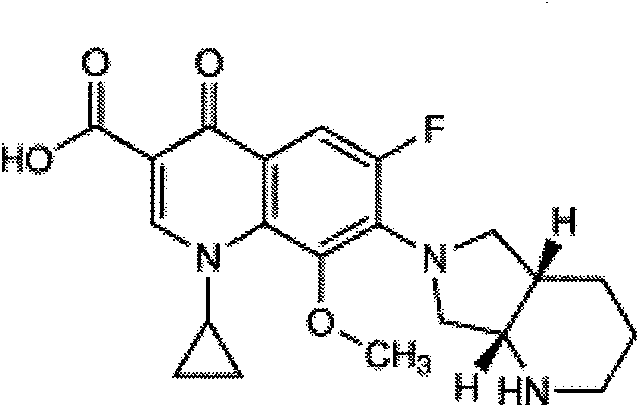

Moxifloxacin aqueous solution type injection

A moxifloxacin and aqueous solution technology, which is applied in the direction of medical preparations of non-active ingredients, organic active ingredients, and inorganic non-active ingredients, can solve problems such as unstable product quality, high production costs, and poor operability, and achieve product The effect of easier quality control, convenient transportation and storage, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

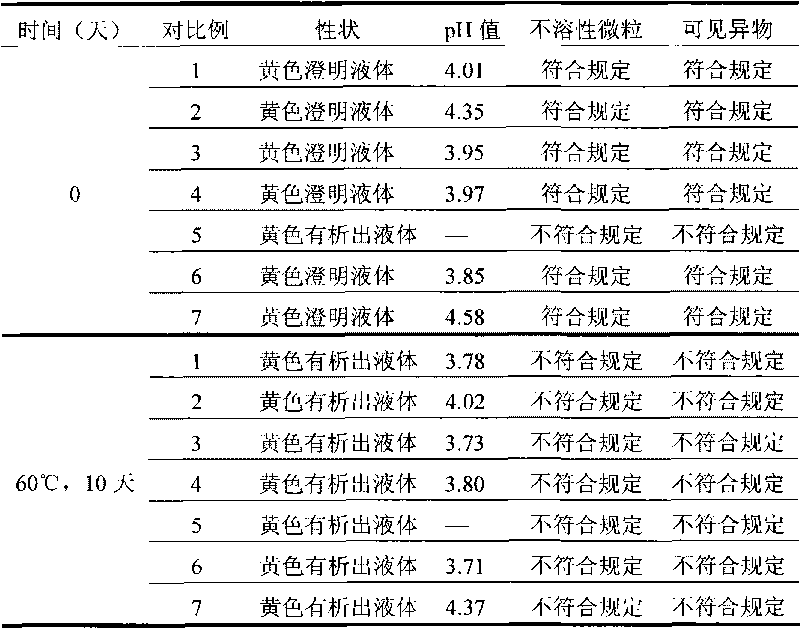

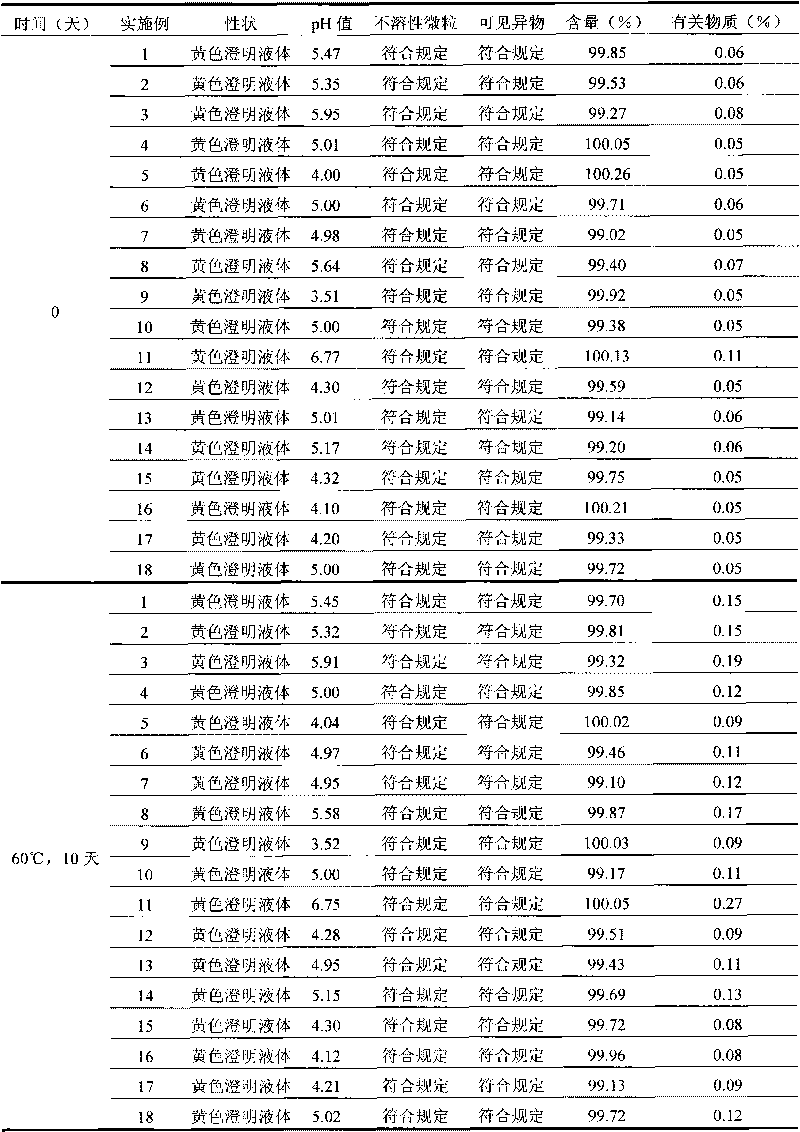

Examples

Embodiment 1

[0069] Sodium acetate trihydrate 65g 0.239mol / L

[0070] Glacial acetic acid to adjust pH

[0071] Add water for injection to 2000ml

[0072] Take 1800ml of water for injection, add the prescribed amount of sodium acetate trihydrate and stir to dissolve, add the prescribed amount of moxifloxacin hydrochloride, stir to dissolve, adjust the pH value to 5.50 with glacial acetic acid, add water for injection to 2000ml. Filter through a 0.22 μm microporous membrane, fill, and sterilize by autoclaving at 121°C for 15 minutes.

[0073] Example 2

[0074] Name of raw and auxiliary materials Amount of 100 sticks Content% (g / ml) / molar concentration

Embodiment 2

[0076] Sodium acetate trihydrate 26g 0.0955mol / L

[0077] Add water for injection to 2000ml

[0078] Take 1800ml of water for injection, add the prescribed amount of moxifloxacin hydrochloride and sodium acetate trihydrate, stir and dissolve, measure the pH value to 5.35, add water for injection to 2000ml. Filter through a 0.22 μm microporous membrane, fill, and sterilize by autoclaving at 121°C for 15 minutes.

[0079] Example 3

[0080] Name of raw and auxiliary materials Amount of 100 sticks Content% (g / ml) / molar concentration

Embodiment 3

[0082] Sodium Lactate 224.12g 1mol / L

[0083] Add water for injection to 2000ml

[0084] Take 1800ml of water for injection, add the prescribed amount of moxifloxacin hydrochloride and sodium lactate, stir to dissolve, add water for injection to 2000ml, and measure the pH value to 5.96. Filter through a 0.22μm microporous membrane, fill, and autoclave at 121°C for 15 minutes.

[0085] Example 4

[0086] Name of raw and auxiliary materials Amount of 100 sticks Content% (g / ml) / molar concentration

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com