Ink composition for optoelectronic device

A technology for optoelectronic devices and compositions, which can be applied in the fields of electro-solid devices, inks, photovoltaic power generation, etc., can solve the problems of controlling viscosity, solubility and film uniformity in the printing process, and the limitation of the size increase of flexible optoelectronic devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] [Preparation example 1]: the preparation of n-butylammonium n-butylcarbamate

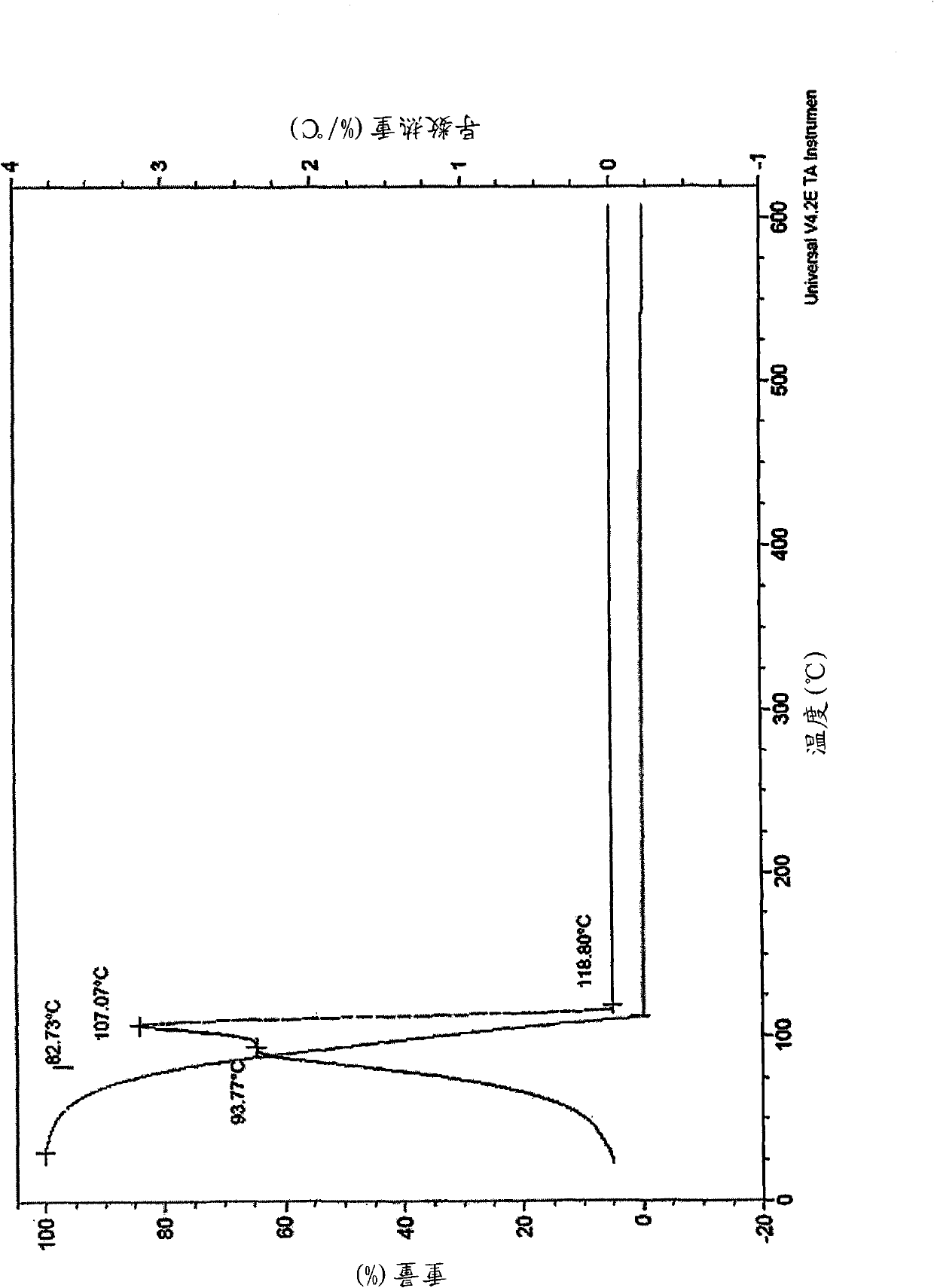

[0054] Into a sealed and pressurized 250 mL reactor equipped with a stirrer and an inlet pipe was introduced at room temperature 100 g (1.367 mol) of n-butylamine, and carbon dioxide gas was gradually introduced thereinto for reaction. As the reaction proceeds, the consumption of carbon dioxide decreases, allowing the reaction mixture to fully react until no more carbon dioxide is consumed. In this way, 128.85 g (99% yield, 0.677 mol) of n-butylammonium n-butylcarbamate were obtained in the form of a white powder. The obtained compound is characterized by thermogravimetric analysis (TGA), and the thermogram is as follows figure 1 shown. as from figure 1 It can be seen that the carbamate compound thermally decomposes completely at temperatures below 120°C.

preparation example 2

[0055] [Preparation example 2]: the preparation of n-octyl carbonate n-octyl ammonium

[0056] Into a 250 mL Schlenk bottle equipped with a stirrer and an inlet tube, 100 g (0.774 mol) of n-octylamine and 6.97 g (0.387 mol) of purified water were introduced while the temperature was kept below 30 °C by utilizing cooling water, and 22 g (0.5 mol) of carbon dioxide gas was gradually added thereto. Then, it was reacted with stirring for 2 hours. As the reaction proceeds, the viscosity of the reaction mixture increases. Finally, 119.08 g (yield 96%, 0.372 mol) of n-octylammonium n-octylcarbonate was obtained as a transparent liquid.

preparation example 3

[0057] [Preparation example 3]: the preparation of pentyl ammonium bicarbonate

[0058] Into a 250 mL Schlenk bottle equipped with a stirrer and an inlet tube, 100 g (1.147 mol) of pentylamine and 20.65 g (1.147 mol) of purified water were introduced at room temperature, and carbon dioxide gas was gradually introduced thereinto for reaction. As the reaction proceeds, the consumption of carbon dioxide decreases, allowing the reaction mixture to fully react until no more carbon dioxide is consumed. In this way, 148.95 g (yield 99%, 1.136 mol) of pentylhydropentylamine bicarbonate was obtained as a clear liquid.

[0059] Preparation and Characterization of Printing Ink Compositions

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com