Control device for providing simulated marine environment for corrosion fatigue test

A marine environment and control device technology, applied in measuring devices, electrical program control, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of inaccurate control, time-consuming and laborious, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

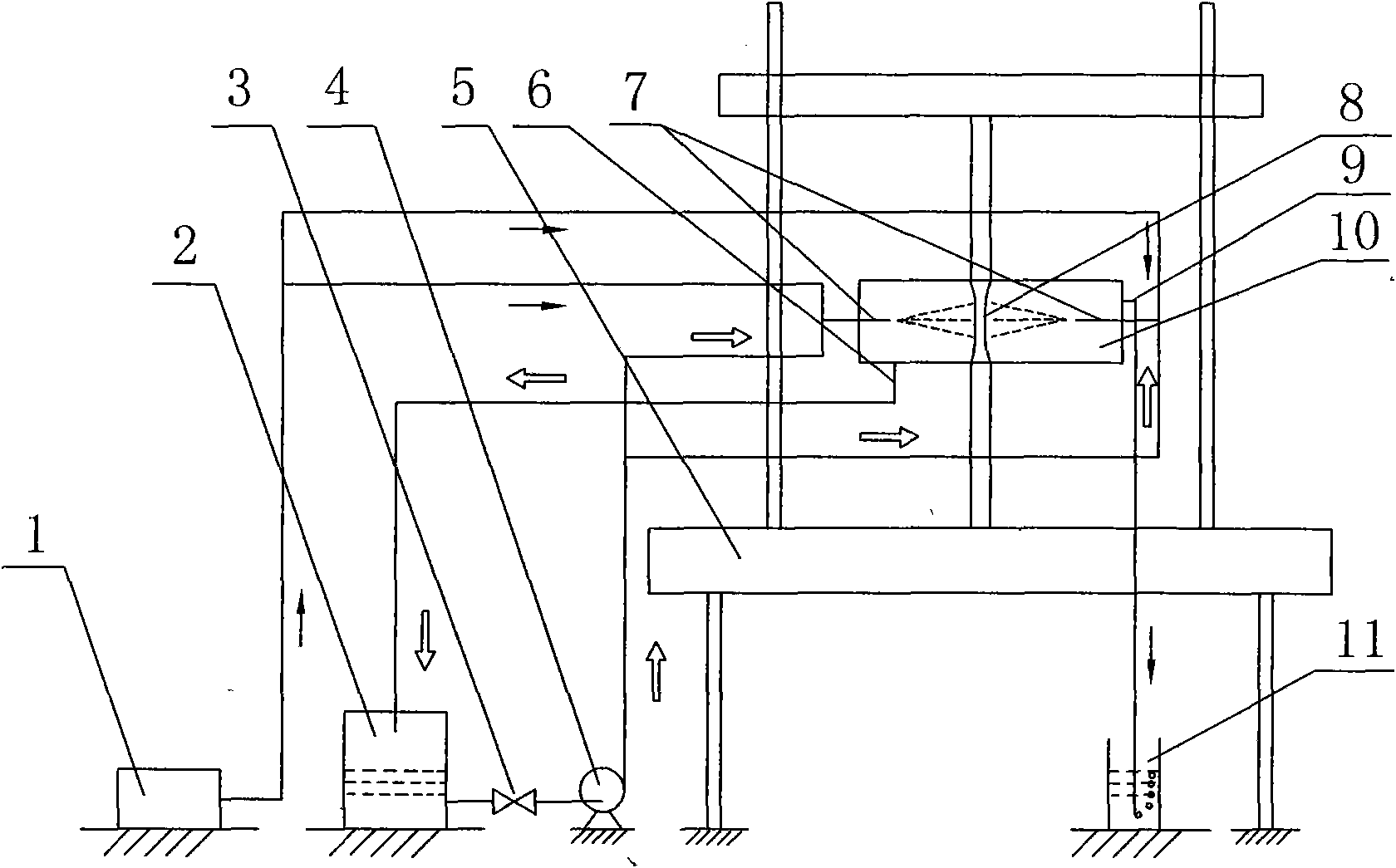

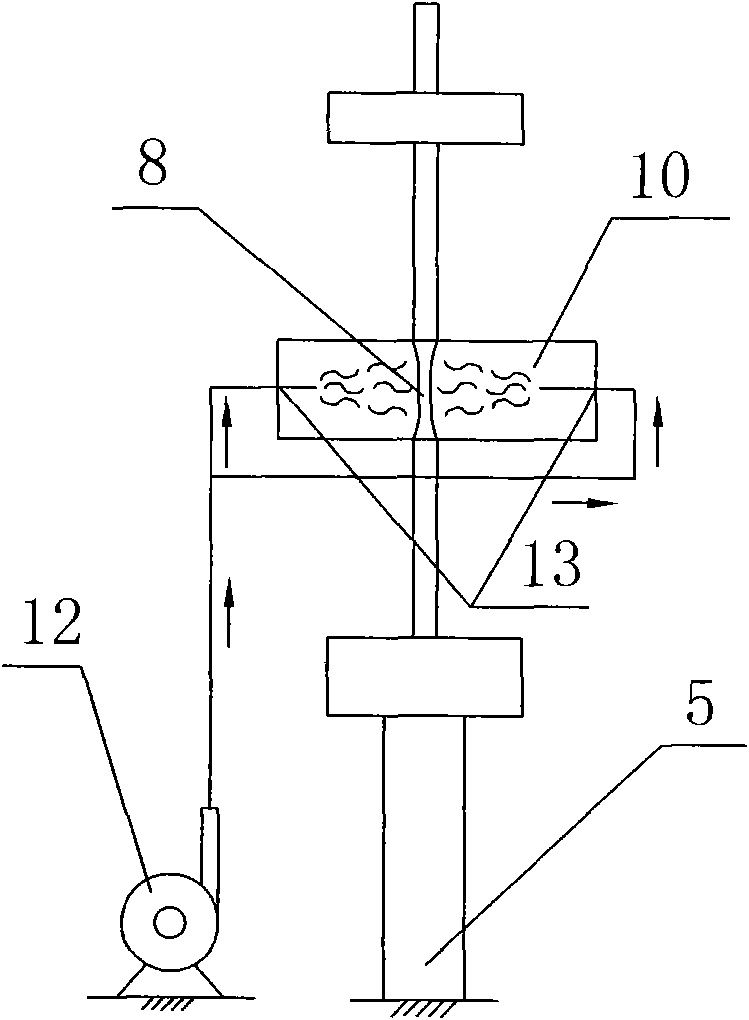

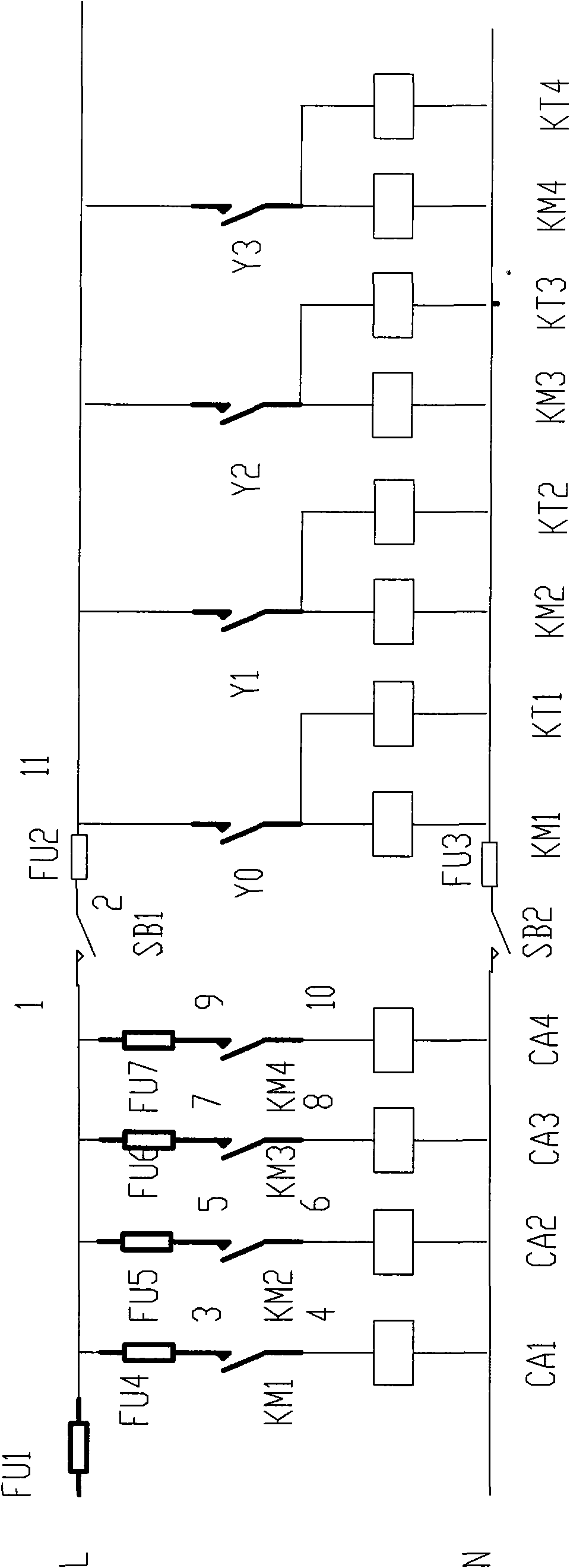

[0023] As shown in Figures 1-3, the control device of the present invention is mainly composed of two systems: a control system and an environment simulation system. The system can simulate seawater flow area, tidal range area and spray splash area. Cooperating with the fatigue test program, the device can realize the corrosion fatigue test in the marine environment with various combinations of environmental spectrum and load spectrum. It is easy to operate and does not need to be manually guarded, so it can complete the task of corrosion fatigue test with strong load (super strength or long time). details as follows:

[0024] As shown in Figures 1 and 3, the environmental simulation system includes: artificial seawater circulation loop, compressed air channel and hot air channel. in,

[0025] The structure and working principle of the artificial seawater circulation circuit are as follows: the water storage tank 2 stores a certain amount of artificial seawater, and the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com