Ultra-fine grained steels having corrosion-fatigue resistance

a technology corrosion resistance, which is applied in the field of ultra-fine grained steels, can solve the problems of reducing the fatigue life of components, no longer valid, and common failure mechanism of sucker rod fatigu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

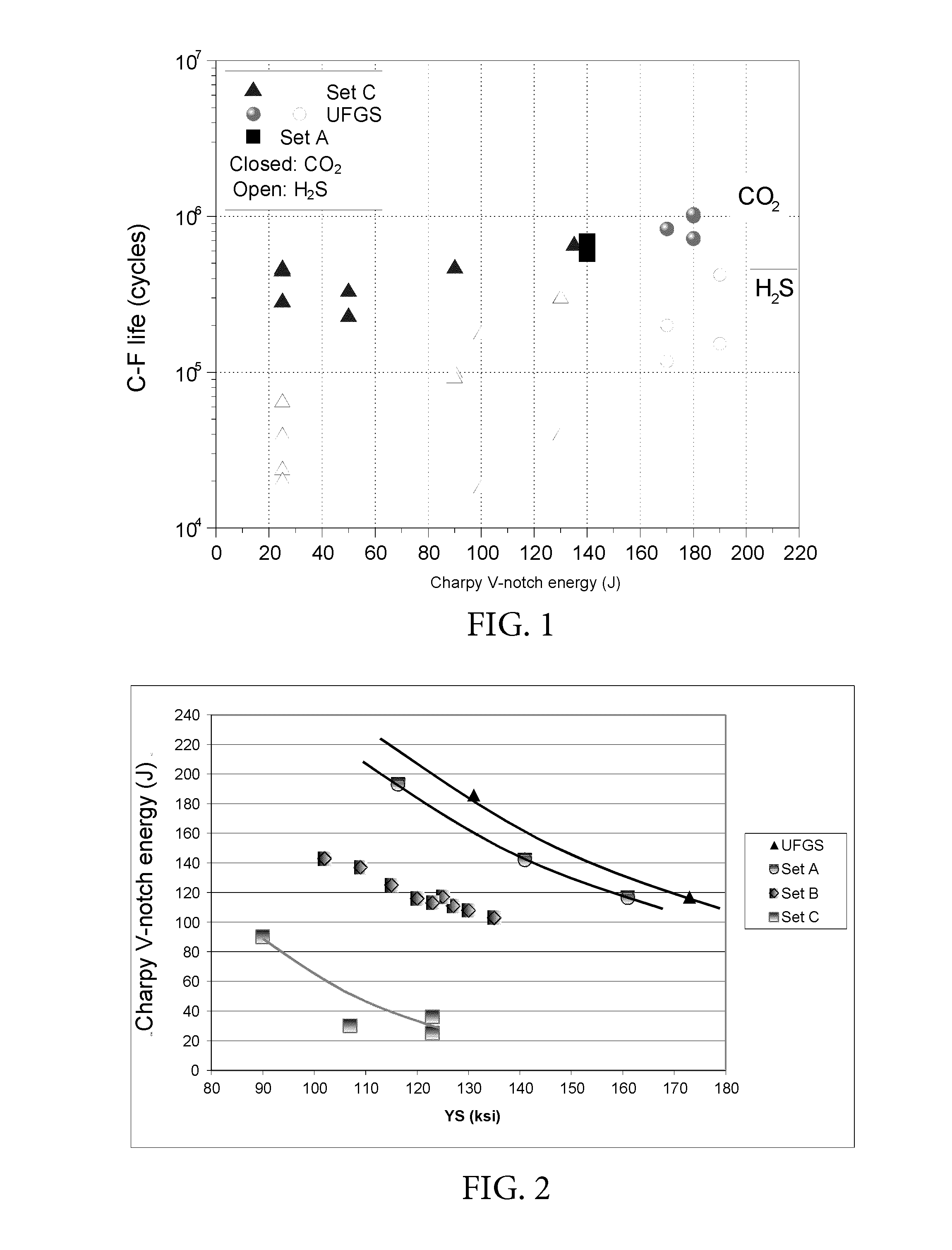

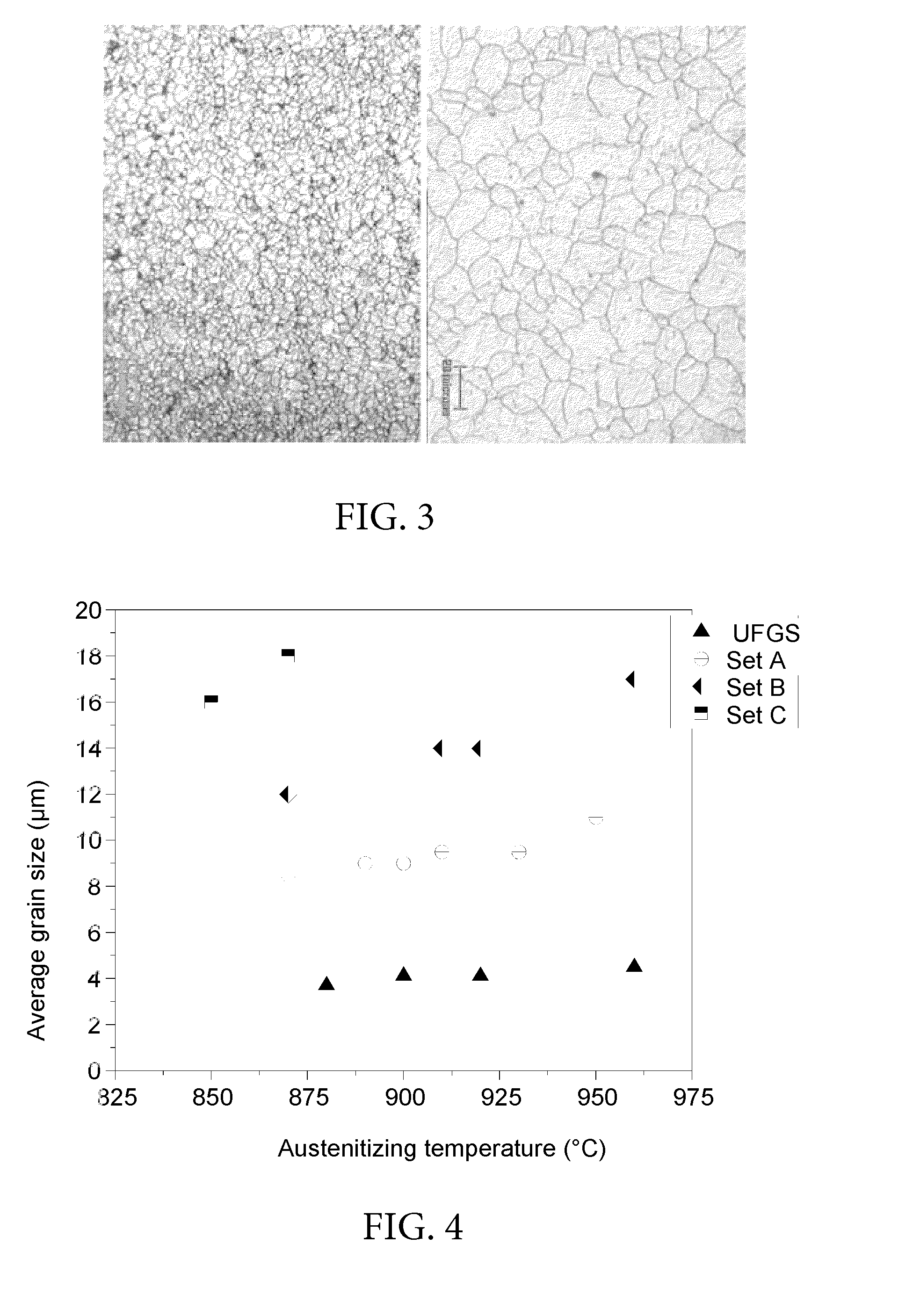

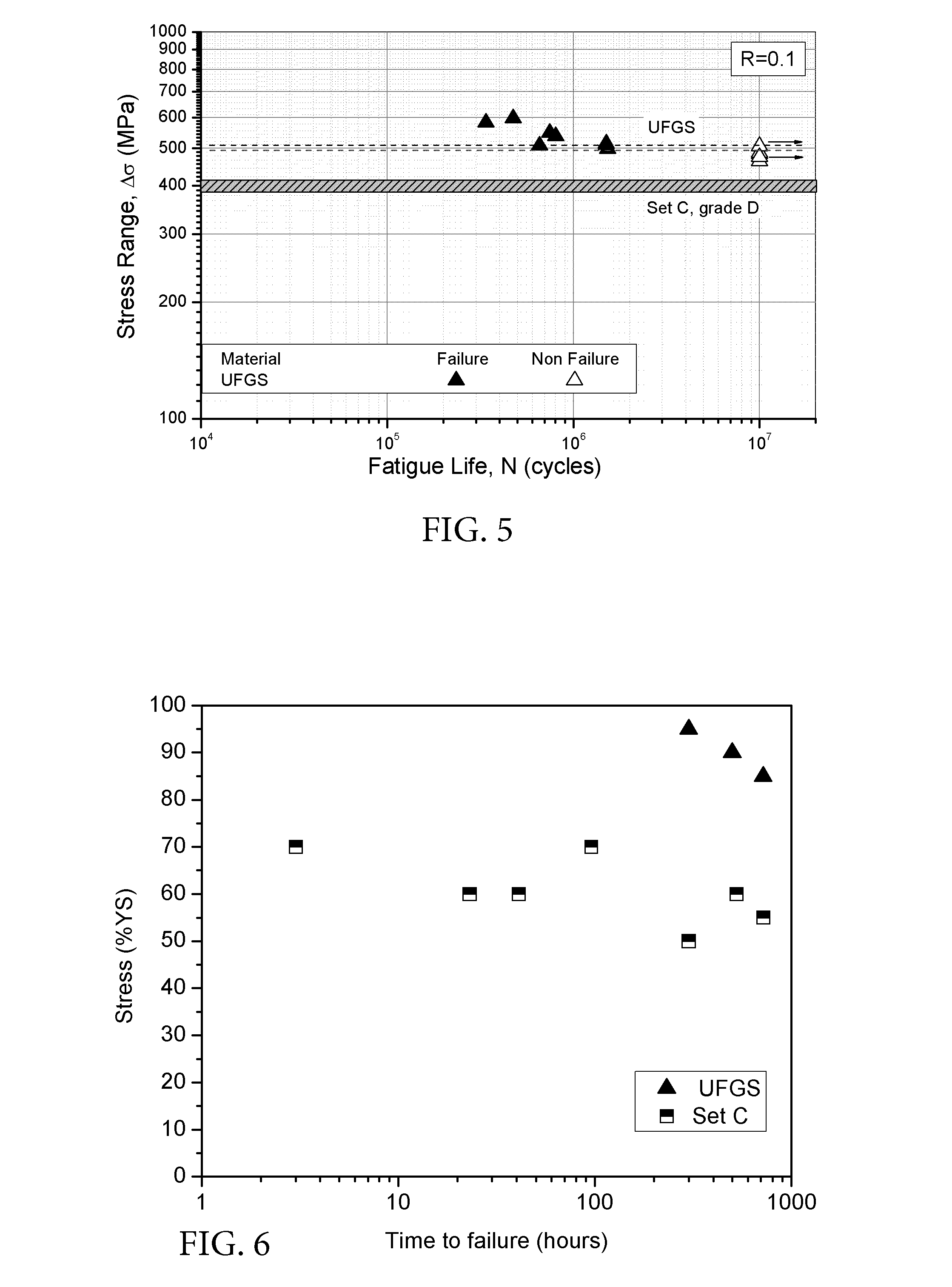

[0144]The below examples illustrate the fatigue corrosion performance of a steel manufactured from embodiments of the above disclosure as compared to other chemical compositions or manufacturing routes.

[0145]Ultra-fine grain steels (UFGS), such as those described above, were manufactured at industrial scale complying with the following equations in order to investigate the effect of different elements and the performance of each steel chemical composition under different conditions (all UFGS steels and Set A):

0.2%

0.15%

[0146]Billets with an outside diameter of 148 mm were produced in a vertical continuous casting machine. Billets were heated up to 1270° C. and hot rolled to diameters ranging from 19 up to 32 mm.

[0147]Bars were then subjected to a fast induction heating reaching a target temperature of about 900° C. in about 4 seconds in the whole section, held at temperature for about 4 seconds and quenched in water down to below 100° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com