Self-conductive type polymer framework resistance reducing agent and production method therefor

A technology of polymer skeleton and production method, applied in the field of self-conductive polymer skeleton drag reducing agent and its production, can solve the problems of long effective time, high cost, and the resistance reducing effect can only be maintained for two to three years, etc. Improve product quality and excellent resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

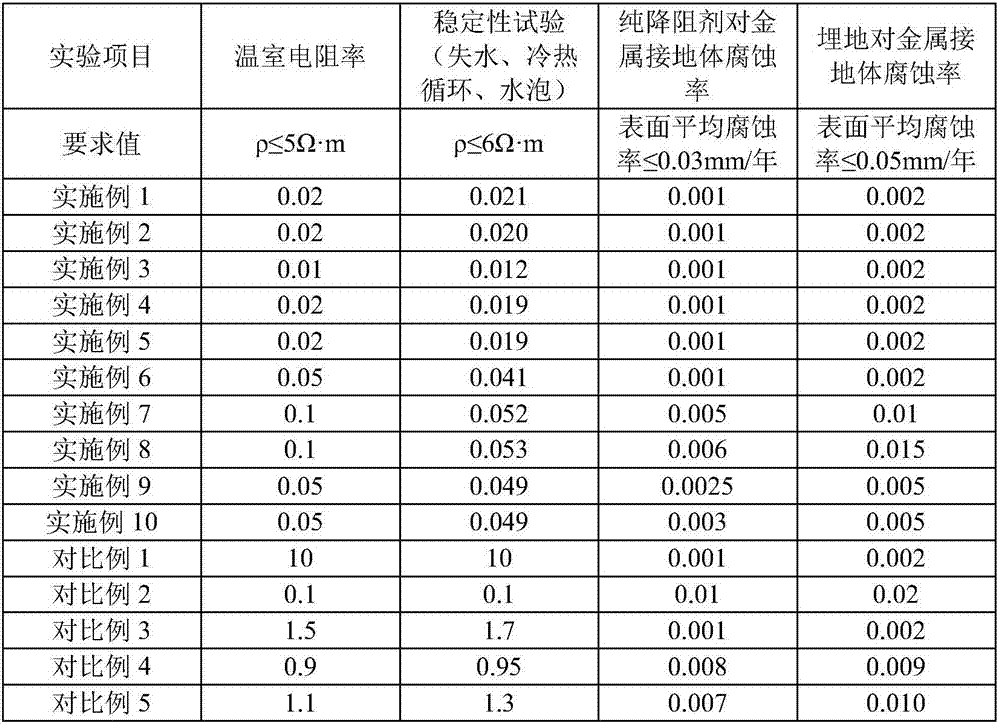

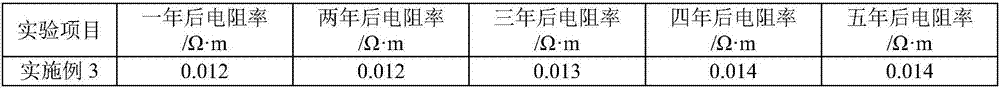

Examples

Embodiment 7

[0040] Example 7: The components and contents of Example 7 and Example 3 are the same, but the difference lies in the pH=6.5 described in Step 3.

Embodiment 8

[0041] Embodiment 8: The components and contents of Embodiment 8 and Embodiment 3 are the same, but the difference lies in the pH=7 described in Step 3.

Embodiment 9

[0042] Example 9: The components and contents of Example 9 and Example 3 are the same, but the difference is that the temperature described in Step 3 is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com