Patents

Literature

36results about How to "Control solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

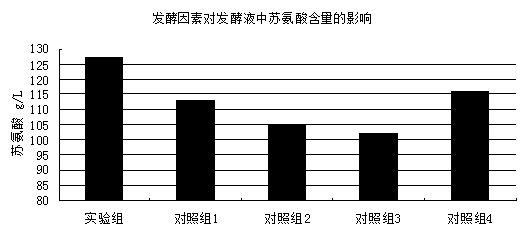

Process for preparing granular type threonine product

ActiveCN104757273AReduce pollutionAvoid pollutionAnimal feeding stuffFertilizer mixturesEnvironmental resistanceMycoprotein

The invention belongs to the technical field of production of amino acids and in particular relates to a process for preparing a granular type threonine product. The process comprises the following steps: (1) preparing threonine fermentation liquor; (2) preparing powdery threonine; (3) preparing threonine granules; (4) refining a mycoprotein; (5) preparing the feed; and (6) preparing an organic fertilizer. According to the process disclosed by the invention, the threonine granules are prepared, moisture absorption and agglomeration can be avoided, the components of the waste mother solution are effectively utilized, wastes are not produced in the whole process, the process is environmentally friendly and pollution-free, and energy conservation and emission reduction are realized.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

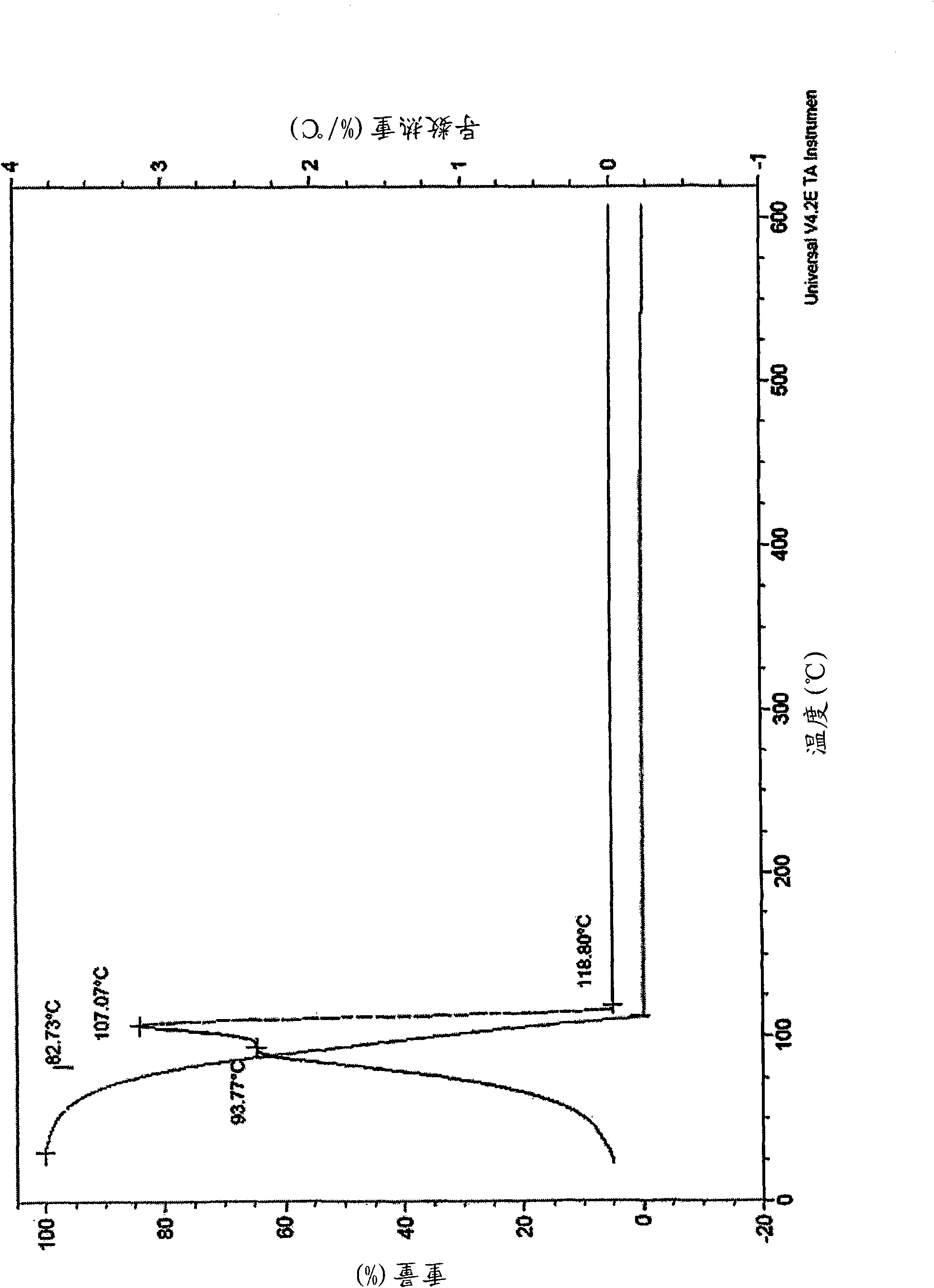

Fermentation preparation technology of granular threonine

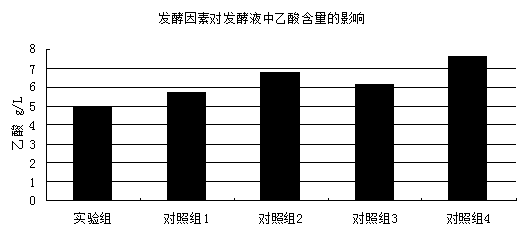

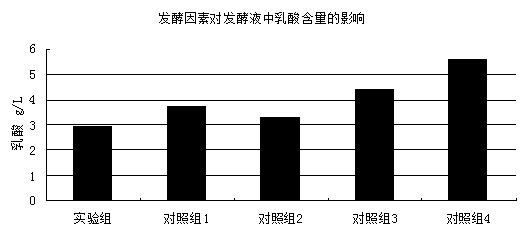

InactiveCN108658798AImprove broken rateImprove filtration efficiencyOrganic compound preparationAmino-carboxyl compound preparationSolubilityFluidized bed drying

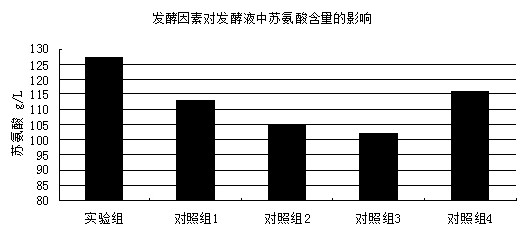

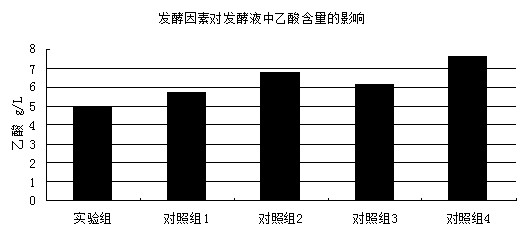

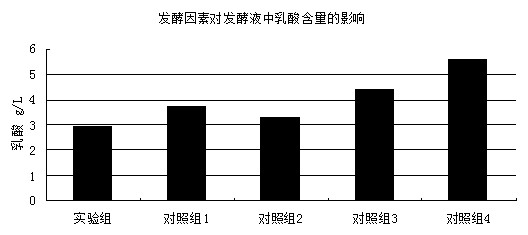

The invention belongs to the technical field of threonine production, and belongs to a fermentation preparation technology of granular threonine. The technology comprises the followings steps: firstlycentrifuging threonine fermentation liquor by a disc centrifuge, collecting supernate, performing filtering through a ceramic membrane, concentrating filtrate, adjusting pH with sulfuric acid, heating the filtrate to 75 DEG C, performing separation by a horizontal spiral centrifuge, removing precipitate, and collecting supernate; performing filtering through an ultrafiltration membrane, collecting filtrate, crystallizing the filtrate through an intermittent single-effect concentrating crystallizing pan, centrifuging and collecting crystals, then drying the crystals at the temperature of 120 DEG C, compressing the crystals into flake crystals, putting the flake crystals into a granulation tower, performing drying by a fluidized bed, performing crushing and granulation, sieving, collectinggranules with target grain sizes, and performing packaging, so as to obtain the granular threonine. The technology has the advantages that threonine is prepared into granules, the flowability can be improved, the threonine is convenient to store and transport, the solubility is convenient to control, and the quality and the additional value of threonine are improved.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Method for synthesizing high molecular weight instant anionic polyacrylamide

The invention discloses a method for synthesizing high molecular weight instant anionic polyacrylamide, which is characterized in that: an alkaline hydrolysis method is adopted, and comprises the following steps of: preparing aqueous solution of acrylamide monomer from the acrylamide monomer by using deionized water, adding a hydrolytic agent, a composite initiator and an auxiliary agent, regulating the pH value to be between 8.5 and 12, introducing nitrogen, expelling oxygen and sealing a system at the temperature of between 10 and 25 DEG C, polymerizing under the heat insulation condition, and hydrolyzing, crushing, drying and grinding to obtain instant anionic polyacrylamide solid powder with the viscosity-average molecular weight of 15,000,000 to 21,000,000 and the dissolution time of shorter than 0.5 hour. A novel coordination agent and a novel pH value regulator are adopted, the method is easy and convenient to operate, the initiation speed of the monomer is high, the dissolution speed of a product is high, the reaction rate and the molecular weight of the product are controllable, the method is suitable for production on different scales, and the product is suitable for industries such as papermaking dispersants, tertiary oil recovery, beneficiation, sewage treatment and the like.

Owner:HEFEI UNIV OF TECH

Polymeric phosphite composition and hydrocyanation of unsaturated organic compounds and the isomerization of unsaturated nitriles

InactiveCN1390241AControl solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsIsomerizationOrganic compound

A polymeric composition, a process for producing the composition, and a process for using the composition in, for example, hydrocyanation or isomerization are disclosed. The composition comprises repeat units derived from (1) a carbonyl compound, a monomer, and phosphorochloridite; (2) phosphorus trichloride, a polyhydric alcohol, and an aromatic diol; or (3) combinations of (1) and (2) in which the nonomer can be a polyhydric alcohol, an amine, combinations thereof. The composition can further comprise a Group VIII metal and optionally a Lewis acid. The composition can be produced by (1) contacting a carbonyl compound with the monomer to produce an intermediate and contacting the intermediate with phosphorochloridite; (2) contacting phosphorus trichloride with a second polyhydric alcohol under a condition sufficient to produce a phosphorus-containing polymer and contacting the phosphorus-containing polymer with an aromatic diol; or (3) contacting an N, N-dialkyl dichlorophosphoramidite with a second polyhydric alcohol to produce a polymer phosphoramidite, contacting the polymer phosphoramidite with an acid such as HC1 to produce the phosphorus-containing polymer, which is then contacted with an aromatic diol. The composition can be used as catalyst, for example, for converting an unsaturated organic compound to a nitrile and isomerizing a nitrile.

Owner:INVISTA TECHNOLOG IES S A R L

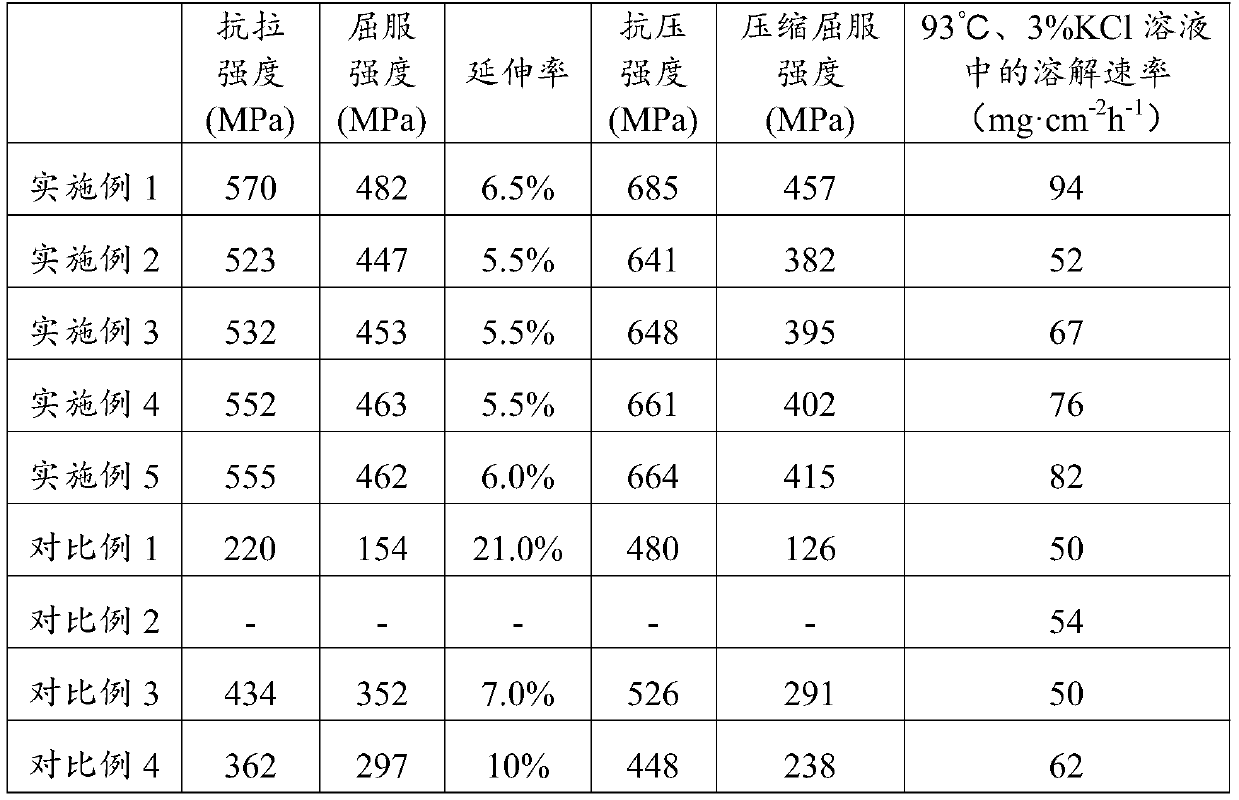

Ultrahigh-strength soluble magnesium alloy as well as preparation method and application thereof

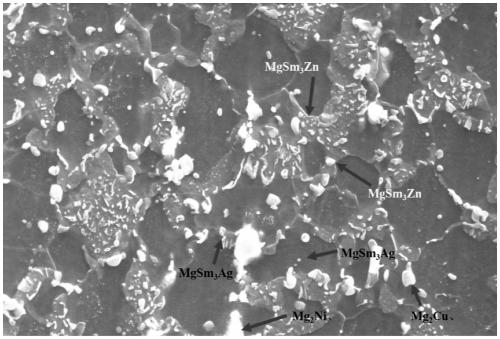

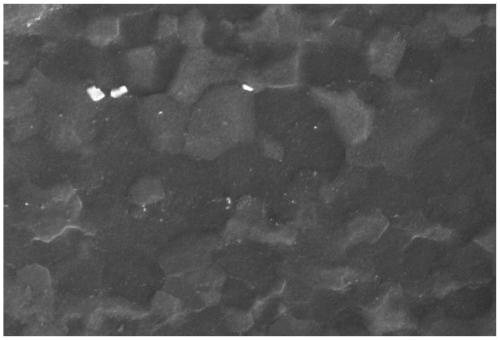

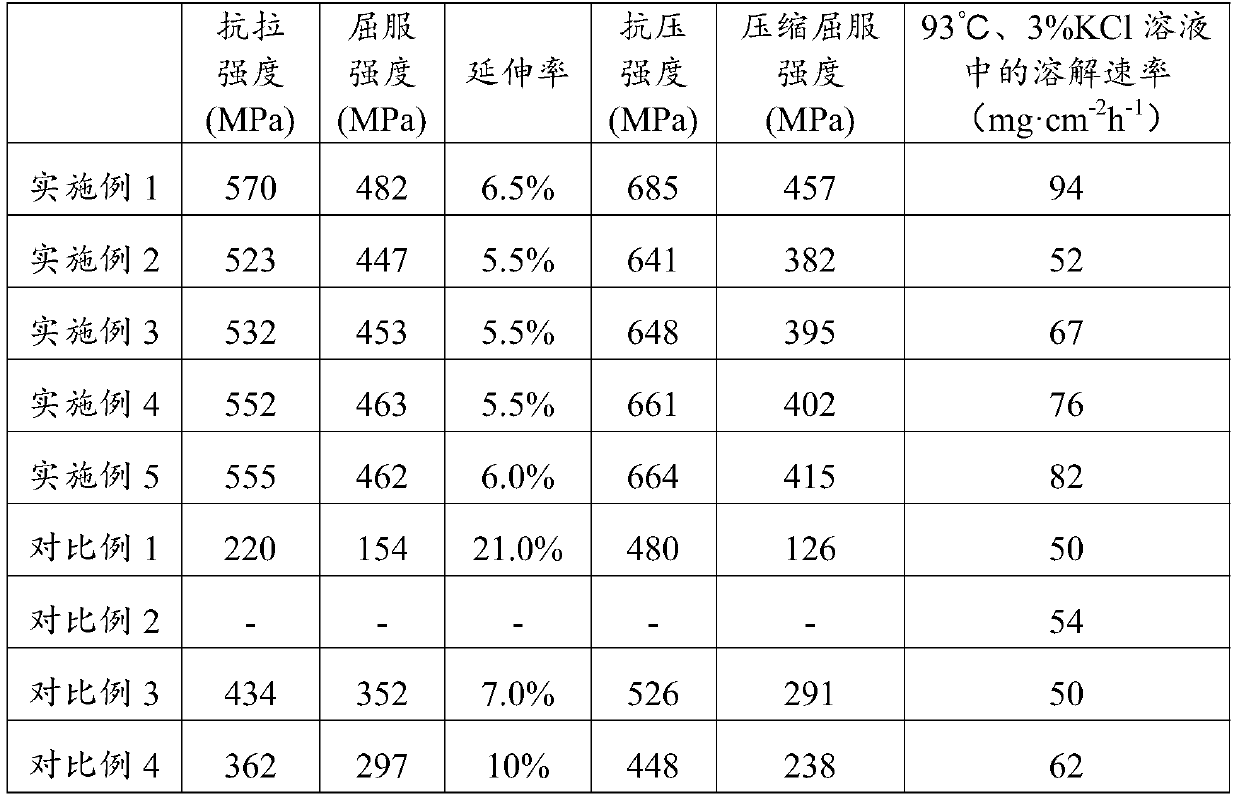

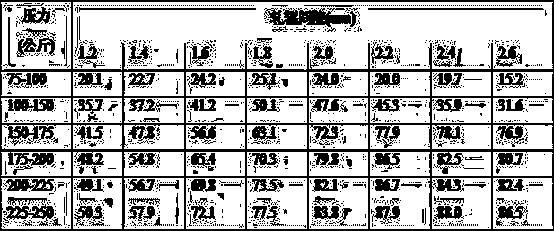

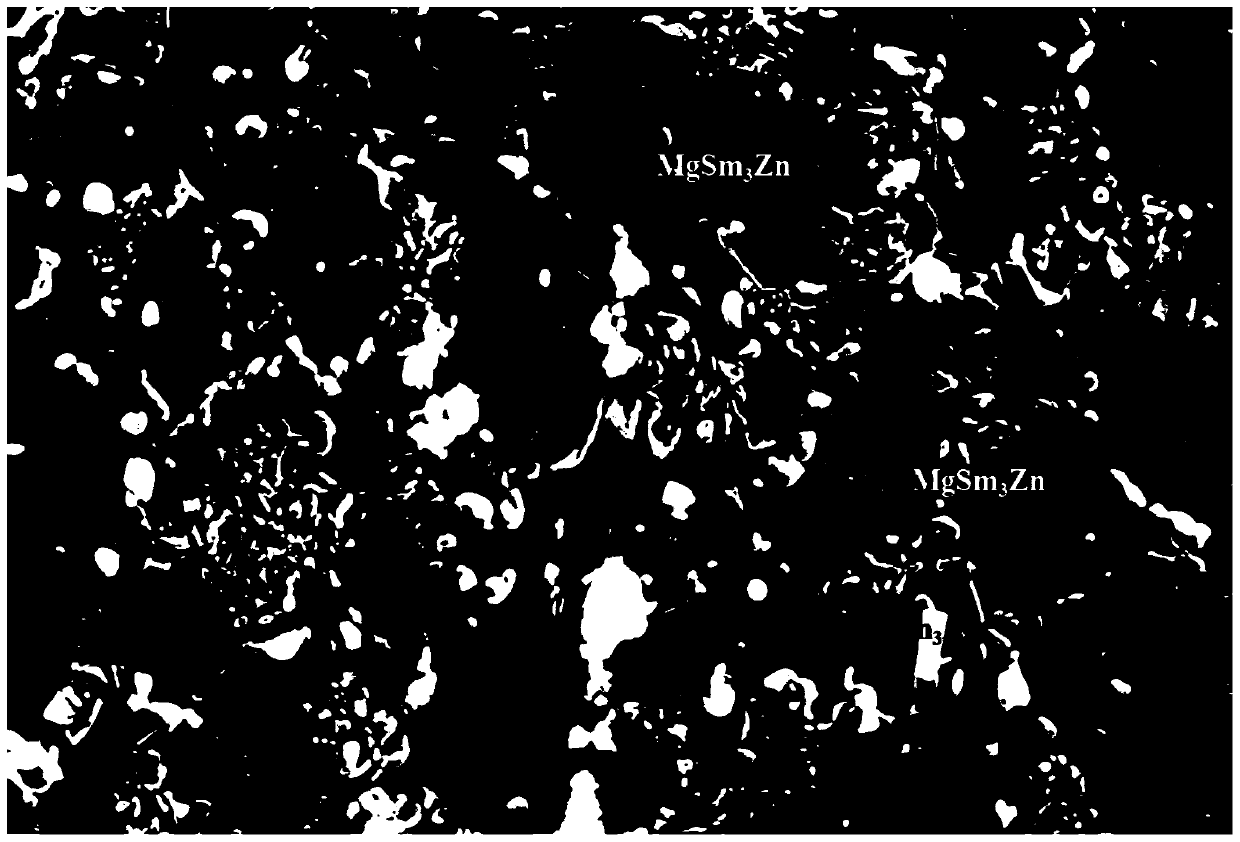

ActiveCN110106416AImprove solid solubilityIncrease supersaturationFluid removalIngotUltimate tensile strength

The invention relates to an ultrahigh-strength soluble magnesium alloy. The ultrahigh-strength soluble magnesium alloy comprises the following components of, in percentage by mass, 6.0-10.0wt% of Sm,0.05-0.2wt% of Sc, 0.2-1.4wt% of Zn, 0.2-0.5wt% of Ag, 0.5-2.0wt% of Cu, 0.5-1.2wt% of Ni, 0%-0.1% of impurity elements and the balance Mg. The preparation method comprises the following steps that the raw materials are mixed according to proportion, the mixture is smelted and refined to obtain melt, the melt is subjected to casting to obtain a cast ingot, the cast ingot is subjected to homogenization treatment on to obtain a blank, the blank is extruded to obtain a forming part, and the forming part is subjected to aging strengthening treatment to obtain the magnesium alloy. The tensile strength of the magnesium alloy is greater than or equal to 520 MPa, and the dissolution rate of the magnesium alloy in 3% KCl solution at 93 DEG C is 52-94 mg * cm <-2> h<-1>.

Owner:重庆昱华新材料科技有限公司

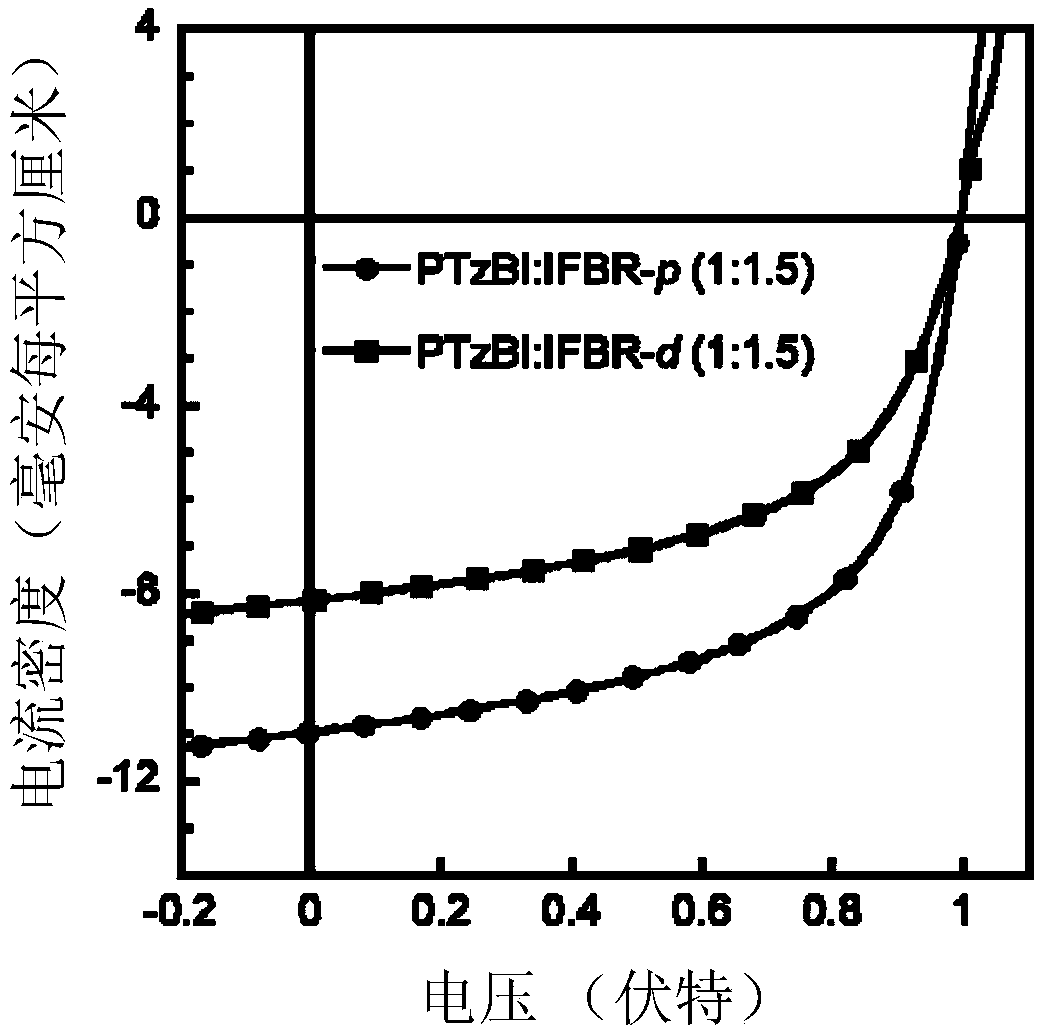

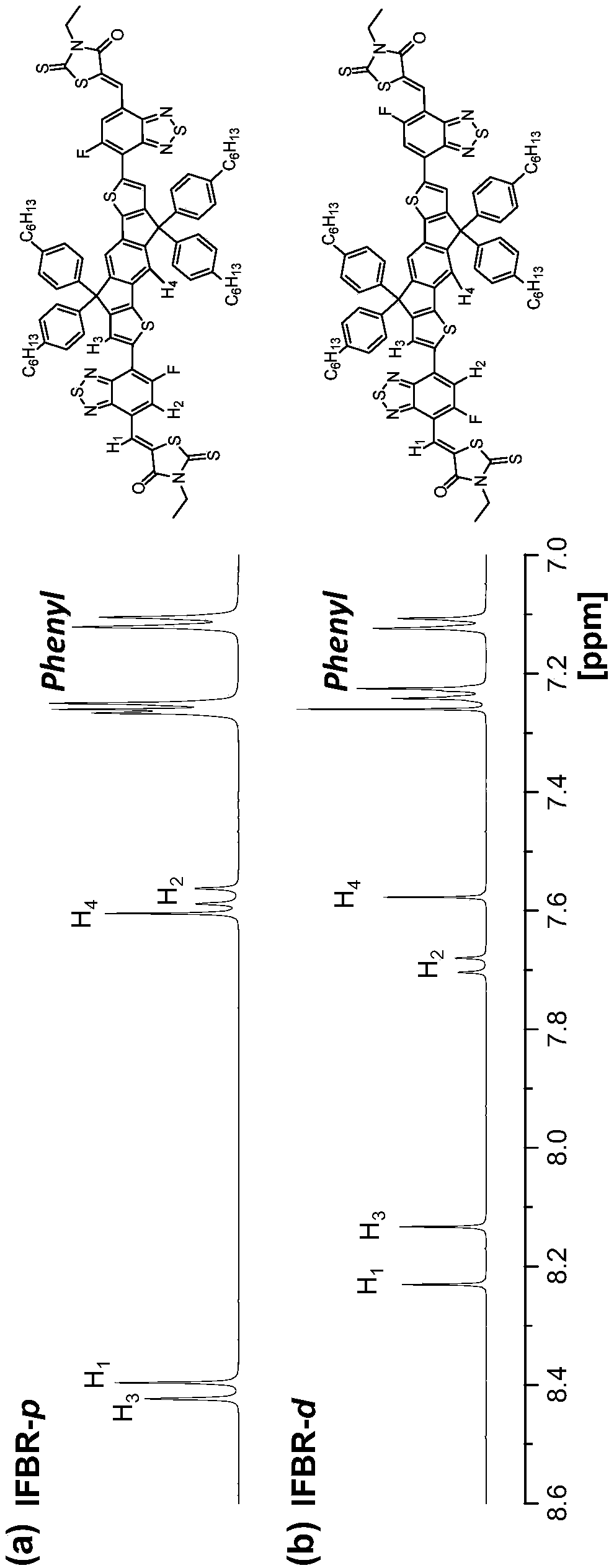

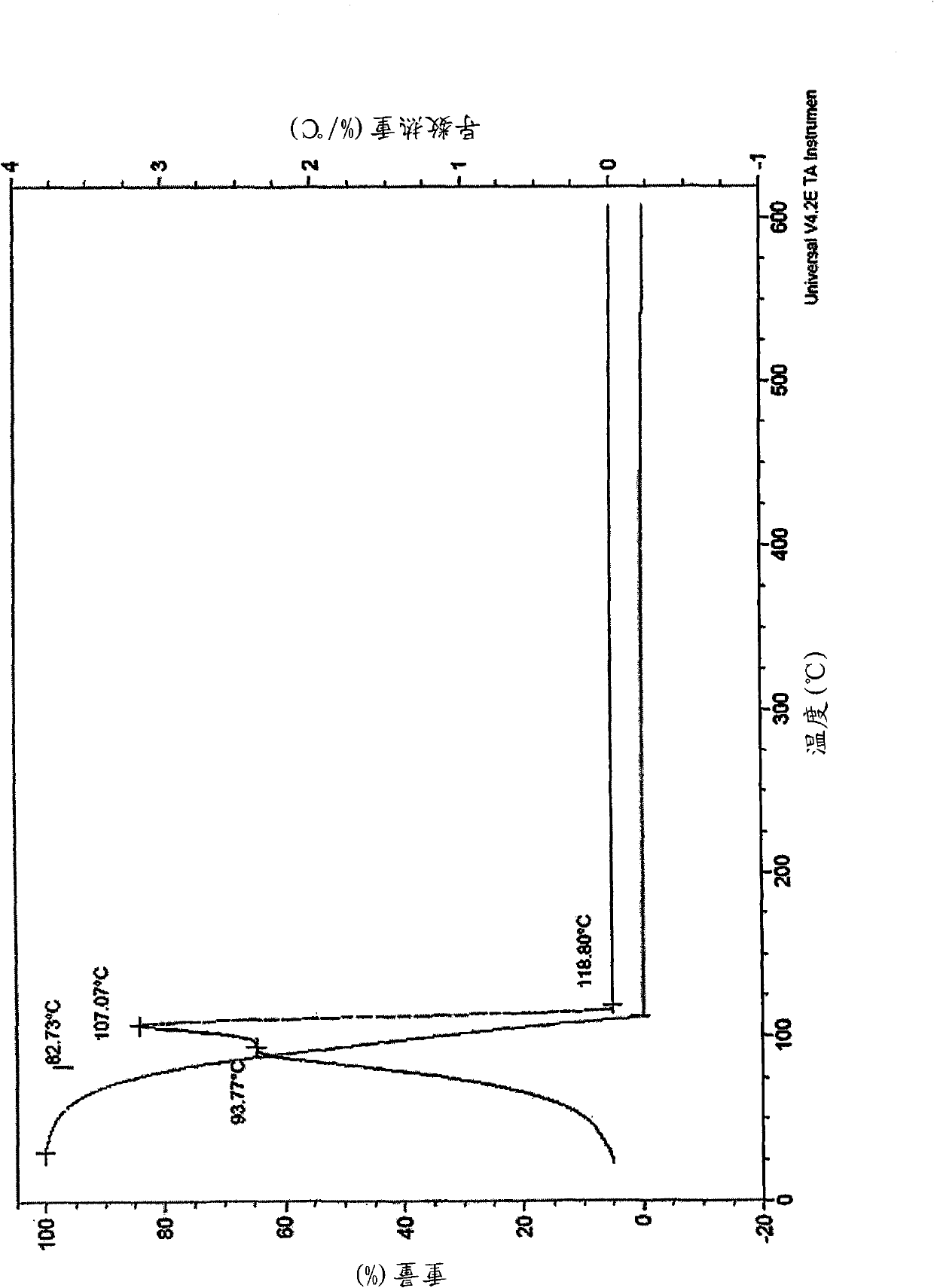

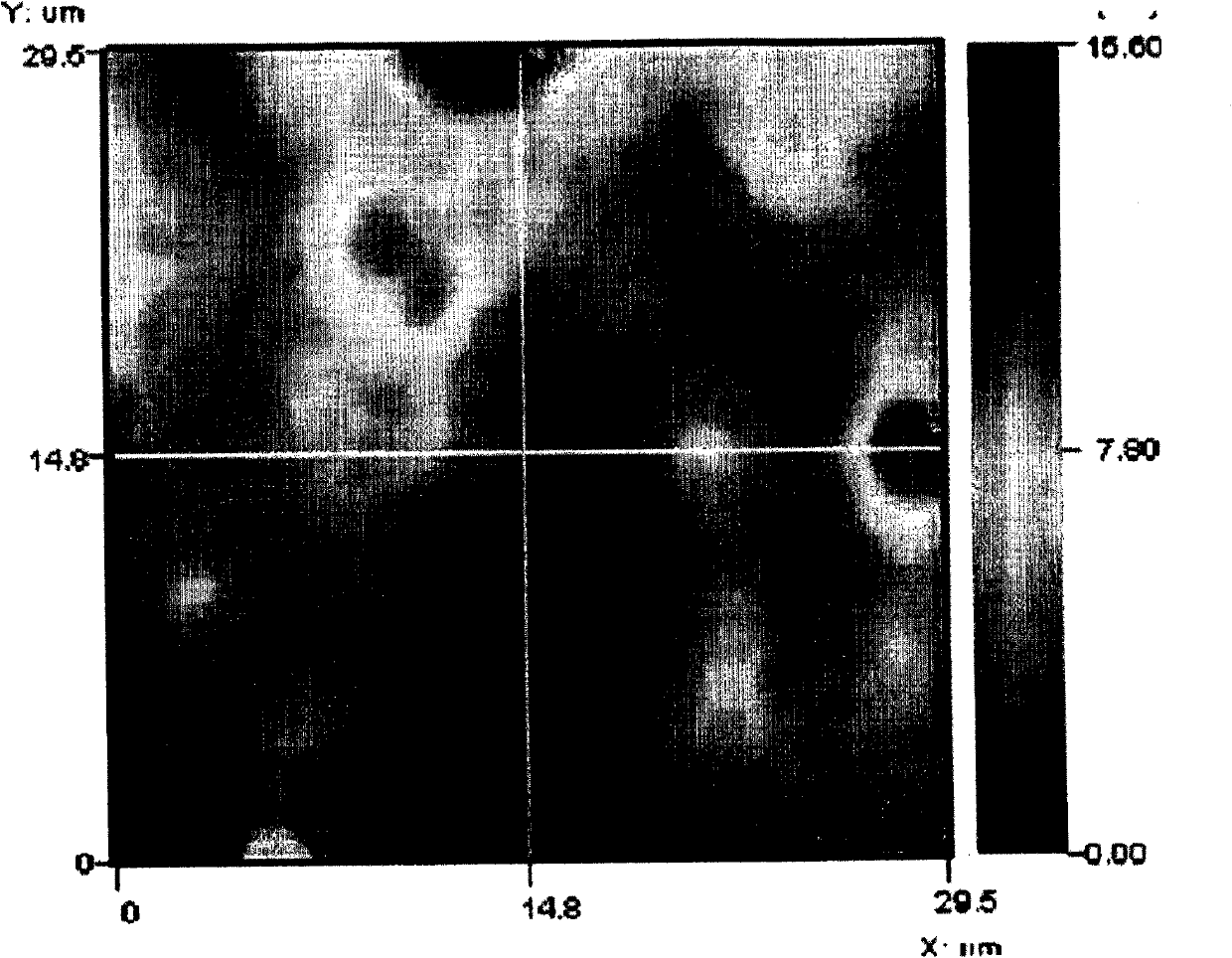

Fluorine atom substituted benzo heterocycle based conjugated molecule material as well as preparation method and application thereof

InactiveCN108218887AAltered intramolecular charge transfer effectsControl solubilityOrganic chemistrySolid-state devicesElectron mobilityComputational chemistry

The invention discloses a fluorine atom substituted benzo heterocycle based conjugated molecule material as well as a preparation method and application thereof. The conjugated molecule material is ofan acceptor-donor-acceptor type structure, wherein an acceptor unit is constructed by using a fluorine atom substituted benzo heterocycle structure and an electron-absorbing dye unit jointly. The conjugated molecule material has the characteristics of easiness in regulation and control of absorption spectrum and molecular energy level, high light absorption, high electron mobility and the like and has a huge application prospect in the fields of organic photovoltaics and organic field-effect transistors.

Owner:SOUTH CHINA UNIV OF TECH

Ink composition for optoelectronic device

InactiveCN102027079AQuality impactSmall sizeFinal product manufactureSolid-state devicesPrinting inkEngineering

The present invention relates to an ink composition for printing capable of inking materials for an optoelectronic device and directly applying the inked materials to a patterning process. More particularly, the present invention relates to a printing ink composition for manufacturing an optoelectronic device capable of direct patterning by adjusting the physical property of a core material so asto be suitable for a printing method in the manufacturing of optoelectronic devices, for example, an organic electroluminescent device or an organic thin film transistor.

Owner:INKTEC CO LTD

Method for using calcium sulfate dihydrate to rapidly prepare short cylindrical calcium sulfate hemihydrate material

The invention belongs to the field of inorganic nonmetallic materials, and discloses a method for using calcium sulfate dihydrate to rapidly prepare a short cylindrical calcium sulfate hemihydrate material. The initial structure of common calcium sulfate dihydrate after being processed recrystallizes, the crystal grows to be complete without the problem of shrinkage cavity, and the prepared shortcylindrical calcium sulfate hemihydrate material has the high using value. By means of different energy possessed by different crystal faces of the crystal, calcium sulfate dihydrate controls dissolution and recrystallization speed of crystal faces in different solution systems according to differences of energy of each crystal face, and accordingly growth behavior control of the short cylindricalmaterial is completed. The method comprises the steps of grinding of calcium sulfate dihydrate, material distribution, thermal solution reaction, separation and cooling. The method can not only effectively solve the problems that calcium sulfate dihydrate is easy to pulverize, the strength is poor, and the stability is low, but also can widen the application field of calcium sulfate, and has theimportant practical meaning on high-efficiency utilization of smoke desulfurized products and gypsum resources.

Owner:NORTHEASTERN UNIV

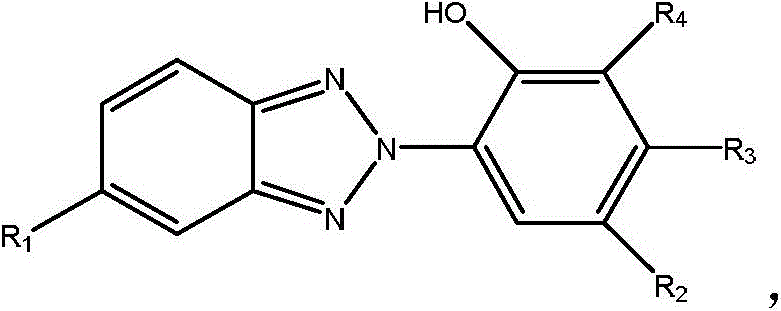

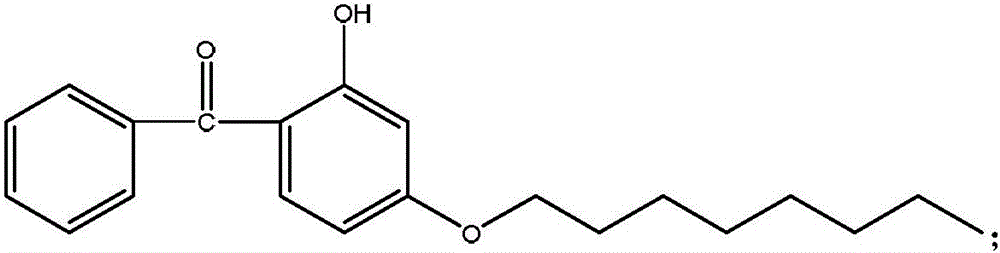

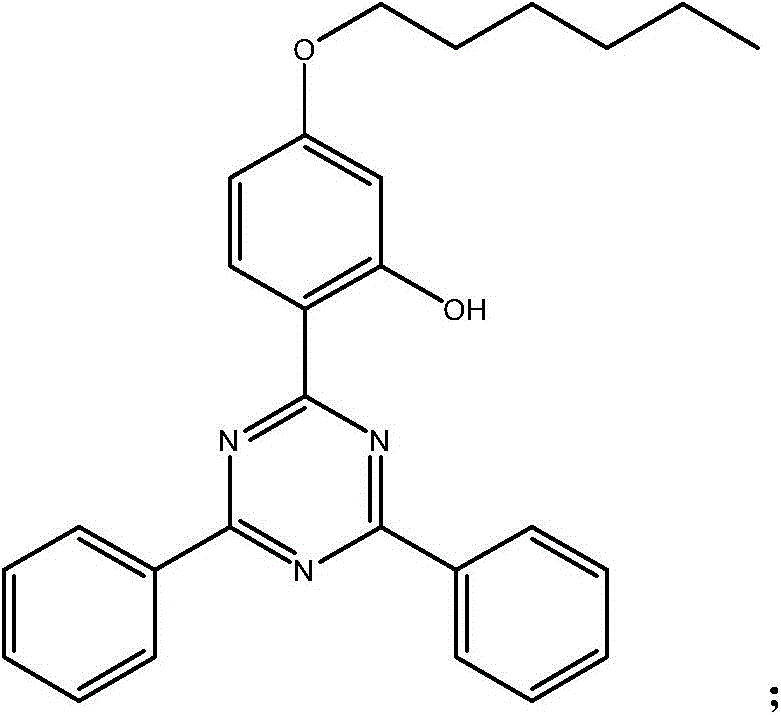

Dyestuff composition with high color fastness to sunlight and application thereof

InactiveCN106009771AImprove light fastnessAvoid pollutionOrganic dyesDyeing processUltravioletUv absorber

The invention discloses a dyestuff composition with high color fastness to sunlight. The dyestuff composition is prepared by a method comprising the following steps: mixing an ultraviolet absorbent with a dyestuff; adding water and a dispersant; sanding, atomizing and drying to obtain the dyestuff composition. According to the dyestuff composition with high color fastness to sunlight, disclosed by the invention, the particle size can be strictly controlled, the mixing uniformity is strictly controlled, the dispersion uniformity of the dyestuff composition in a dyeing solution is guaranteed and colors can be accurately controlled.

Owner:HANGZHOU SHINYANG SAMWOO FINE CHEM CO LTD

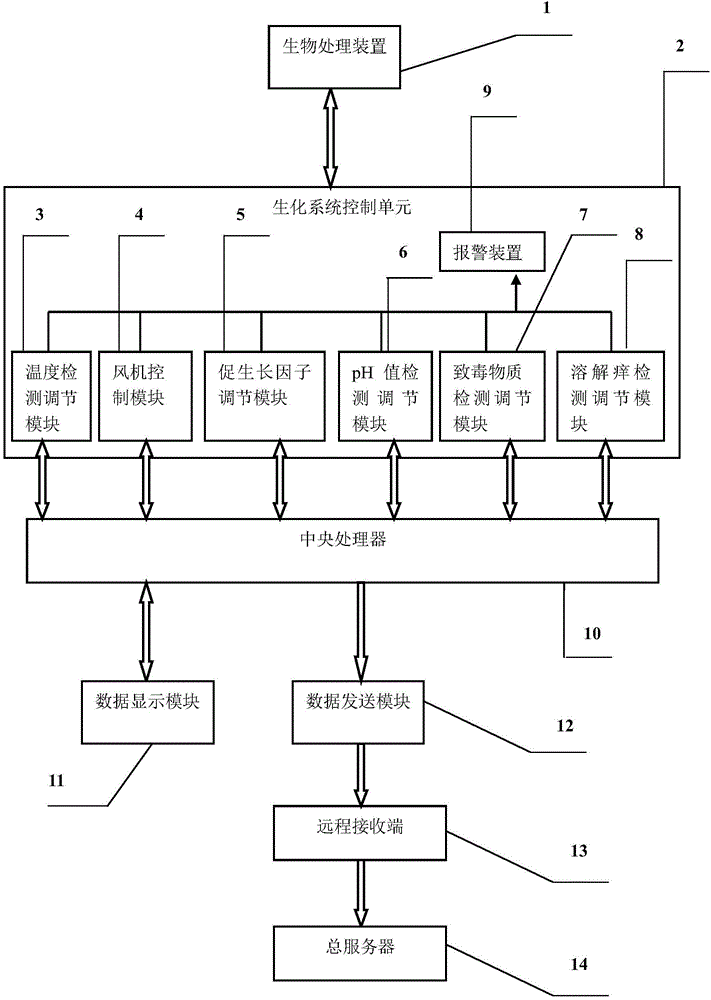

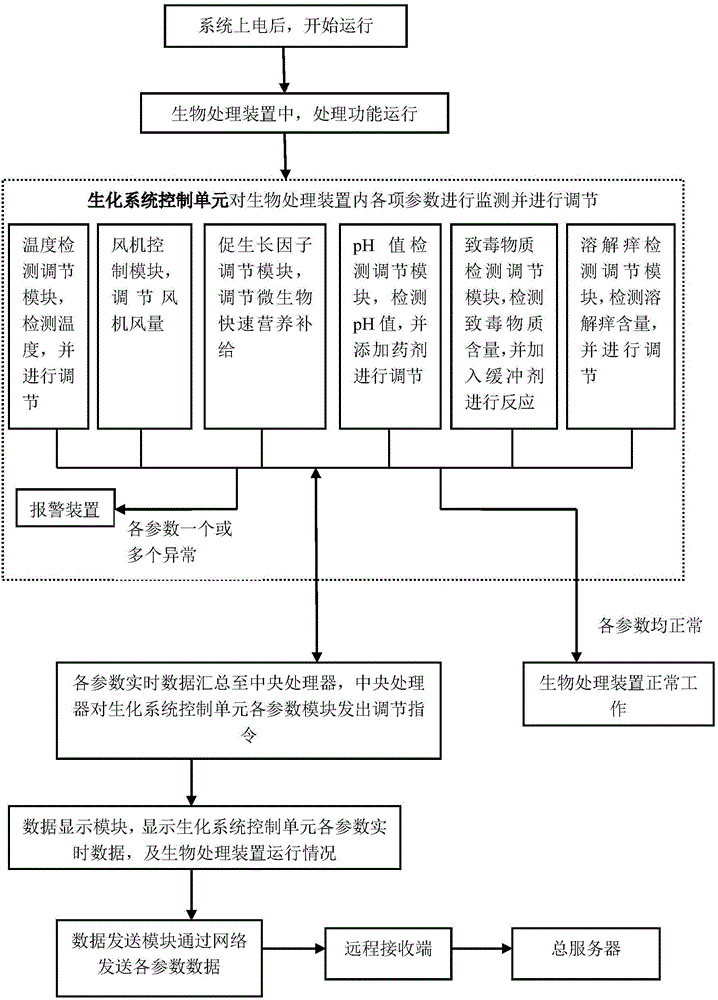

Control method for remote control system for water treatment intelligent running

InactiveCN104102256ATemperature controlControl fan air volumeSimultaneous control of multiple variablesBiological water/sewage treatmentData displayReal-time data

The invention discloses a control method for a remote control system for water treatment intelligent running. The control method comprises the following steps that: after the system is electrified, each unit is started to run, a treatment function in a biological treatment device starts to run, the control unit of a biochemical system is started, and used for detecting various parameters in the biological treatment device, if one or more parameters exceed a preset safety range value, then an alarm device gives an alarm, a central processor sends a regulation instruction to the control unit of the biochemical system, and regulates the parameters which exceed the safety range value; if the various parameters are all normal, then the control unit of the biochemical system normally runs, and the biological treatment device normally runs; the central processor summarizes the data of each parameter in the control unit of the biochemical system in real time, and displays the real-time data of each parameter and the running condition of the biological treatment device through a data display module; a data sending module connected with the central processor is connected with a remote receiving end through a network, and sends the real-time data of each parameter to a main server.

Owner:YUANHUANJING ENVIRONMENTAL PROTECTION TECH SHANGHAI CO LTD

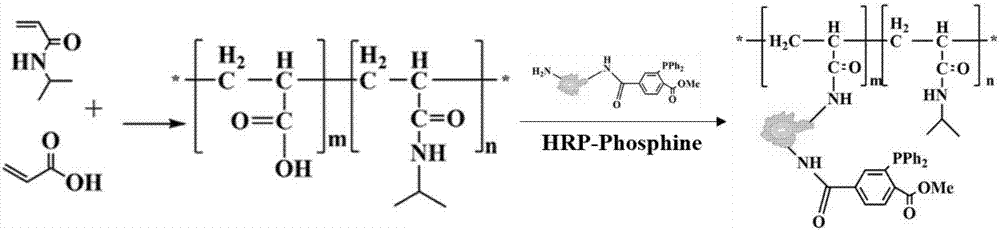

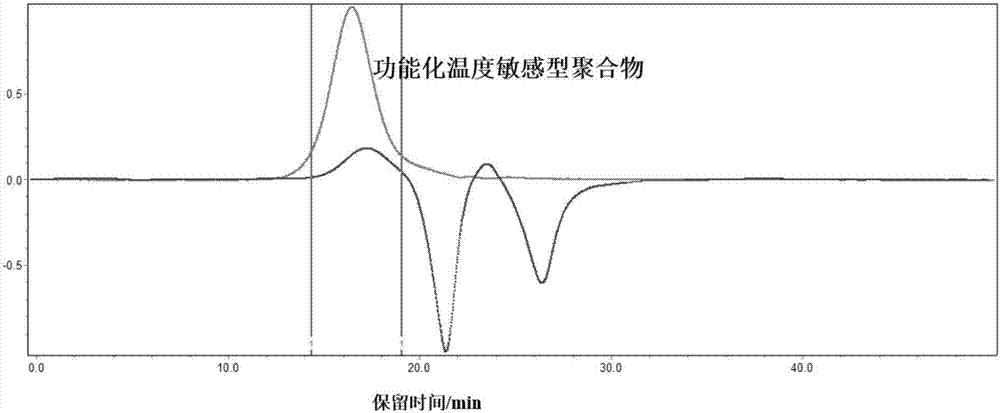

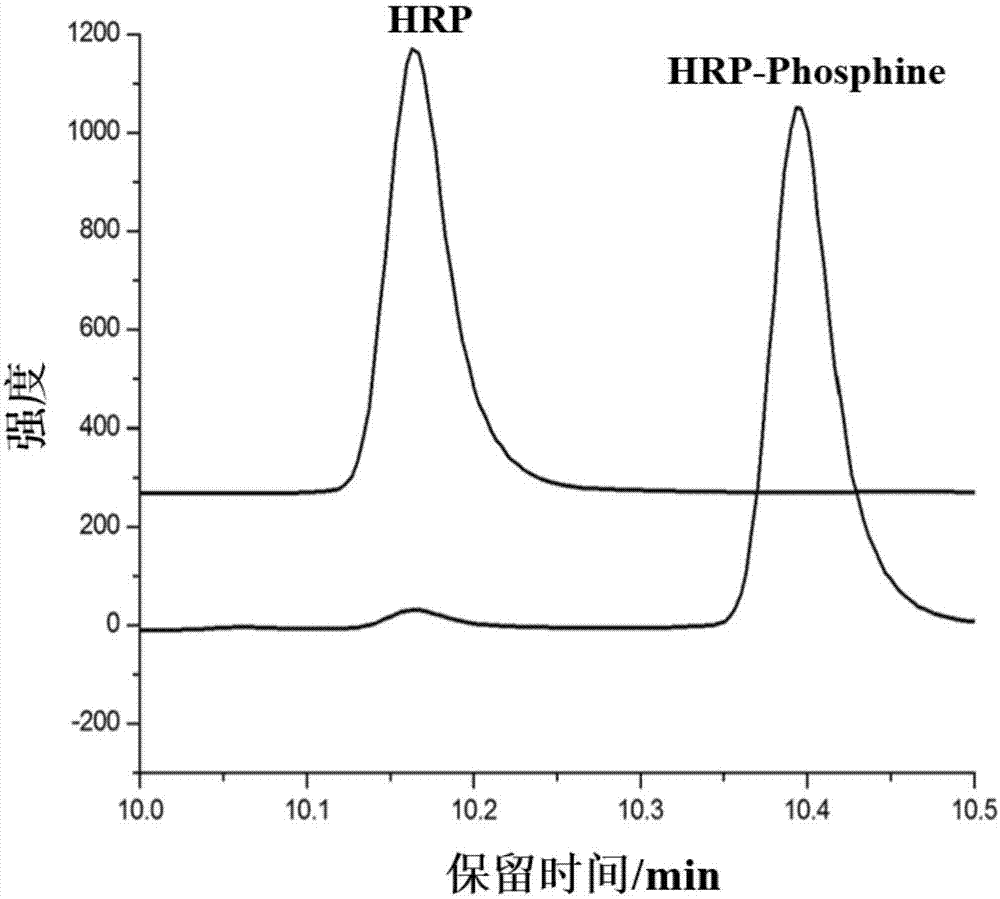

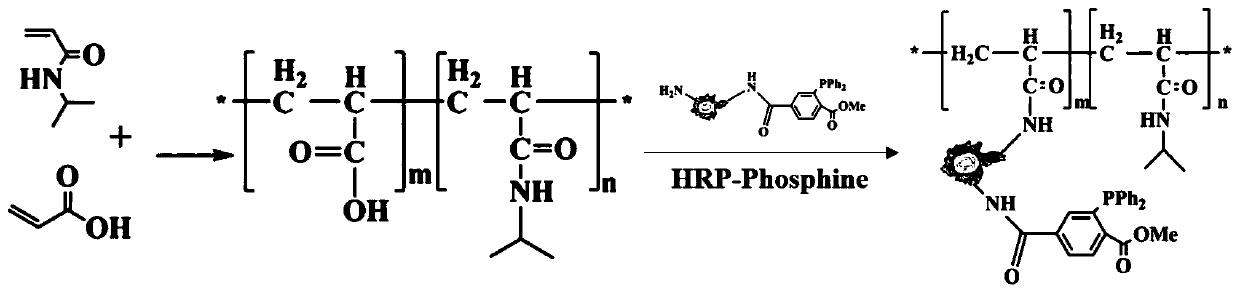

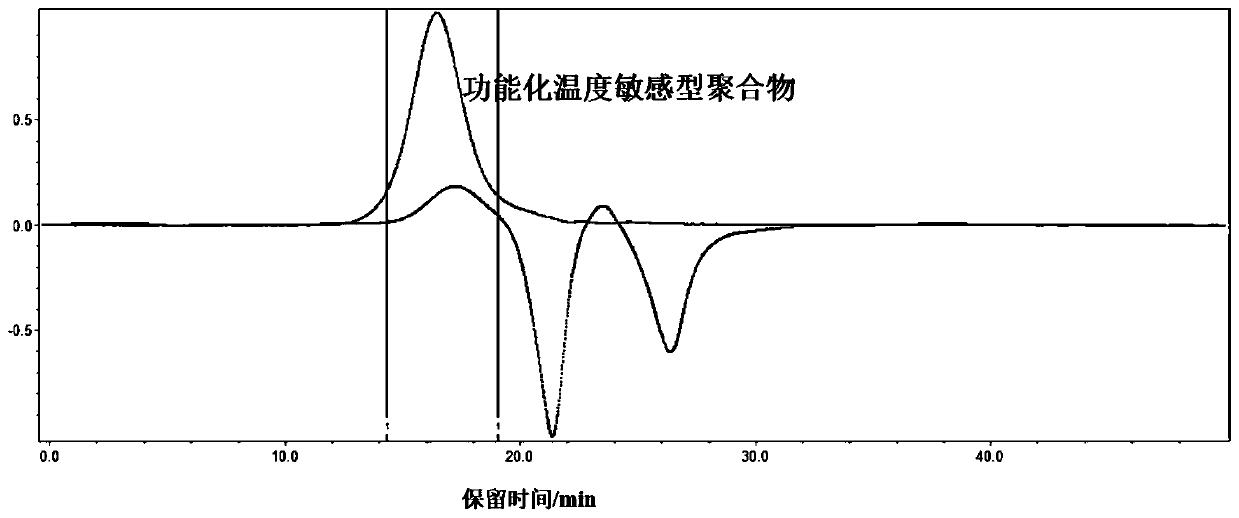

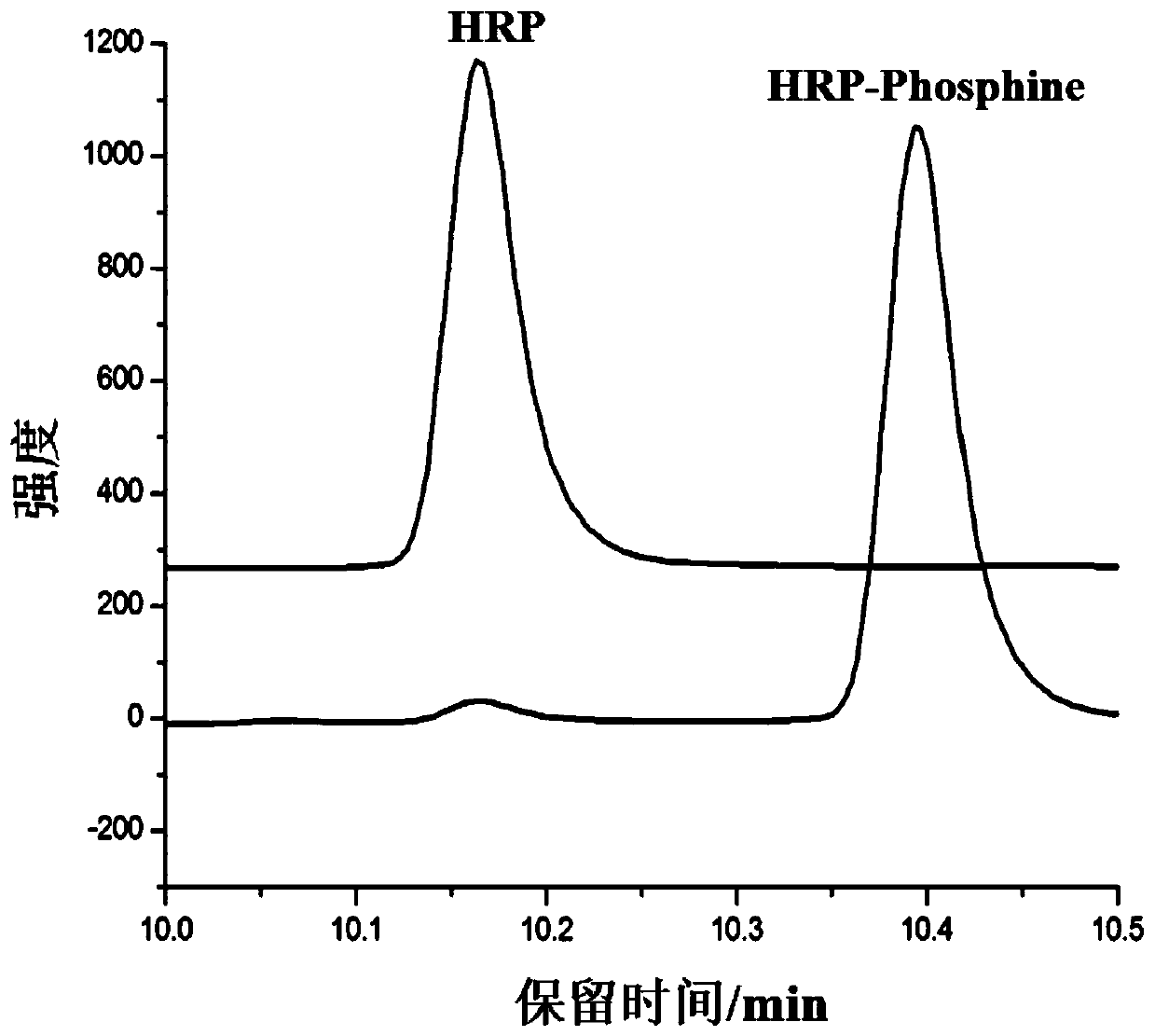

Functionalized temperature-sensitive polymer, preparation method of same, and application of same in (PTM) protein detection

ActiveCN107964066AIncrease the number ofImprove bindingChemiluminescene/bioluminescenceBiological testingProtein targetProtein detection

The invention discloses a functionalized temperature-sensitive polymer, a preparation method of same, and an application of same in (PTM) protein detection. The structure formula of the functionalizedtemperature-sensitive polymer is represented as the formula I, wherein R is CH2, r is 0 or 1, m is any natural number from 20 to 750, n is any natural number from 110-1120, and the structure in the specification is horse radish peroxidase unit. The functionalized temperature-sensitive polymer is a linear polymer, which is produced through a free radical polymerization reaction and has a large number of modificable loci. After functional modification, the temperature-sensitive polymer having a plurality of HRP and a large number of triphenyl phosphine groups can be produced. Compared with an antibody strategy in which only single HRP is carried in the prior art, increasing of numbers of the HRP and the triphenyl phosphine groups can effectively increase the combination capability between the polymer and azide-labeled target proteins and signal amplification effect of chemical-luminescence.

Owner:ACAD OF MILITARY SCI ACAD OF MILITARY MEDICAL SCI BEIJING INST OF LIFEOMICS

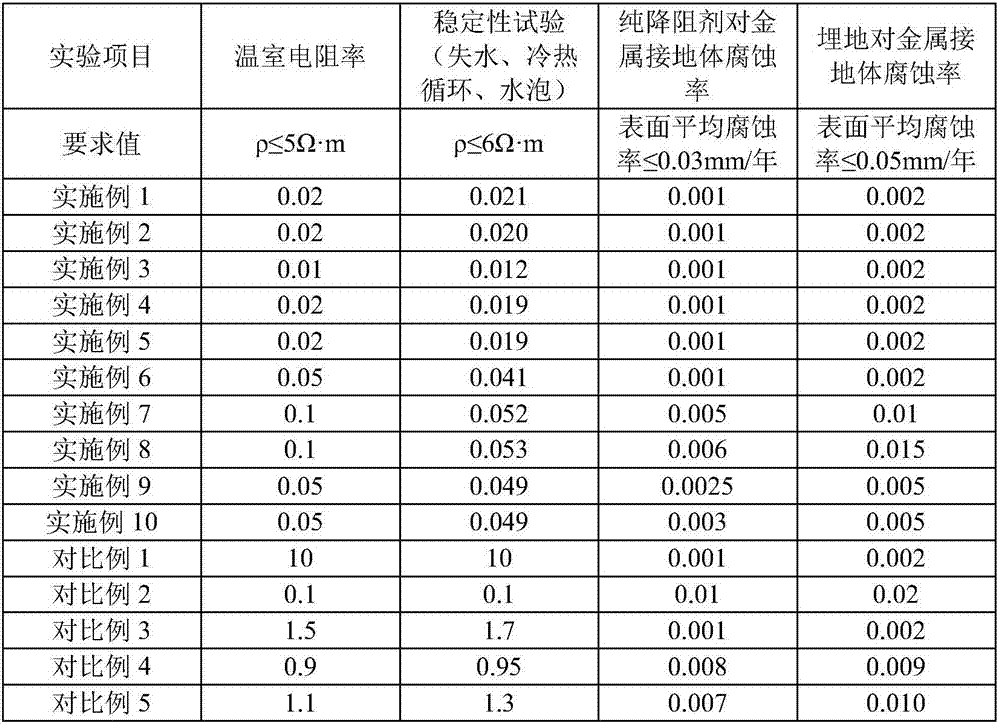

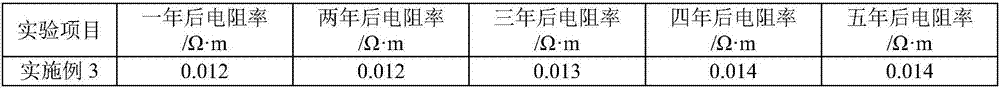

Self-conductive type polymer framework resistance reducing agent and production method therefor

ActiveCN106876002AProduct quality is easy to controlImprove product qualityOrganic conductorsCable/conductor manufactureEnvironment effectSulfite salt

The invention relates to a self-conductive type polymer framework resistance reducing agent. The self-conductive type polymer framework resistance reducing agent comprises the following raw materials in parts by weight: 50-60 parts of N-hydroxymethyl acrylamide, 30-40 parts of N, N'-methylene bisacrylamide, 25-30 parts of acetylenedicarboxylic acid, 15-20 parts of manganese chloride, 8-13 parts of sodium sulfite, 100-130 parts of water and 3-8 parts of aqueous dispersant. The self-conductive type polymer framework resistance reducing agent has the advantages of effective and durable resistance reduction and capability of not being affected by the environment.

Owner:BEIJING XINGTIANTONG TELECOMM TECH CO LTD

Production technology of granular threonine

ActiveCN109706195AIncrease productionReduce generationOrganic compound preparationMicroorganism based processesCentrifugationThreonine

The invention belongs to the technical field of the production of amino acids, and discloses a production technology of granular threonine. The production technology comprises the following steps of step (1) preparing fermentation mediums; step (2) performing fermentation; step (3) performing centrifugation; and step (4) preparing the granular threonine. The threonine is high in yield and few in by-products.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Granular threonine extraction and preparation process

InactiveCN111018732AEfficient separationImprove qualityOrganic compound preparationOrganic chemistry methodsChromatographic separationThreonine

The invention belongs to the technical field of amino acid production, and discloses a granular threonine extraction and preparation process. The granular threonine extraction and preparation processcomprises the following steps: step 1) fermentation; step 2) fermentation liquor separation and extraction; step 3) concentration and crystallization; step 4) crystal separation; step 5) drying; step6) primary mother liquor crystallization and separation; step 7) chromatographic separation; step 8) crystallization and separation; and step 9) granulation. The extraction process comprises that in aseparation and extraction stage after threonine fermentation, threonine fermented mash is treated by using a ceramic membrane and a horizontal screw centrifuge in a combined manner, and granular threonine is obtained through a dry rolling granulation process. The process can improve the yield of granular threonine, is simple and feasible, effectively reduces the environment-friendly sewage treatment pressure and production loss, and has a wide application prospect.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

A kind of ultra-high strength dissolvable magnesium alloy and its preparation method and application

ActiveCN110106416BImprove solid solubilityIncrease supersaturationFluid removalIngotUltimate tensile strength

The invention relates to an ultrahigh-strength soluble magnesium alloy. The ultrahigh-strength soluble magnesium alloy comprises the following components of, in percentage by mass, 6.0-10.0wt% of Sm,0.05-0.2wt% of Sc, 0.2-1.4wt% of Zn, 0.2-0.5wt% of Ag, 0.5-2.0wt% of Cu, 0.5-1.2wt% of Ni, 0%-0.1% of impurity elements and the balance Mg. The preparation method comprises the following steps that the raw materials are mixed according to proportion, the mixture is smelted and refined to obtain melt, the melt is subjected to casting to obtain a cast ingot, the cast ingot is subjected to homogenization treatment on to obtain a blank, the blank is extruded to obtain a forming part, and the forming part is subjected to aging strengthening treatment to obtain the magnesium alloy. The tensile strength of the magnesium alloy is greater than or equal to 520 MPa, and the dissolution rate of the magnesium alloy in 3% KCl solution at 93 DEG C is 52-94 mg * cm <-2> h<-1>.

Owner:重庆昱华新材料科技有限公司

Composite oil-displacing agent for improving recovery efficiency as well as preparation method and application of composite oil-displacing agent

ActiveCN113621359AImprove utilization efficiencySuitable supercritical densityFluid removalDrilling compositionCyclopenteneActive agent

The invention discloses a composite oil-displacement agent for improving the recovery efficiency and a preparation method and application thereof, and belongs to the technical field of carbon dioxide displacement. The composite oil-displacing agent is obtained by mixing supercritical carbon dioxide and a surfactant according to a weight ratio of (100-1000): 1, the preparation method of the surfactant comprises the following steps: in formic acid, reacting a first monomer with formaldehyde to obtain a first reactant; reacting a second monomer with acyl chloride to obtain a second reactant; in the presence of an initiator, carrying out polymerization reaction on the first reactant and the second reactant to obtain the surfactant, wherein the first monomer is selected from at least one of 3-phenyl-4-pentene-1-amine, 4-pentene-1-amine, 4-methyl-pentene-1-amine and 2-amino-4-pentenoic acid, the second monomer is at least one of 1-butene, 1-pentene, 1-hexene and cyclopentene.

Owner:DESHI ENERGY TECH GRP CO LTD +1

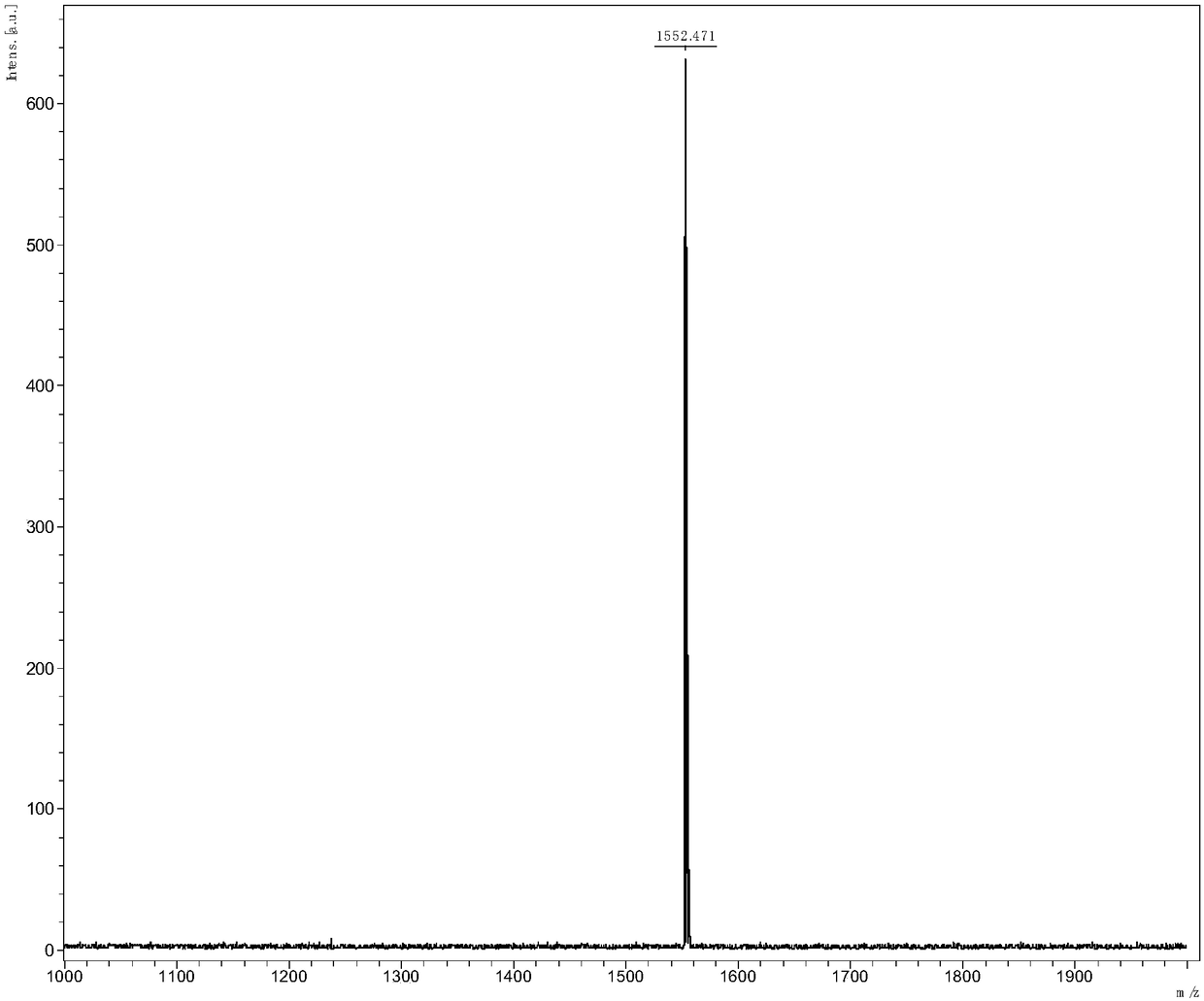

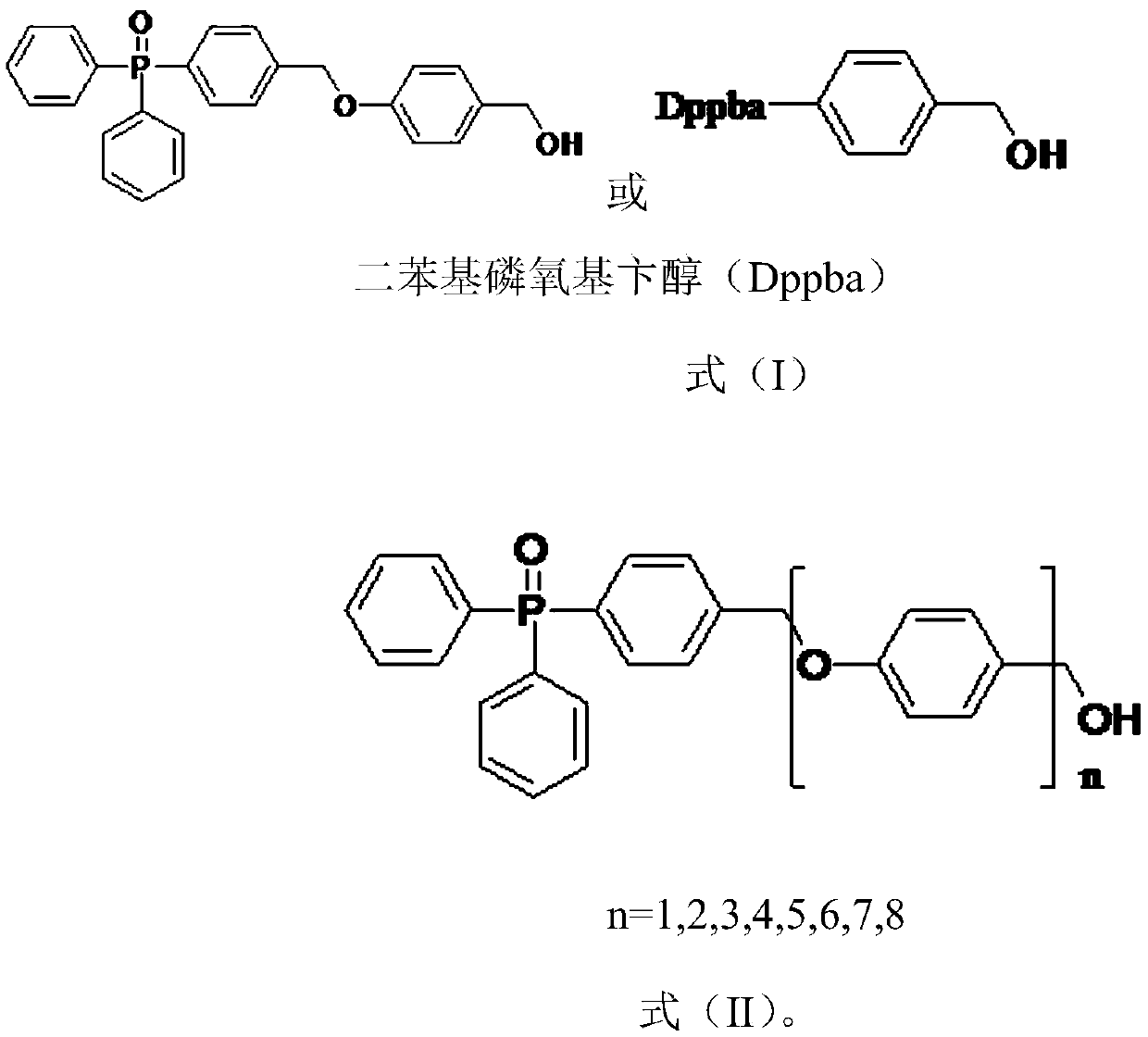

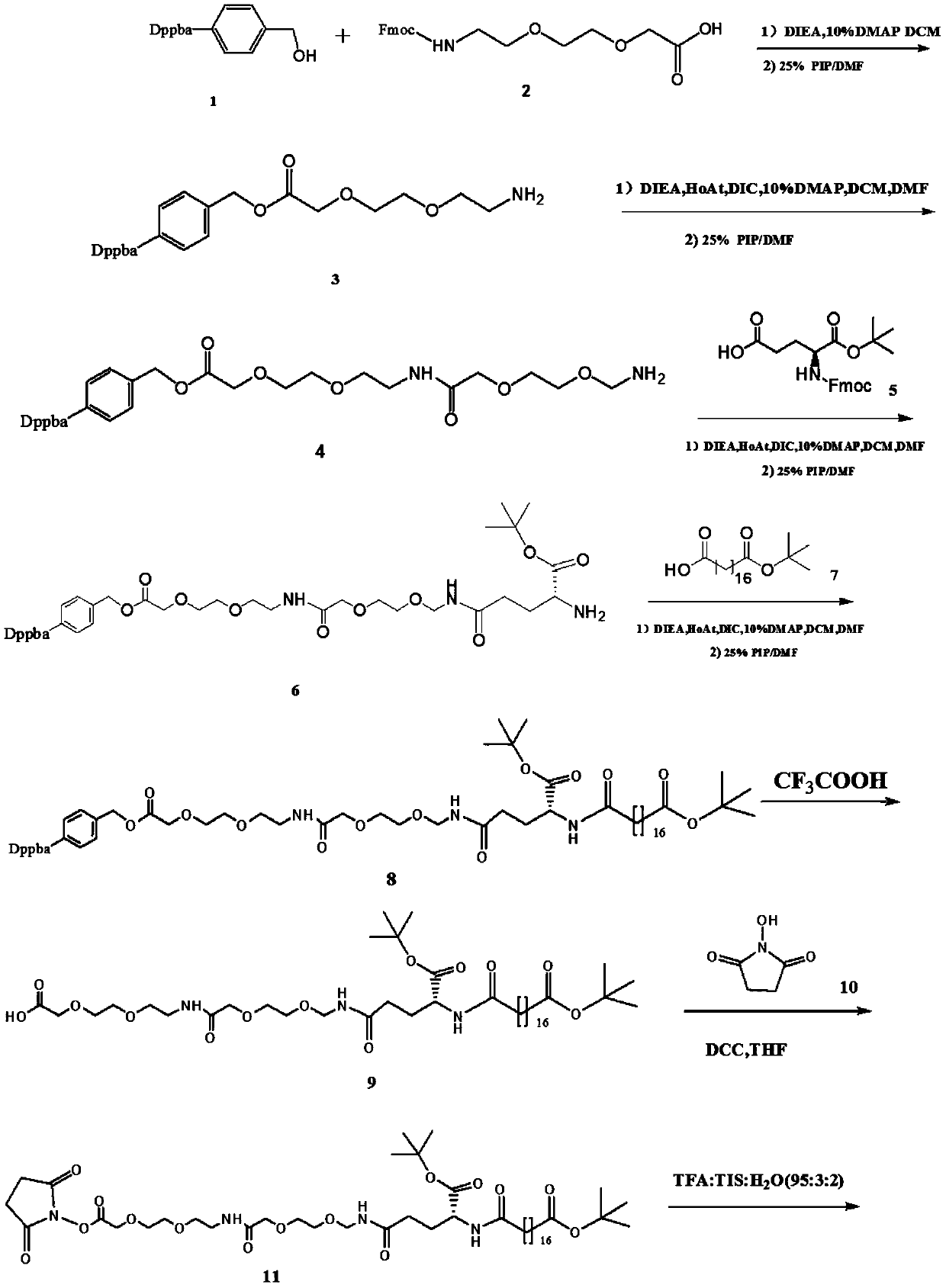

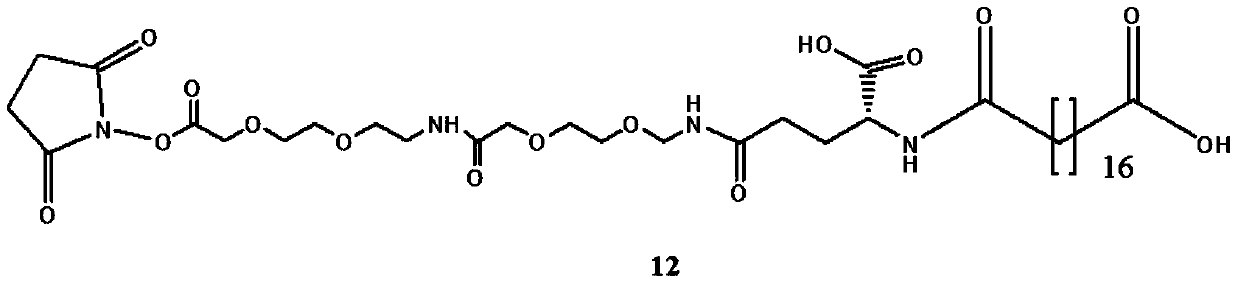

Preparation method for semaglutide intermediate

InactiveCN110423251AControl solubilityControlling StereoselectivityGroup 5/15 element organic compoundsBulk chemical productionHigh pressureCombinatorial chemistry

The invention discloses a preparation method for a semaglutide intermediate. The preparation method comprises the following steps: (A) synthesis of a protective group compound 1 and an analog of the compound 1; (B) synthesis of a compound 3; (C) synthesis of a compound 4; (D) synthesis of a compound 6; (E) synthesis of a compound 8; (F) synthesis of a compound 9; (G) synthesis of a compound 11; (H) synthesis of a compound 12; and (I) reversed-phase high-performance liquid chromatographic purification of a crude semaglutide product, gel chromatographic refining and desalting to obtain a refinedsemaglutide product. The polypeptide product containing special element aided groups in the invention has high purity and does not require multiple high-pressure liquid-phase preparation operations,so production process is greatly simplified and production cost is lowered.

Owner:南京迪维奥医药科技有限公司

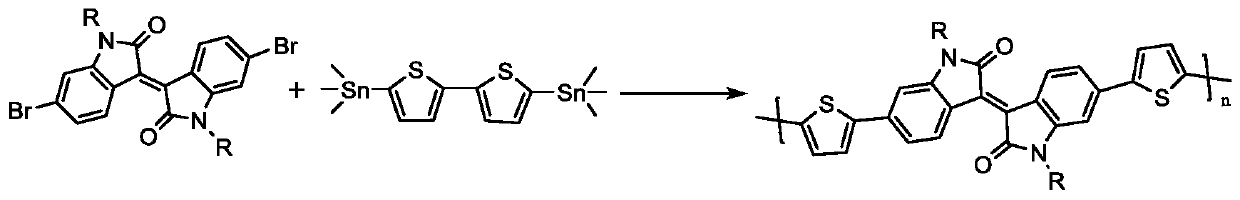

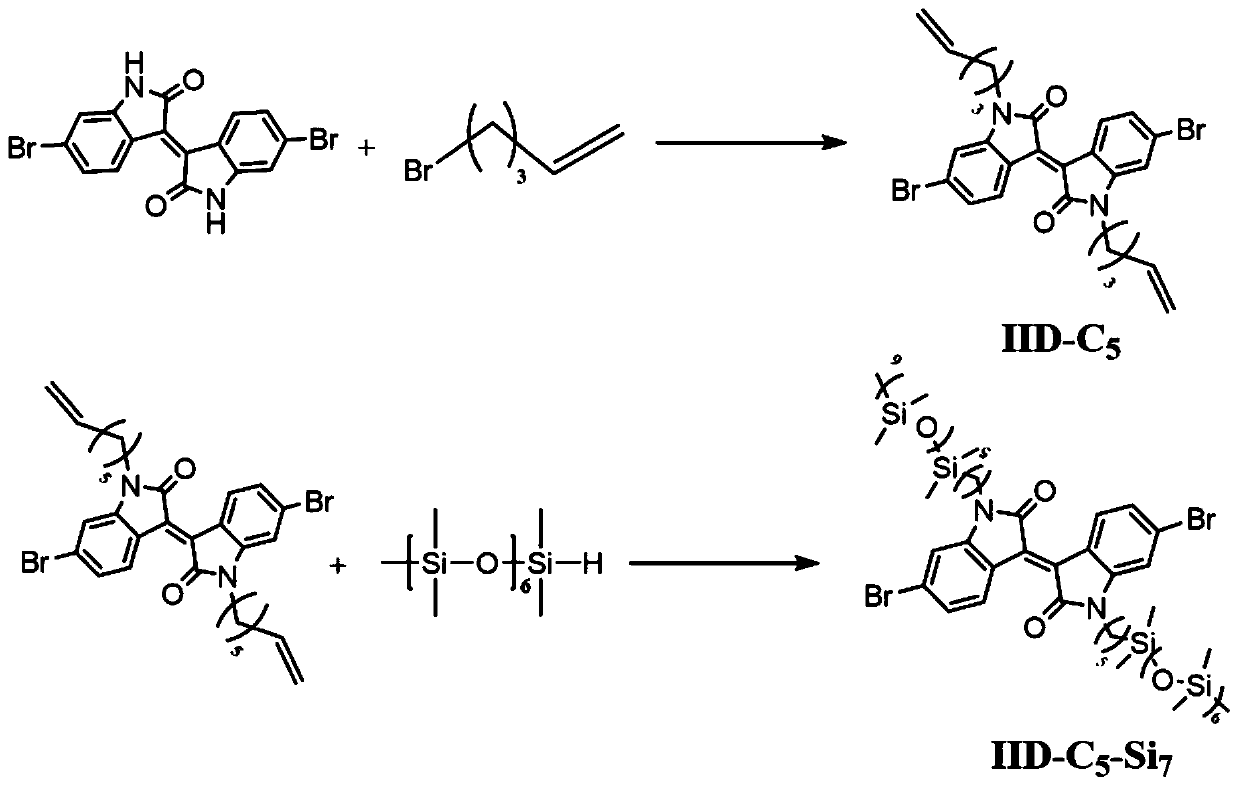

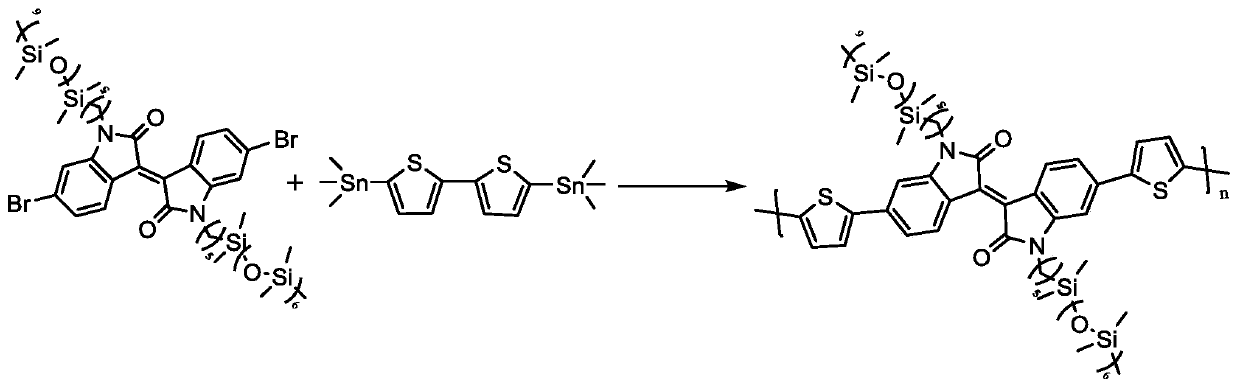

Highly-soluble high-performance semiconductor conjugated polymer and synthetic method thereof

InactiveCN109836560AControl solubilityHigh charge transportSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityPolymer science

The invention discloses a highly-soluble high-performance semiconductor conjugated polymer and a synthetic method thereof. By introducing length-adjustable long straight hybrid siloxy group chain as aside chain, a series of highly-soluble high-performance bioxindol conjugated polymers are obtained. The synthesized novel high-performance semiconductor conjugated polymer can be used as a hole charge transfer material and applied to organic field-effect transistors. The semiconductor conjugated polymer of the invention has great solubility, and can be dissolved in solvents such as chloroform, toluene, hexane and ethyl acetate, etc. The invention is of great guiding significance for designing and synthesizing the high-performance semiconductor conjugated polymer for non-chlorine solvent processing.

Owner:HEFEI UNIV OF TECH

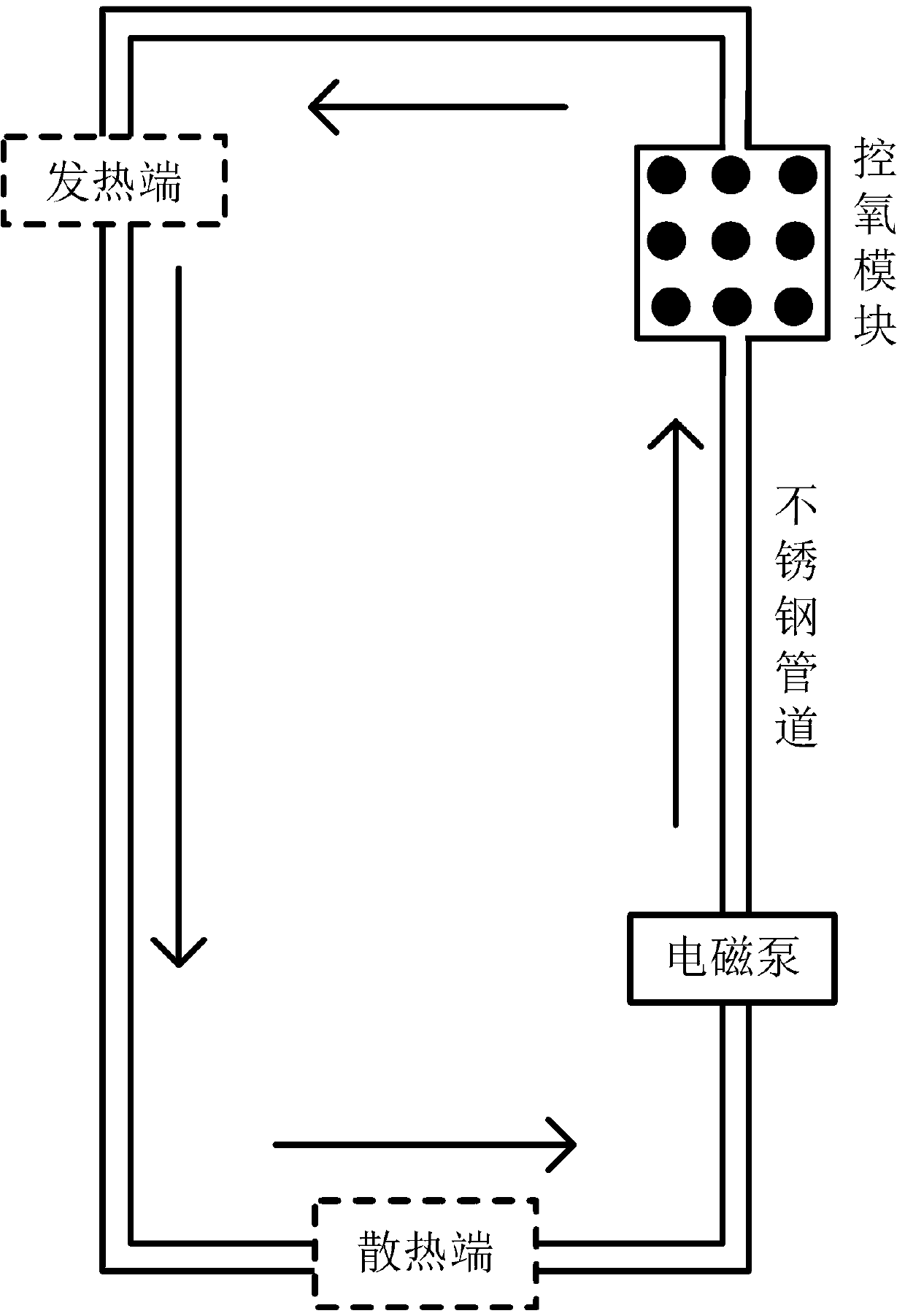

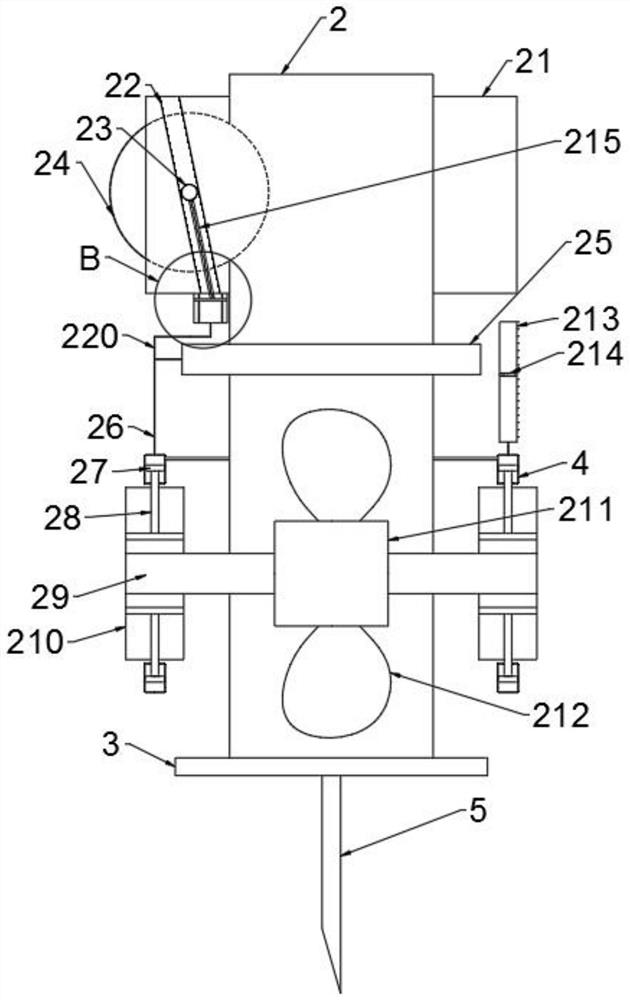

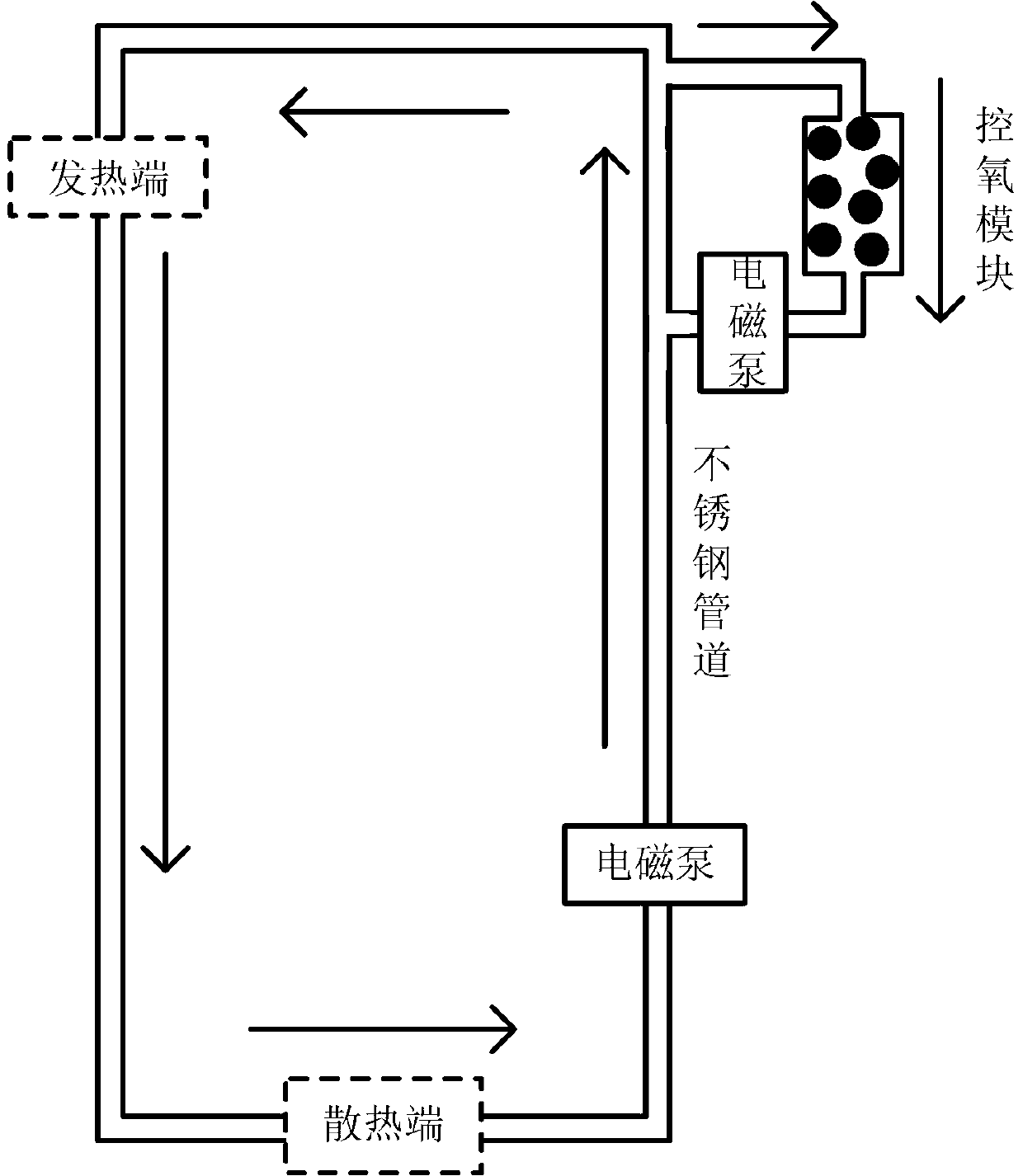

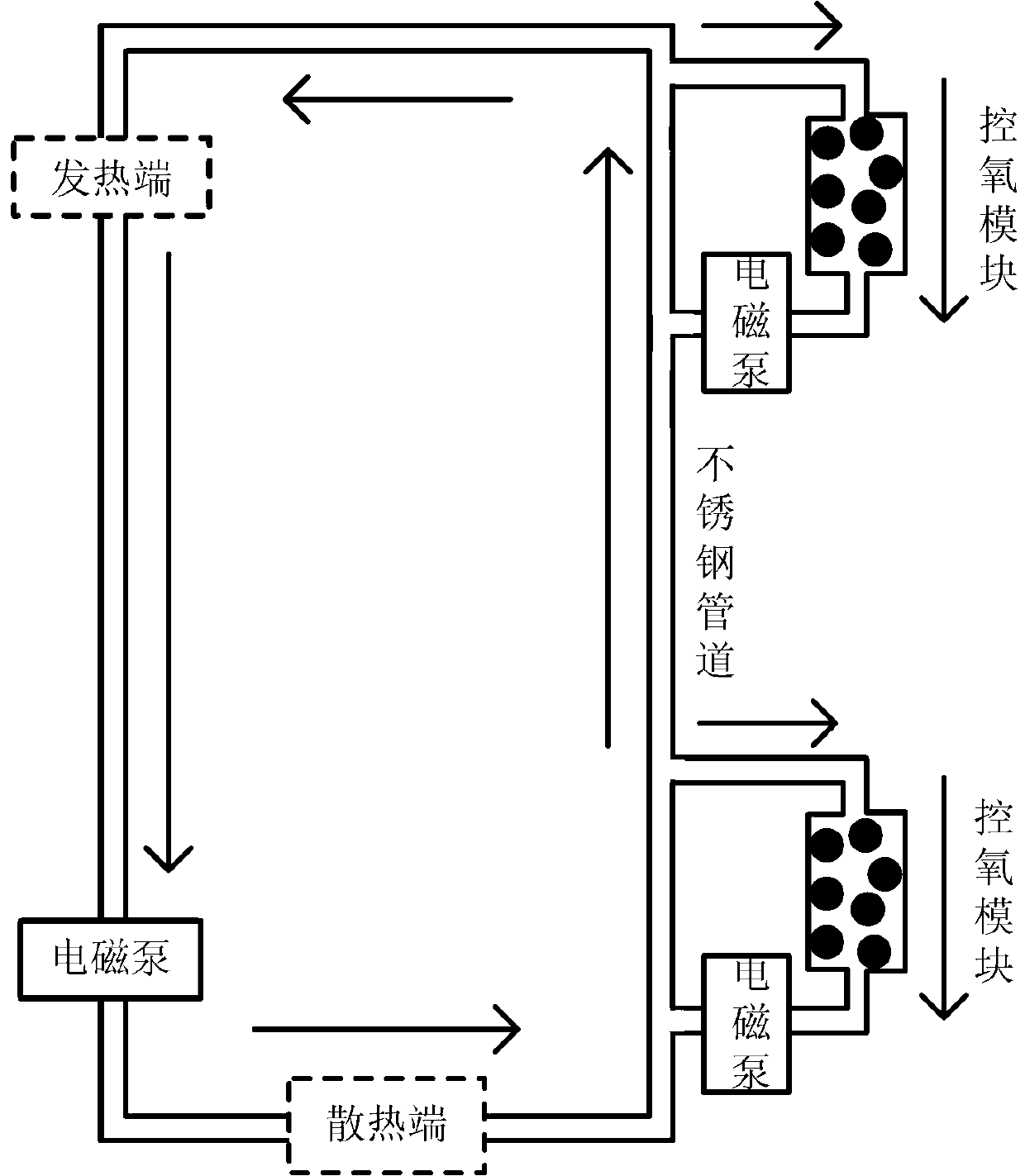

Oxygen-control type pipeline-corrosion-resistant liquid metal for 40-80 DEG c of electronic chip and process thereof.

InactiveCN110343926AStrongly corrosiveReduce corrosion rateMetallic material coating processesLiquid metalOxygen

The invention discloses an oxygen-control type pipeline-corrosion-resistant liquid metal for 40-80 DEG c of an electronic chip and a process thereof. The alloy comprises the following components in percentage, by weight, the alloy composition is 0.2-0.5wt% of Hf, 0.4-1.0wt% of Co, 4.0-8.0wt% of Bi, 2.0-5.0wt% of Zn, 5.0-10.0wt.% of In,1.0-2.0wt.% of Cd, 5.0-8.0wt.% of Pb, and the balance of gallium; wherein the oxide composition for controlling the oxygen activity is pbo: 30.0-40.0wt% of PbO, 2.0-4.0wt% of CuO,10.0-20.0wt% of AgO, 4.0-6.0wt% of CdO, 5.0-8.0wt% of NiO, and the balance of Fe2O3.Through controlling the oxygen activity by adopting an oxygen control module, the stable compact oxidation film can be effectively generated on the surface of the stainless steel pipeline to inhibitcorrosion of the liquid metal to the pipeline material, the method has the characteristics that the process is simple, the implementation cost is low, the heat dissipation is efficient, the service life of the heat dissipation component is prolonged, and the service life of the heat dissipation component is obvious.

Owner:深圳市兴荣晟物业管理有限公司

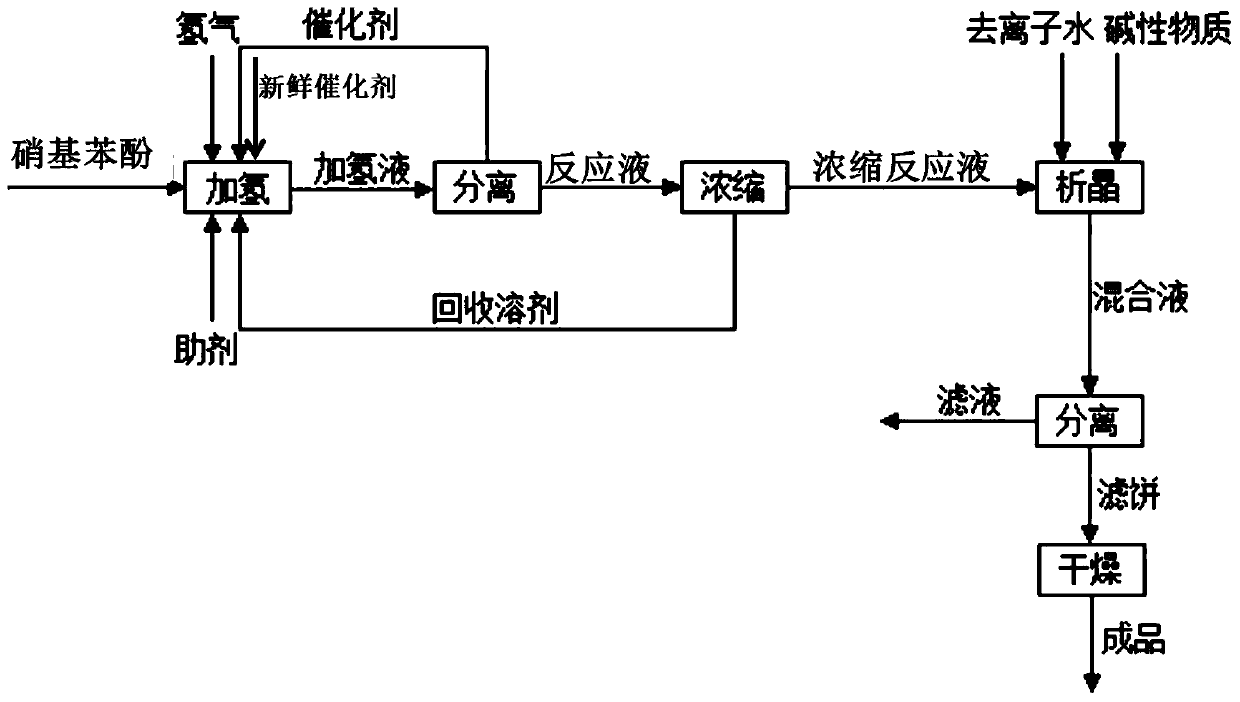

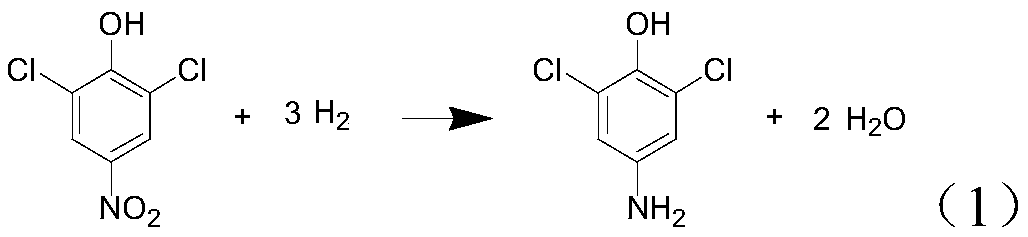

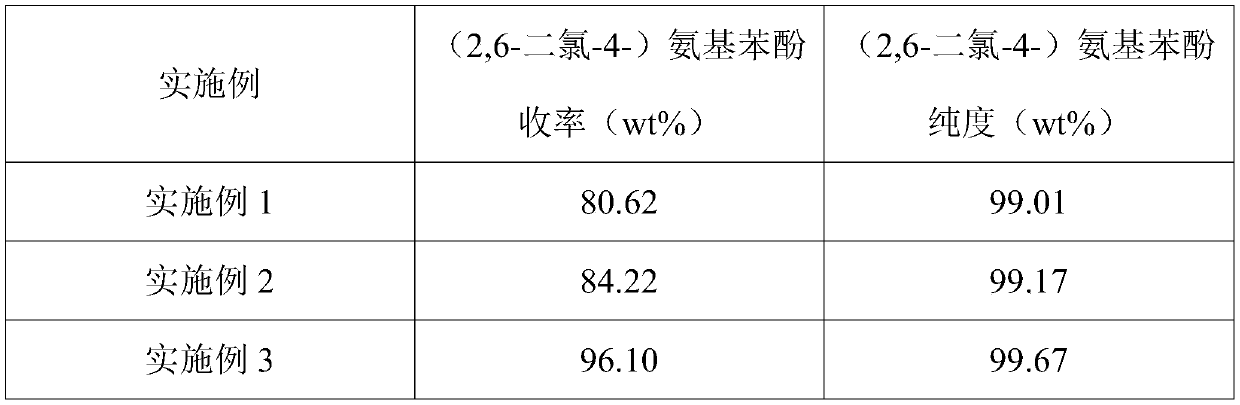

Synthesis method of aminophenol

PendingCN111302955ASimple post-processingLess side effectsOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolNitrobenzene

The invention provides a synthesis method of aminophenol. According to the method, by reacting nitrophenol with hydrogen under the conditions of an auxiliary agent and a solvent, an aminophenol product with high selectivity and yield can be prepared, the auxiliary agent can well control the reaction depth of nitrophenol and hydrogen, thereby inhibiting the side reaction, enhancing the purity of the final product, overcoming the problems of poor selectivity and high three-waste amount in the common hydrazine hydrate, sodium hydrosulfite and other reducing agents in the prior art, and having higher industrial application value.

Owner:JIANGSU YANGNONG CHEM GROUP +3

Functionalized temperature-sensitive polymer and its preparation method and application in (ptm) protein detection

ActiveCN107964066BIncrease the number ofImprove bindingChemiluminescene/bioluminescenceBiological testingPolymer scienceProtein detection

Owner:ACAD OF MILITARY SCI ACAD OF MILITARY MEDICAL SCI BEIJING INST OF LIFEOMICS

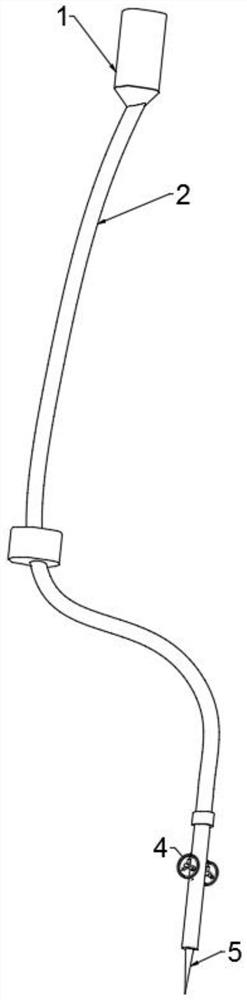

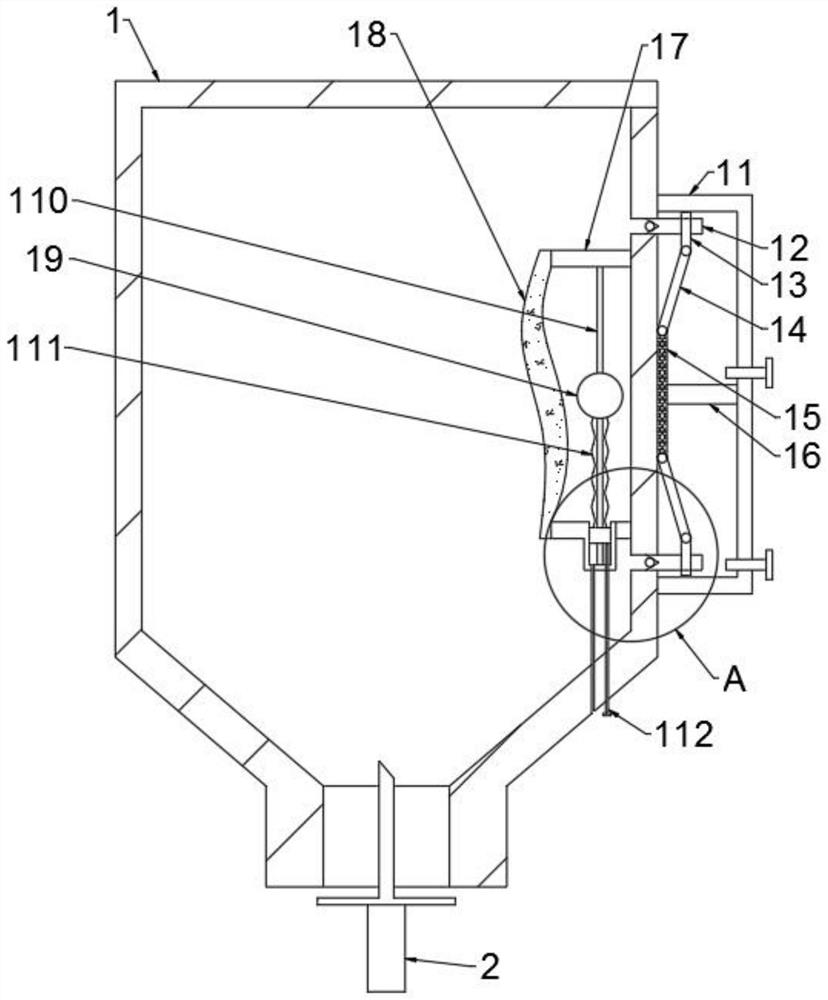

Anti-permeation intravenous infusion device for operating room

InactiveCN113694295AConcentration judgmentControl solubilityInfusion devicesFlow controlOperating theatresSurgery

The invention discloses an anti-permeation intravenous infusion device for an operating room, which comprises an infusion bottle, and is characterized in that a concentration regulation and control mechanism is arranged on one side of the infusion bottle, the concentration regulation and control mechanism comprises a concentration detection assembly and a concentration regulation and control assembly, the concentration detection assembly is fixedly mounted in the infusion bottle, the concentration regulation and control assembly is arranged on one side of the infusion bottle, an infusion tube is installed at the lower end of the infusion bottle, an anti-permeation mechanism is arranged in the infusion tube, the anti-permeation mechanism comprises a speed detection assembly, an anti-permeation assembly and a display assembly, the speed detection assembly is arranged in the infusion tube, the anti-permeation assembly is fixedly installed on the upper side of the speed detection assembly, the display assembly is fixedly installed on the upper side of the display assembly, and a speed regulation and control mechanism is arranged on one side of the infusion tube. According to the invention, the device has the characteristics of permeation prevention and capability of regulating and controlling the concentration of a hypertonic solution.

Owner:南京节益控科技有限公司

Electronic chip 80-120 degree oxygen control type pipeline corrosion resistance liquid metal and process thereof

InactiveCN110306090AQuick responseIncrease consumptionSemiconductor/solid-state device detailsSolid-state devicesLiquid metalOxygen

The invention discloses electronic chip 80-120 degree oxygen control type pipeline corrosion resistance liquid metal and a process thereof. According to the weight percentage, an alloy comprises 0.2%-0.4% of Ag, 0.1%-0.3% of Ni, 4.0%-6.0% of Sb, 8.0%-10.0% of Zn, 15.0%-20.0% of In, 3.0%-5.0% of Bi, 1.0%-3.0% of Pb and the balance gallium; and oxide for controlling the oxygen activity comprises 10.0%-20.0% of PbO, 4.0%-8.0% of SnO2, 1.0%-2.0% of TaO, 5.0%-8.0% of MnO2, 2.0%-4.0% of CoO and the balance Fe2O3. The liquid metal is packaged in the pipeline, an oxygen control module is adopted for controlling the oxygen activity, a stable and dense oxide film can be effectively formed on the surface of the stainless steel pipeline, and the corrosion of the liquid metal to pipeline materials is inhibited. The liquid metal has the advantages that the technology process is simple, the implementation cost is low, the heat dissipation is efficient, and the service life of a heat dissipation component is obviously improved.

Owner:深圳市兴荣晟物业管理有限公司

Ink composition for optoelectronic device

InactiveCN102027079BQuality impactSmall sizeFinal product manufactureSolid-state devicesOrganic filmPhysical chemistry

The present invention relates to a printing ink composition capable of inking a material for an optoelectronic device and directly applying the inked material to a patterning process. More specifically, the present invention relates to a printing ink composition for the manufacture of optoelectronic devices, which can be adapted to optoelectronic devices (such as organic electroluminescent devices or organic thin film transistors) by adjusting the physical properties of core materials. Printing method in manufacturing and directly patterning.

Owner:INKTEC CO LTD

A process for preparing granular threonine product

ActiveCN104757273BReduce pollutionAvoid pollutionAccessory food factorsFertilizer mixturesMycoproteinThreonine

The invention belongs to the technical field of production of amino acids and in particular relates to a process for preparing a granular type threonine product. The process comprises the following steps: (1) preparing threonine fermentation liquor; (2) preparing powdery threonine; (3) preparing threonine granules; (4) refining a mycoprotein; (5) preparing the feed; and (6) preparing an organic fertilizer. According to the process disclosed by the invention, the threonine granules are prepared, moisture absorption and agglomeration can be avoided, the components of the waste mother solution are effectively utilized, wastes are not produced in the whole process, the process is environmentally friendly and pollution-free, and energy conservation and emission reduction are realized.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

A kind of oil washing agent for carbon dioxide displacement and its preparation method and application

The application discloses an oil washing agent for carbon dioxide displacement and its preparation method and application, belonging to the field of carbon dioxide displacement oil recovery. The preparation of the oil washing agent comprises the following steps: in formic acid, the first monomer reacts with formaldehyde to obtain the first reactant; after reacting the first reactant with borane, an oxidizing agent is added and reacted under alkaline conditions to form The second reactant; the aromatic hydrocarbon and the second monomer react to obtain the third reactant, and the second reactant and the third reactant react under heating conditions to obtain the oil washing agent; wherein, the first monomer is selected from At least one of 3-phenyl-4-penten-1-amine, 4-penten-1-amine, 4-methyl-penten-1-amine and 2-amino-4-pentenoic acid The second monomer is selected from at least one of succinic anhydride, 2,3-dimethylsuccinic anhydride, glutaric anhydride and adipic anhydride; the aromatic hydrocarbon is selected from benzene, toluene and ethylbenzene at least one.

Owner:SHANDONG DESHI CHEM IND CO LTD +1

Production process of granular threonine

ActiveCN109706195BIncrease productionReduce generationOrganic compound preparationMicroorganism based processesBiotechnologyCentrifugation

The invention belongs to the technical field of amino acid production, and discloses a production process of granular threonine, which includes the following steps: step 1) preparation of fermentation medium, step 2) fermentation, step 3) centrifugation, and step 4) preparation of granular threonine acid. The invention has high threonine yield and less by-products.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

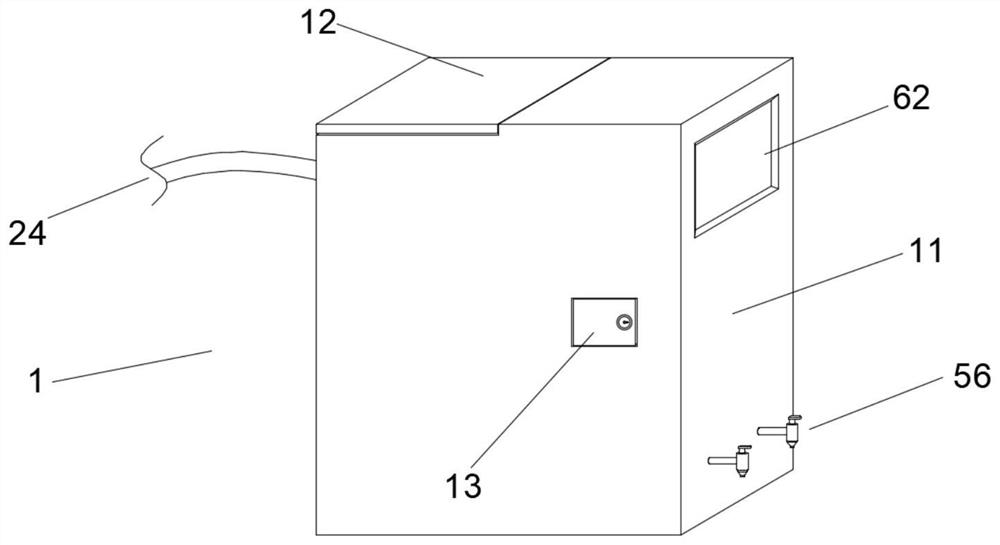

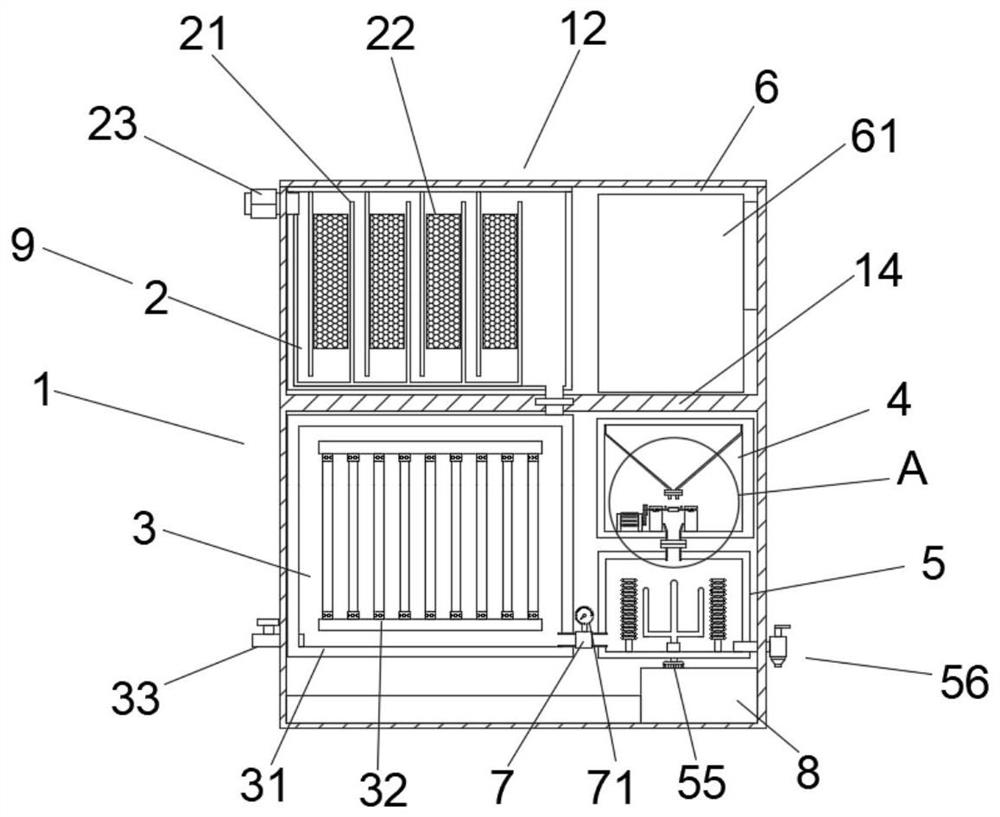

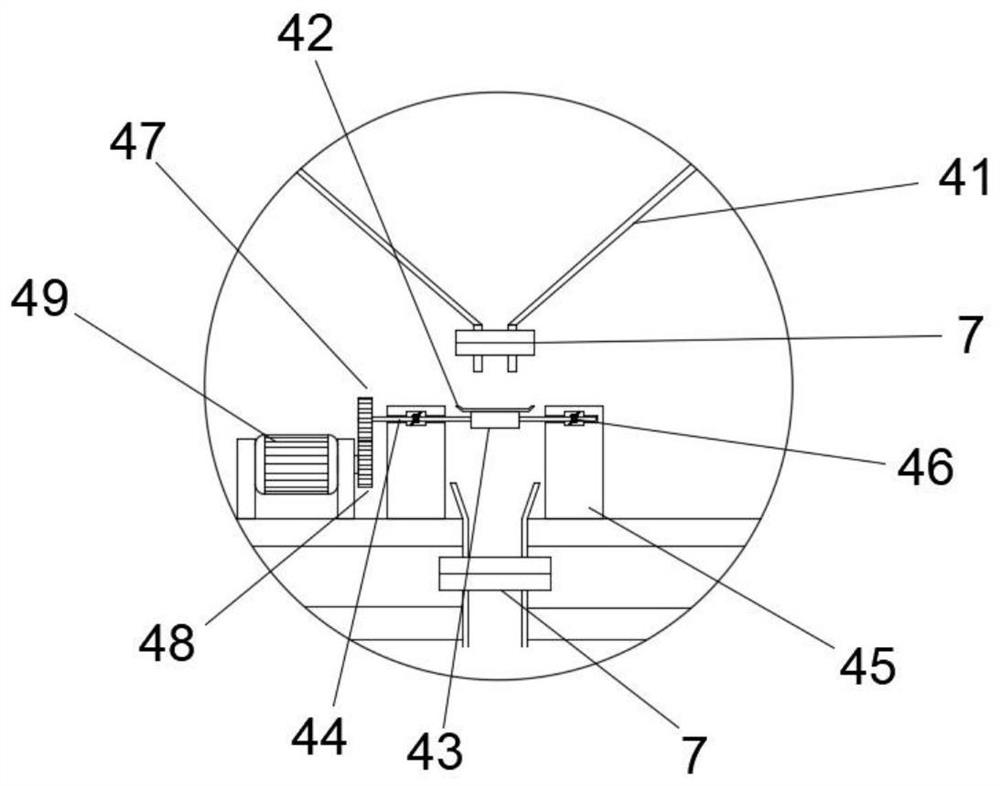

Central water processor carbon quantum dot water manufacturing machine

InactiveCN113233687AUp to standardAvoid pollutionWater treatment parameter controlWater/sewage treatment by irradiationControl systemProcess engineering

The invention discloses a central water processor carbon quantum dot water manufacturing machine. The machine comprises a device body, the device body being composed of a box body and a box cover, the box cover being in threaded connection to one side of the top of the box body through screws, a feeding opening being fixedly formed in the outer wall of one side of the box body, and the interior of the box body being divided into a plurality of areas through partition plates; a multifunctional system, arranged in the box body and comprising a water purification system, a sterilization system, a feeding system, a mixing system and a control system, and the water purification system, the sterilization system, the feeding system, the mixing system and the control system being connected with one another through electromagnetic valve pipes. According to the central water processor carbon quantum dot water making machine, municipal water entering the box body can be purified and sterilized through the water purification system and the sterilization system so that the municipal water can reach the use standard, and independent control over circulation of water or raw materials of all system units can be achieved through electromagnetic valve pipes and a control room between all the systems.

Owner:CHENGCHENG INVESTMENT GRP CO LTD

Electronic chip 120-180 degree oxygen control type pipeline corrosion resisting type liquid metal and technology thereof

InactiveCN110317988AStrongly corrosiveReduce corrosion rateSemiconductor/solid-state device detailsSolid-state devicesComputer moduleLiquid metal

The invention discloses electronic chip 120-180 degree oxygen control type pipeline corrosion resisting type liquid metal and a technology thereof. Alloy consists of the following components in a percent by weight: 4.0-6.0wt% of Sn, 0.2-0.5wt% of Au, 1.0-3.0wt% of Hg, 8.0-10.0wt% of Zn, 20.0-30.0wt% of In, 4.0-5.0wt% of Cd, 2.0-4.0wt% of Pb and the balance of Ga. Oxides for controlling oxygen activity consist of the following components in a percent by weight: 10.0-15.0wt% of PbO, 5.0-10.0wt% of Bi2O3, 2.0-5.0wt% of ZnO, 1.0-3.0wt% of CdO, 5.0-10.0wt% of In2O3 and the balance of Fe2O3. By encapsulating the liquid metal in a pipeline and using an oxygen control module to control oxygen activity, a stable and dense oxide film can be effectively produced on the surface of the stainless steelpipeline to inhibit the corrosion of the liquid metal to the pipeline material. The technology is characterized in simple technical process, low implementing fees, efficient cooling, the prolonging ofthe service life of a cooling component and remarkable effect.

Owner:深圳市兴荣晟物业管理有限公司

A kind of composite oil displacement agent used for enhancing carbon dioxide flooding oil recovery and its preparation method and application

ActiveCN113621359BImprove utilization efficiencySuitable supercritical densityFluid removalDrilling compositionCyclopenteneActive agent

Owner:DESHI ENERGY TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com