Particulate electrode material having coating made of crystalline inorganic material and/or inorganic-organic hybrid polymer and method for production thereof

A polymer coating and electrode material technology, applied in the direction of electrode manufacturing, active material electrodes, hybrid capacitor electrodes, etc., can solve problems such as rising resistance and difficulties, and achieve low resistance value, high safety, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1 - Preparation of Nanostructured Particulate Coatings on Particulate Electrode Materials

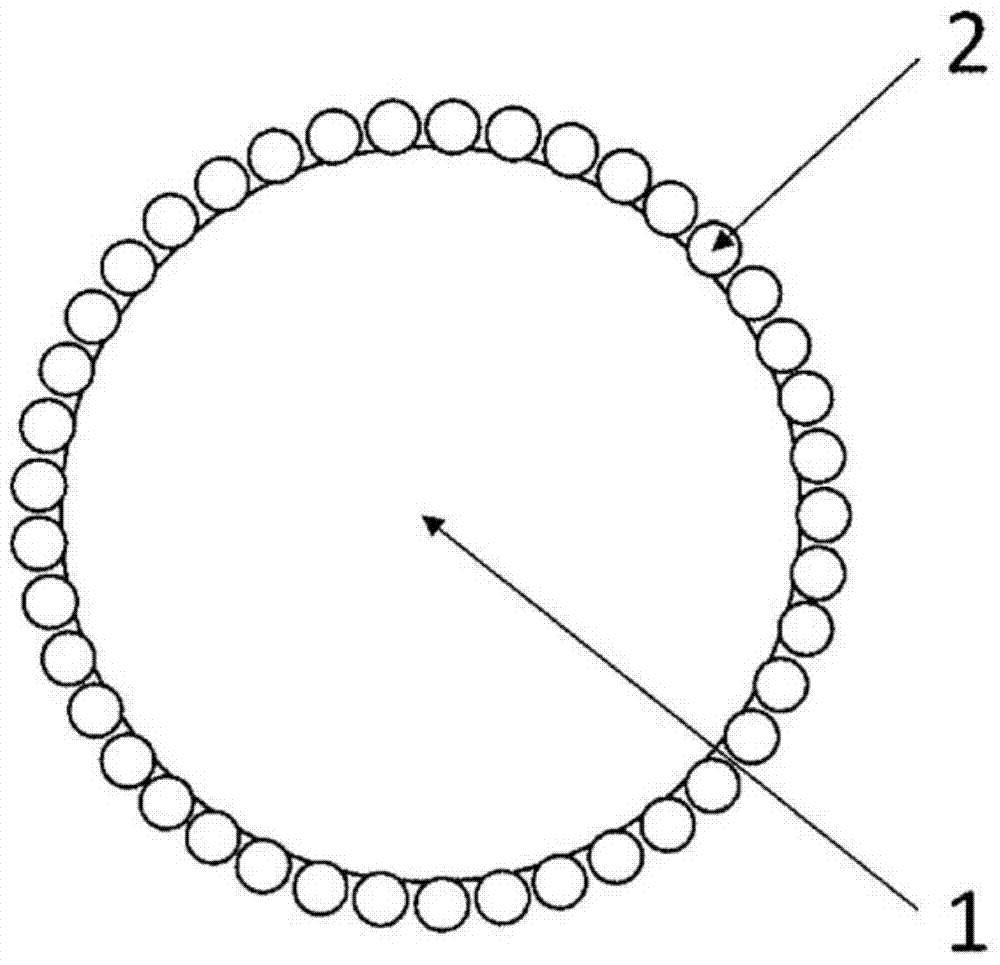

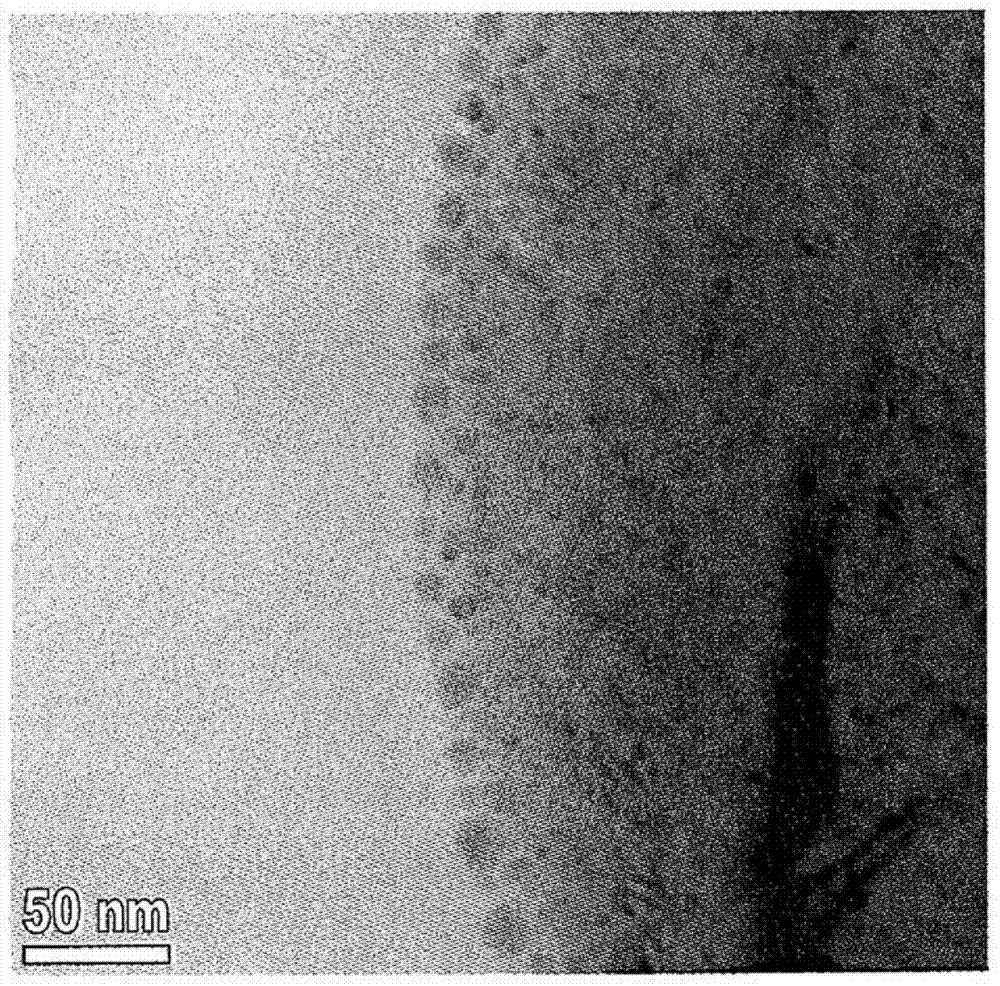

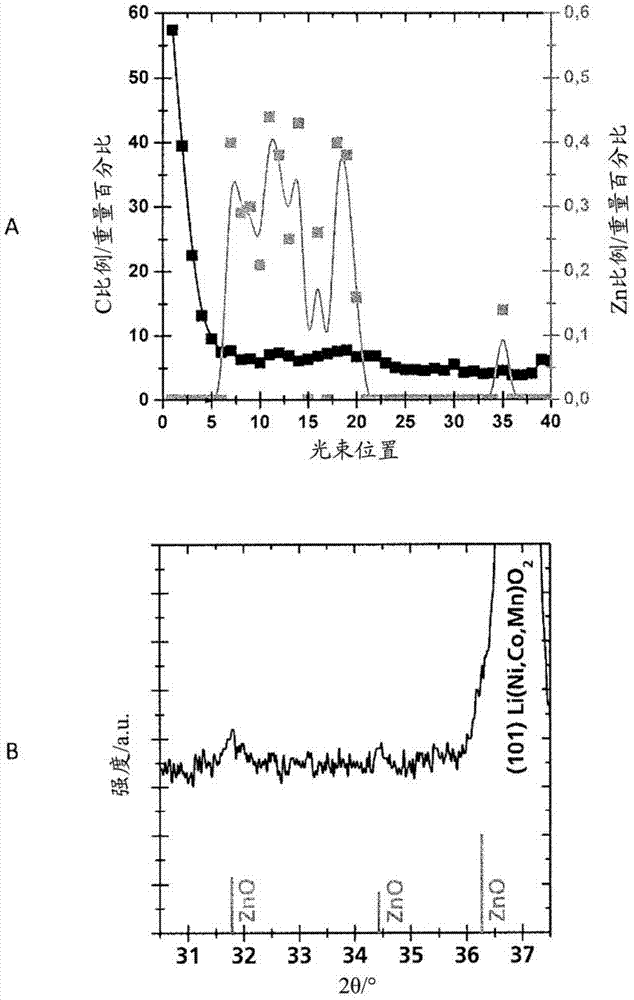

[0082] An example is Li(Ni,Co,Mn)O 2 Zinc oxide fine-grained coating on the surface, which consists of tiny (d<20nm), almost the same size, uniformly distributed zinc oxide crystallites.

[0083] Preparation by a modified Pechini sol-gel method, a further development of the process for preparing unstructured particle coatings is possible:

[0084] 500 mL of water and ethanol were added to a 1000 mL flask at a ratio of 1:8. Under the condition of continuous stirring, 1.34 g of zinc acetate was firstly added, and then 500 μL of nitric acid (10 mol / L) was added dropwise to the solution. Subsequently, 2.57 g of citric acid and 30 g of polyethylene glycol were added.

[0085] In parallel with this, 40g of Li(Ni,Co,Mn)O to be coated 2 Dispersed into another 100 mL of solvent (1:8 ratio of water to ethanol).

[0086] After stirring for 1 hour, 100 mL had Li(Ni, Co, Mn)O ...

Embodiment 2

[0089] Example 2 - Preparation method of hybrid polymer coating on particulate electrode material

[0090] Synthesis of Li-ion-conducting hybrid polymers (=coating materials)

[0091] In a 250 mL flask, 152 g (0.29 mol) of 2-methoxypolyethylenepropoxytrimethoxysilane were stirred with 2.634 g of lithium hydroxide (mixture 1).

[0092] In parallel, 23.6 g (0.1 mol) of 3-glycidyloxypropyltrimethoxysilane and 140 g of diethyl carbonate were weighed into a 100 mL flask, to which was added 2.7 g (0.15 mol) of distilled water (mixture 2) . The mixture is stirred.

[0093] After reaching the clear point of mixture 2, a homogeneous mixture 1 was added thereto.

[0094] After a few days, the solvent was centrifuged at 40° C. and a pressure of 28 mbar.

[0095] Coating method

[0096] In a 1L flask, under the condition of argon, weigh 30g of the battery material. Subsequently, 400 g of dimethyl carbonate and 0.9 g of coating material (optionally containing lithium salt or 0....

Embodiment 3

[0099] Example 3 - Preparation of Nanostructured Particulate Coatings and Hybrid Polymer Coatings on Particulate Electrode Materials method

[0100] Step 1: Synthesis of electron-conducting coatings prepared from metal oxide crystallites

[0101] 500 mL of water and ethanol at a ratio of 1:8 were added to a 1000 mL flask.

[0102] Under continuous stirring, 1.34 g of zinc acetate (optionally containing a small portion of aluminum acetate) was first added, and then 500 μL of nitric acid (10 mol / L) was added dropwise to the solution.

[0103] Subsequently, 2.57 g of citric acid and 30 g of polyethylene glycol were added. In parallel with this, 40g of Li(Ni,Co,Mn)O to be coated 2 Dispersed into another 100 mL of solvent (1:8 ratio of water to ethanol).

[0104] After stirring for 1 hour, 100 mL of Li(Ni, Co, Mn)O 2 A solvent for the microparticles is added to the coating solution. The mixture was then stirred for a further 24 hours.

[0105] Subsequently, the coated m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com