Sub-ultrasonic high-frequency fatigue testing machine

A fatigue testing machine, sub-ultrasonic technology, applied in the direction of applying repeated force/pulsation force to test material strength, etc., can solve problems such as time and economic cost constraints, material fatigue, fatigue size effect, etc., to shorten the test cycle and reduce Frequency effect and size effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

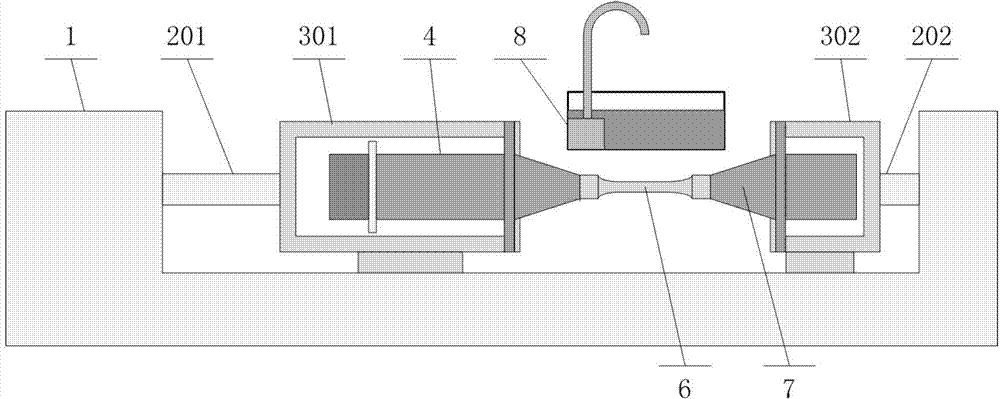

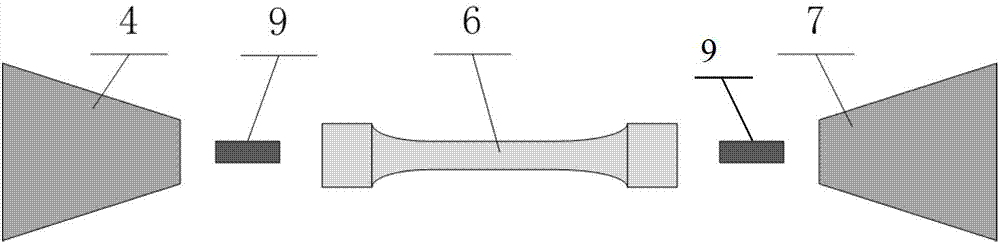

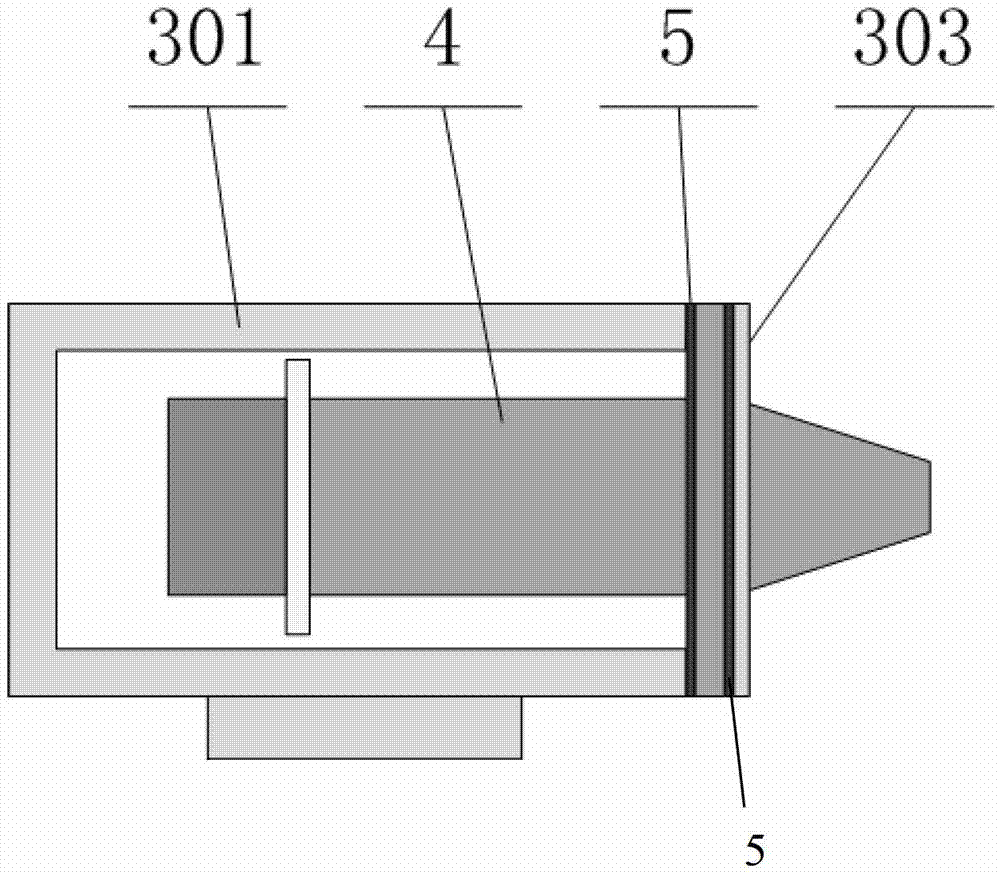

[0028] Reference attached figure 1 Shown in -7, the high-frequency fatigue testing machine of the present invention is by a transducer that converts electrical energy into mechanical energy as a driving force source, and relies on its inverse piezoelectric effect or magnetostrictive effect to convert alternating voltage into alternating voltage. deformation, and then provide vibration excitation to the system. The specific structure is as follows:

[0029] Test body 1, static load output shaft 201, fixed shaft 202, main jig 301, slave jig 302: one end of the test body 1 is fixedly provided with the fixed shaft 202 and the slave jig 302, and the other end of the test body 1 is provided with a The telescopic static load output shaft 201, the slide rail structure is adopted between the main jig 301 and the test bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com