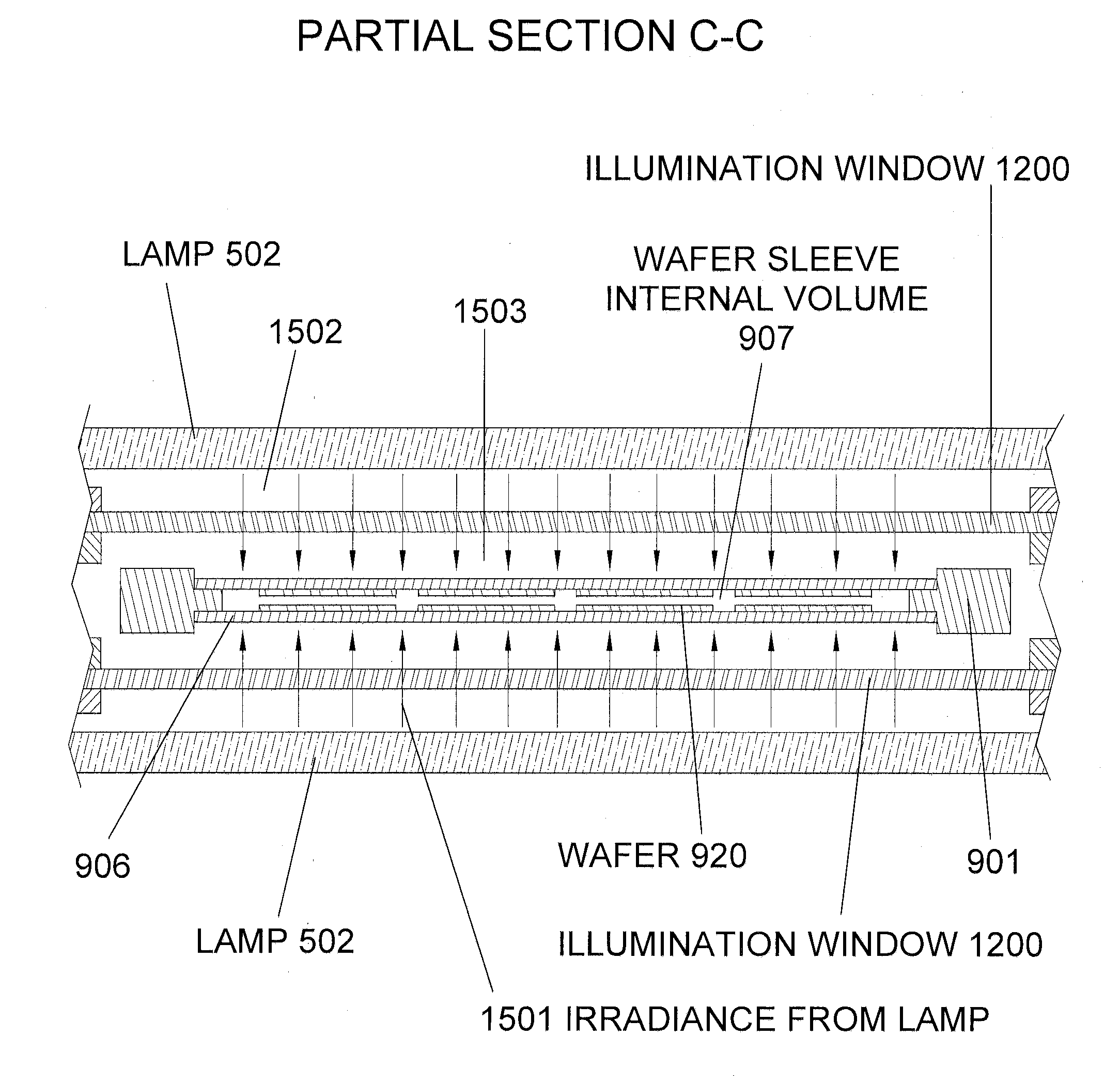

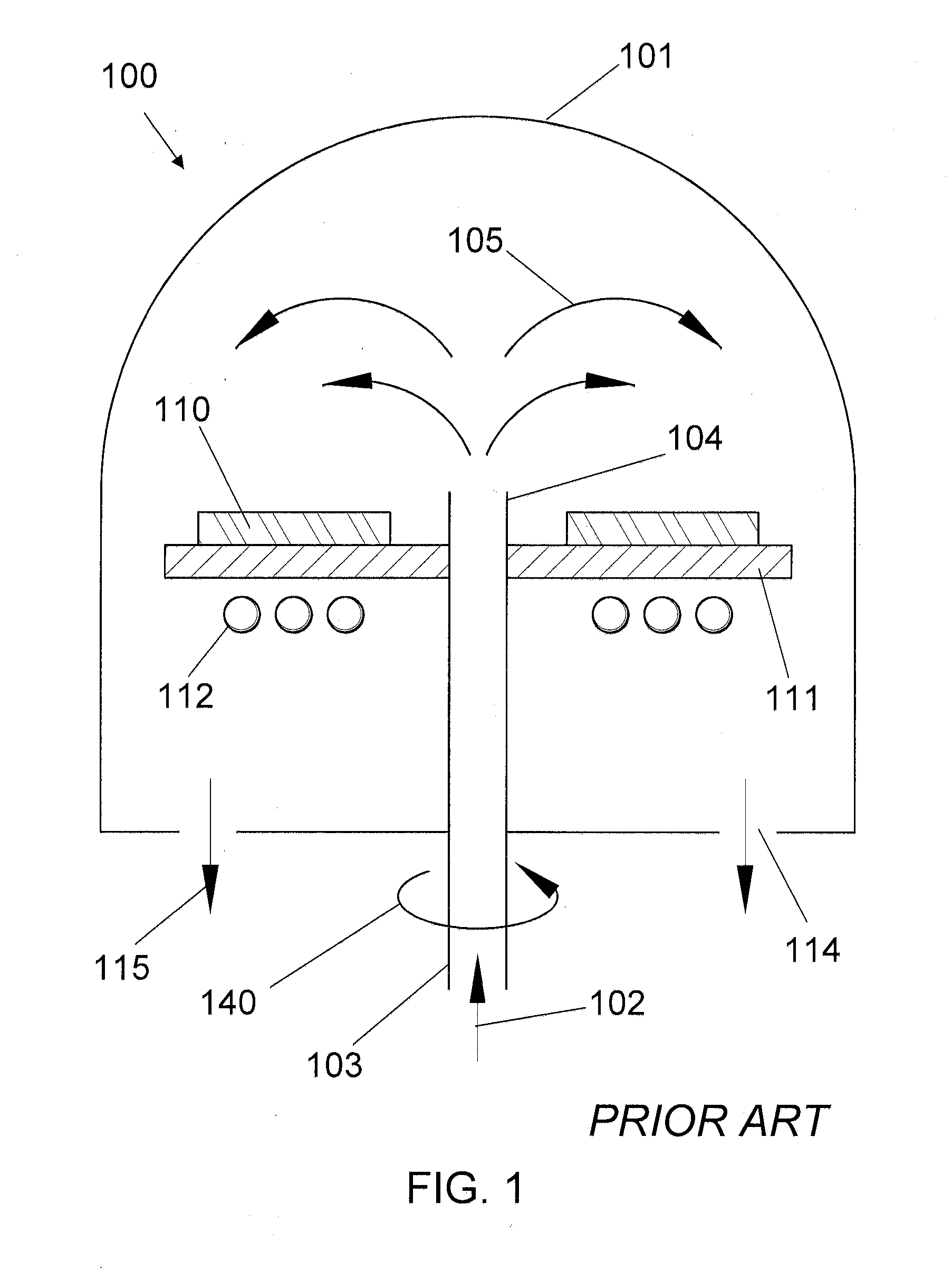

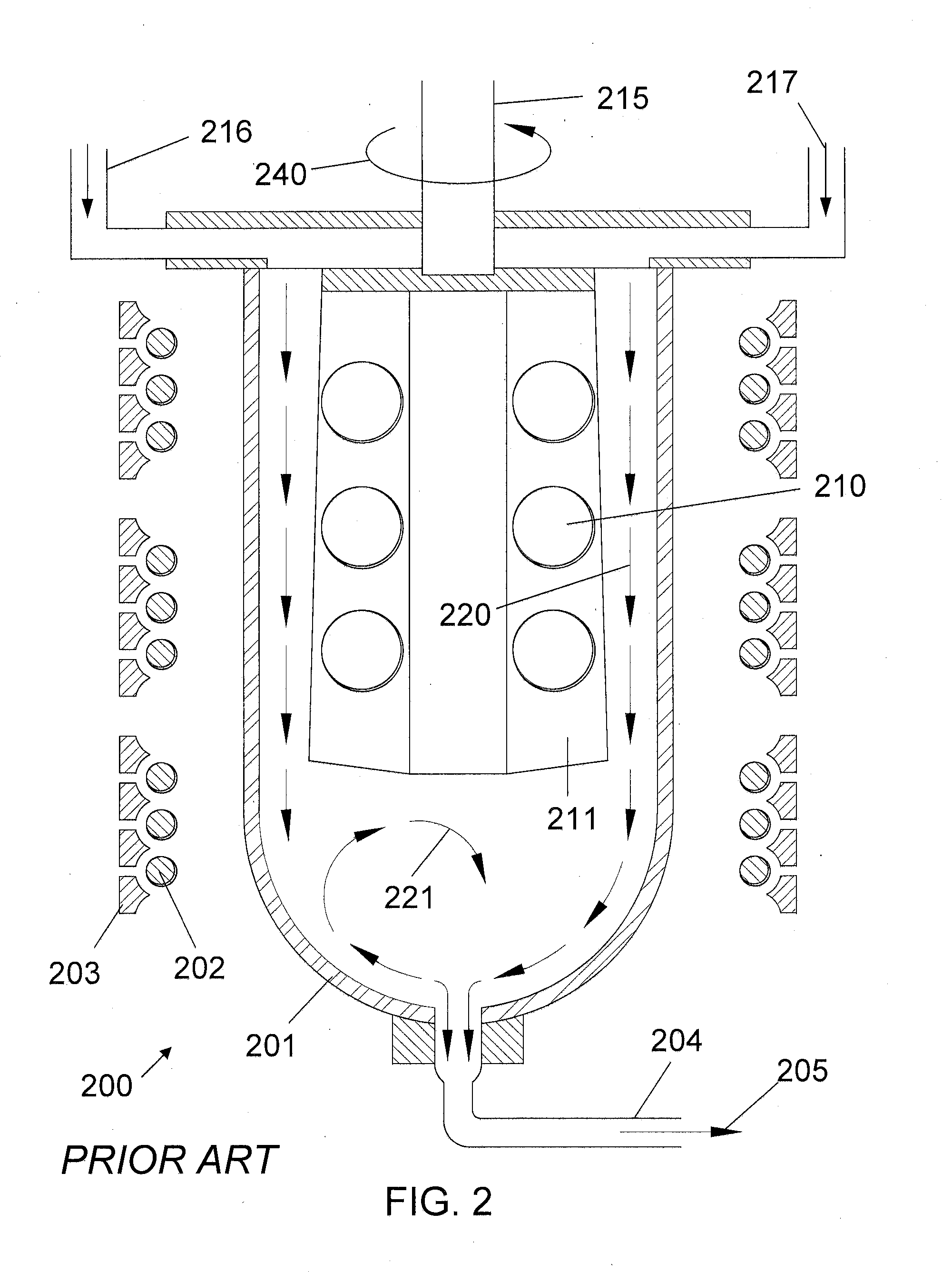

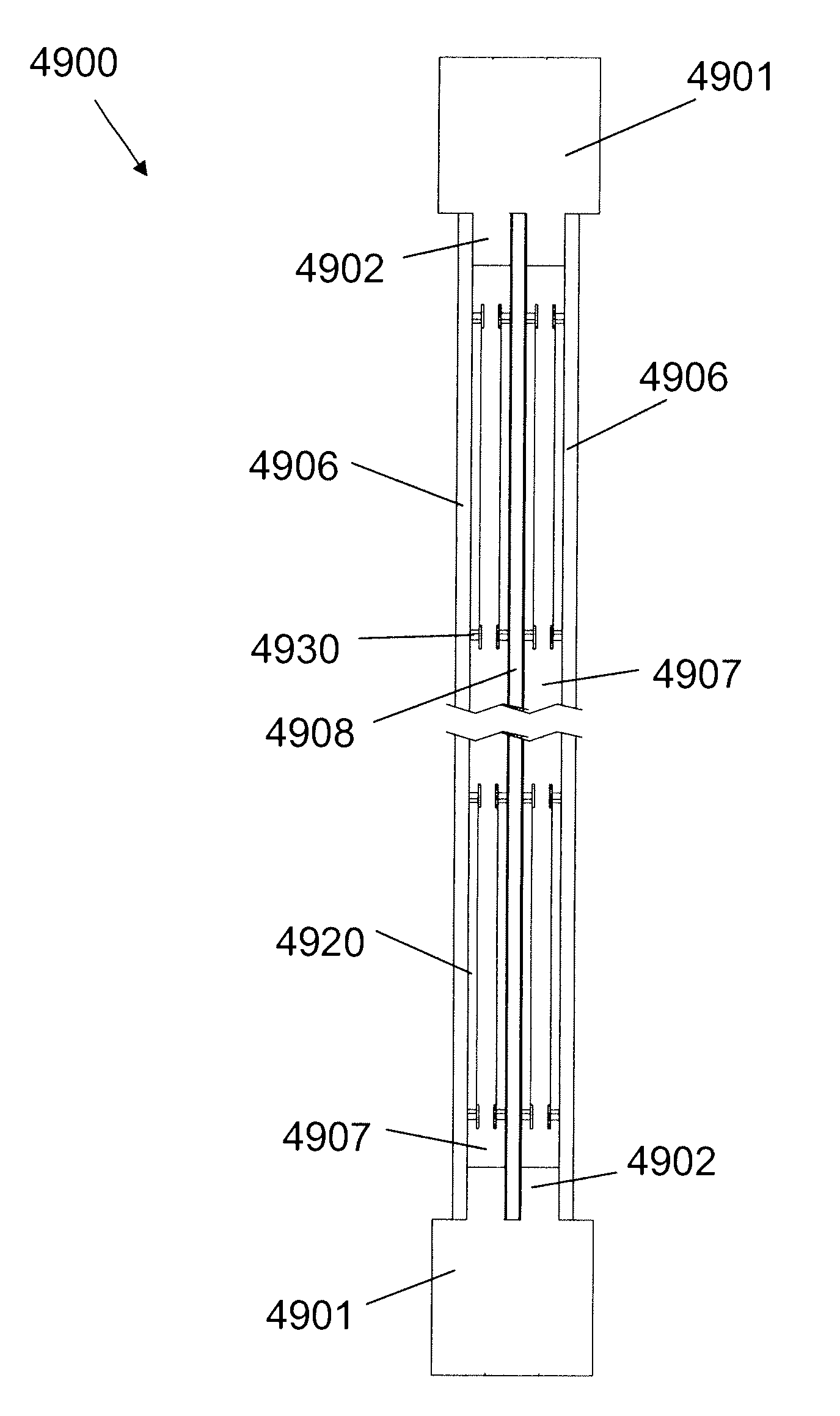

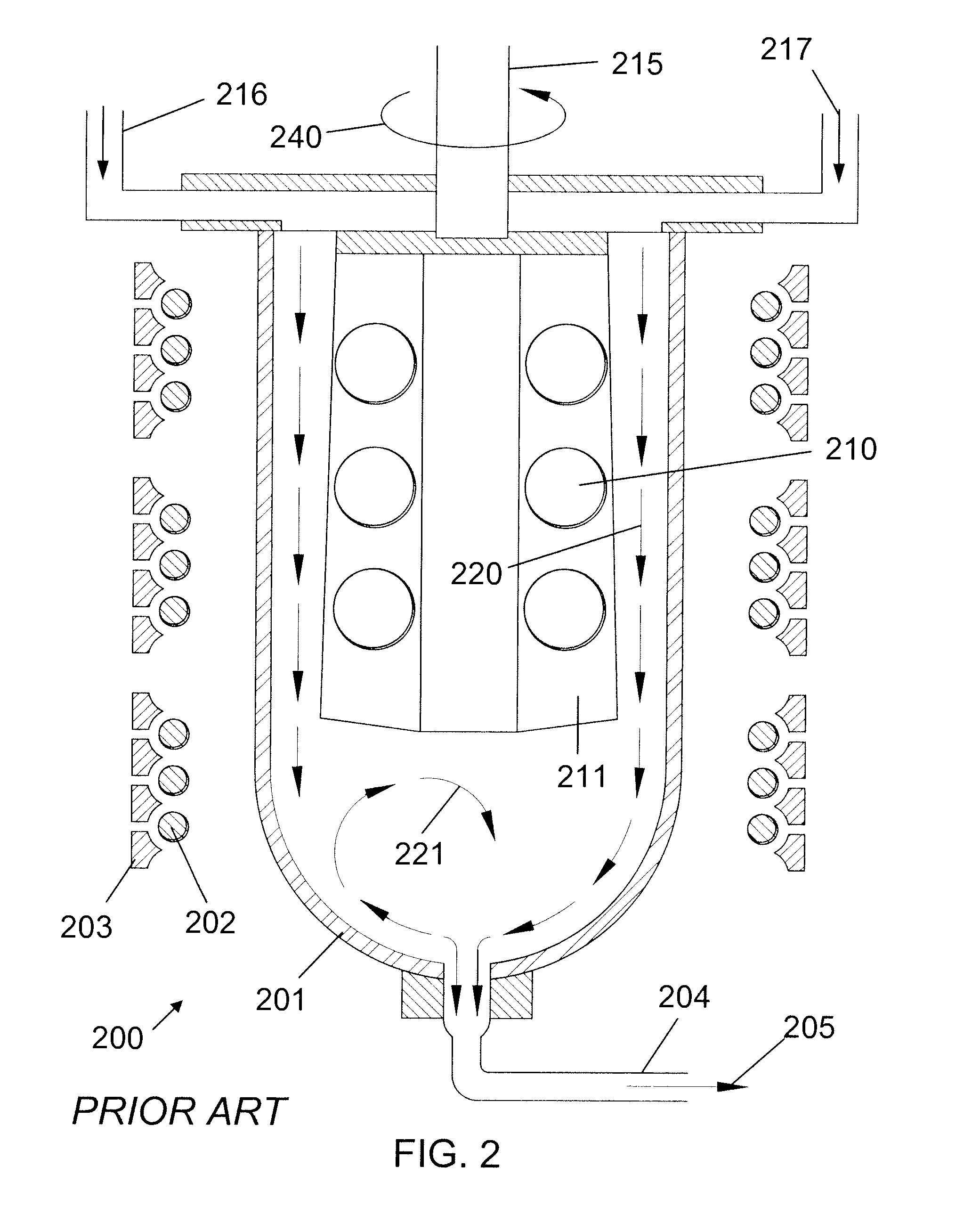

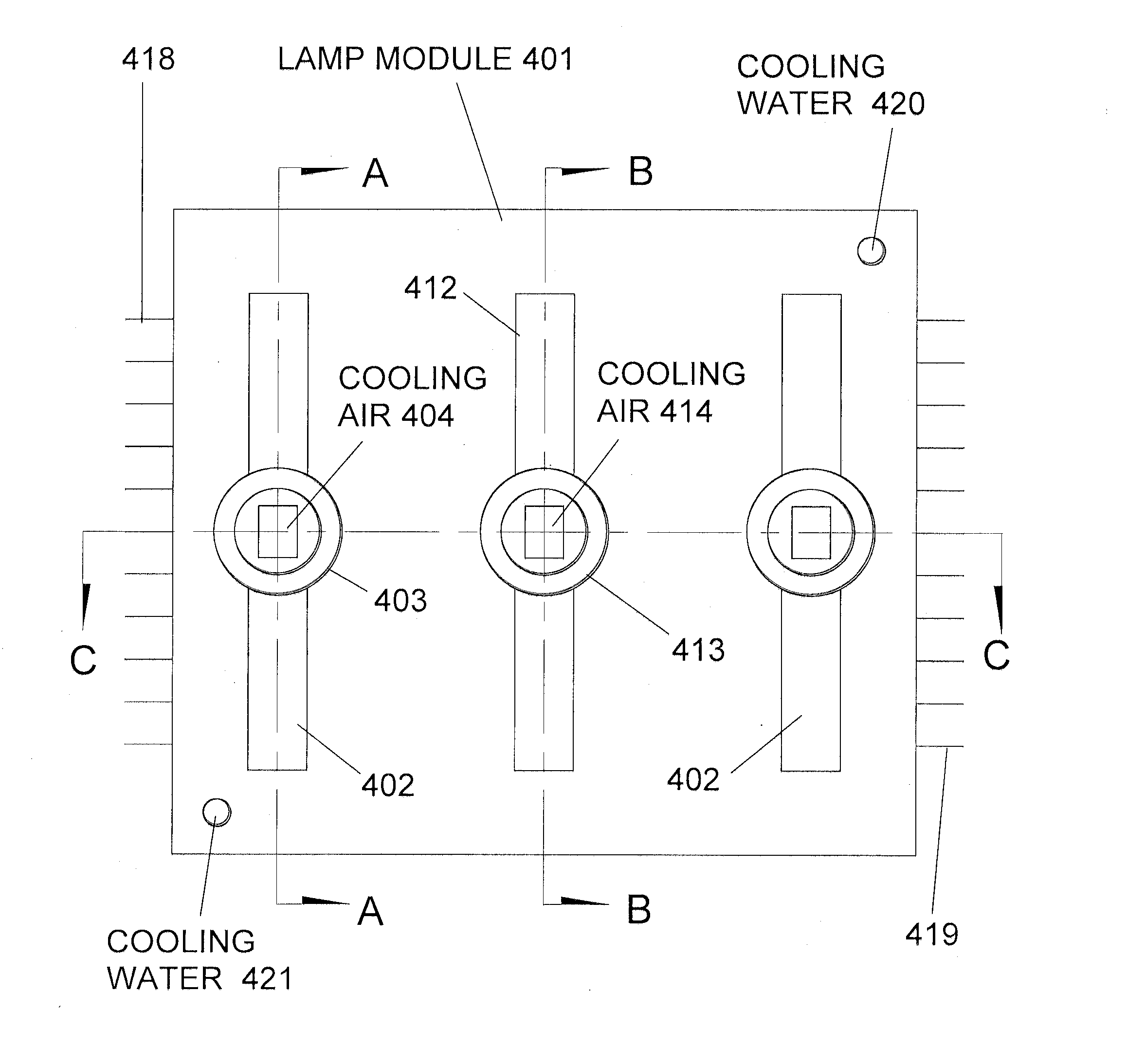

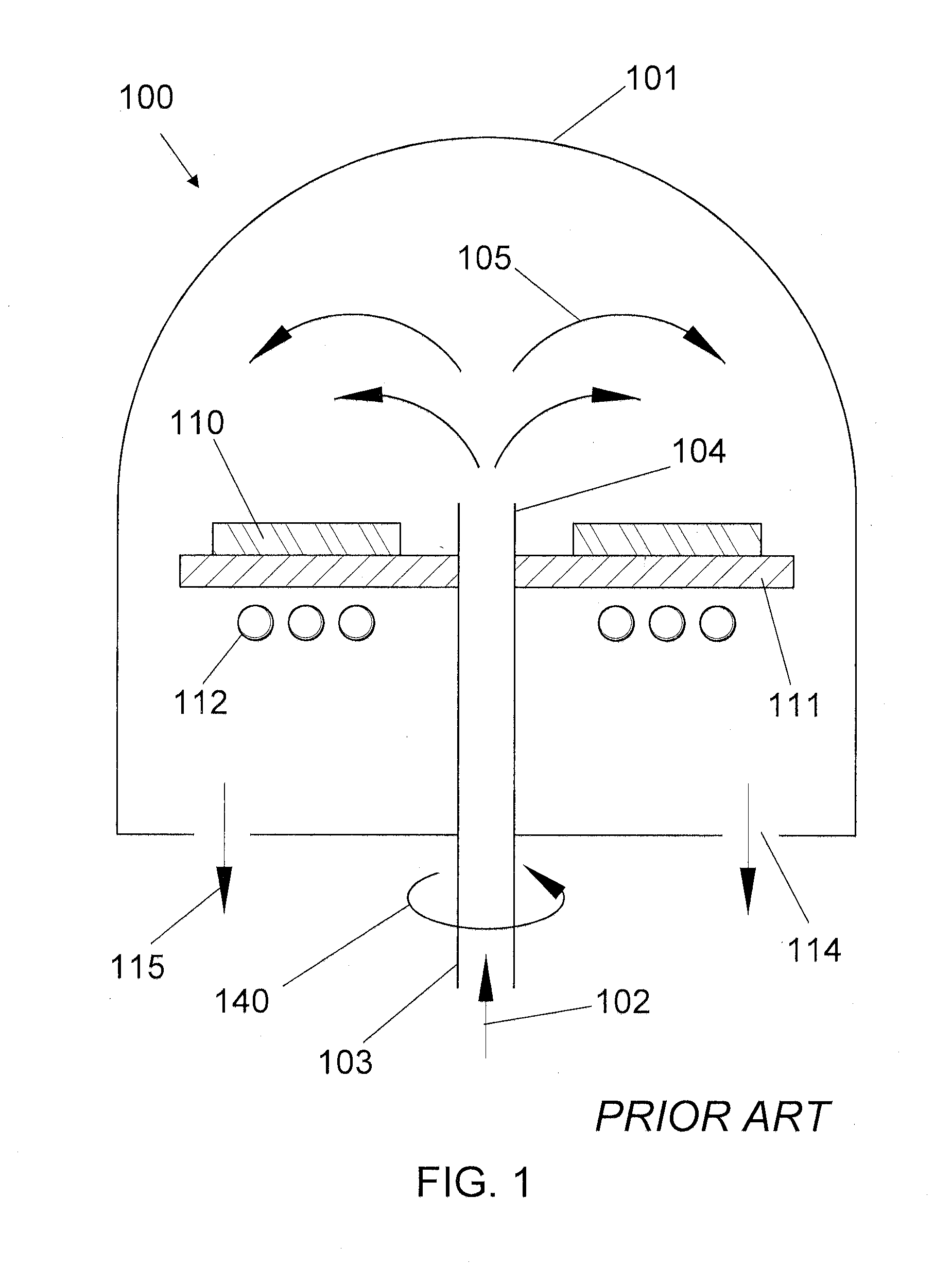

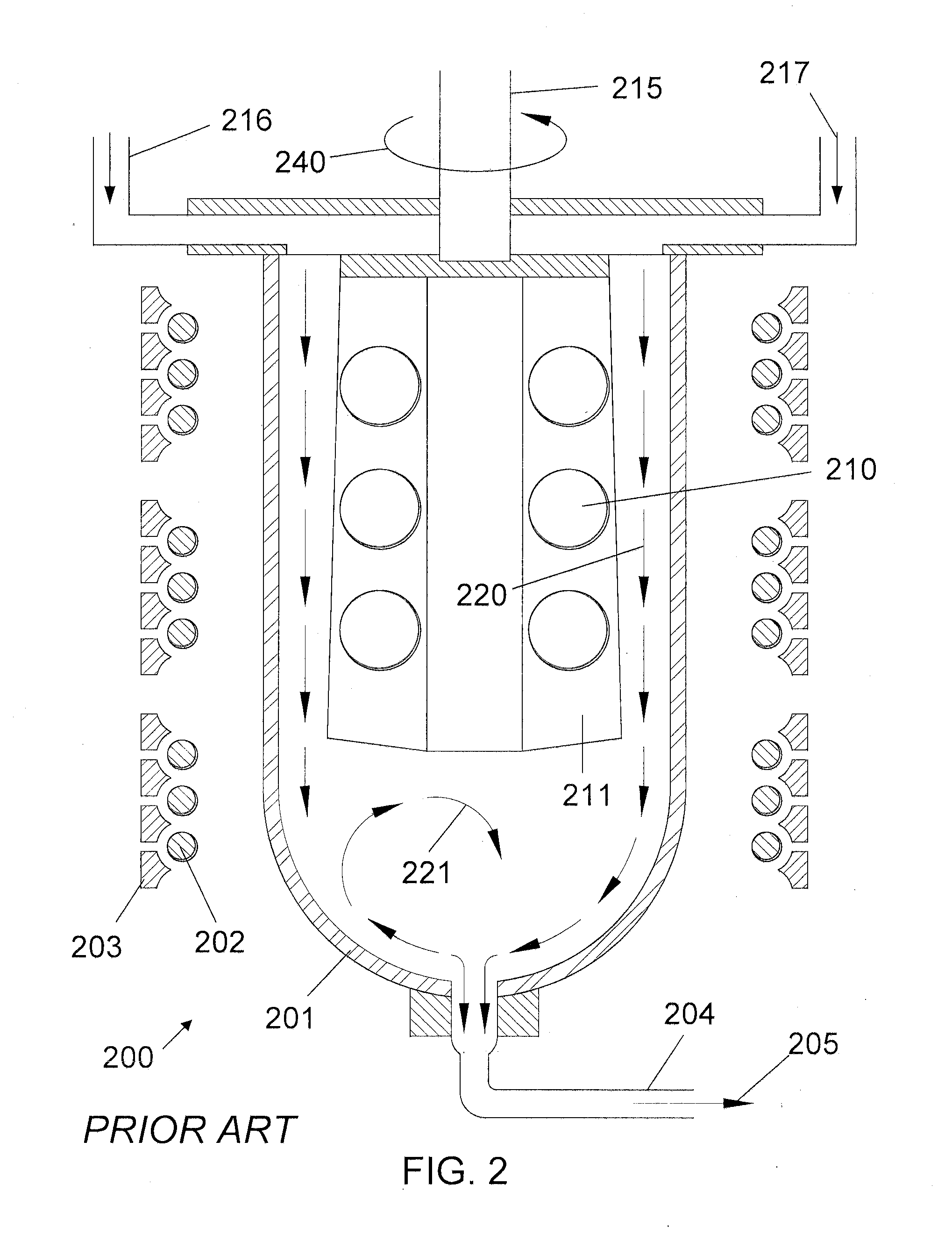

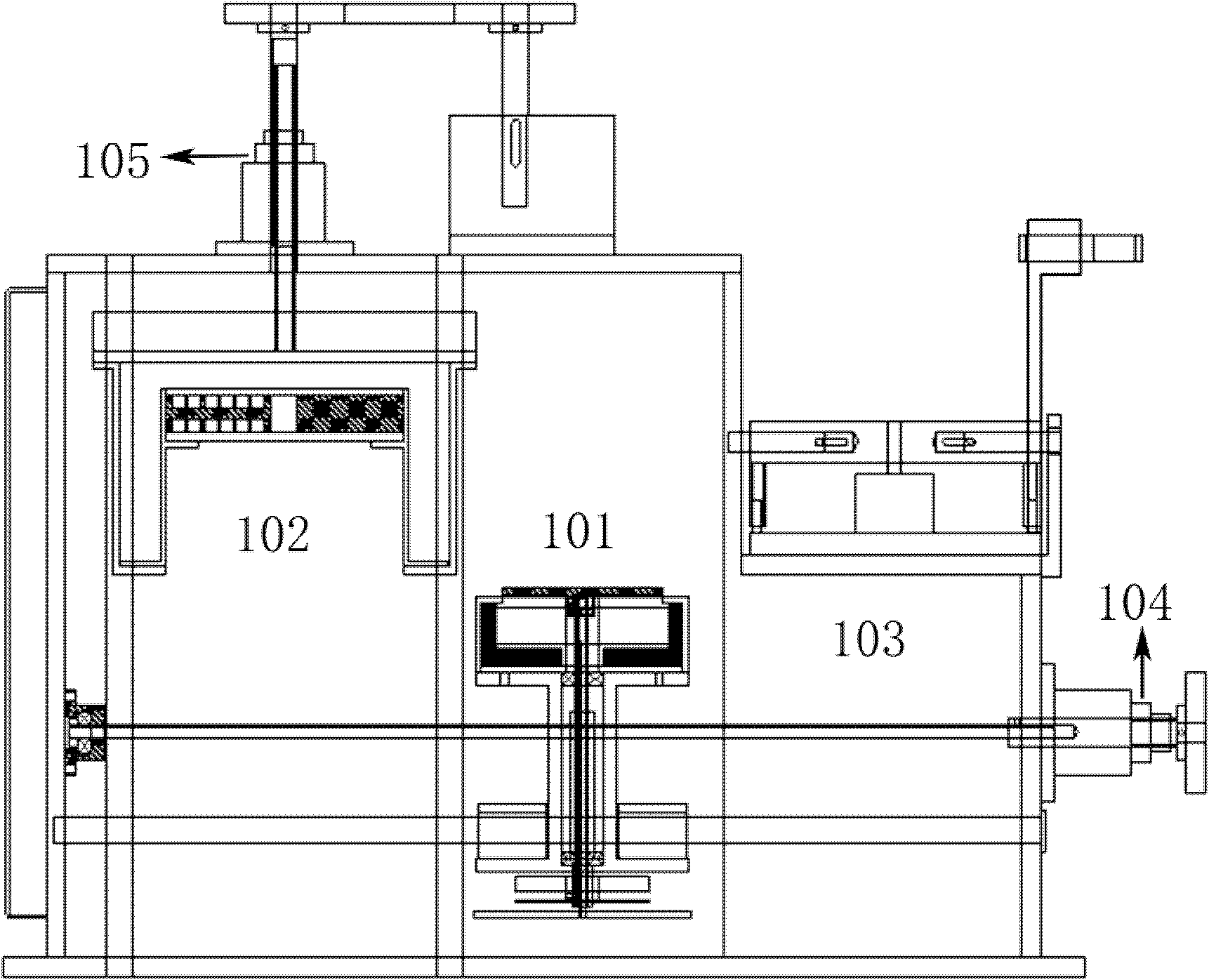

High throughput multi-wafer epitaxial reactor

ActiveUS20100263587A1Improving deposit uniformityImprove throughputAfter-treatment apparatusPolycrystalline material growthWaferingReactor system

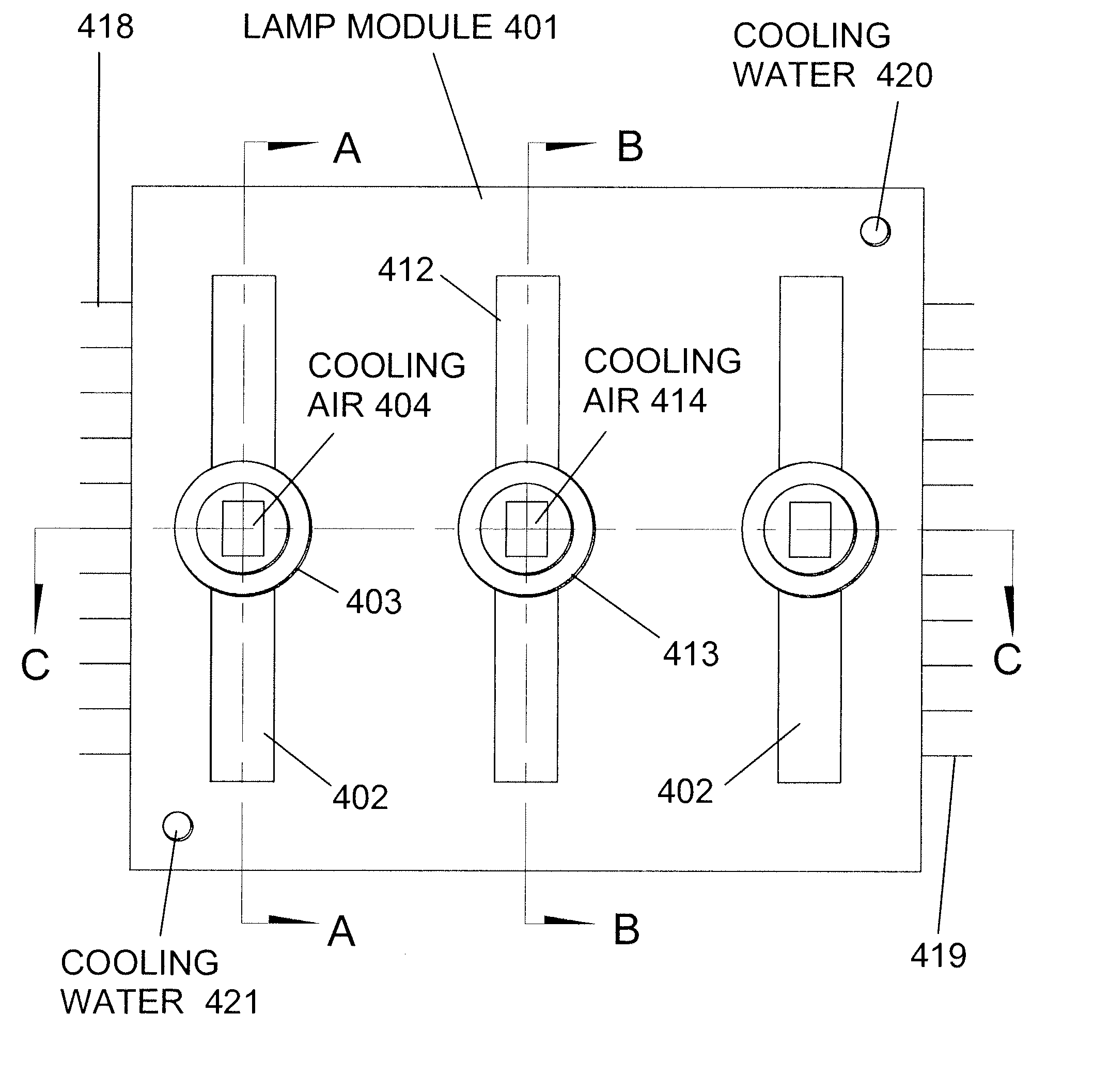

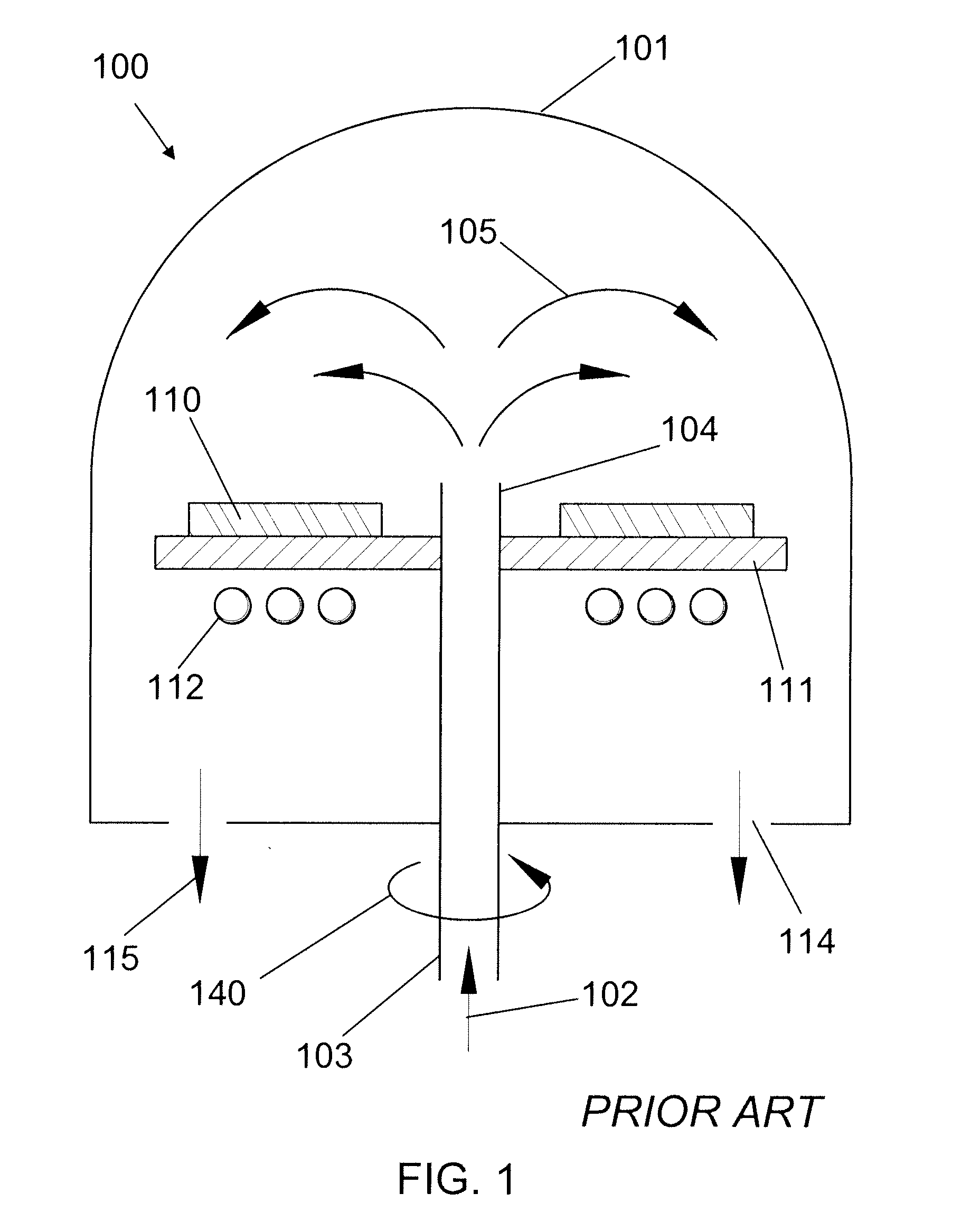

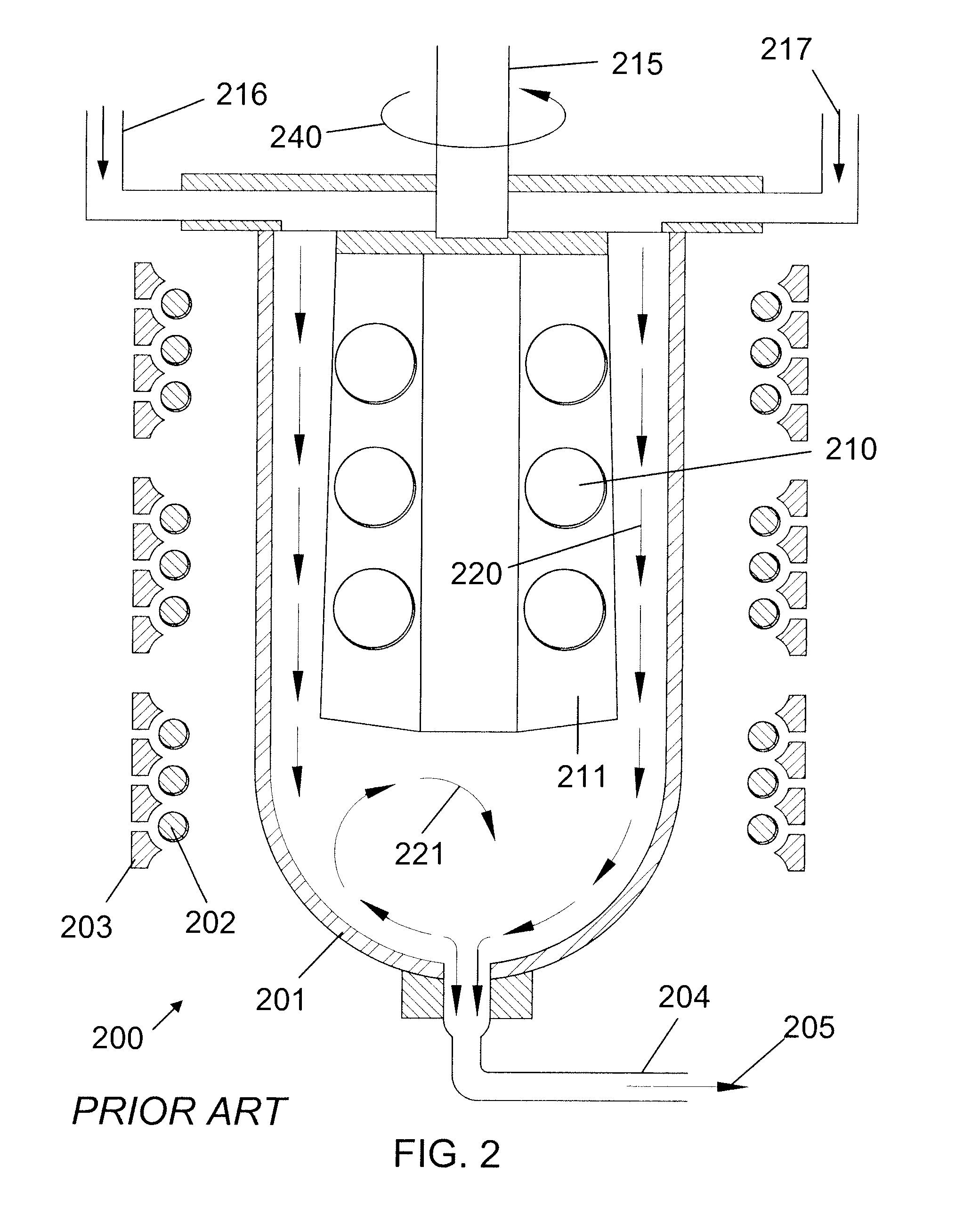

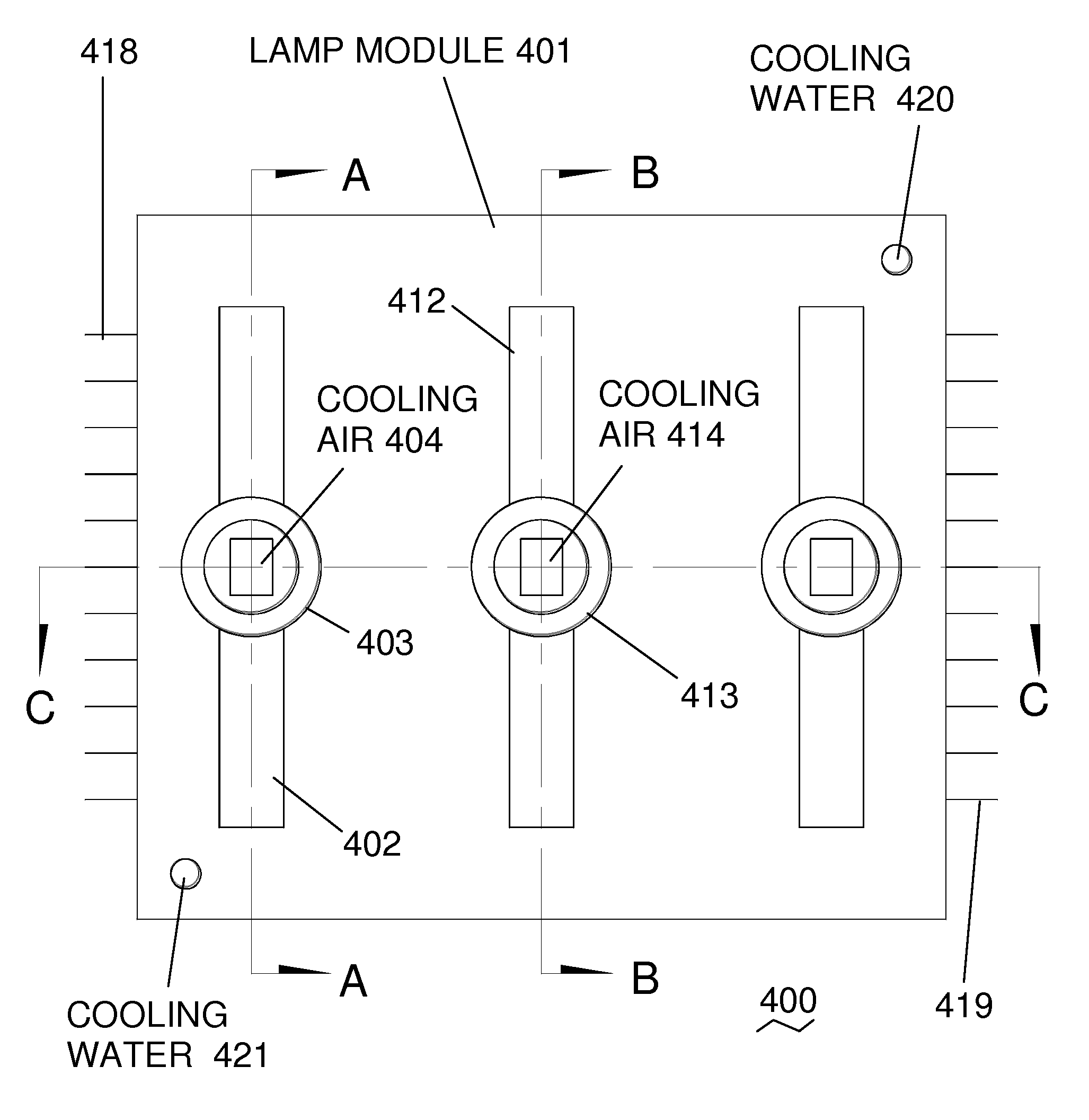

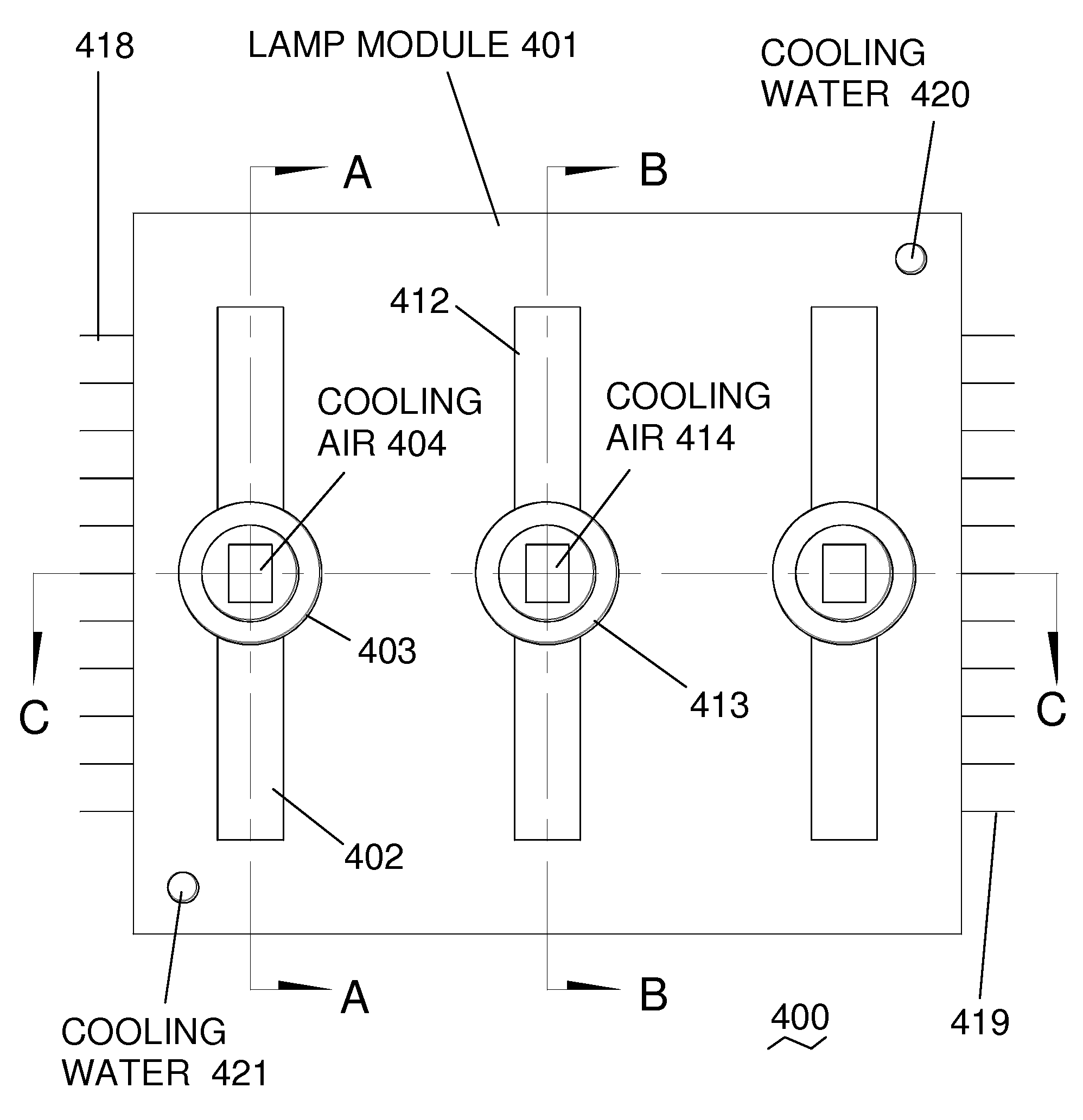

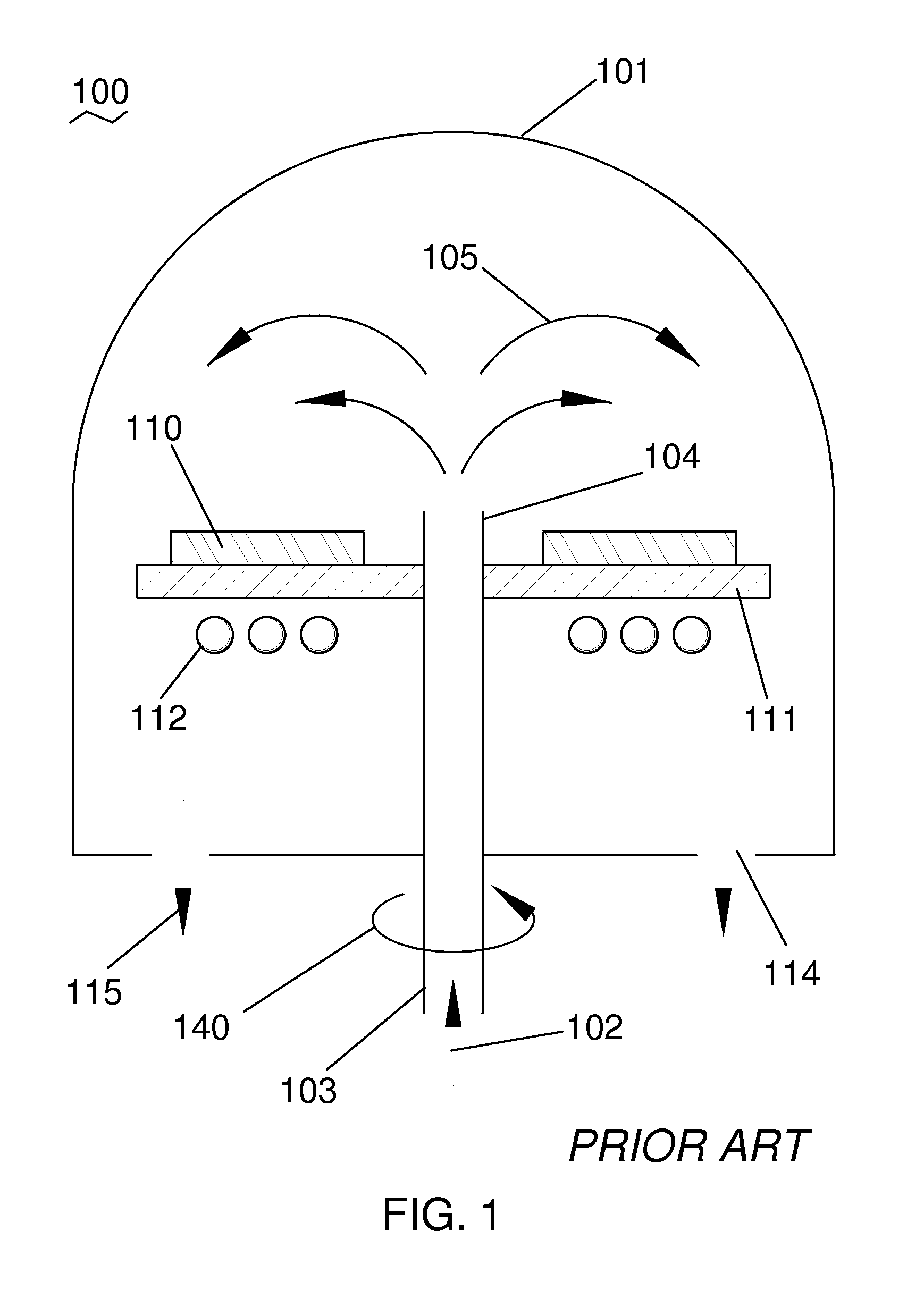

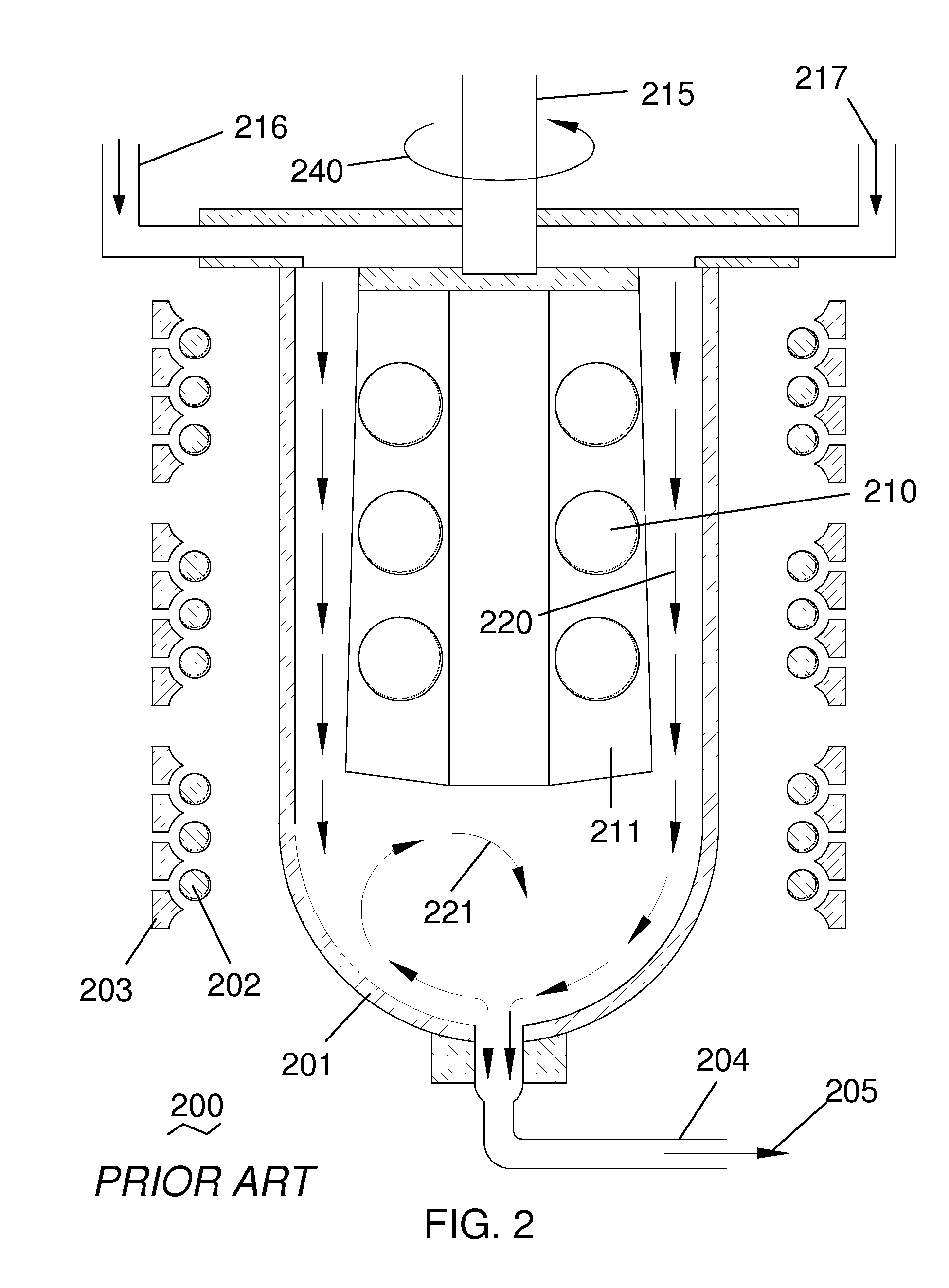

An epitaxial reactor enabling simultaneous deposition of thin films on a multiplicity of wafers is disclosed. During deposition, a number of wafers are contained within a wafer sleeve comprising a number of wafer carrier plates spaced closely apart to minimize the process volume. Process gases flow preferentially into the interior volume of the wafer sleeve, which is heated by one or more lamp modules. Purge gases flow outside the wafer sleeve within a reactor chamber to minimize deposition on the walls of the chamber. In addition, sequencing of the illumination of the individual lamps in the lamp module may further improve the linearity of variation in deposition rates within the wafer sleeve. To improve uniformity, the direction of process gas flow may be varied in a cross-flow configuration. Combining lamp sequencing with cross-flow processing in a multiple reactor system enables high throughput deposition with good film uniformities and efficient use of process gases.

Owner:SVAGOS TECHNICK INC

High Throughput Multi-Wafer Epitaxial Reactor

ActiveUS20100215872A1Improve throughputSimple designPolycrystalline material growthSemiconductor/solid-state device manufacturingReactor systemProcess engineering

An epitaxial reactor enabling simultaneous deposition of thin films on a multiplicity of wafers is disclosed. During deposition, a number of wafers are contained within a wafer sleeve comprising a number of wafer carrier plates spaced closely apart to minimize the process volume. Process gases flow preferentially into the interior volume of the wafer sleeve, which is heated by one or more lamp modules. Purge gases flow outside the wafer sleeve within a reactor chamber to minimize wall deposition. In addition, sequencing of the illumination of the individual lamps in the lamp module may further improve the linearity of variation in deposition rates within the wafer sleeve. To improve uniformity, the direction of process gas flow may be varied in a cross-flow configuration. Combining lamp sequencing with cross-flow processing in a multiple reactor system enables high throughput deposition with good film uniformities and efficient use of process gases.

Owner:SVAGOS TECHNICK INC

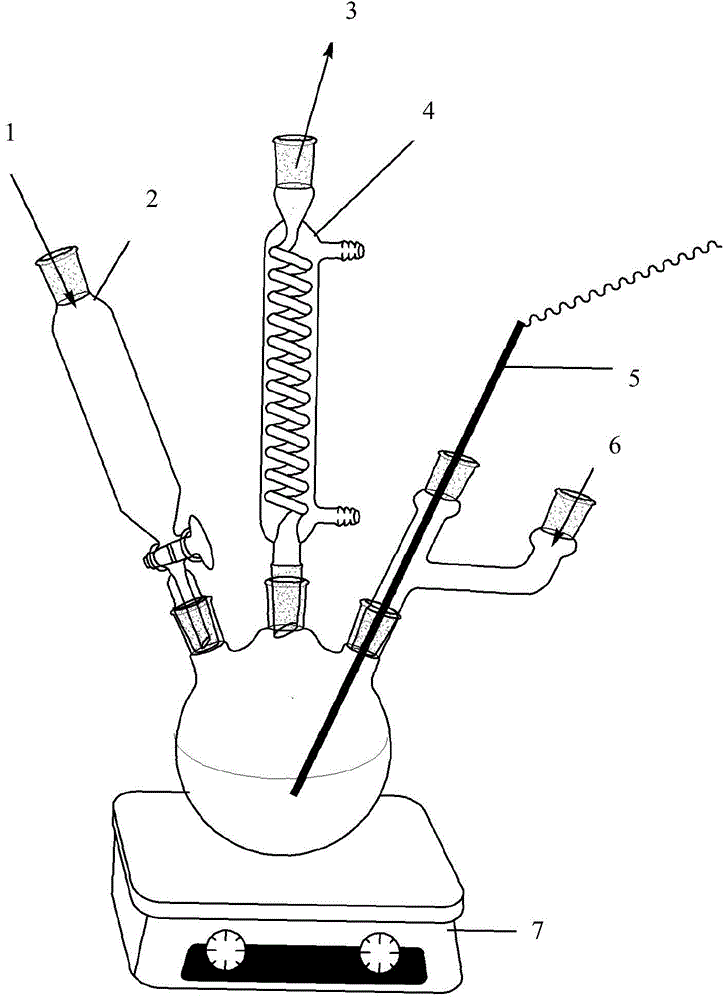

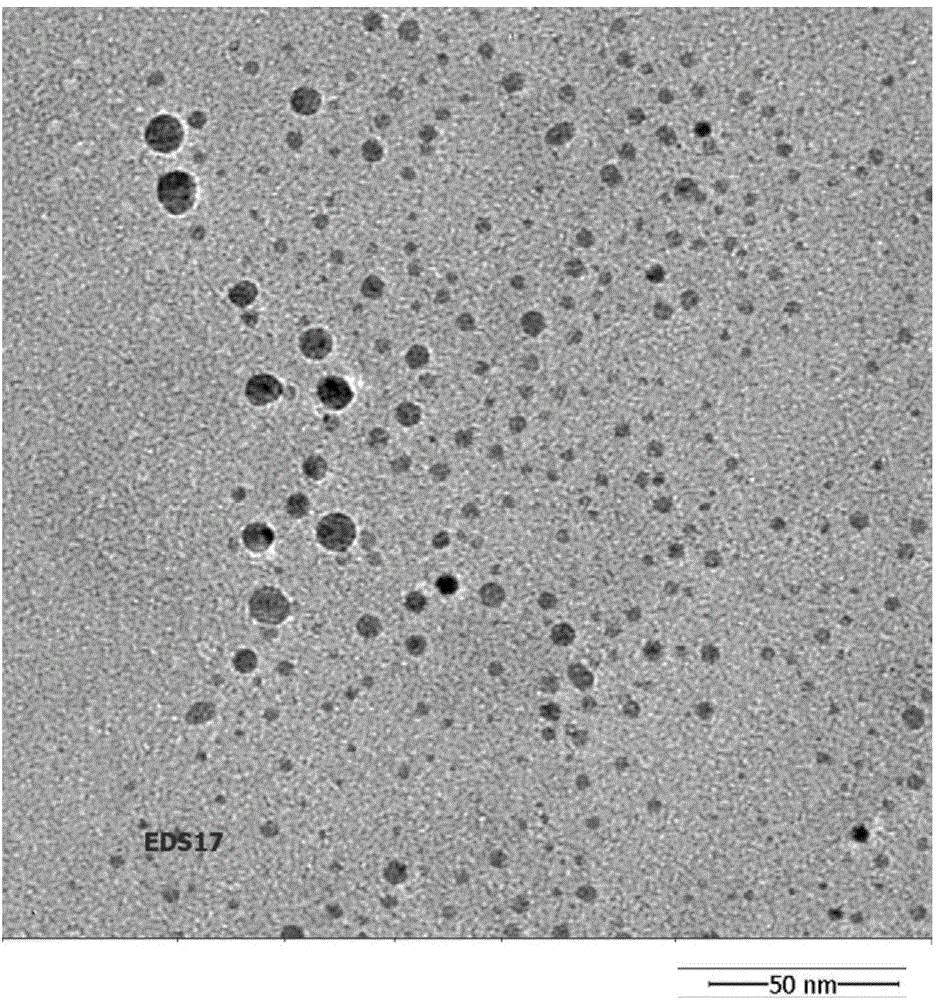

Preparation method of magnetic silicon carbide ceramic nano particles

The invention provides a preparation method of magnetic silicon carbide ceramic nano particles, and relates to silicon carbides. The method comprises the steps that 1, magnetic metallo-organic compounds and polycarbosilane react in a solution, magnetic metal sol is obtained; 2, the magnetic metal sol obtained from the step 1 and pitch are mixed and react, then solvents are eliminated, and a mixture with the evenly distributed magnetic metal polycarbosilane precursors and pitch is obtained; 3, the mixture obtained in the step 2 is placed in a high temperature furnace, air or oxygen is led into the high temperature furnace to oxygenize the mixture, then the mixture is cooled, and cross-linking by-products are obtained; 4, the cross-linking by-products are placed in the high temperature furnace, inert gases are led to the high temperature furnace to carbonize the cross-linking by-products, the cross-linking by-products are cooled, and carbon-scattered magnetic silicon carbide ceramic nano particles are obtained; 5, the carbon-scattered magnetic silicon carbide ceramic nano particles are heated in an air atmosphere to an oxygenolysis decomposition temperature for carbon removing, and the magnetic silicon carbide ceramic nano particles are obtained. The magnetic silicon carbide ceramic nano particles can attenuate certain electromagnetic radiation due to the fact that the magnetic silicon carbide ceramic nano particles have both magnetic loss and dielectric loss, and an electromagnetic wave absorption effect is achieved.

Owner:XIAMEN UNIV

Electrically conductive coatings and method of their use

InactiveUS20070029307A1Maintain coating propertyReadily apparentHeating element materialsConductive coatingSolvent

It has been discovered that finely ground elemental graphite enhances the electrical conductivity of a coating when added to conductive amorphous carbon, using any one of several different binders in formulating the coating. The coating can be energized with electrical energy creating an electrical resistance heat element. Such combination of amorphous carbon and elemental graphite particles, ranging in size from about 0.001 to less than 1 micron, creates a more uniform conductive coating compared to use of larger sized particles, where the amount of conductive particles ranges from about 5 to about 80 weight-% based on the non-volatile solids content of the coating formulation (e.g., without solvent and other components that evolve (are driven off) from the coating during drying).

Owner:PROGRESSIVE COATINGS TECH

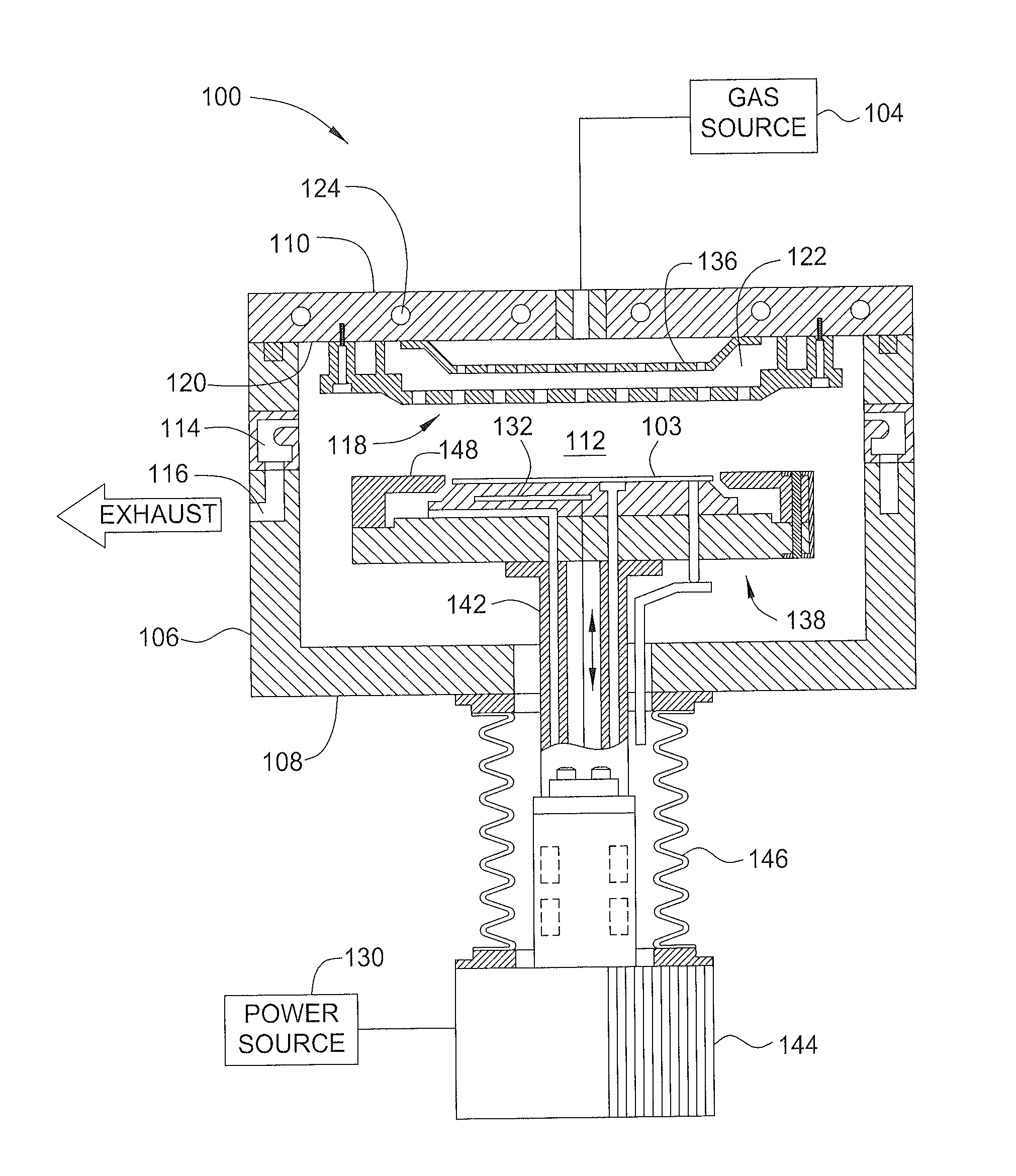

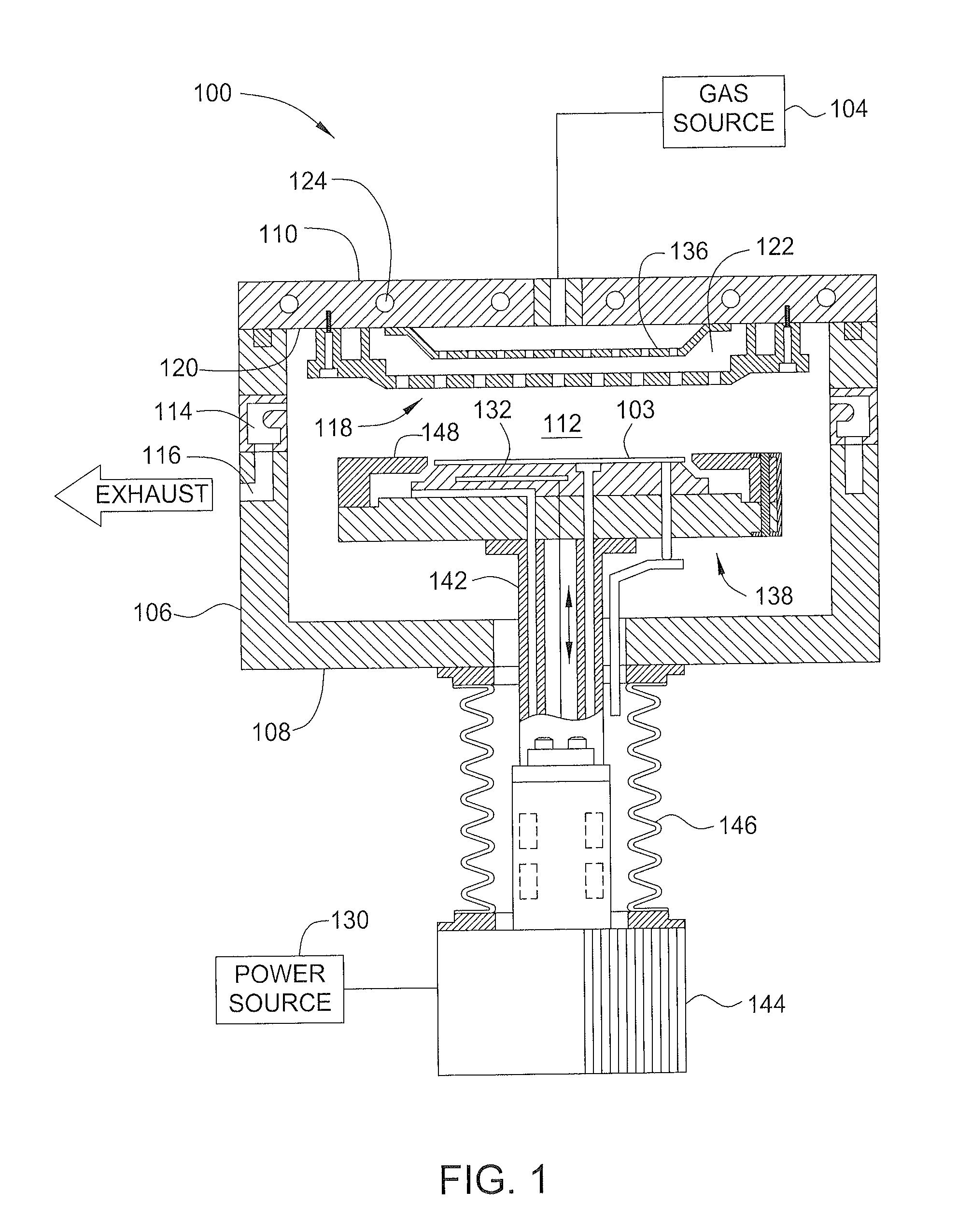

Method of reducing tungsten film roughness and resistivity

InactiveUS20140147589A1Low resistivityReduce roughnessChemical vapor deposition coatingDeposition temperatureNucleation

Methods for controlling crystal size in bulk tungsten layers are disclosed herein. Methods for depositing a bulk tungsten metal layer can include positioning a substrate with a barrier layer in a processing chamber, forming a tungsten nucleation layer, post-treating the nucleation layer with one or more treatment gas cycles including an activating gas and a purging gas, heating the substrate to a deposition temperature, and depositing a bulk tungsten layer with alternating nitrogen flow on the nucleation layer. The post-treatment cycling can be applied optionally to the bulk metal deposition with alternating nitrogen flow.

Owner:APPLIED MATERIALS INC

High throughput epitaxial deposition system for single crystal solar devices

InactiveUS20140318442A1Improve throughputSimple designAfter-treatment apparatusPolycrystalline material growthComputer moduleSingle crystal

An epitaxial reactor enabling simultaneous deposition of thin films on a multiplicity of wafers is disclosed. During deposition, a number of wafers are contained within a wafer sleeve comprising a number of wafer carrier plates spaced closely apart. Process gases flow preferentially into the interior volume of the wafer sleeve, which is heated by one or more lamp modules. To improve uniformity, the direction of process gas flow may be varied in a cross-flow configuration and the wafers may be mounted at a small angle to the plane of the wafer carrier plates, wherein the wafers are configured in pairs along the direction of gas flow and wherein along the direction of gas flow the angular mounting of the wafers provides a smaller gap between opposed wafer surfaces on said parallel wafer carrier plates in the center of said wafer sleeve than at the periphery of said wafer sleeve.

Owner:CRYSTAL SOLAR INC

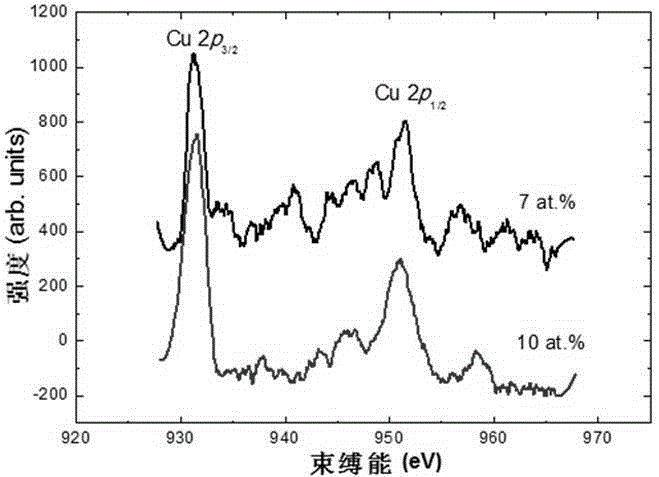

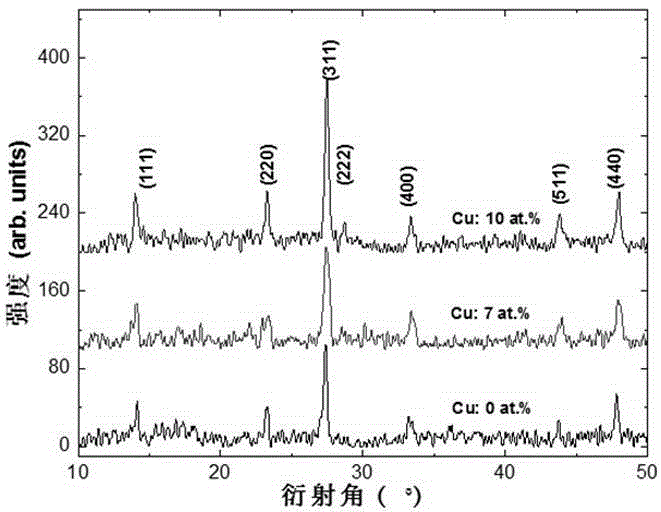

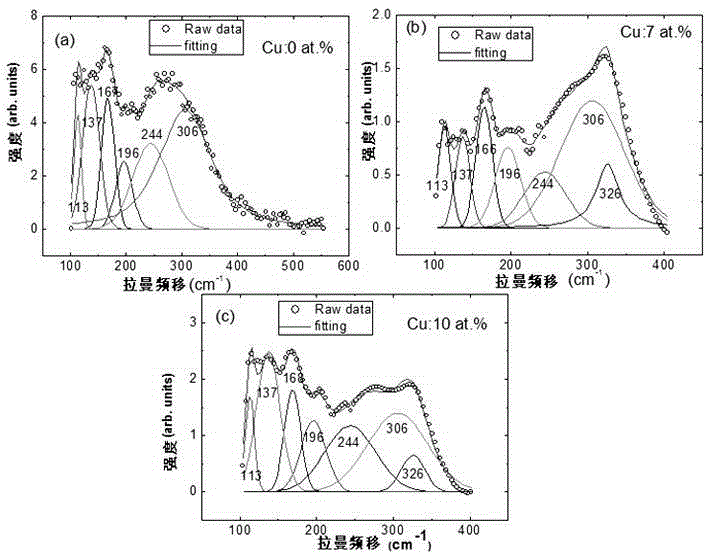

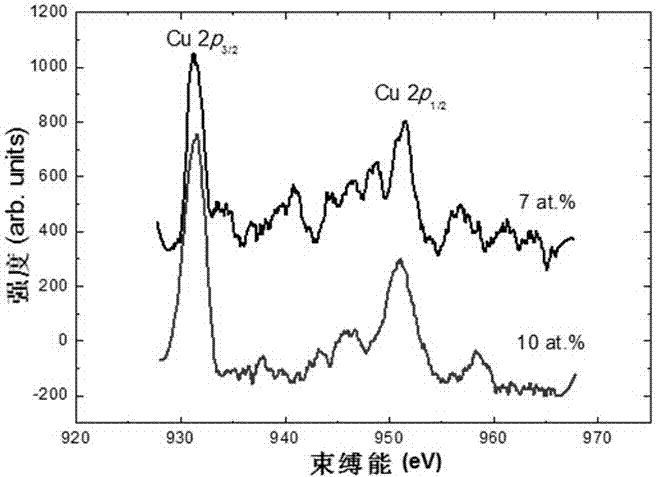

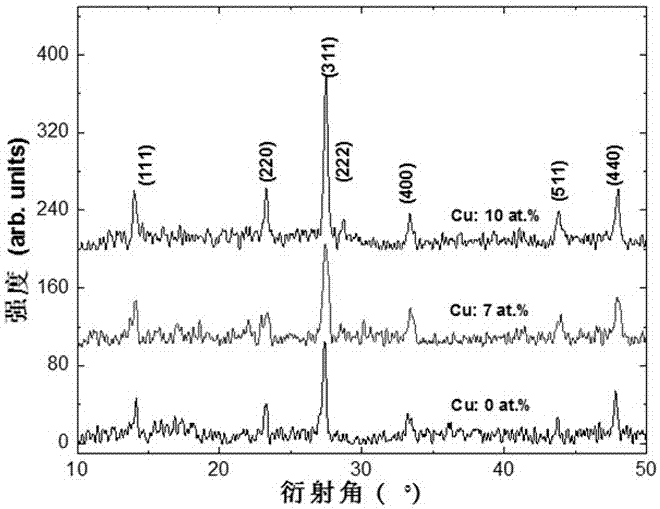

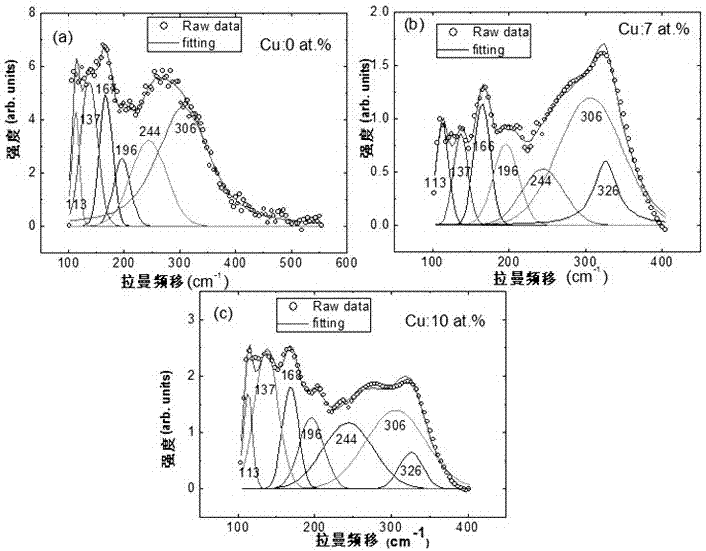

Cu-doped indium sulfide film preparation method

InactiveCN105428217AEasy to manufactureHigh puritySemiconductor/solid-state device manufacturingPhotovoltaic energy generationFilm resistancePhysical chemistry

The present invention discloses a Cu-doped indium sulfide film preparation method. According to the method, a vacuum evaporation method is adopted, a thin Cu layer is evaporated between two layers of indium sulfide films, and then Cu is diffused into the indium sulfide films by thermal annealing, so that the aim of preparing a Cu-doped indium sulfide film is fulfilled. According to the method disclosed by the present invention, doping concentration can be controlled by controlling the amount of the evaporated Cu, thereby fulfilling the aim of reducing film resistivity to varying degrees. The film prepared by the method disclosed by the present invention can be used as a buffer layer of a solar cell.

Owner:FUZHOU UNIV

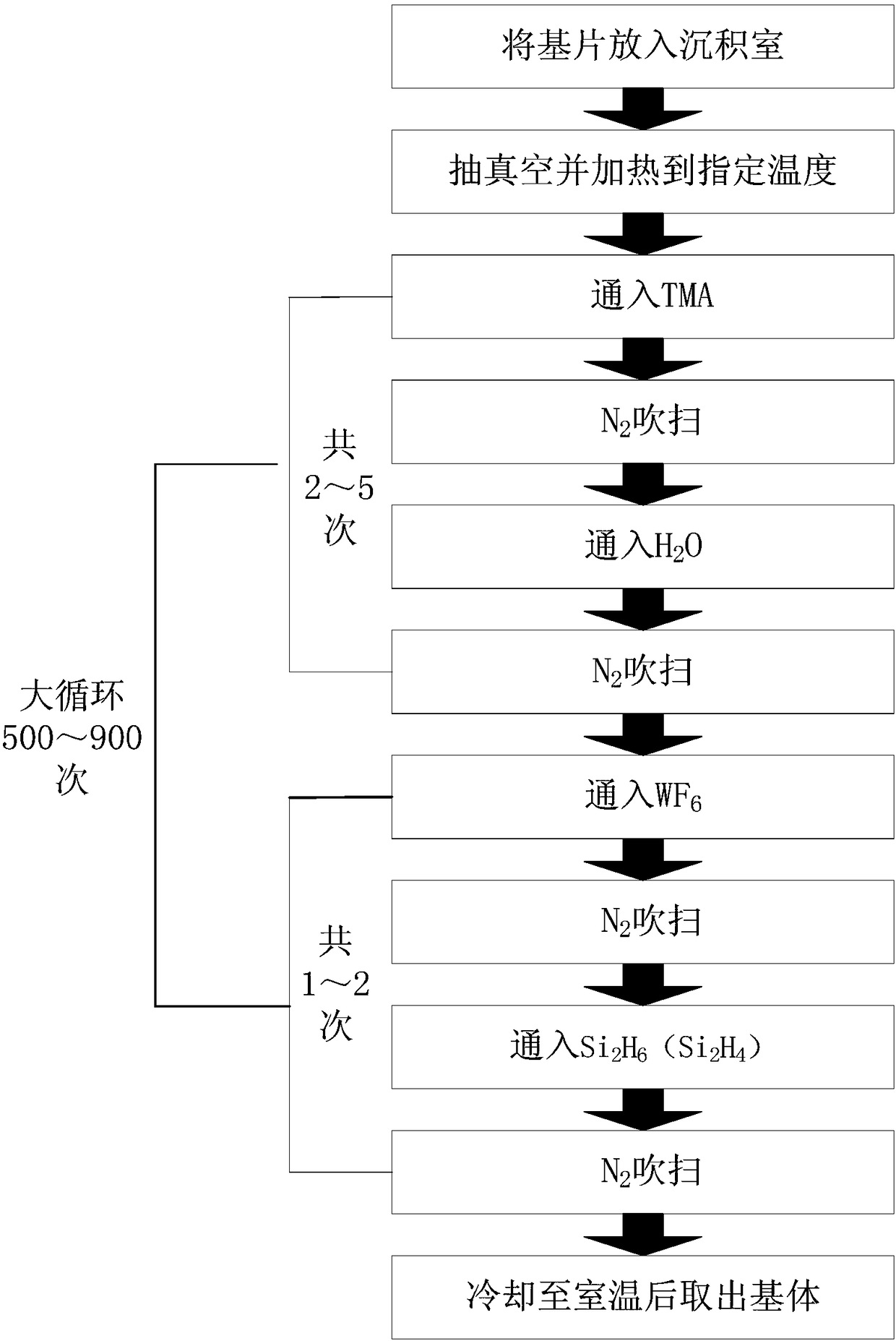

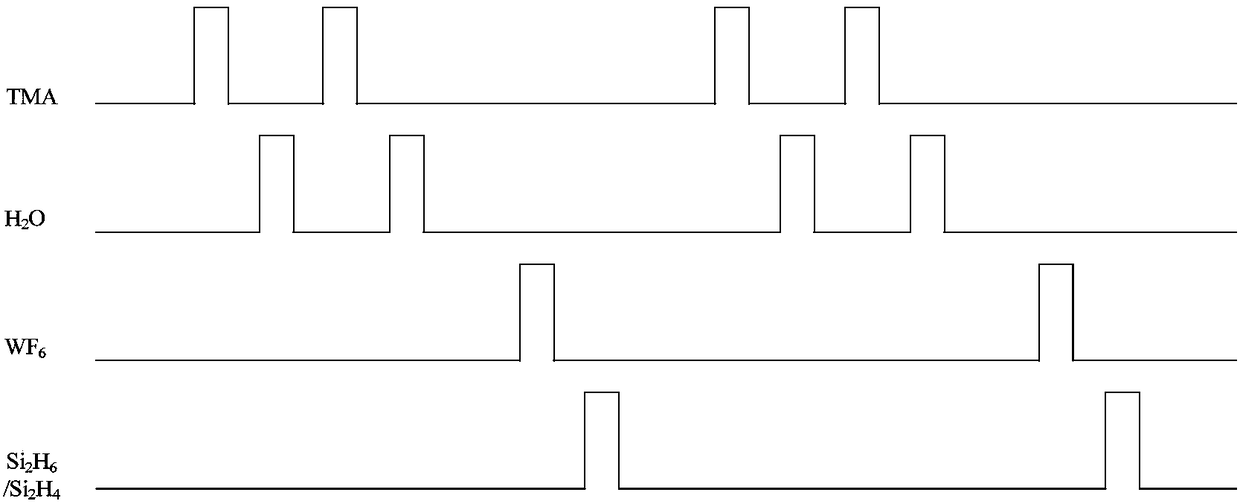

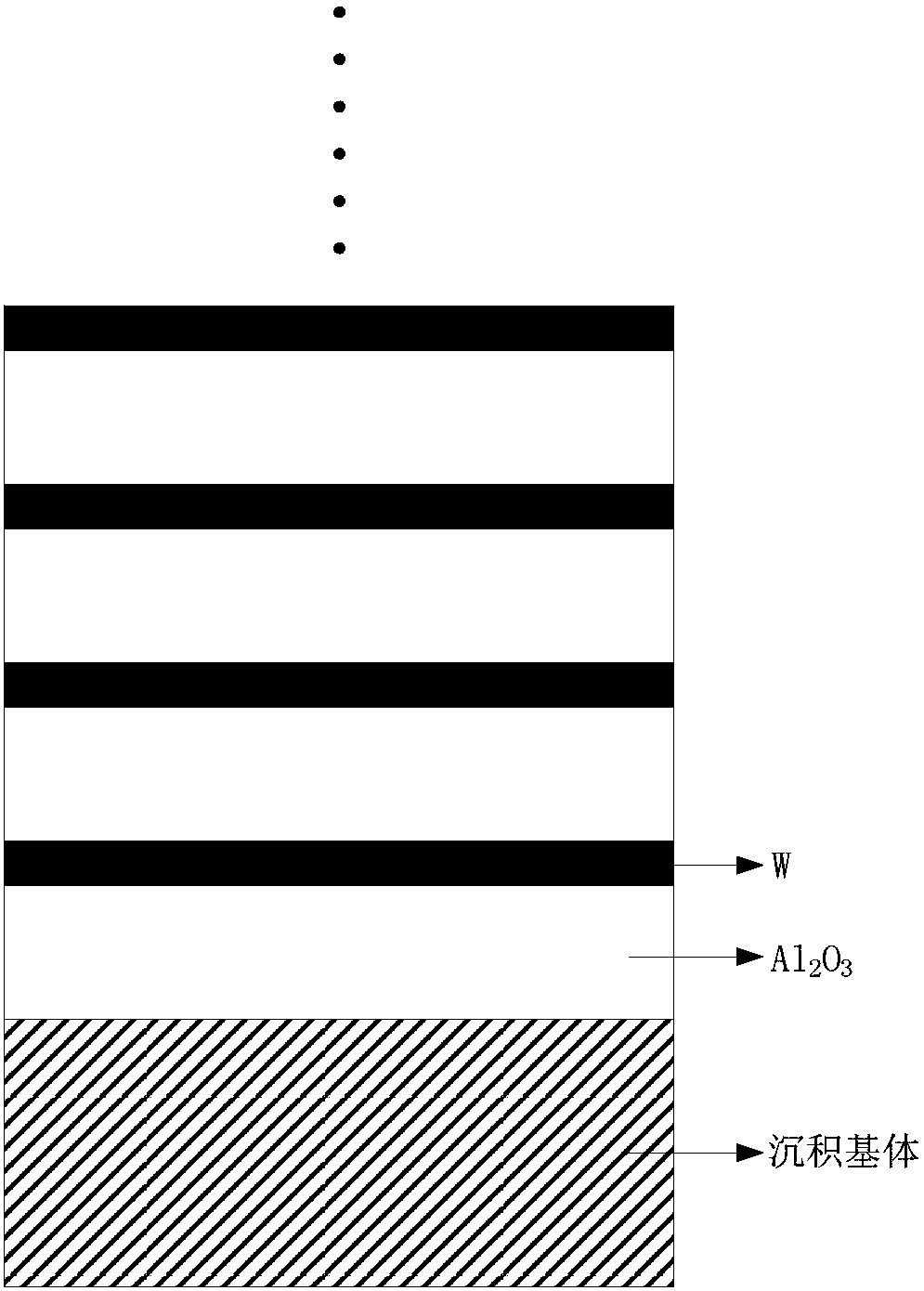

Method for preparing W-doped Al2O3 high-resistance membrane through atomic layer deposition

InactiveCN108588679AReduce surface roughnessFlat surfaceChemical vapor deposition coatingHigh resistanceOxygen

The invention relates to a method for preparing an W-doped Al2O3 high-resistance membrane through atomic layer deposition and aims at solving the problems that in the prior art,the thickness and the doping ratio of the membrane cannot be accurately controlled, and particularly defects exist when the accuracy of controlling the thickness of the membrane reaches an atom level and large-area uniformgrowth is realized at the same time. The method comprises the following steps of (1) putting a matrix into a deposition chamber; (2) vacuumizing the deposition chamber, heating the matrix; (3) performing Al2O3 deposition circulation for 2-5 times, wherein single Al2O3 deposition comprises the following steps of (3.1) introducing a precursor Al source into the deposition chamber, and purging the deposition chamber with the Al source at deposition chamber exposure set time; (3.2) introducing a precursor oxygen source to obtain a single layer Al2O3; and (3.3 ) purging the deposition chamber; (4)performing W deposition for 1-2 times, wherein the step of performing W deposition for 1-2 times comprises the following steps of (4.1) introducing a precursor W source into the deposition chamber, and purging the deposition chamber; (4.2) introducing a reducer to obtain a single-layer W metal element; and (4.3) purging the deposition chamber; and (5) sequentially conducting the step (3) and the step (4) repeatedly for many times to obtain the W-doped Al2O3 high-resistance membrane.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

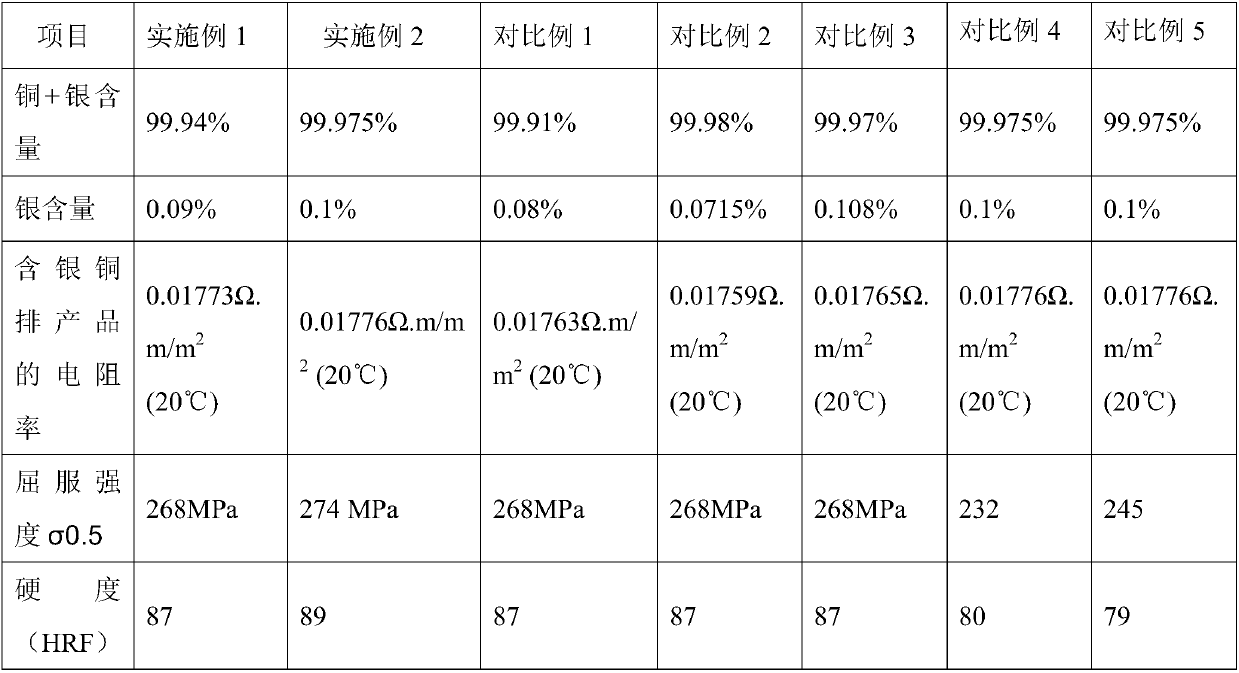

High throughput multi-wafer epitaxial reactor

ActiveUS8298629B2Improve throughputSimple designPolycrystalline material growthSemiconductor/solid-state device manufacturingReactor systemComputer module

An epitaxial reactor enabling simultaneous deposition of thin films on a multiplicity of wafers is disclosed. During deposition, a number of wafers are contained within a wafer sleeve comprising a number of wafer carrier plates spaced closely apart to minimize the process volume. Process gases flow preferentially into the interior volume of the wafer sleeve, which is heated by one or more lamp modules. Purge gases flow outside the wafer sleeve within a reactor chamber to minimize wall deposition. In addition, sequencing of the illumination of the individual lamps in the lamp module may further improve the linearity of variation in deposition rates within the wafer sleeve. To improve uniformity, the direction of process gas flow may be varied in a cross-flow configuration. Combining lamp sequencing with cross-flow processing in a multiple reactor system enables high throughput deposition with good film uniformities and efficient use of process gases.

Owner:SVAGOS TECHNICK INC

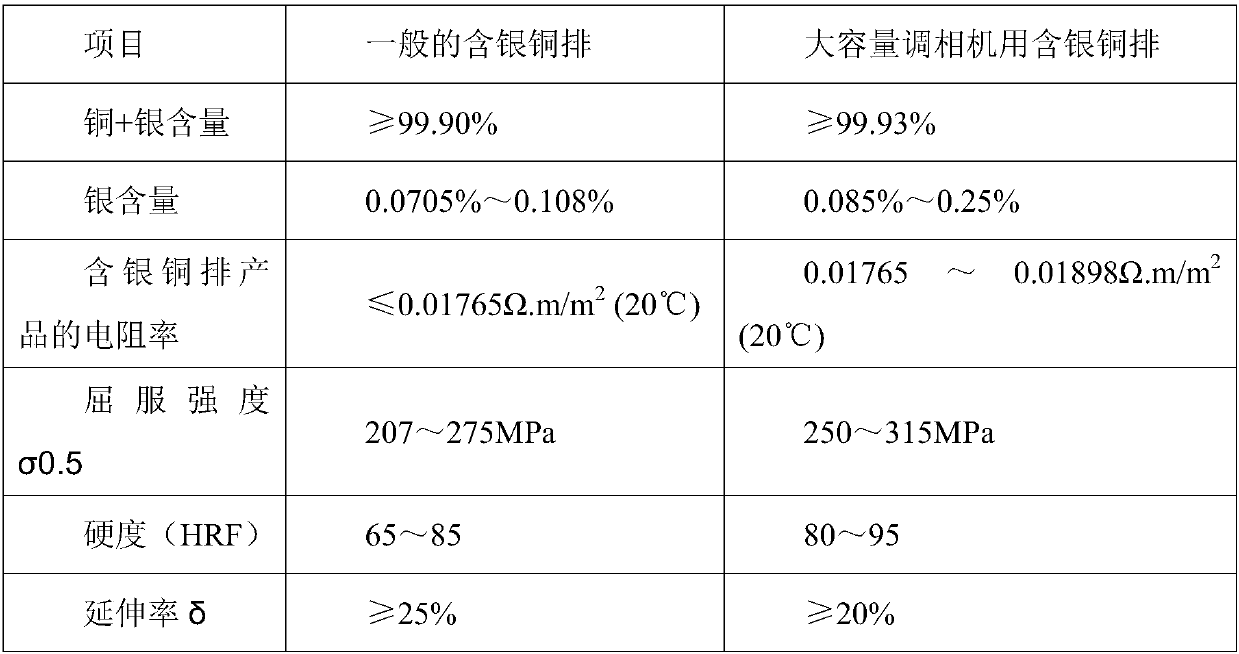

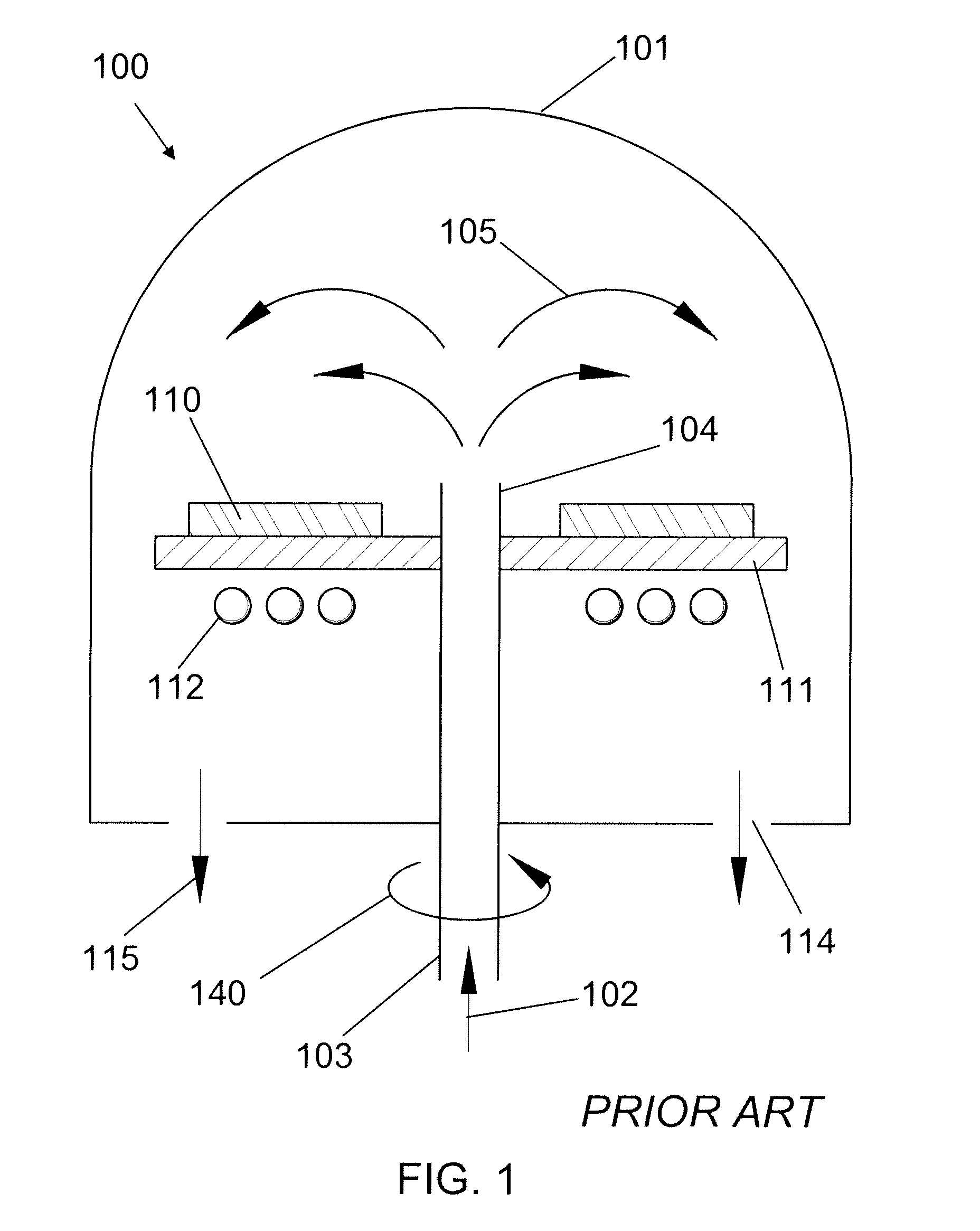

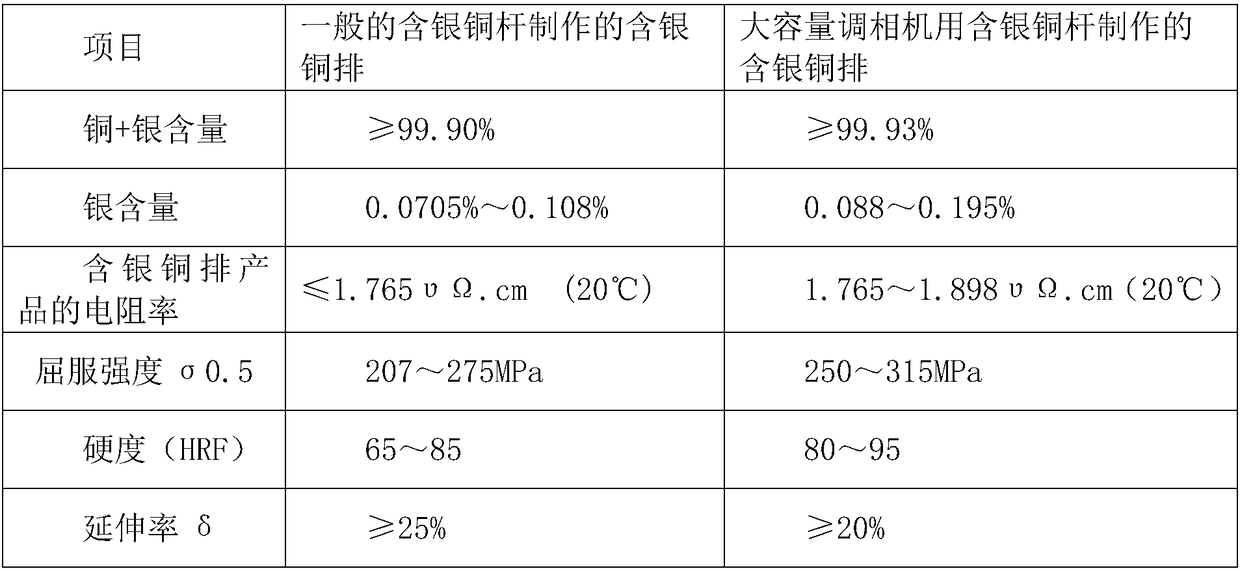

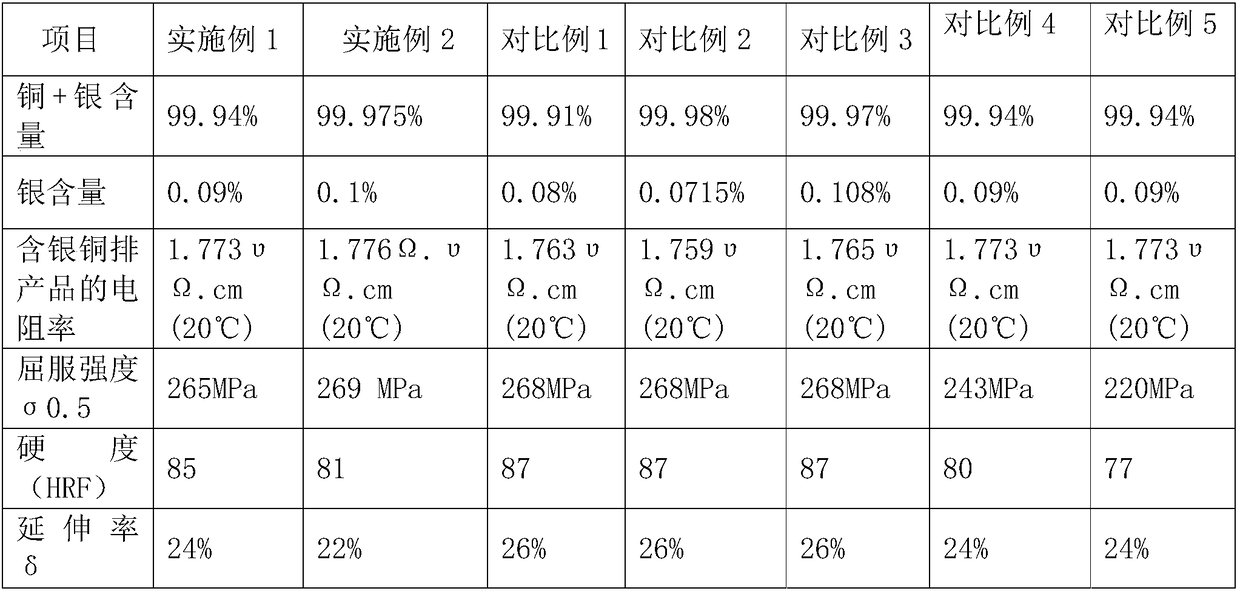

Preparation method of silver-containing copper bar for large-capacity phase regulator

ActiveCN107755451AReduce running noiseReduce vibrationMetal/alloy conductorsMaterials preparationMetalworking

The invention relates to the field of nonferrous metal processing, in particular to a preparation method of a silver-containing copper bar for a large-capacity phase regulator. The preparation methodcomprises the following steps: material preparation; step 2, up-drawing continuous casting; step 3, continuous extrusion; step 4, finished product drawing. The scheme has the beneficial effects that the resistivity of the silver-containing copper bar product is controlled within 0.01765-0.01898 omega.m / m<2>, the conductivity deviation is small, and the use demands of a rotor coil of the large-capacity air-cooled phase regulator are met.

Owner:重庆鸽牌电线电缆有限公司

High throughput multi-wafer epitaxial reactor

ActiveUS8673081B2Improve throughputSimple designAfter-treatment apparatusPolycrystalline material growthWaferingReactor system

Owner:SVAGOS TECHNICK INC

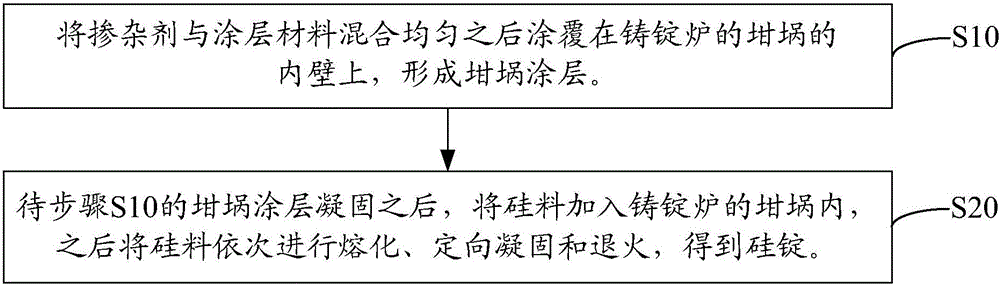

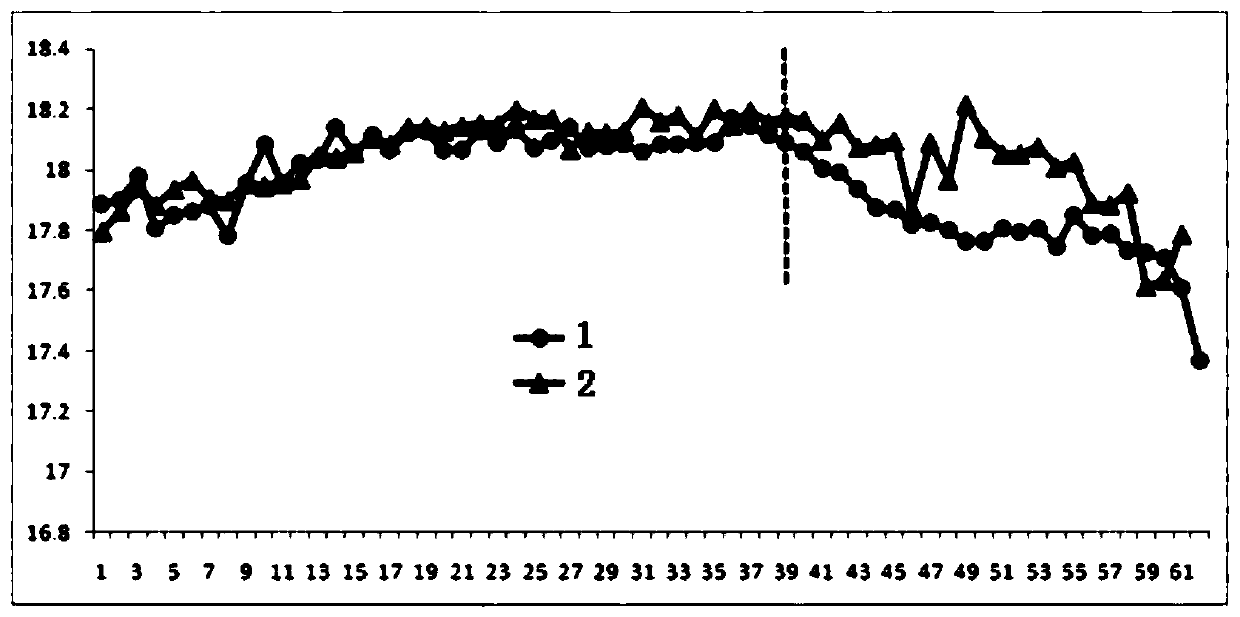

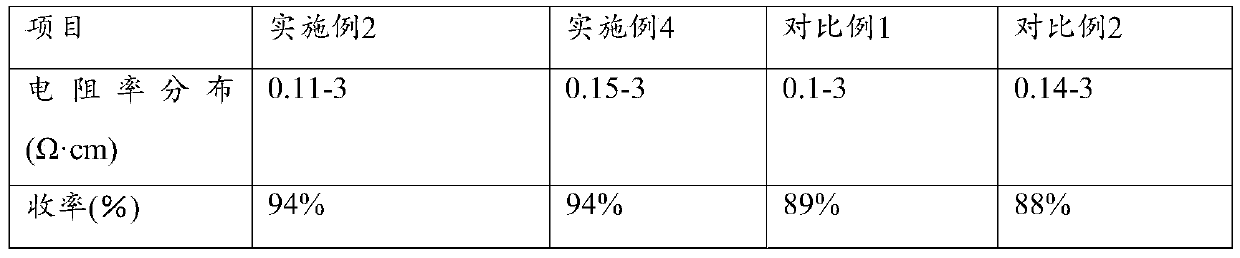

Silicon ingot and preparation method thereof

InactiveCN105780114AControl resistivityUniform resistivity distributionPolycrystalline material growthFrom frozen solutionsDopantCrucible

Owner:JIANGSU XIEXIN SILICON MATERIAL TECH DEV

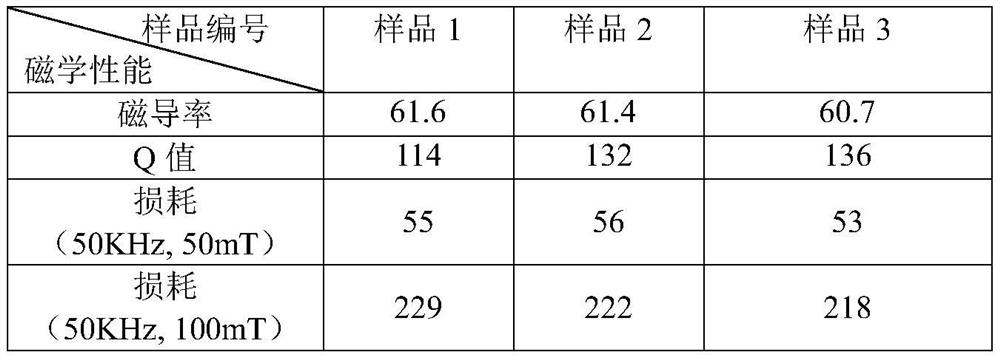

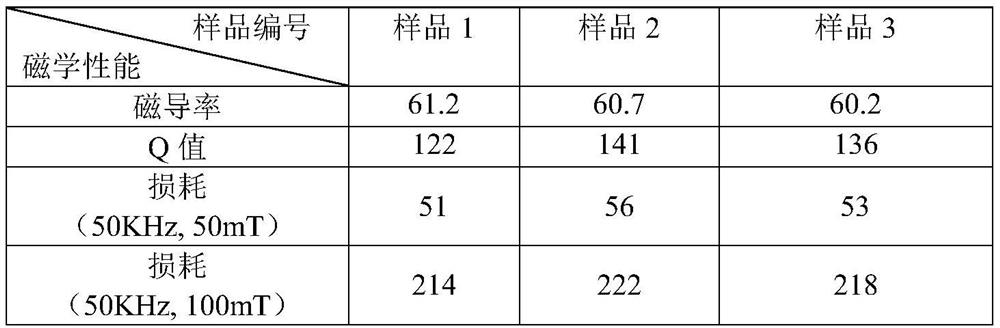

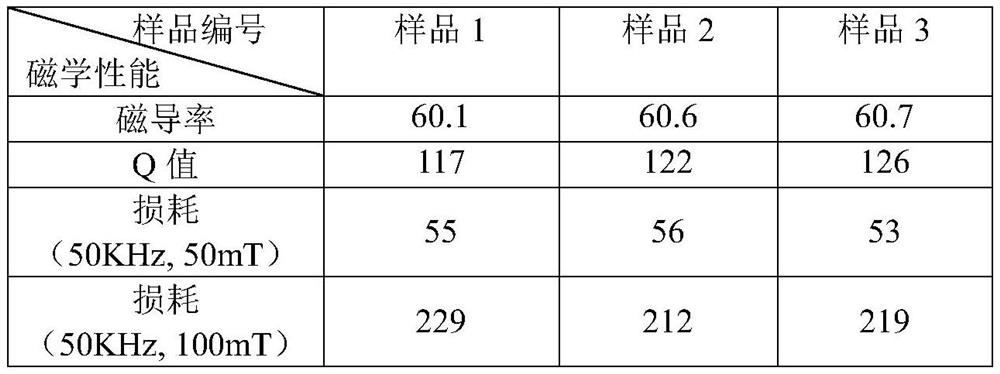

Ferrite-coated FeSiAl metal magnetic powder core and preparation method thereof

PendingCN112562956AAvoid breakingHigh resistivityInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingFerrite (magnet)

The invention relates to the technical field of magnetic materials, in particular to a ferrite-coated FeSiAl metal magnetic powder core and a preparation method thereof. The preparation method comprises the following steps of (1) mixing, heating, stirring and drying FeSiAl metal soft magnetic powder and an aqueous solution of soluble ferric salt; (2) mixing with a soluble hydroxide solution, stirring at normal temperature, and drying; (3) uniformly mixing with a binder and a lubricant, and carrying out compression molding to obtain a green body; and (4) carrying out heat treatment on the greenbody in vacuum or nitrogen or hydrogen, cooling and spraying to obtain the ferrite-coated FeSiAl metal magnetic powder core. The uniform iron hydroxide layer is formed on the outer surface of the FeSiAl metal soft magnetic powder through a chemical co-deposition method, the iron hydroxide layer is converted into the compact and uniform ferrite insulating layer through compression molding and high-temperature heat treatment, breakage of the ferrite insulating layer in the pressing process is avoided, the ferrite insulating layer on the outer layer is ferromagnetic, the magnetic dilution effectcan be reduced, and the magnetic performance of the composite material is further improved.

Owner:HANGZHOU DIANZI UNIV

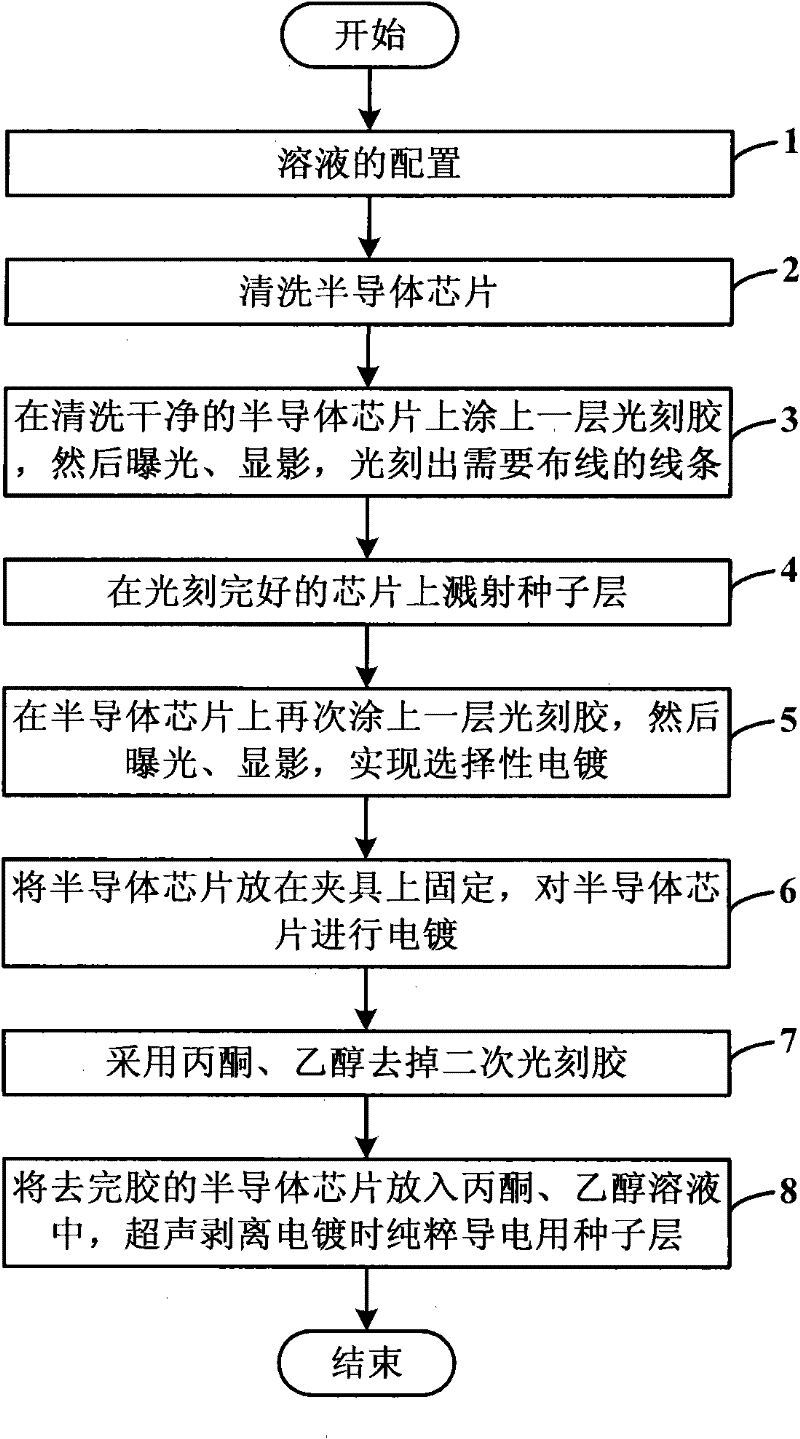

Gold-iron alloy interconnection wire and manufacturing method thereof

InactiveCN102299138AMature technologyMeet the intensitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipAlloy

The invention discloses a gold-iron alloy interconnection wire and a manufacturing method thereof. The gold-iron alloy interconnection wire contains two elements of gold and iron, and the iron content is between 0.1% and 0.5%. The method includes: configuring the solution; cleaning the semiconductor chip; coating a layer of photolithography on the cleaned semiconductor chip glue, then expose and develop, photoetch the lines that need to be wired; sputter the seed layer on the chip; coat a layer of photoresist on the semiconductor chip again, then expose and develop, and expose the lines that need to be electroplated, no need The place where the electroplating is thickened is protected with photoresist to achieve selective electroplating; the semiconductor chip is fixed on the fixture, and the semiconductor chip is electroplated; the secondary photoresist is removed with acetone and ethanol; Put it into acetone and ethanol solution, and ultrasonically peel off the purely conductive seed layer during electroplating. The invention satisfies the needs of high power and high frequency compound semiconductor interconnection strength and resistivity.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Conductive silicon carbide single crystal and preparation method thereof

ActiveCN112725893AReduce dislocation densityReduce stressPolycrystalline material growthFrom condensed vaporsCarbide siliconSingle crystal substrate

The invention provides a conductive silicon carbide single crystal. Doped elements comprise nitrogen and an element of which the atomic radius is greater than that of silicon. The resistivity of the conductive silicon carbide single crystal is from 0.01 [Omega]. cm to 0.05 [Omega]. cm; the doping concentration of the element having an atomic radius greater than the atomic radius of silicon is 0.1%-10% of the concentration of the nitrogen element. According to the silicon carbide crystal, on the basis of doping of a nitrogen element, through introduction of an element of which the atomic radius is greater than that of silicon and control of the concentrations of nitrogen and the element of which the atomic radius is greater than that of silicon, the resistivity is ensured to meet the requirements of a conductive silicon carbide single crystal substrate, lattice distortion caused by the size difference of nitrogen atoms and carbon atoms can be compensated, the internal stress of the crystal is reduced, and the dislocation density in the crystal is reduced. The invention also provides a preparation method of the conductive silicon carbide single crystal.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD +3

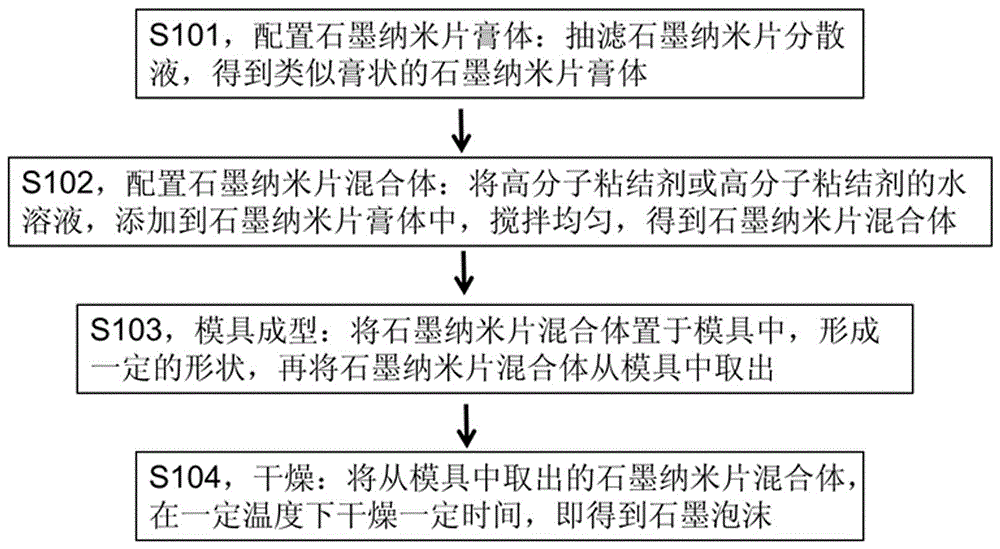

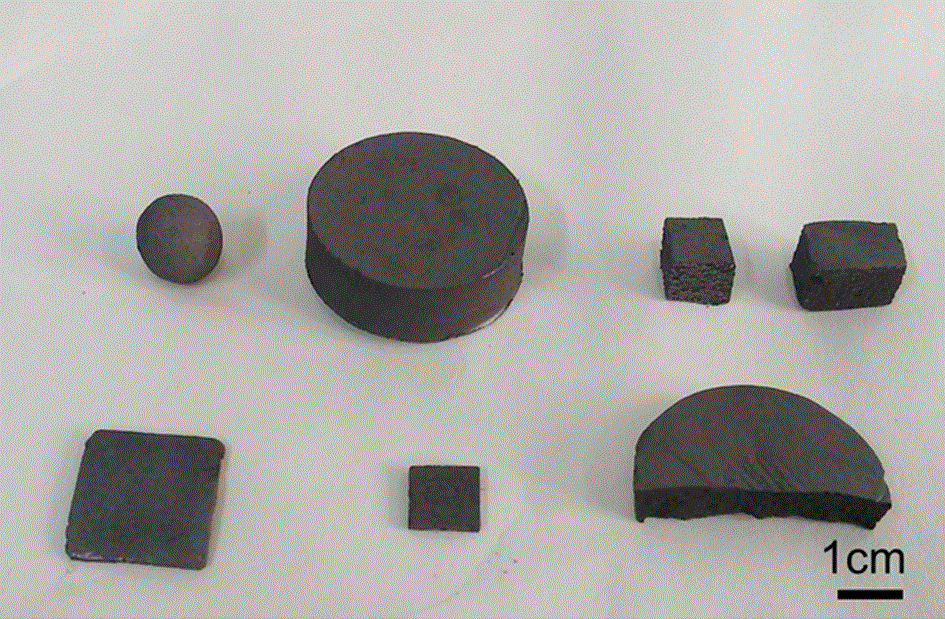

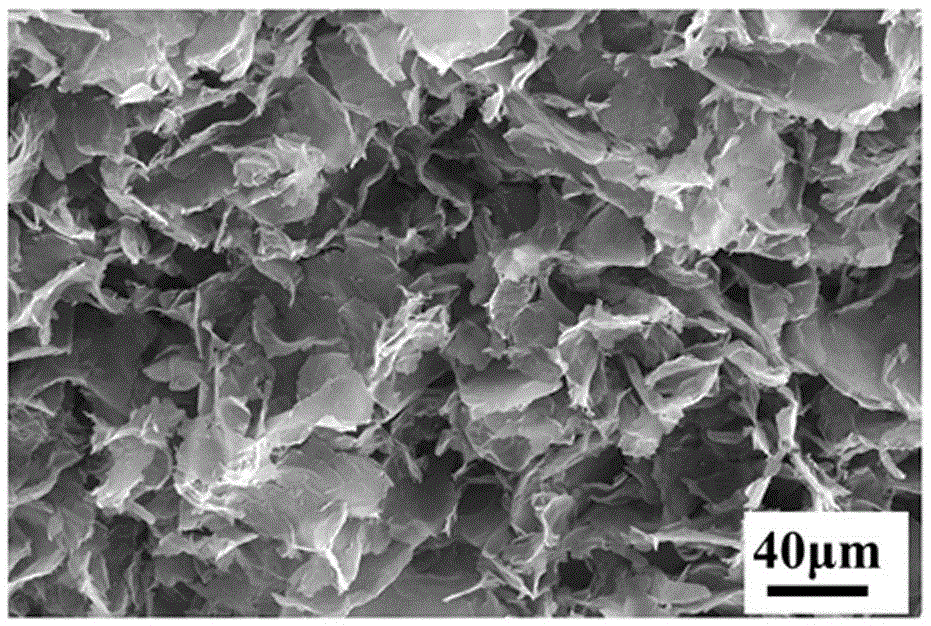

Graphite foam and preparation method thereof

ActiveCN106673700AHigh compressive strengthImprove thermal conductivityCeramic extrusion diesCeramicwareHigh pressure cellElectromagnetic shielding

The invention provides a preparation method of graphite foam. The method comprises the following steps that graphite nanosheets are used as raw materials; a small number of macromolecular bonding agents are added; through template forming, the graphite foam is formed after the drying. The preparation method provided by the invention is simple and convenient, and can be used for forming graphite foam in various shapes; in addition, the prepared graphite foam has the controllable density and uniform pores. The prepared graphite foam also has the advantages of high pressure-resistant intensity, low resistance, oil absorbability, high heat conductivity and the like, can be widely applied to the fields of heat radiators, heat conduction pads, electromagnetic shielding materials and the like, and has wide application prospects.

Owner:HARBIN INST OF TECH AT WEIHAI

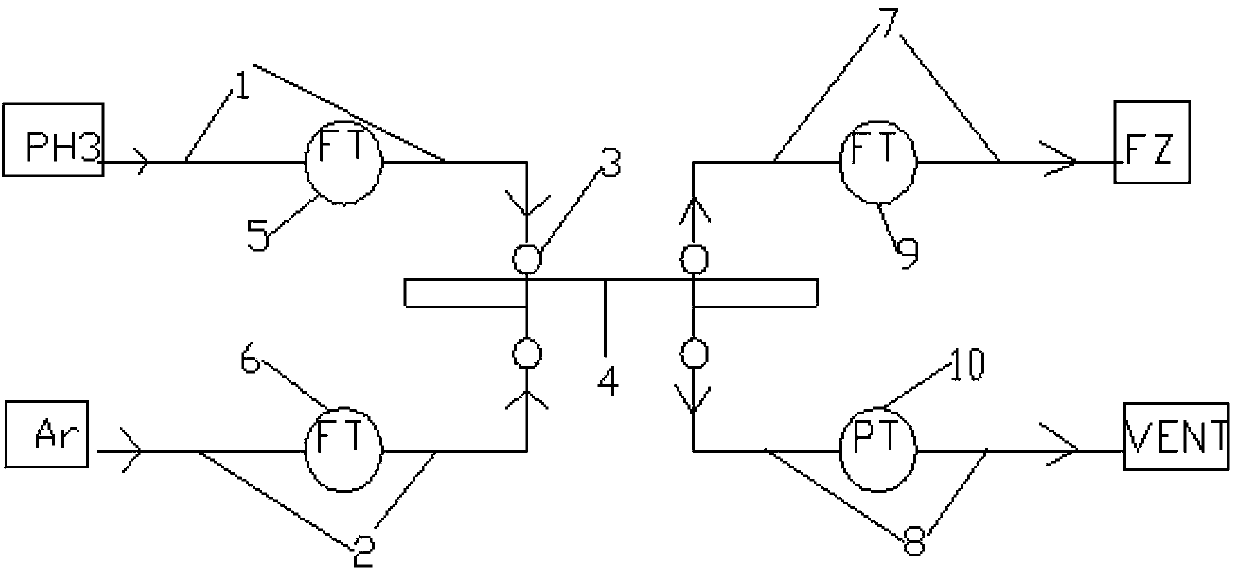

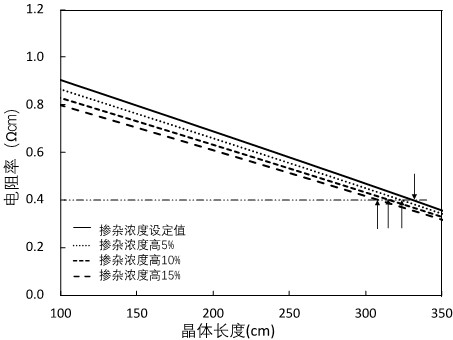

Gas phase mixing system device and method used for obtaining zone-melting silicon single crystal with wide specific resistance range

InactiveCN103866377AControl resistivityReduce manufacturing costBy zone-melting liquidsGas phaseZone melting

The invention provides a gas phase mixing system device and a gas phase mixing system method used for obtaining zone-melting silicon single crystal with wide specific resistance range. The gas mixing system device comprises a phosphine gas pipeline, an argon pipeline, a furnace gas pipeline, and an exhausting pipeline; the four pipelines are connected with a bridge-shaped pipeline via VCO interfaces respectively; the phosphine gas pipeline and the argon pipeline are connected with one end of the bridge-shaped pipeline, and the furnace gas pipeline and the exhausting pipeline are connected with the other end of the bridge-shaped pipeline; the phosphine gas pipeline, the argon pipeline, and the furnace gas pipeline are all provided with mass flowmenters; and the exhausting pipeline is provided with a pressure control meter. The gas phase mixing system device is used for gas phase mixing; in molten globule phase of silicon single crystal growth via zone melting method, phosphine gas and argon are mixed in the bridge-shaped pipeline, and a mixture is delivered into the furnace gas pipeline; after the molten globule phase, crystal leading, shouldering, diameter equalizing and ending are carried out, and zone-melting silicon single crystal with a specific resistance range of 0.1 to 2000omega.cm is obtained by changing the amount of phosphine gas injected into a zone melting furnace.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

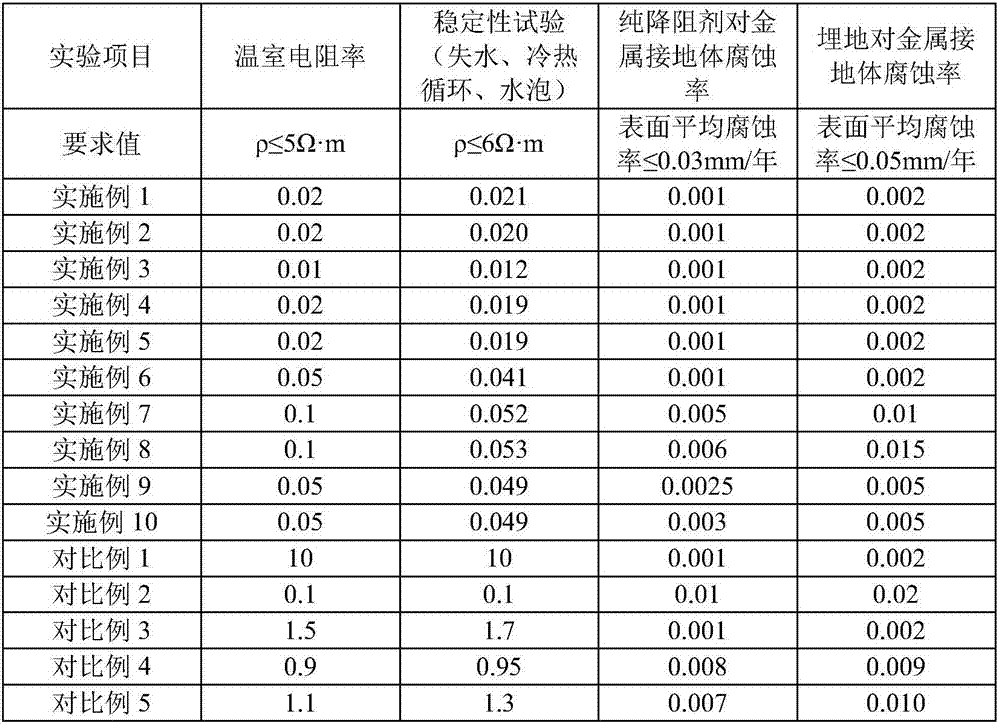

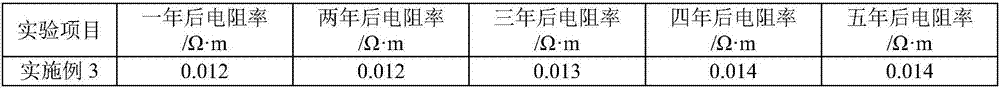

Self-conductive type polymer framework resistance reducing agent and production method therefor

ActiveCN106876002AProduct quality is easy to controlImprove product qualityOrganic conductorsCable/conductor manufactureEnvironment effectSulfite salt

The invention relates to a self-conductive type polymer framework resistance reducing agent. The self-conductive type polymer framework resistance reducing agent comprises the following raw materials in parts by weight: 50-60 parts of N-hydroxymethyl acrylamide, 30-40 parts of N, N'-methylene bisacrylamide, 25-30 parts of acetylenedicarboxylic acid, 15-20 parts of manganese chloride, 8-13 parts of sodium sulfite, 100-130 parts of water and 3-8 parts of aqueous dispersant. The self-conductive type polymer framework resistance reducing agent has the advantages of effective and durable resistance reduction and capability of not being affected by the environment.

Owner:BEIJING XINGTIANTONG TELECOMM TECH CO LTD

Method for preparing silver-contained copper rod for large-capacity phase modifier

The invention relates to the field of metal machining, in particular to a method for preparing a silver-contained copper rod for a large-capacity phase modifier. The method comprises the following steps that of 1, material preparation; 2, upcasting continuous casting unit preparation; 3, parameter adjustment; 4, power frequency melting furnace using; and 5, rod guiding. The silver-contained copperrod manufactured through the scheme is adopted as a base material for manufacturing a silver-contained copper bar product, the conductivity deviation of the obtained silver-contained copper bar product is small, and the use need of a rotor winding of the phase modifier can be met.

Owner:重庆鸽牌电线电缆有限公司

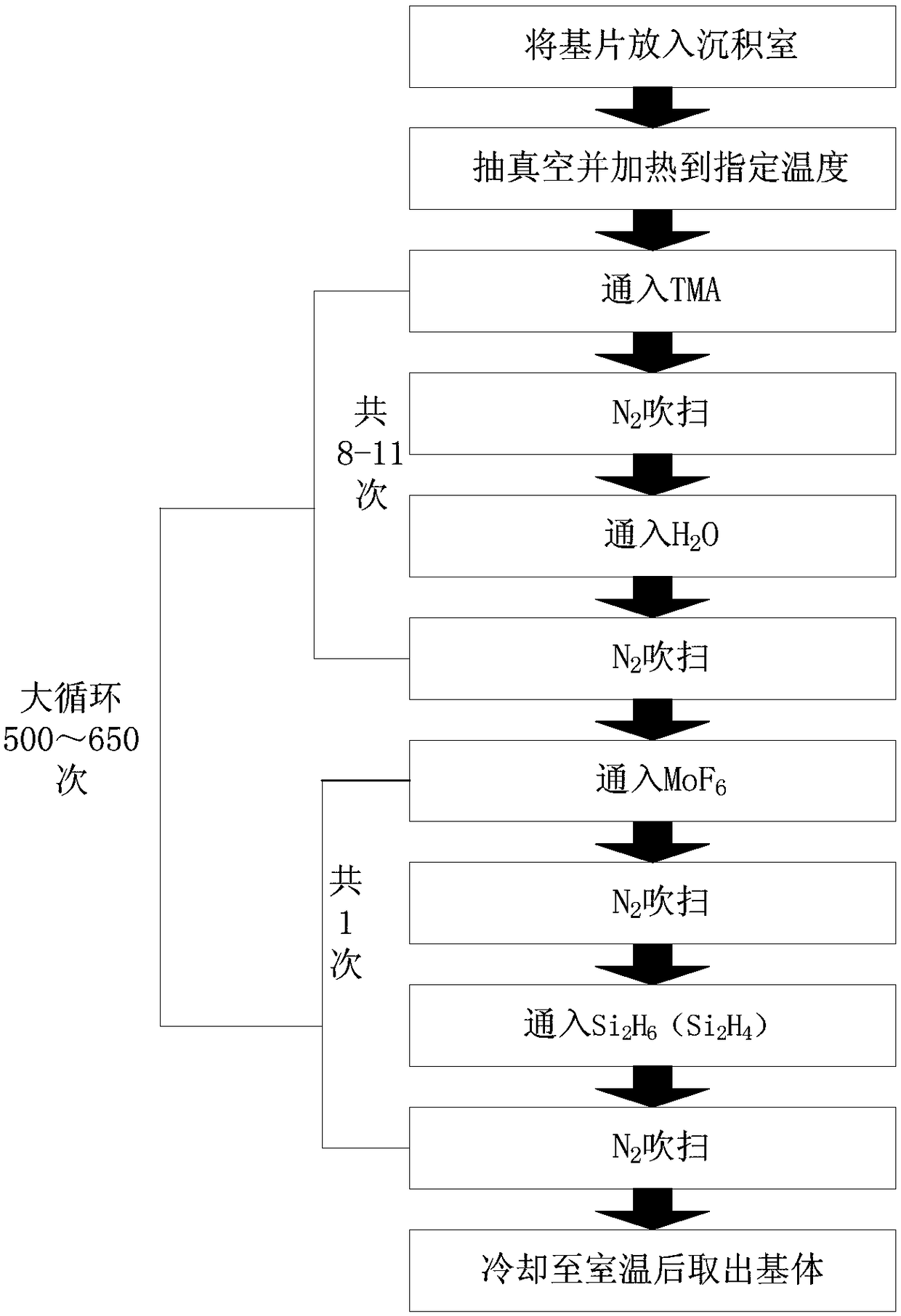

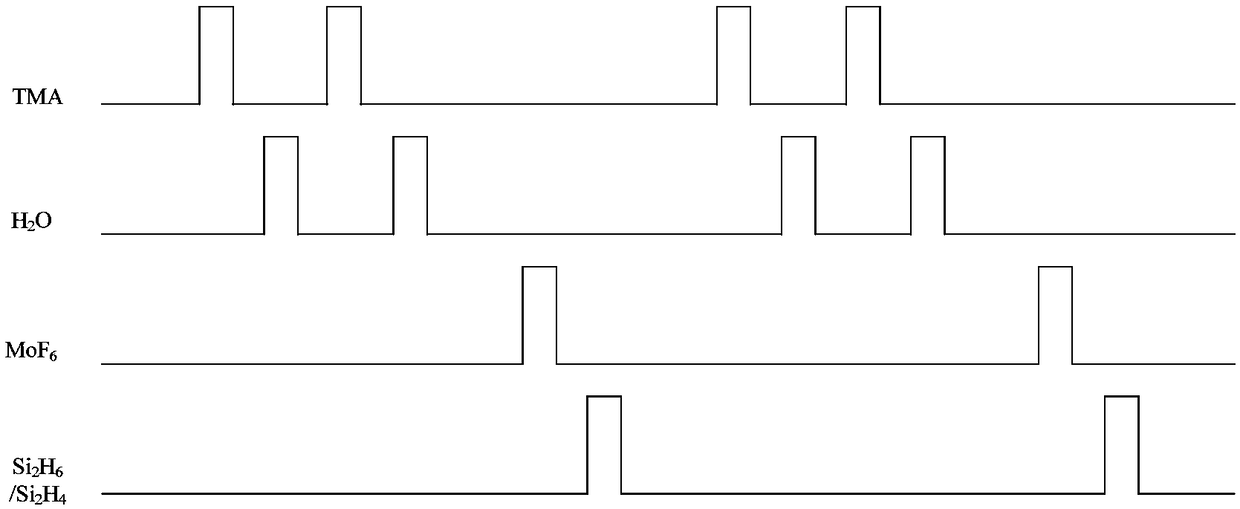

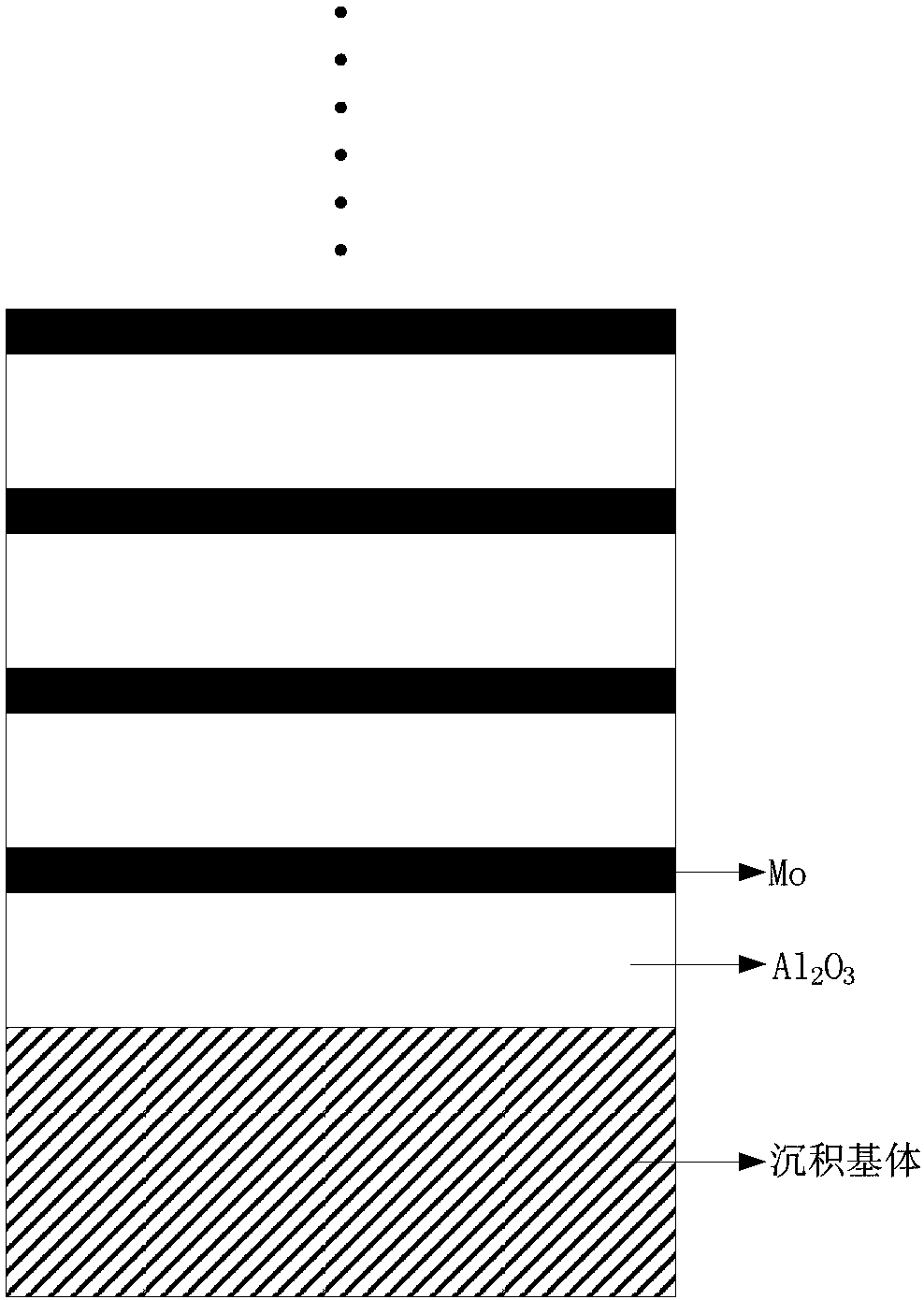

Method for preparing Mo-doped Al2O3 high-resistance film by atomic layer deposition

InactiveCN108588680AReduce surface roughnessFlat surfaceChemical vapor deposition coatingHigh resistanceAtomic layer deposition

The invention relates to a method for preparing a Mo-doped Al2O3 high-resistance film by atomic layer deposition, and solves the problems of incapability of precisely controlling the film thickness and the mixing ratio, in particular existence of defects on the aspects of control of the film thickness precision reaching the atomic grade and synchronous realization of large-area uniform growth in the prior art. The method comprises the following steps: 1) a basal body is put in a deposition chamber; 2) the deposition chamber is vacuumized; and the basal body is heated; 3) 8-11 times of Al2O3 deposition circulation are performed; and single Al2O3 deposition comprises the following steps: 3.1) a precursor Al source is introduced into the deposition chamber; the Al source is exposed in the deposition chamber by set time; and the deposition chamber is purged; 3.2) a precursor oxygen source is introduced to obtain single-layer Al2O3; and 3.3) the deposition chamber is purged; 4) once Mo deposition is performed: 4.1) a precursor Mo source is introduced in the deposition chamber; and the deposition chamber is purged; 4.2) a reducing agent is introduced to obtain single-layer Mo metal simple substances; and 4.3) the deposition chamber is purged; and 5) the steps 3) and 4) are repeated by multiple times in sequence to obtain the Mo-doped Al2O3 high-resistance film.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

High throughput multi-wafer epitaxial reactor

ActiveUS20140311403A1Improve throughputSimple designAfter-treatment apparatusPolycrystalline material growthReactor systemWafering

An epitaxial reactor enabling simultaneous deposition of thin films on a multiplicity of wafers is disclosed. During deposition, a number of wafers are contained within a wafer sleeve comprising a number of wafer carrier plates spaced closely apart to minimize the process volume. Process gases flow preferentially into the interior volume of the wafer sleeve, which is heated by one or more lamp modules. Purge gases flow outside the wafer sleeve within a reactor chamber to minimize deposition on the chamber walls. Sequencing of the illumination of the individual lamps in the lamp module may further improve the linearity of variation in deposition rates within the wafer sleeve. To improve uniformity, the direction of process gas flow may be varied in a cross-flow configuration. Combining lamp sequencing with cross-flow processing in a multiple reactor system enables high throughput deposition with good film uniformities and efficient use of process gases.

Owner:SVAGOS TECHNICK INC

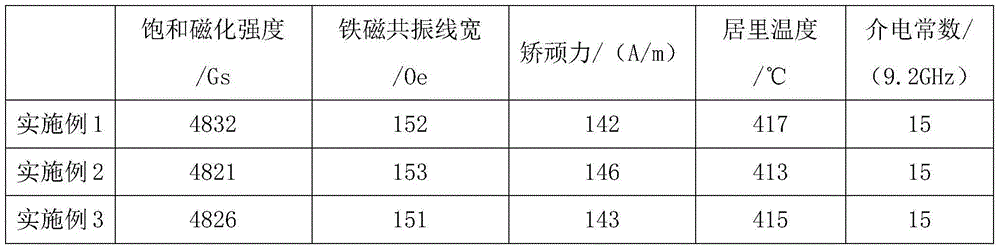

LiZn ferrite material with low coercive force

The invention discloses a LiZn ferrite material with low coercive force, which comprises raw materials of Fe2O3, ZnO, Li2CO3, Bi2O3, Mn3O4, Nb2O5, and polyvinyl alcohol, wherein the mole ratio of Fe2O3 to ZnO to Li2CO3 is (45-50):(10-15):(6-8); the mass fractions of Bi2O3, Mn3O4, and Nb2O5 are 1.5-2.2%, 1.5-2%, and 0.15-0.25%, based on the mass sum of Fe2O3, ZnO, and Li2CO3; and the mass fraction of polyvinyl alcohol is 14-17% based on the mass sum of Fe2O3, ZnO, Li2CO3, Bi2O3, Mn3O4, and Nb2O5. The LiZn ferrite material with low coercive force is prepared through the following steps: first ball milling, pre-sintering, second ball milling, pelleting and moulding, and sintering.

Owner:ANHUI HUALIN MAGNETIC TECH

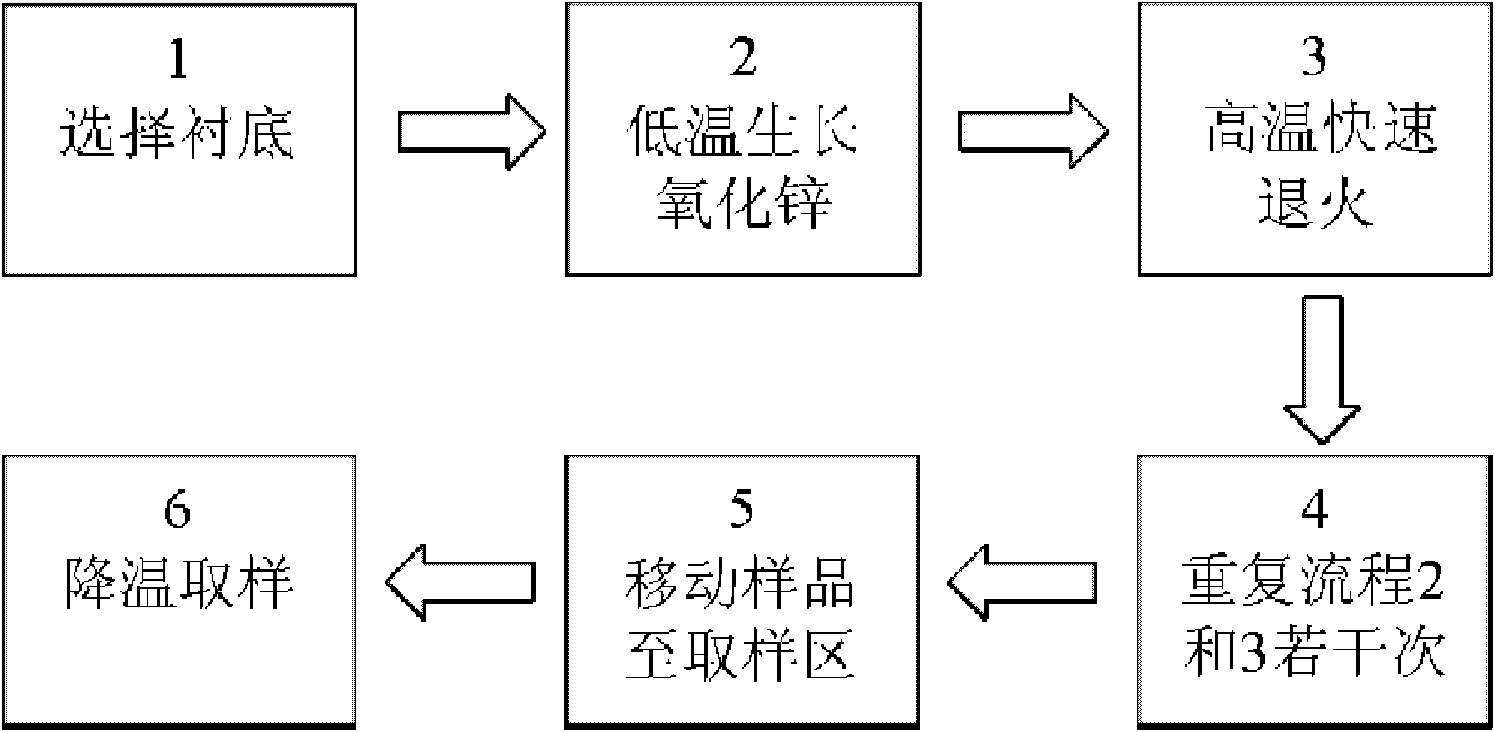

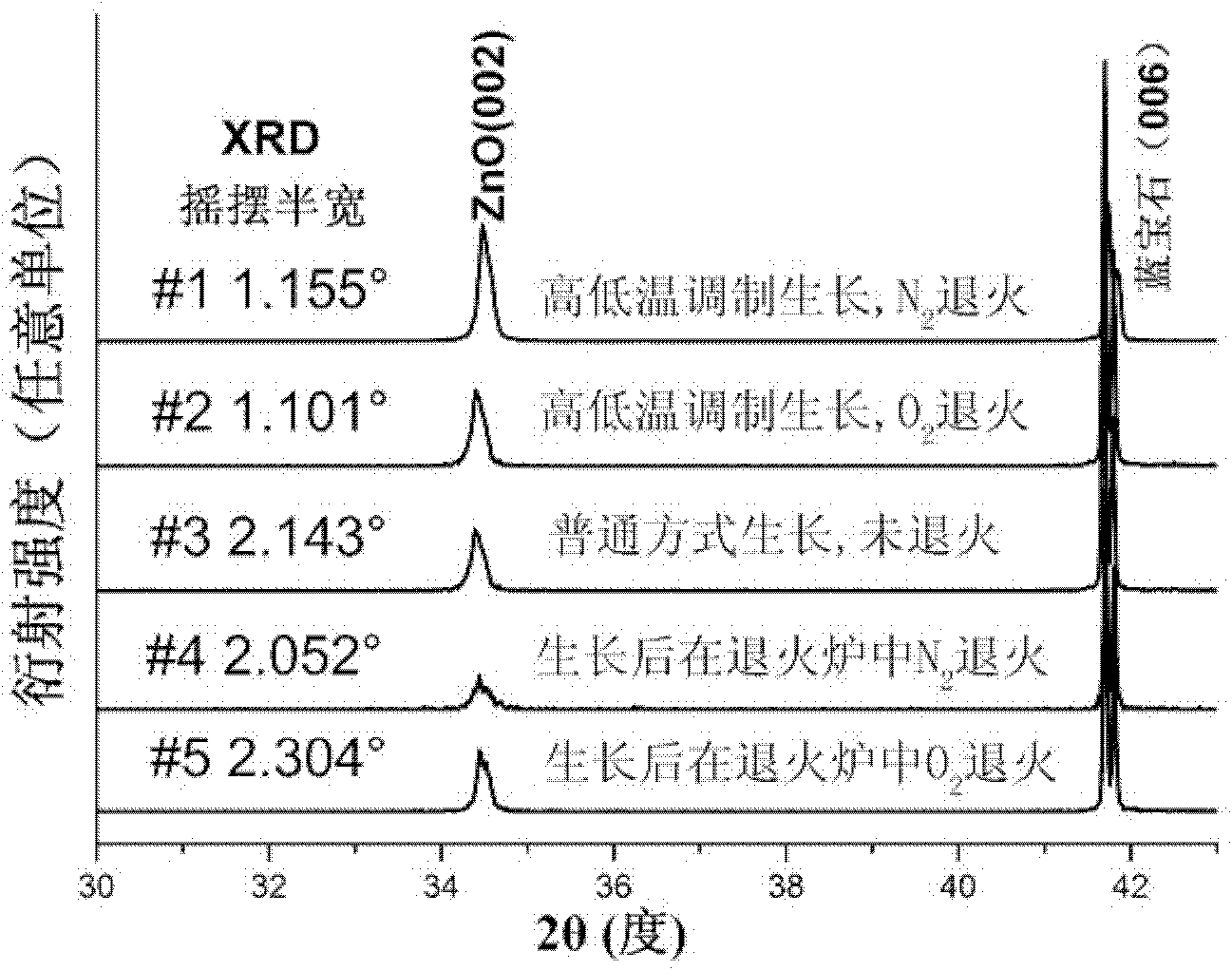

Method for growing zinc oxide material by modulating temperature periodically

InactiveCN102206856ASimple methodLow costPolycrystalline material growthFrom chemically reactive gasesChemistryOrganic chemicals

The invention discloses a method for growing a zinc oxide material by modulating temperature periodically. The method comprises the following steps of: 1, selecting a substrate and zincifying the substrate in a low-temperature growing area of metal organic chemical vapor deposition (MOCVD) equipment; 2, inflating a zinc-source-containing metal organic compound and nitrous oxide into the low-temperature growing area of the MOCVD equipment by using carrier gas and growing a layer of low-temperature zinc oxide material on the substrate in the low-temperature growing area; 3, stopping inflating the metal organic compound and the nitrous oxide, transferring the zinc oxide material growing at low temperature from the low-temperature growing area of a reaction chamber to a high-temperature annealing area by using a transmission device of the MOCVD equipment and annealing quickly at high temperature; 4, transferring the substrate on which the zinc oxide material grows and which is annealed quickly at high temperature from the high-temperature annealing area to the low-temperature growing area by using the transmission device and repeating the step 2 and the step 3 for multiple times; and 5, transferring the substrate on which the zinc oxide material grows to a sampling area when the temperature of the low-temperature growing area is reduced to room temperature, taking a sample out and finishing the growth of the zinc oxide material.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

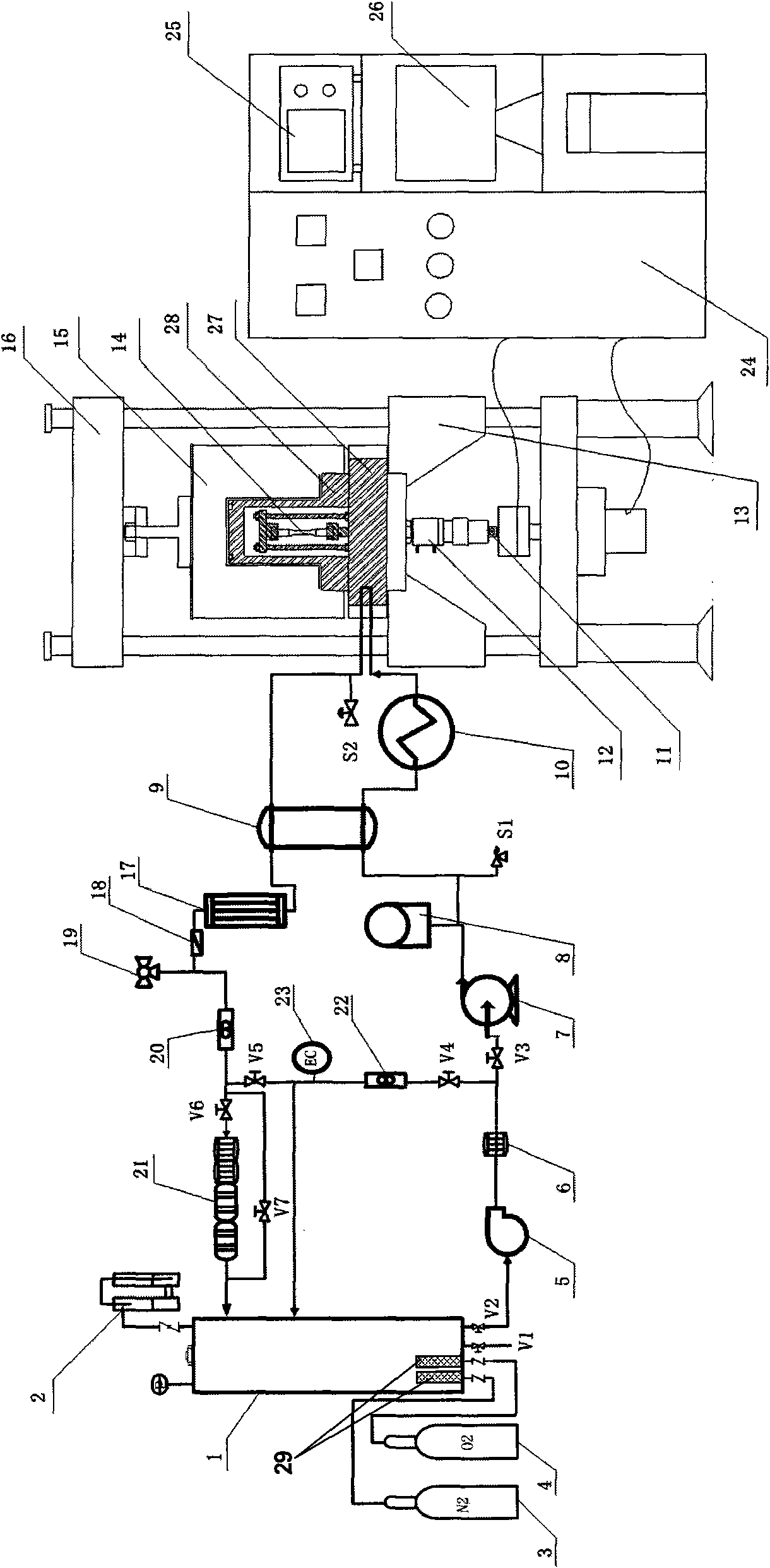

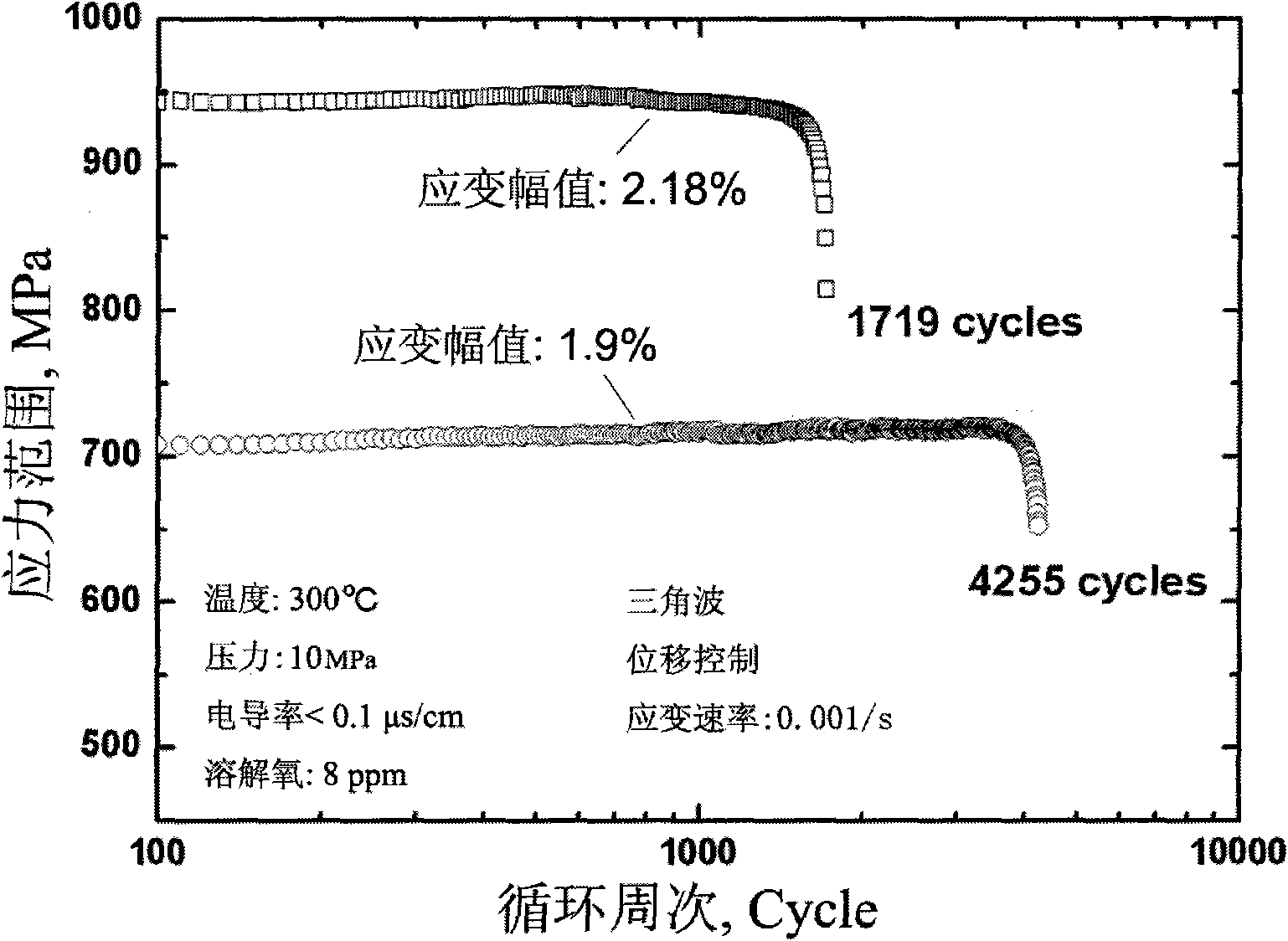

Corrosion fatigue test apparatus with high temperature and high pressure circulating water

ActiveCN102346114BTemperature controlControl pressureMaterial strength using tensile/compressive forcesFatigue loadingWater storage tank

The invention belongs to the field of material testing, specifically to a corrosion fatigue test apparatus with high temperature and high pressure circulating water. With the present invention, the problems of the complex structure and the cumbersome use and maintenance in the prior art are solved. The apparatus is provided with a high temperature and high pressure circulating water system, an autoclave and a fatigue machine. The high temperature and high pressure circulating water system is communicated with the autoclave. A test sample is placed in the autoclave, and is connected with a loading part of the fatigue machine. The high temperature and high pressure circulating water system comprises a water storage tank, a circulation pump, a high pressure pump, a buffer tank, a heat exchanger, a preheater, a condenser, a back pressure valve and an ion exchange resin. An inlet of the autoclave is connected with the heat exchanger through a pipeline. The pipeline is provided with the preheater. An outlet of the autoclave is connected with the heat exchanger through the pipeline. The high temperature and high pressure circulating water system is provided for providing high temperature and high pressure water required by the test. The fatigue machine is provided for performing fatigue loading for the test sample in the autoclave. A control system controls the high temperature and high pressure circulating water system and the fatigue machine.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

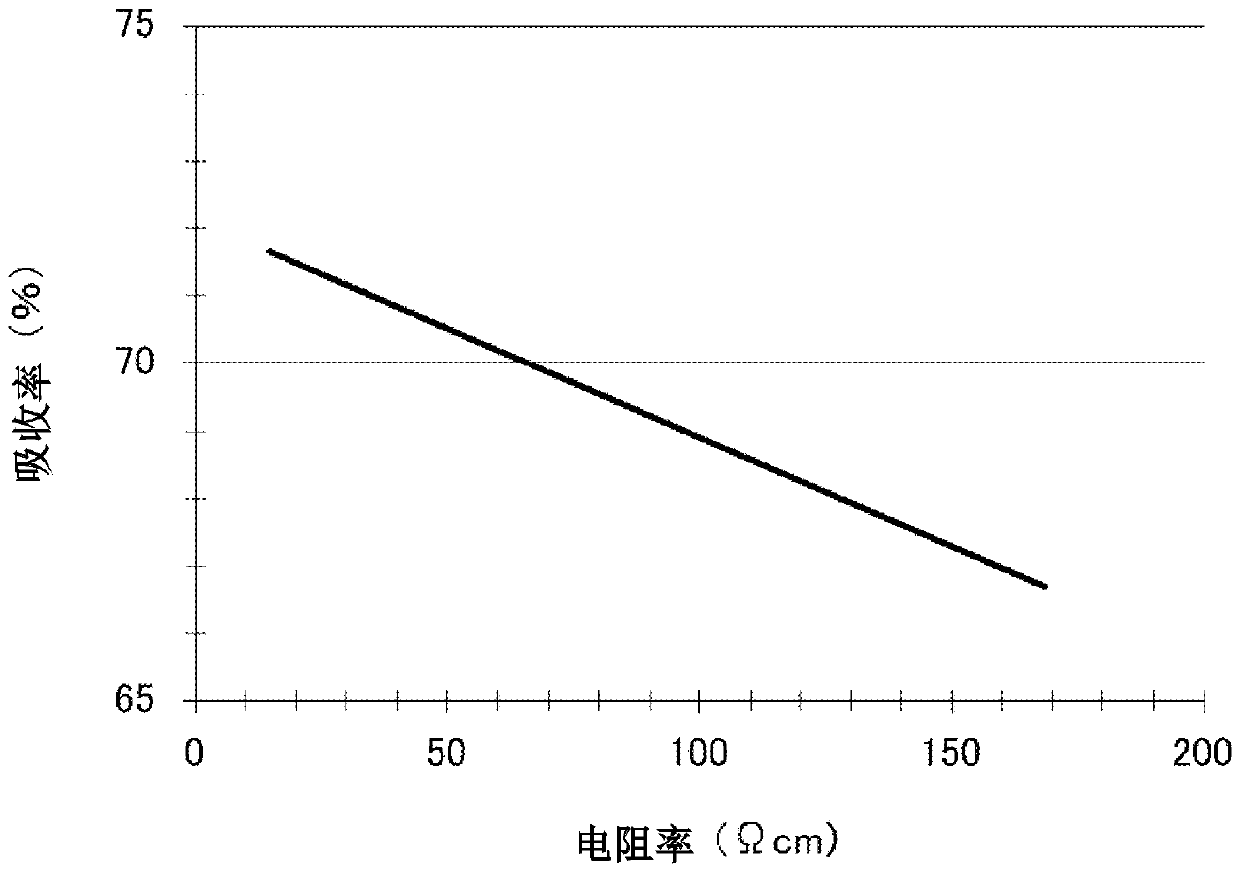

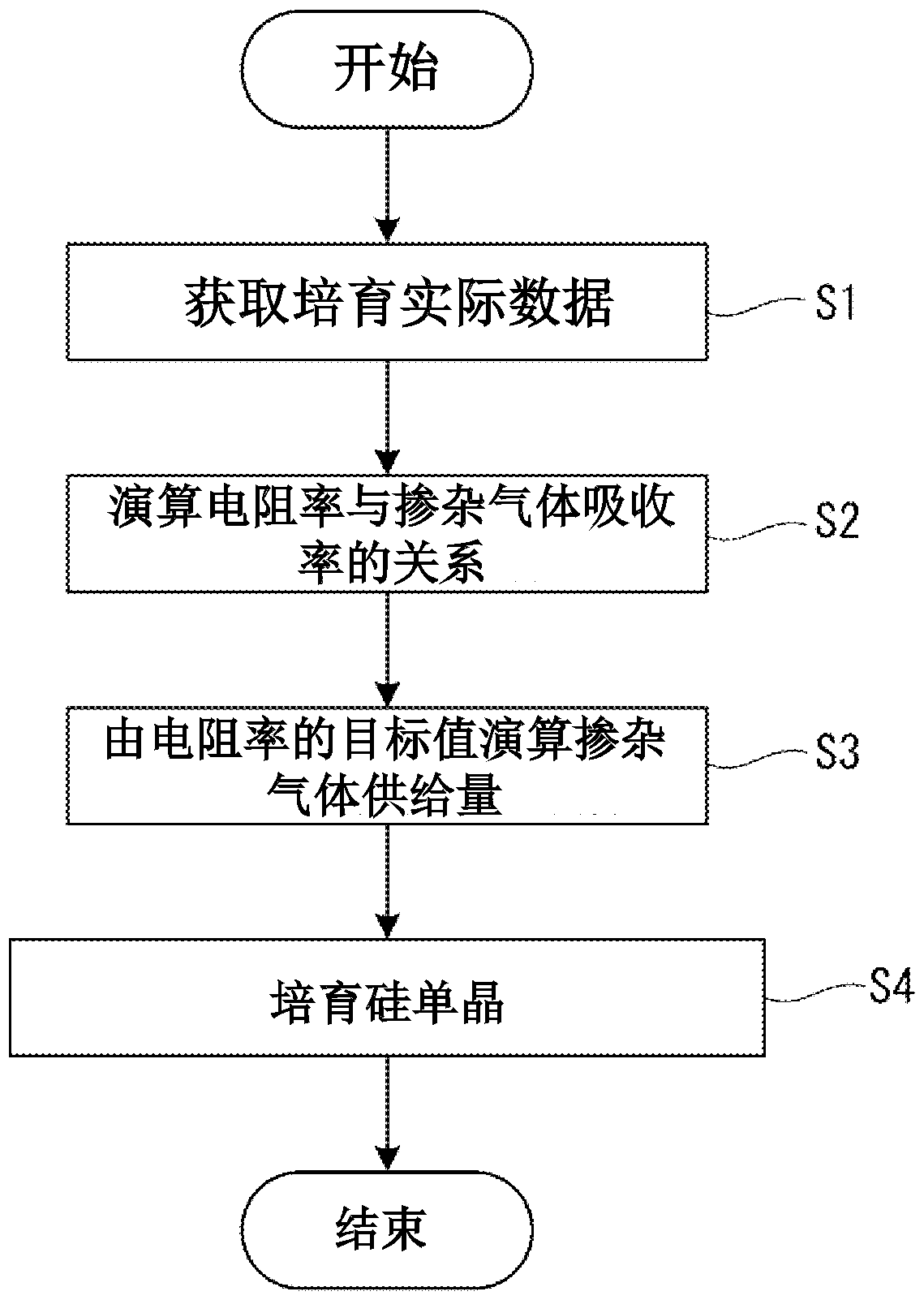

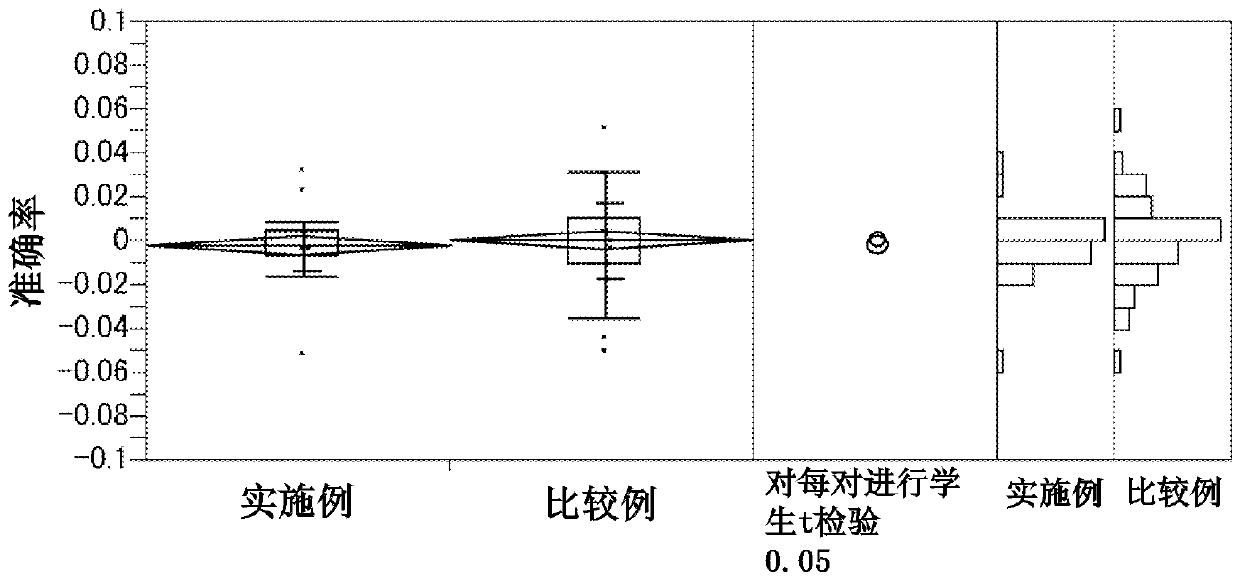

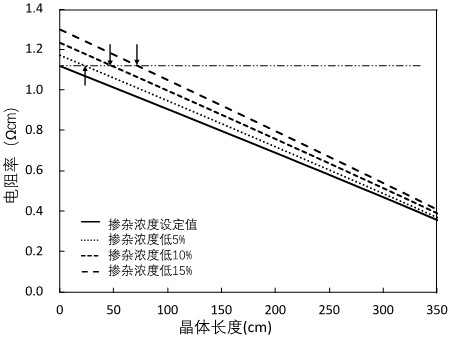

Manufacturing method for silicon single crystal

ActiveCN110004491AControl resistivityPolycrystalline material growthBy zone-melting liquidsSingle crystalAbsorption rate

Disclosed is a manufacturing method for a silicon single crystal, in which the silicon single crystal is grown by an FZ method for controlling the resistivity while blowing a dopant gas into a moltenband region. The method comprises the steps: (S1) acquiring actual data for growing the silicon single crystal by means of a prescribed growing device; step (S2), based on the cultivation actual data,calculating the relationship between the actual value of the resistivity of the silicon single crystal and the doping gas absorption rate of the silicon single crystal; (S3) calculating the amount ofdoped gas supplied on the basis of the relationship between the actual value of the resistivity and the absorption rate of the doped gas and the target value of the resistivity of the silicon singlecrystal manufactured using the same cultivation device; (S4) controlling the resistivity of the cultured silicon single crystal while blowing the dopant gas by using the calculated dopant gas supply amount.

Owner:SUMCO CORP

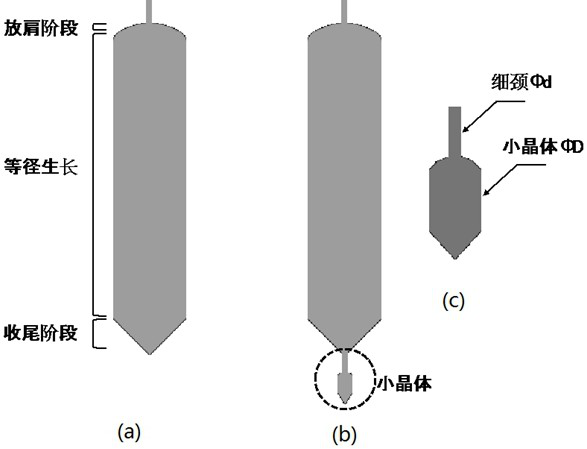

Growing method of monocrystalline silicon and monocrystalline silicon

ActiveCN112680787ATest accuratePrecise control of concentrationPolycrystalline material growthBy pulling from meltDopantPhysical chemistry

The invention discloses a growth method of monocrystalline silicon and monocrystalline silicon, and belongs to the technical field of monocrystalline silicon. The growth method of the monocrystalline silicon comprises the following steps of: putting a set amount of polycrystalline silicon raw material and a dopant into a growth container; carrying out crystal growth by adopting a pulling method; continuously growing a to-be-detected crystal at the last stage of an ending stage; calculating the concentration of the dopant in the remainder of the growth container by testing the resistivity of the to-be-detected crystal; and calculating the supplement amount of the dopant according to the concentration of the dopant in the remainder so as to supplement the concentration of the dopant to a set value for the growth of the next crystal. According to the method, the concentration of the dopant in the remainder can be more accurately tested, the concentration of the dopant in the growth container before the next crystal grows can be accurately controlled, the resistivity of the crystal can be more accurately controlled, the resistivity of the crystal is prevented from deviating from a target value to a certain extent, and the product percent of pass is increased.

Owner:杭州晶宝新能源科技有限公司

Crucible for casting polysilicon ingot and method for preparing same, polysilicon ingot and method for preparing same

ActiveCN106591942BHigh yieldImprove life expectancyPolycrystalline material growthSingle crystal growth detailsFiberDopant

The invention provides a crucible for polycrystalline-silicon ingot casting. The crucible comprises a crucible body and a doping layer. The crucible body comprises a base and a side wall extending upwards from the base, the doping layer is attached to the internal surface of the portion, between the portion the first height away from the base and the portion the second height away from the base, of the side wall, the first height is the distance from the fused silicon liquid level formed after a prefilled silicon material in the crucible is fused to the base of the crucible body, and the second height is the distance from the upper surface of a silicon ingot when fused silicon liquid is fully converted into a solid silicon ingot to the base of the crucible body; the material of the doping layer comprises silica wool or carbon fibers and a doped material loaded in silica wool or carbon fibers, the doped material comprises a first doping agent, and the first doping agent comprises P-shaped doping elements and any one of N-shaped doping elements and / or germanium elements; the initial atomic volume concentration of the first doping agent in the prefilled silicon material in the crucible is 1*10<13>-7*10<18> atmos / cm<3>. By means of the crucible, the heat transmission speed of the side wall of the crucible can be effectively decreased, the temperature of the doping layer is reduced, and it is avoided that the first doping agent is fused in advance.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

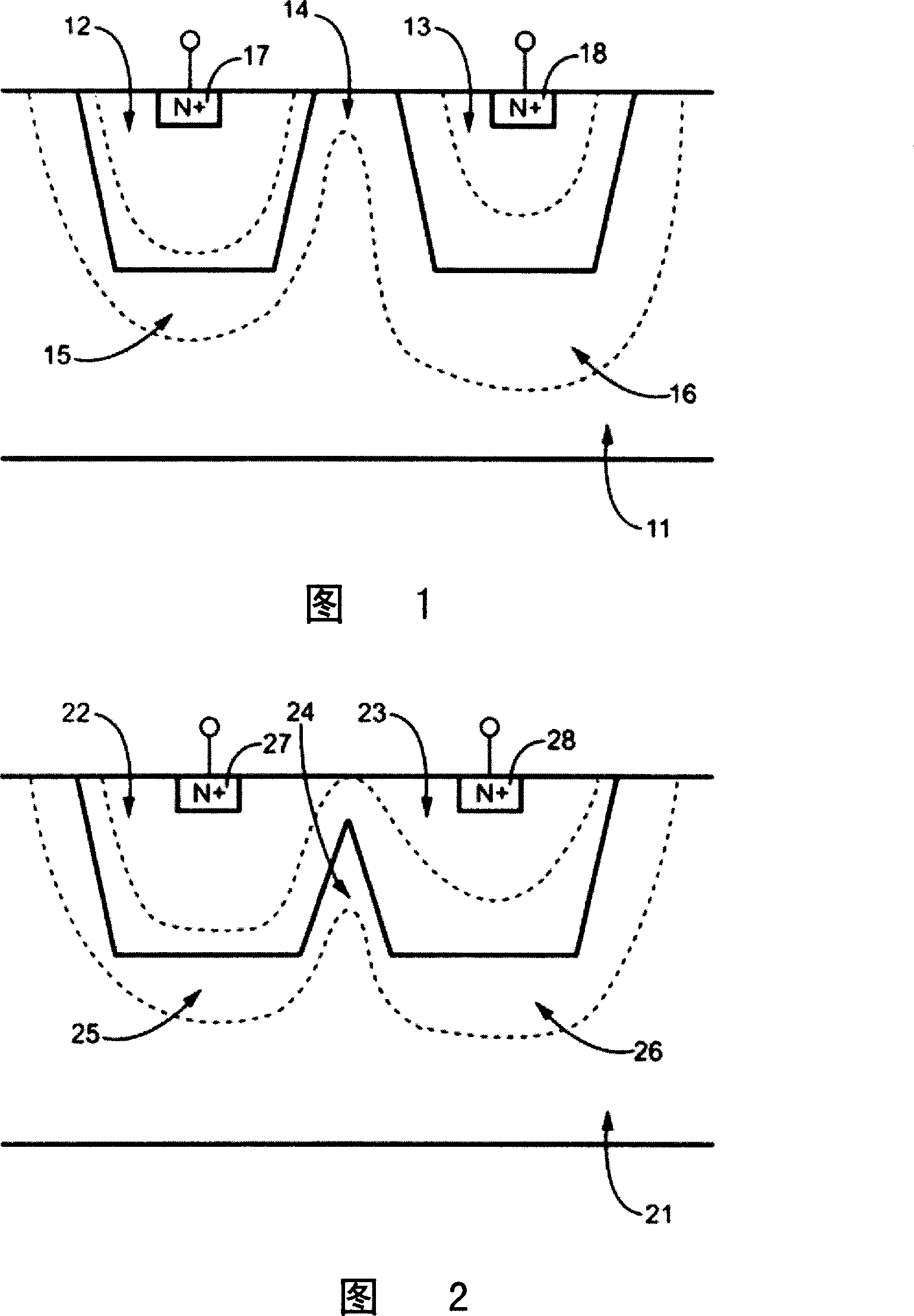

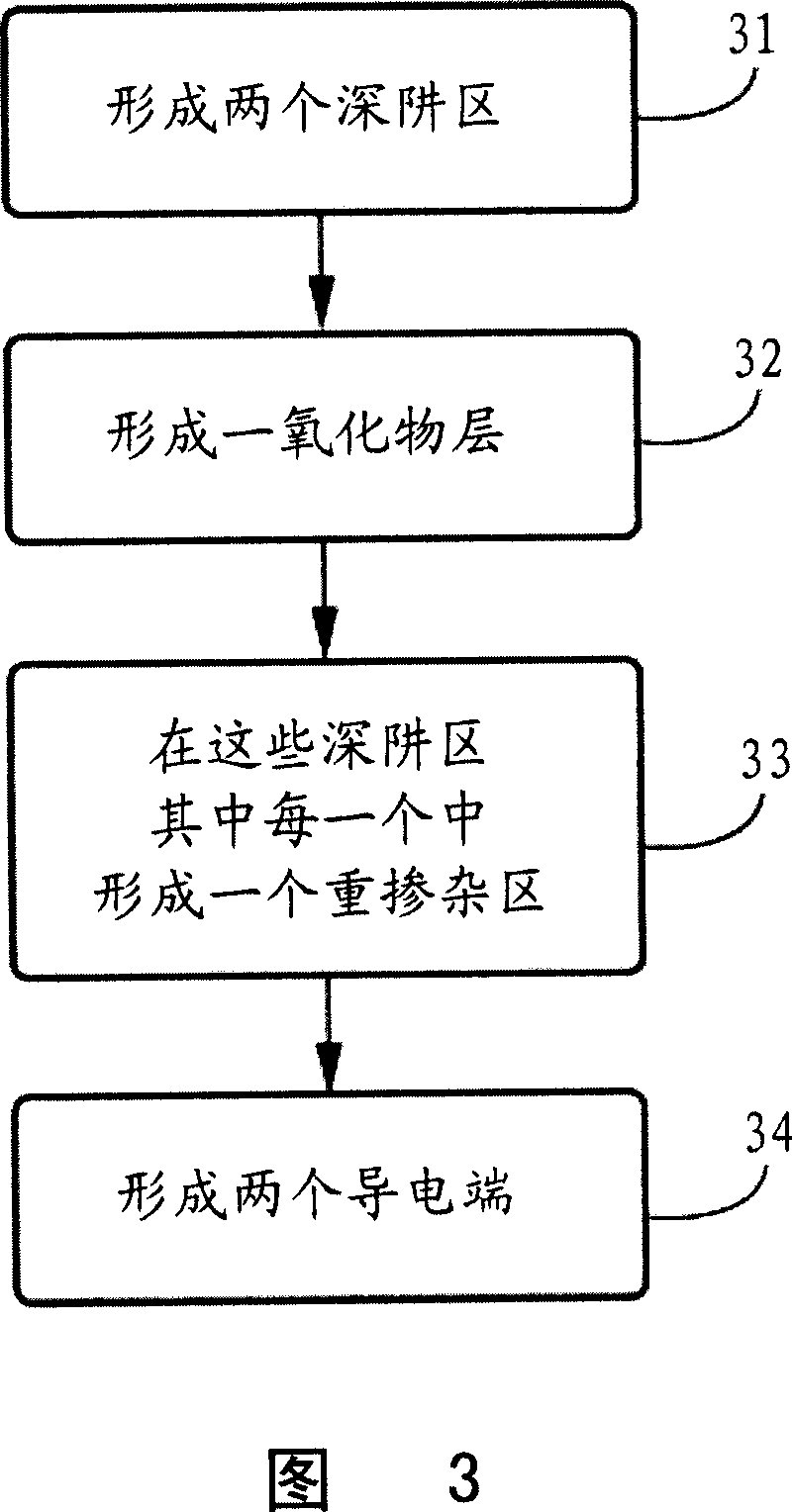

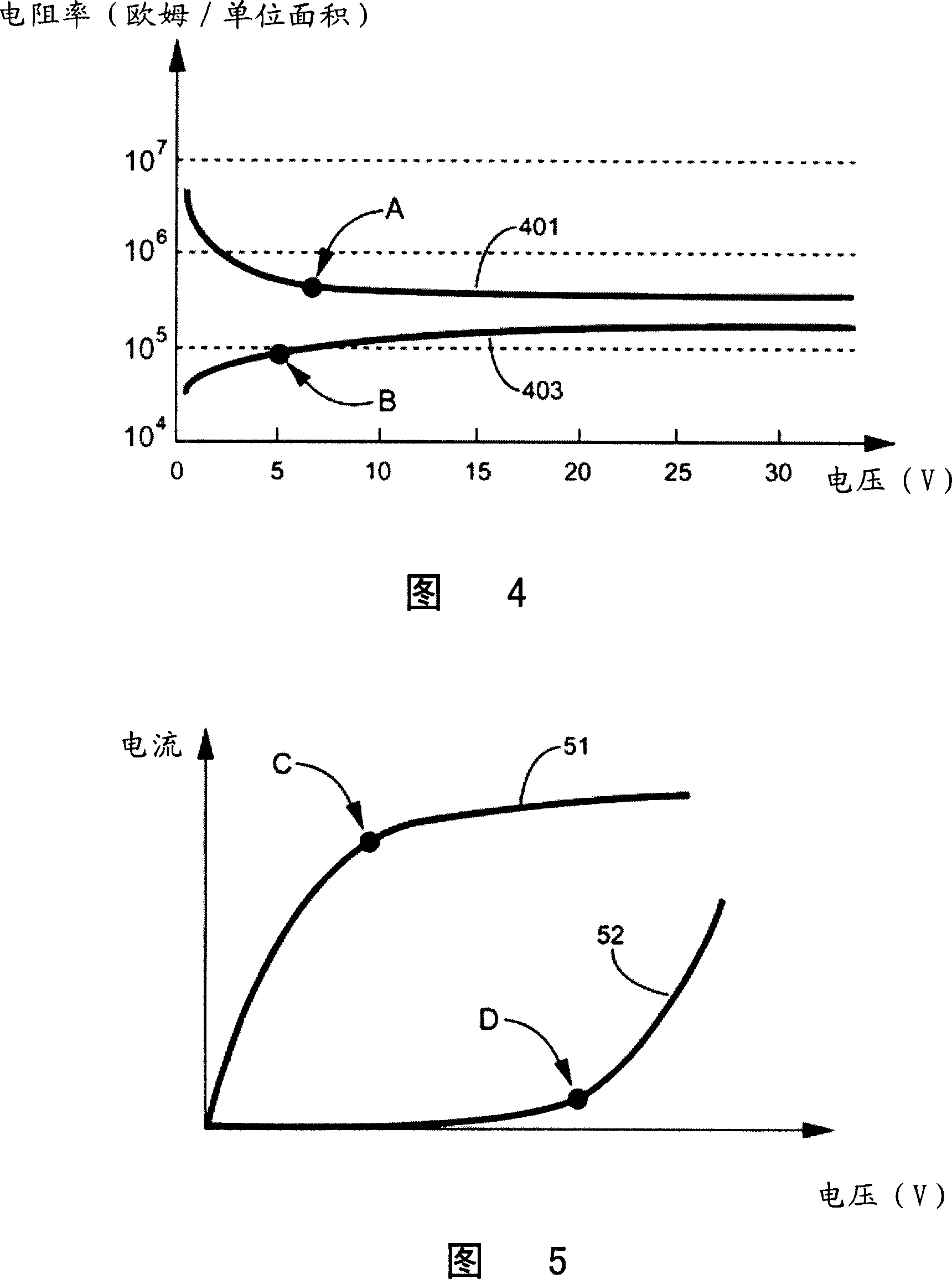

Voltage-controlled semiconductor construction, resistor, and method for manufacturing same

InactiveCN101022108AHigh resistivityControl resistivitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureVoltage controlled resistor

The invention provides a voltage-controlled semiconductor structure, a voltage-controlled resistor and a manufacturing method thereof. The semiconductor structure comprises a substrate, a first adulteration trap and a second adulteration trap. The substrate is adulterated with a first type ion. The first adulteration trap has a second type ion and is formed in the substrate. The second adulteration trap has a second type ion and is formed in the substrate. The first type ion and the second type ion are inter-complementary. A resistor is formed between the first adulteration trap and the second adulteration trap. The electrical resistivity of the resistor is controlled by a differential voltage. An electrical resistivity of the resistor is related to a first deepness of the first adulteration trap, a second deepness of the second adulteration trap and a distance between the first adulteration trap and the second adulteration trap. The electrical resistivity of the resistor is higher than an electrical resistivity of a trap type resistor formed in a single adulteration trap having the second type ion.

Owner:SYST GEN

A kind of method for preparing Cu-doped indium sulfide film

InactiveCN105428217BEasy to manufactureHigh puritySemiconductor/solid-state device manufacturingPhotovoltaic energy generationFilm resistanceElectrical battery

The present invention discloses a Cu-doped indium sulfide film preparation method. According to the method, a vacuum evaporation method is adopted, a thin Cu layer is evaporated between two layers of indium sulfide films, and then Cu is diffused into the indium sulfide films by thermal annealing, so that the aim of preparing a Cu-doped indium sulfide film is fulfilled. According to the method disclosed by the present invention, doping concentration can be controlled by controlling the amount of the evaporated Cu, thereby fulfilling the aim of reducing film resistivity to varying degrees. The film prepared by the method disclosed by the present invention can be used as a buffer layer of a solar cell.

Owner:FUZHOU UNIV

Conductive material co-doping conductive concrete and preparation method thereof

The invention provides a conductive concrete compounded with conductive materials and a preparation method thereof. The concrete is composed of cement, silica fume, carbon fiber, carbon nanomaterials (carbon nanotubes + carbon black + graphite), nano-zinc oxide, water reducing agent, filling Material, dispersant, defoamer, and water. The preparation method of the multifunctional conductive concrete mixed with conductive materials is simple and the performance is excellent. Replacing some carbon fibers with carbon nanomaterials has lower cost and stable electrical conductivity than traditional conductive concrete. Adding nano-zinc oxide can significantly improve the electrical conductivity of concrete. In the case of electrification, the concrete has good electrothermal performance, and it is applied to airport pavement, bridge deck and cement concrete pavement. It can melt ice and snow, detect road loads, cracks and expansion of concrete structures; It has good electromagnetic properties, can effectively shield electromagnetic waves, reduce electromagnetic radiation, and reduce electromagnetic interference.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com