Method for constructing three-dimensional abrasion map of copper-based powder metallurgy wet friction material

A technology of wet friction material and powder metallurgy, which is applied in the direction of testing wear resistance, etc., to shorten the test period and reduce the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

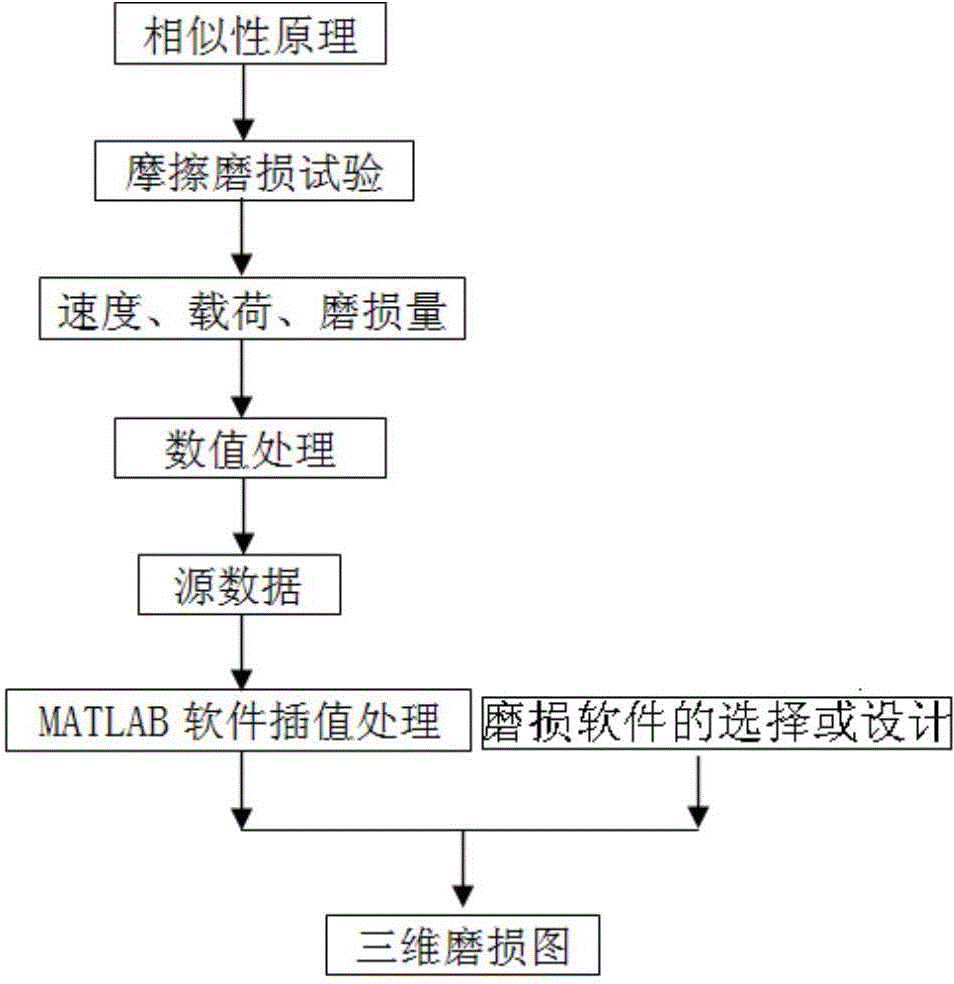

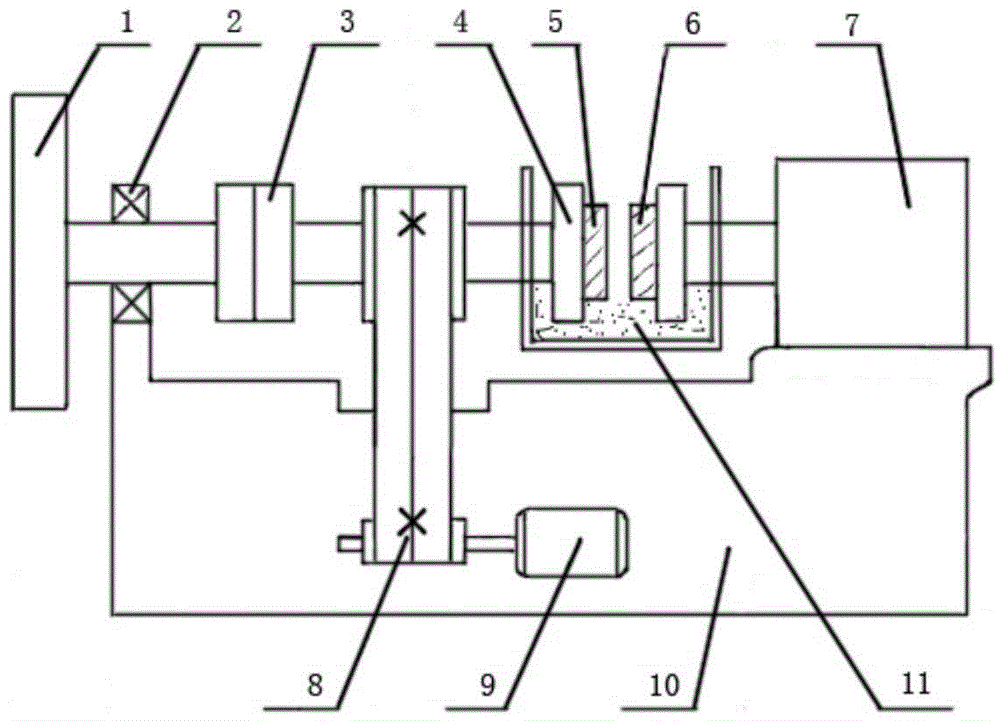

Method used

Image

Examples

Embodiment 2

[0086] In order to illustrate the effectiveness of the data obtained in the present invention, the inventor also carries out the following comparative experiments:

[0087] The scaling test described in the step of embodiment 1 is compared with the 1:1 bench test under the condition parameters of table 1; (the operating conditions of the two are basically the same)

[0088] Table 1 Comparison of test parameters

[0089]

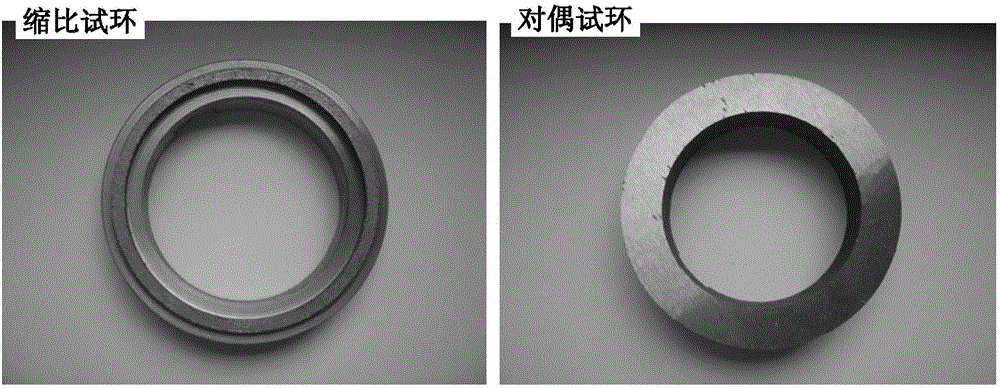

[0090] The size of the friction test ring used in the 1:1 bench test is Φ520×470, and the size of the friction test ring used in the scale test is Φ67×61mm. The test results obtained from the 1:1 bench test were made Figure 8 (a), the test results obtained from the scale-down test are made into Figure 8 (b), compare Figure 8 (a) and Figure 8 (b), it can be seen that the 1:1 bench test curve is relatively smoother and less fluctuating than the scale test curve, but the basic trend of the friction curves of the two is the same, and the parameters suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com