Method for preparing silver-contained copper rod for large-capacity phase modifier

A technology of camera and large capacity, which is applied in the field of preparation of silver-containing copper rods for large-capacity cameras, can solve the problem that the conductivity of silver-containing copper bars is difficult to control, cannot meet the use requirements of camera rotor windings, and the silver-containing copper bars conduct electricity. Problems such as large performance deviation, to achieve the effect of small deviation in electrical conductivity, meeting the needs of use, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

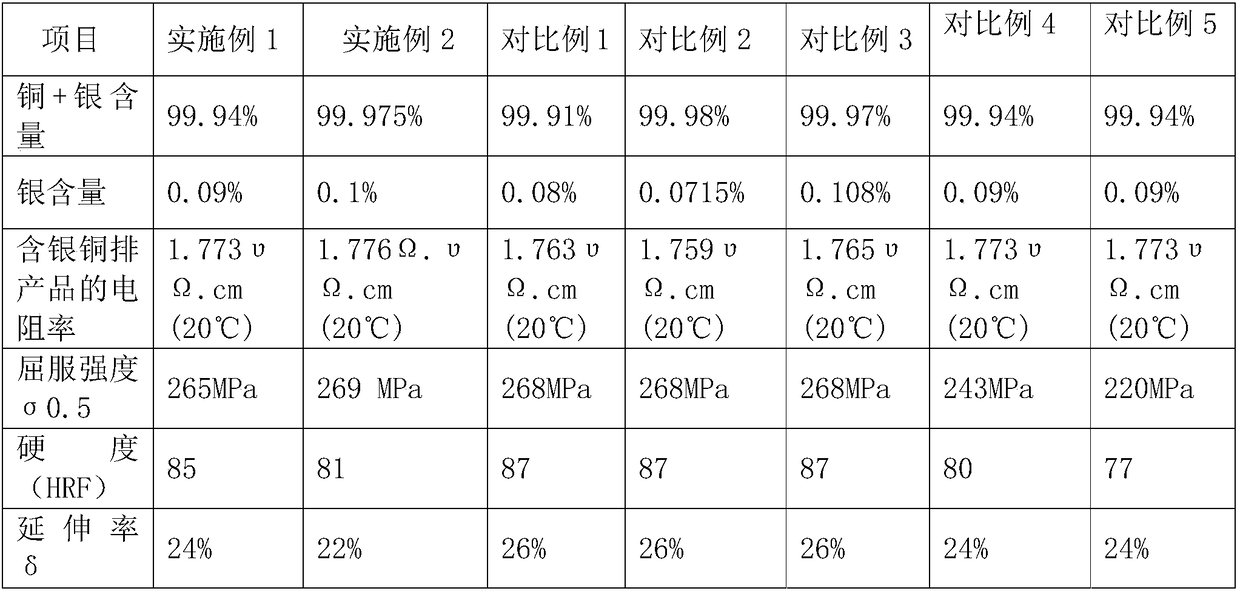

Embodiment 1

[0034] A method for preparing a silver-containing copper rod for a large-capacity condenser, the steps are as follows:

[0035] Step 1, material preparation: take silver, iron and copper respectively; Impurities, so the sum of the weight percentages of the material components will not be as high as 100%, and the rest are impurities.

[0036] Step 2: Prepare the upward continuous casting unit: the upward continuous casting unit includes a power frequency melting furnace, a traction system, and a melt cooling crystallization system.

[0037] Step 3. Parameter adjustment: adjust the cooling water volume of the melt cooling and crystallization system, so that the water pressure in the melt cooling and crystallization system is kept at 0.26Mpa, and the temperature is kept at 26°C; the traction system includes guide rods, and the pitch of guide rods is 5.5mm .

[0038] Step 4. Power frequency melting furnace: There is molten copper water in the power frequency melting furnace, and...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the preparation method of a silver-containing copper rod for a large-capacity condenser uses the following steps:

[0042]Step 1. Material preparation: take silver, iron and copper respectively; and the weight percentages of the material components are: silver 0.1%, iron 0.001-0.005%, and the total content of copper and silver is equal to 99.975%. Because all contain impurity in general copper, silver, so the summation of weight percentage of material composition can not be up to 100%, all the other are impurity.

[0043] Step 2: Prepare the upward continuous casting unit: the upward continuous casting unit includes a power frequency melting furnace, a traction system, and a melt cooling crystallization system.

[0044] Step 3. Parameter adjustment: adjust the cooling water volume of the melt cooling and crystallization system, so that the water pressure in the melt cooling and crystallization system is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com