Dyestuff composition with high color fastness to sunlight and application thereof

A dye composition and color fastness technology, applied in the field of dyes, can solve the problems of color change and final color difference, unable to guarantee color uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

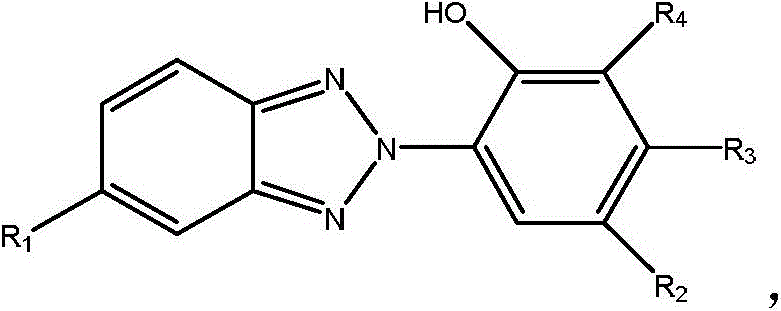

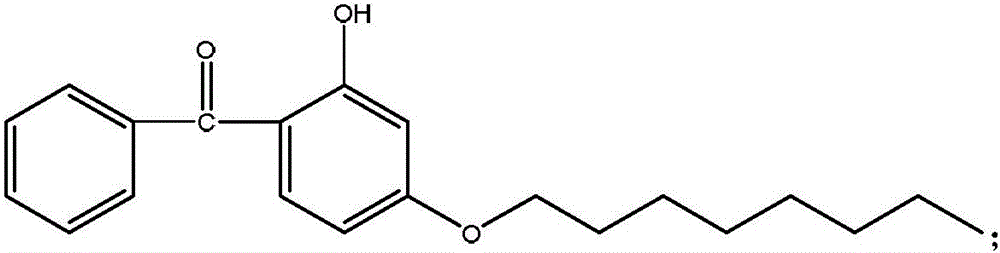

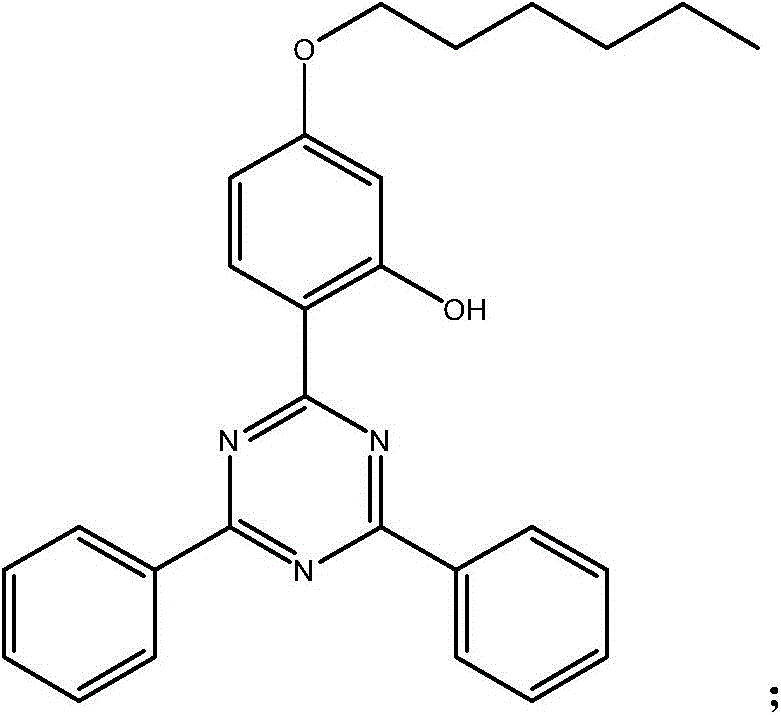

Method used

Image

Examples

Embodiment 1-7

[0073] Mix the ultraviolet absorber and the dye, add water and / or organic solvent, and dispersant, perform sand grinding, and spray dry to obtain the dye composition described in this application. Wherein, the weight ratio of the total amount of dye to the amount of UV absorber is 1:0.05-0.5; the weight ratio of the total amount of dye and UV absorber to water is 1:2-5; if additives are added to the system , then the consumption of auxiliary agent is 50~200wt% of the total consumption of described dyestuff and ultraviolet absorber; If organic solvent is added in the system, then the weight ratio of the consumption of organic solvent and water consumption is 1: 50~500. See Table 1 for each component and its consumption in Examples 1-7.

[0074] Prepare the prepared disperse dye composition with deionized water to prepare disperse dye suspensions with a concentration of 0.1-20.0g / 100mL; take 20mL of uniformly dispersed disperse dye suspensions, add 80-130mL deionized water to mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com