Life-based design method for fatigue strength of ultrahigh-pressure container

A design method and fatigue strength technology, applied in the field of fatigue strength design of ultra-high pressure vessels based on life, can solve the problems of inability to accurately consider the influence of local structural stress distribution, large safety margin, and failure of ultra-high pressure vessels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

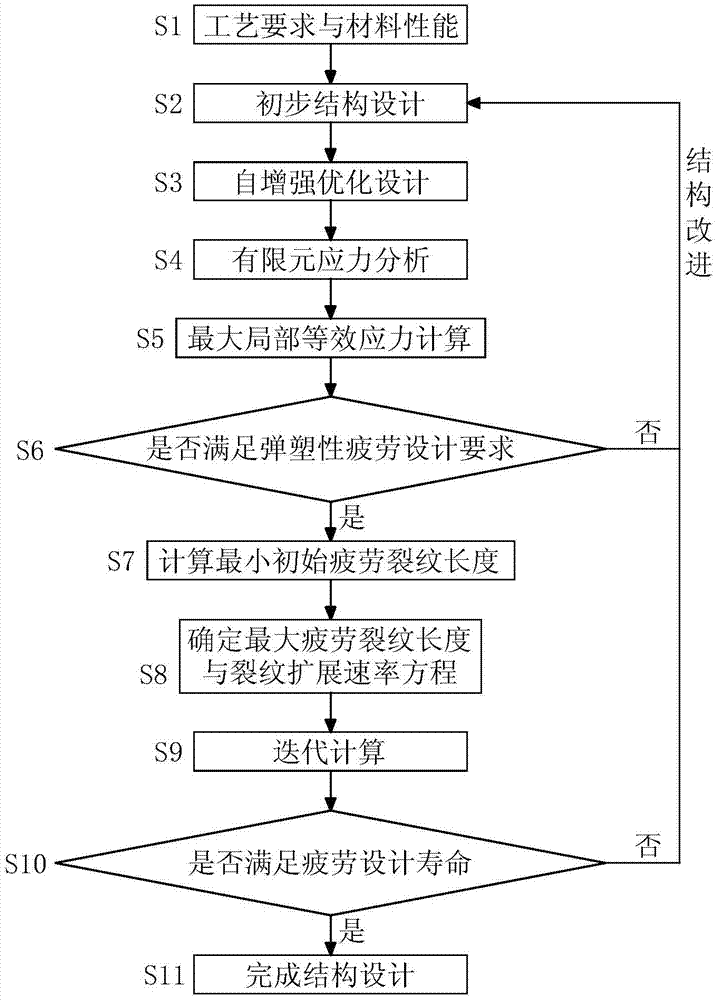

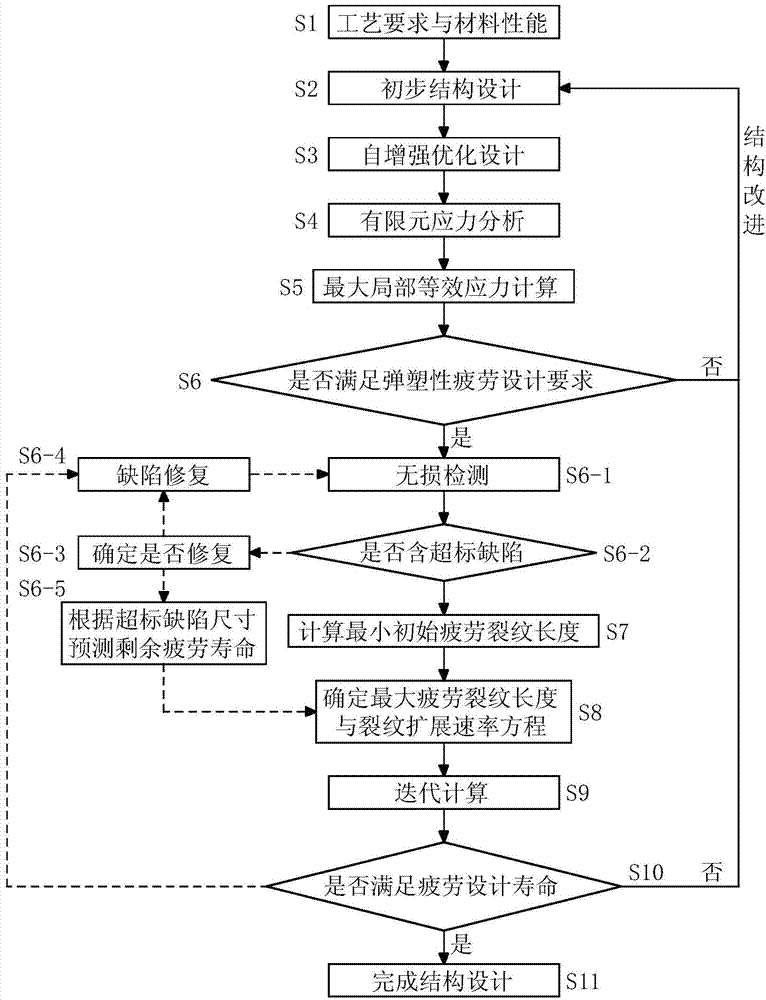

Method used

Image

Examples

Embodiment 1

[0088] In order to explain the present invention, an ultra-high pressure reaction tube used in the production of low-density polyethylene in the petrochemical industry is taken as an example to introduce the entire design process and give the design life.

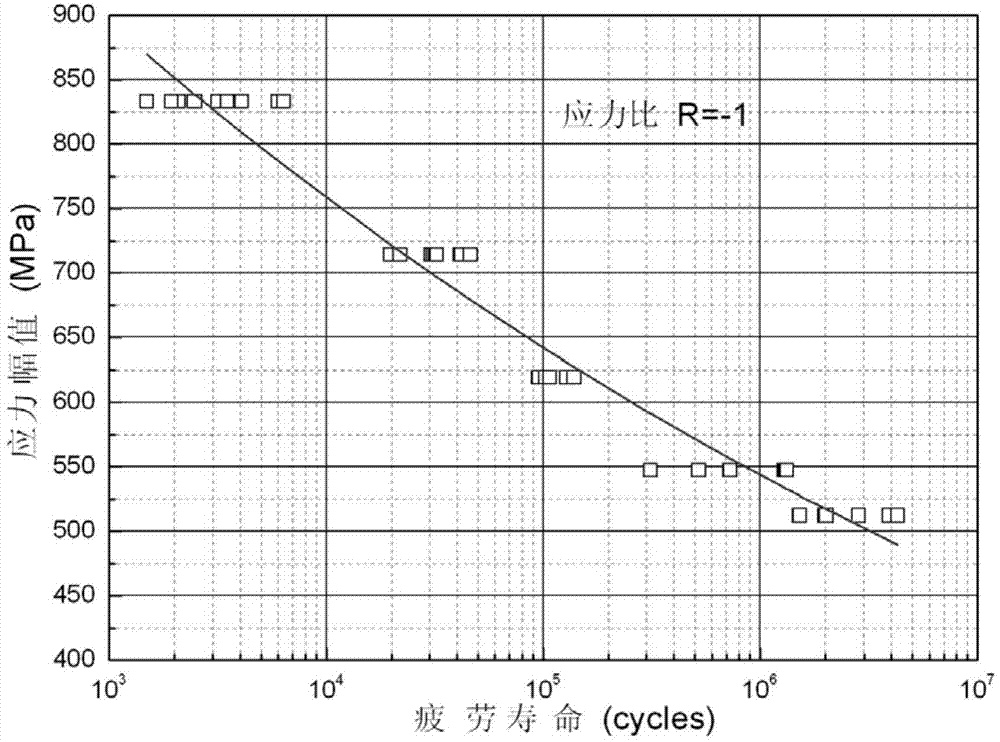

[0089] The working pressure of the equipment is 245MPa and the temperature is 90°C. The material is AISI4340 alloy steel pipe, and its yield strength is σ s =1026MPa, the tensile strength is σ b =1091MPa, the measured fatigue performance curve (S-N curve) of stress ratio R=-1 see figure 2 , take a safety factor of 15 for the life, and take a safety factor of 1.5 for the stress amplitude to establish a design curve, and convert the average stress to the design curve through the Goodman formula. The fatigue design curve of R=0 is shown in image 3 .

[0090] 1) Carry out preliminary structural design according to process requirements and material properties

[0091] When only considering the ultra-high pressure reaction ...

Embodiment 2

[0112]Taking the fatigue crack growth of AISI4333M4 alloy steel with excessive defects as an example, it is further illustrated that the method of the present invention is more accurate and reasonable than the linear fatigue life calculation method based on fracture mechanics.

[0113] ①Using AISI4333M4 alloy steel for fatigue crack growth test, the results are shown in Figure 7 , the fatigue crack has experienced 100600 cycles from the threshold value to fracture.

[0114] ②Aiming at the fatigue crack growth rate, the linear relational expression is used for life prediction. Firstly, the correlation coefficient is obtained by fitting in the logarithmic coordinate system, and the following Paris relational expression is established:

[0115] da / dN=1.15×10 -29 (ΔK) 2.93

[0116] The fatigue life obtained by integration is only 19956 cycles, which is far lower than the measured fatigue life.

[0117] 3. Apply the method in the present invention to carry out life prediction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com