Granular threonine extraction and preparation process

A preparation process, technology of threonine, applied in the field of separation, extraction and preparation of granular threonine, can solve the problems of easy moisture absorption and agglomeration, reduce the use value of mother liquor, and unfavorable addition, so as to improve quality and added value, Ease of storage and transportation, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

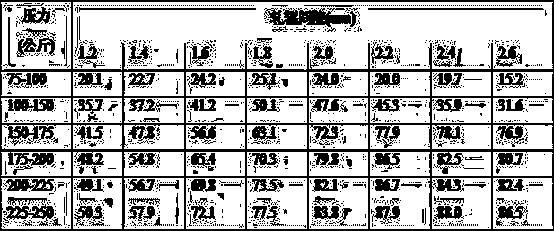

Image

Examples

Embodiment 1

[0024] Including the following steps:

[0025] Step 1) Fermentation: Escherichia coli engineering bacteria seed solution (the concentration of the seed solution is 1×10 8 cfu / mL) according to 10% of the inoculum amount into a fermenter containing fermentation medium for fermentation, the temperature is 30°C, the tank pressure is 0.04MPa, the ventilation rate is 0.5vvm, the rotation speed is 100rpm, and the fermentation time is 36h, then Inject Chlamydomonas reinhardtii according to 10% inoculum (the concentration of Chlamydomonas reinhardtii is 1×10 5 cfu / mL), continue to ferment for 48 hours, stop the fermentation, and collect the fermented liquid;

[0026] The components of the fermentation medium are: glucose 20g / L, glycerol 20g / L, corn steep liquor 20g / L, ammonium sulfate 2g / L, potassium dihydrogen phosphate 0.2g / L, dipotassium hydrogen phosphate 0.2g / L, Magnesium sulfate heptahydrate 0.1g / L, ferrous sulfate heptahydrate 0.01g / L, manganese sulfate monohydrate 0.01g / L, pH...

Embodiment 2

[0036] Including the following steps:

[0037] Step 1) Fermentation: Escherichia coli engineering bacteria seed solution (the concentration of the seed solution is 1×10 8cfu / mL) according to the inoculation amount of 6%, was inserted into the fermenter containing the fermentation medium for fermentation, the temperature was 32°C, the tank pressure was 0.04MPa, the ventilation rate was 0.4vvm, the rotation speed was 100rpm, and the fermentation time was 48h. Then insert Chlamydomonas reinhardtii (the concentration of Chlamydomonas reinhardtii is 1×10 5 cfu / mL), continue to ferment for 48 hours, stop the fermentation, and collect the fermented liquid;

[0038] The components of the fermentation medium are: glucose 30g / L, glycerol 30g / L, corn steep liquor 30g / L, ammonium sulfate 3g / L, potassium dihydrogen phosphate 0.3g / L, dipotassium hydrogen phosphate 0.3g / L, Magnesium sulfate heptahydrate 0.2g / L, ferrous sulfate heptahydrate 0.02g / L, manganese sulfate monohydrate 0.02g / L, pH...

Embodiment 3

[0048] Including the following steps:

[0049] Step 1) Fermentation: Escherichia coli engineering bacteria seed solution (the concentration of the seed solution is 1×10 8 cfu / mL) according to 10% of the inoculum amount into a fermenter containing fermentation medium for fermentation, the temperature is 30°C, the tank pressure is 0.04MPa, the ventilation rate is 0.5vvm, the rotation speed is 100rpm, and the fermentation time is 36h, then Inject Chlamydomonas reinhardtii according to 10% inoculum (the concentration of Chlamydomonas reinhardtii is 1×10 5 cfu / mL), continue to ferment for 48 hours, stop the fermentation, and collect the fermented liquid;

[0050] The components of the fermentation medium are: glucose 20g / L, glycerol 20g / L, corn steep liquor 20g / L, ammonium sulfate 2g / L, potassium dihydrogen phosphate 0.2g / L, dipotassium hydrogen phosphate 0.2g / L, Magnesium sulfate heptahydrate 0.1g / L, ferrous sulfate heptahydrate 0.01g / L, manganese sulfate monohydrate 0.01g / L, pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com