Device and method for monitoring friction and corrosion fatigue damage to twisted type lifting steel wire rope of super deep vertical shaft

A monitoring device and a fatigue damage technology, which are applied in measurement devices, weather resistance/light resistance/corrosion resistance, and wear resistance testing, etc., can solve problems such as the inability to realize the friction corrosion fatigue damage characteristics of steel wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings.

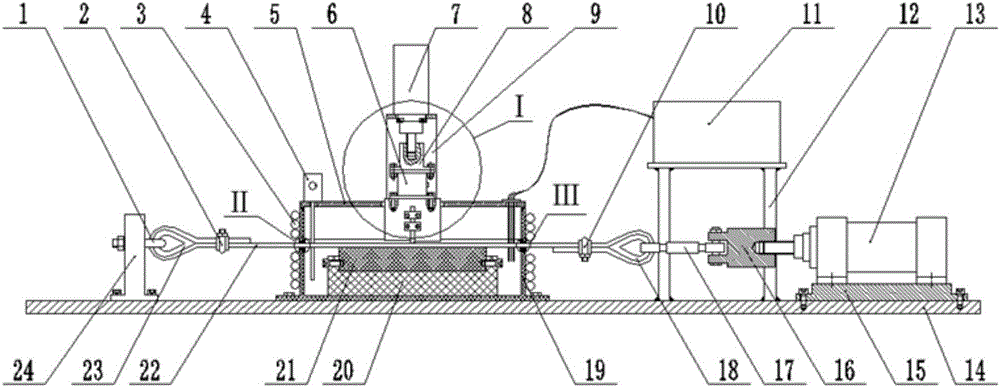

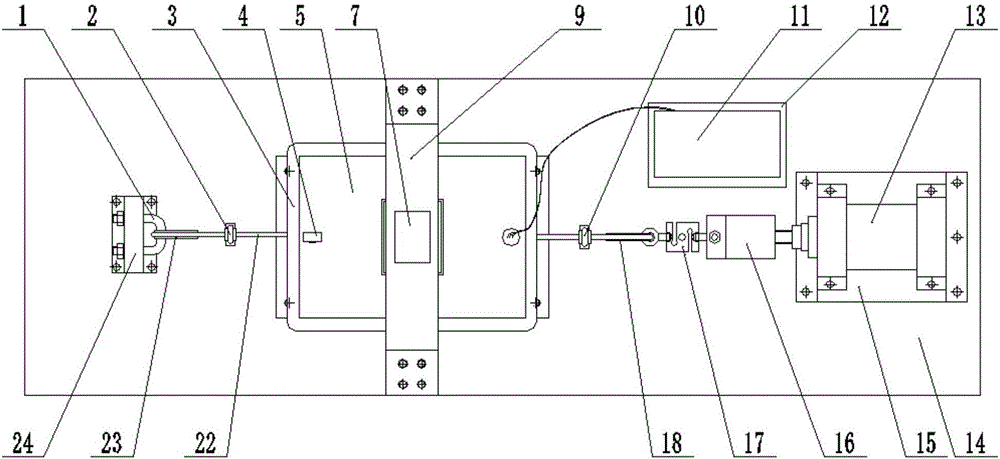

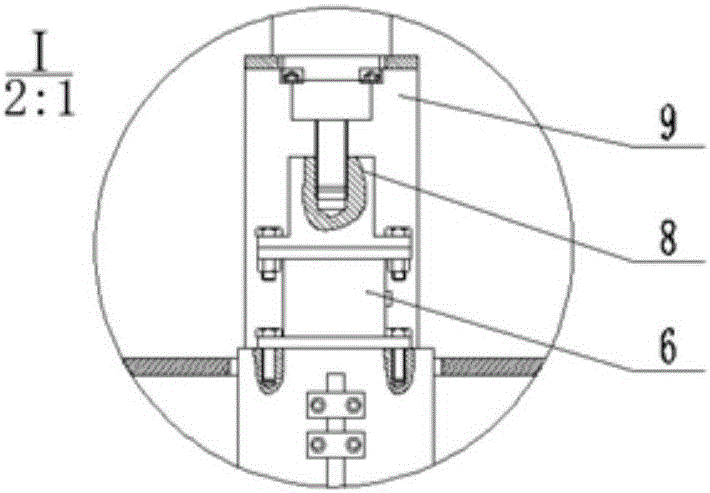

[0032] The friction and corrosion fatigue damage monitoring device of winding hoisting wire rope for ultra-deep shaft includes support system, tension-tension fatigue system, dynamic loading system, constant temperature corrosion system and monitoring system.

[0033] The support system includes a base plate 14, a gantry support 9, an electrochemical workstation support 12, a servo electric cylinder A support 15, and a friction pad support 20. The gantry support 9 is fixed on the base plate 14 by screws, and the electrochemical workstation support 12 is fixed by welding. On the bottom plate 14, the servo electric cylinder A bracket 15 is fastened on the bottom plate 14 by screws, and the friction lining bracket 20 is fixed on the bottom plate of the corrosion-resistant box 19 by corrosion-resistant screws.

[0034] The pull-pull fatigue system includes a U-shaped piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com