Production process of granular threonine

A production process and technology for threonine, applied in microorganisms, microorganism-based methods, preparation of organic compounds, etc., can solve problems such as increased fermentation cost, difficulty in separating products, and difficult control of fermentation process, and achieve improved quality and added value. , Control solubility, strengthen the effect of CO2 fixation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The production technology of granular threonine, it comprises the steps:

[0030] Step 1) Preparation of fermentation medium: glucose 25g / L, glycerin 20g / L, corn steep liquor 20g / L, ammonium sulfate 2g / L, potassium dihydrogen phosphate 0.1g / L, dipotassium hydrogen phosphate 0.1g / L, heptahydrate Magnesium sulfate 0.1g / L, ferrous sulfate heptahydrate 5mg / L, manganese sulfate monohydrate 5mg / L, isoleucine 200mg / L, fulvic acid 10mg / L, pH 5.5;

[0031] Step 2) Fermentation: Escherichia coli engineering bacteria K12△dapA seed solution (the concentration of the seed solution is 1×10 8 cfu / mL) according to 12% of the inoculum amount was inserted into the fermenter containing the fermentation medium for fermentation, the temperature was 30°C, the tank pressure was 0.03MPa, the ventilation rate was 0.4vvm, the rotation speed was 100rpm, and the fermentation time was 36h, and then Add inositol 100mg / L, continue fermentation and cultivation for 24 hours, control the sugar content ...

Embodiment 2

[0035] The production technology of granular threonine, it comprises the steps:

[0036] Step 1) Preparation of fermentation medium: glucose 30g / L, glycerol 15g / L, corn steep liquor 15g / L, ammonium sulfate 2g / L, potassium dihydrogen phosphate 0.2g / L, dipotassium hydrogen phosphate 0.2g / L, heptahydrate Magnesium sulfate 0.2g / L, ferrous sulfate heptahydrate 10mg / L, manganese sulfate monohydrate 10mg / L, isoleucine 300mg / L, fulvic acid 20mg / L, pH 5.5;

[0037] Step 2) Fermentation: Escherichia coli engineering bacteria K12△dapA seed solution (the concentration of the seed solution is 1×10 8 cfu / mL) according to the inoculum amount of 10-12%, put it into the fermenter containing the fermentation medium for fermentation, the temperature is 30°C, the tank pressure is 0.04MPa, the ventilation volume is 0.6vvm, the rotation speed is 100rpm, and the fermentation time is 32h , then add inositol 200mg / L, continue fermentation and cultivation for 28h, control the sugar content to 0.4% by ...

Embodiment 3

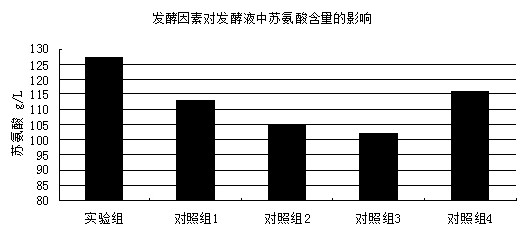

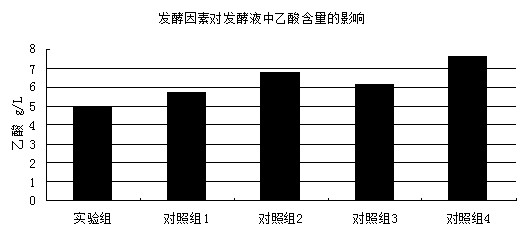

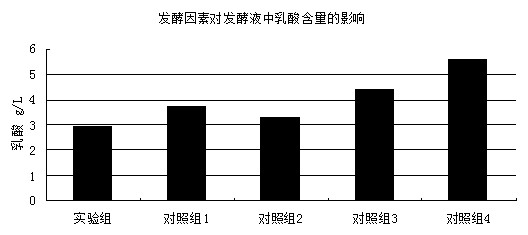

[0041] The influence of different factors in the fermentation process of the present invention on the yield of threonine, the content of by-products such as acetic acid and lactic acid.

[0042] Set group:

[0043] Experimental group: Example 1;

[0044] Control group 1: No addition of isoleucine, the rest are the same as in Example 1;

[0045] Control group 2: do not add fulvic acid, all the other are the same as embodiment 1;

[0046] Control group 3: without adding inositol, the rest are the same as in Example 1;

[0047] Control group 4: Glycerin was replaced by glucose of the same quality, and the rest were the same as in Example 1.

[0048] The contents of threonine, acetic acid and lactic acid in the final fermentation liquid of each group were as follows: Figure 1-3 shown. By setting up a control group, the effects of fermentation factors such as glycerin, fulvic acid, isoleucine and inositol on threonine, acetic acid and lactic acid were detected; Figure 1-3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com