Fatigue testing machine for lifetime measurement of cantilever parts

A fatigue testing machine and cantilever technology, which is used in the testing of mechanical components, the testing of machine/structural components, and measuring devices, etc., can solve problems such as the inability to directly and accurately characterize the fatigue life parameters of cantilevers, and achieve fast experimental speed. , to ensure the effect of persuasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

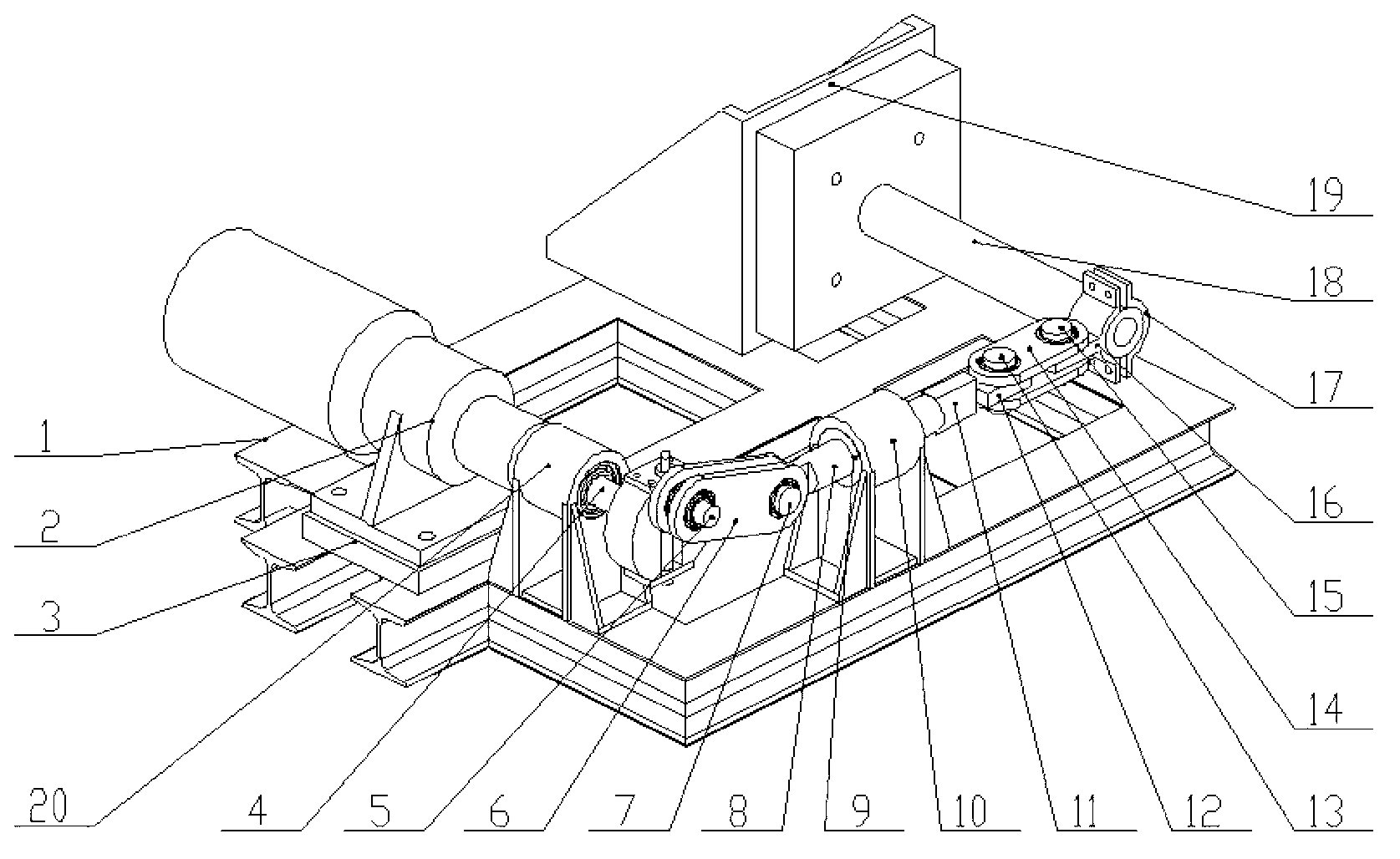

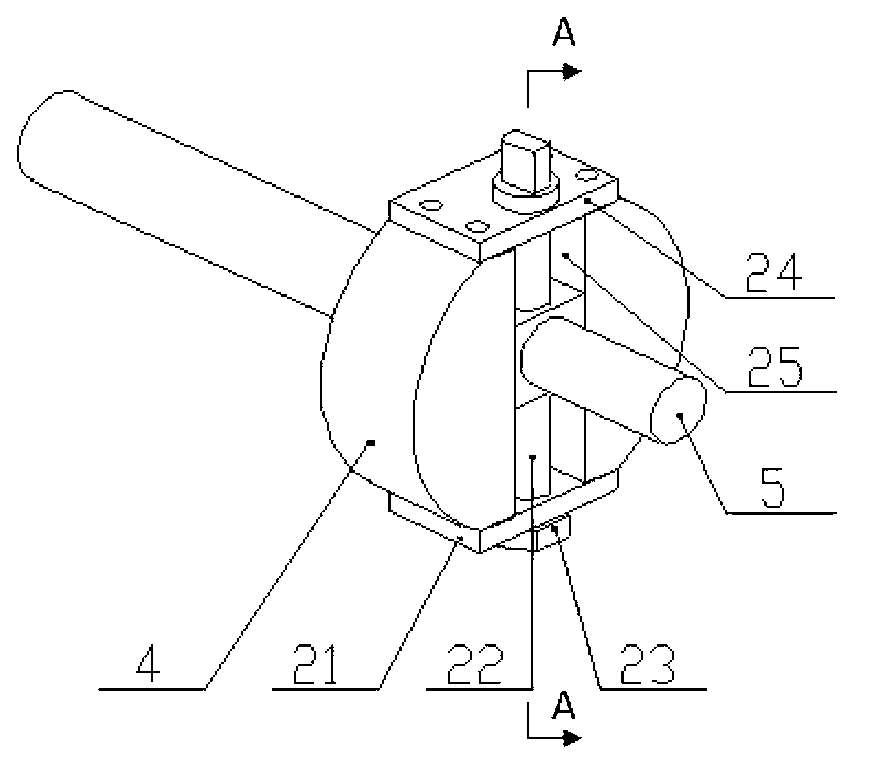

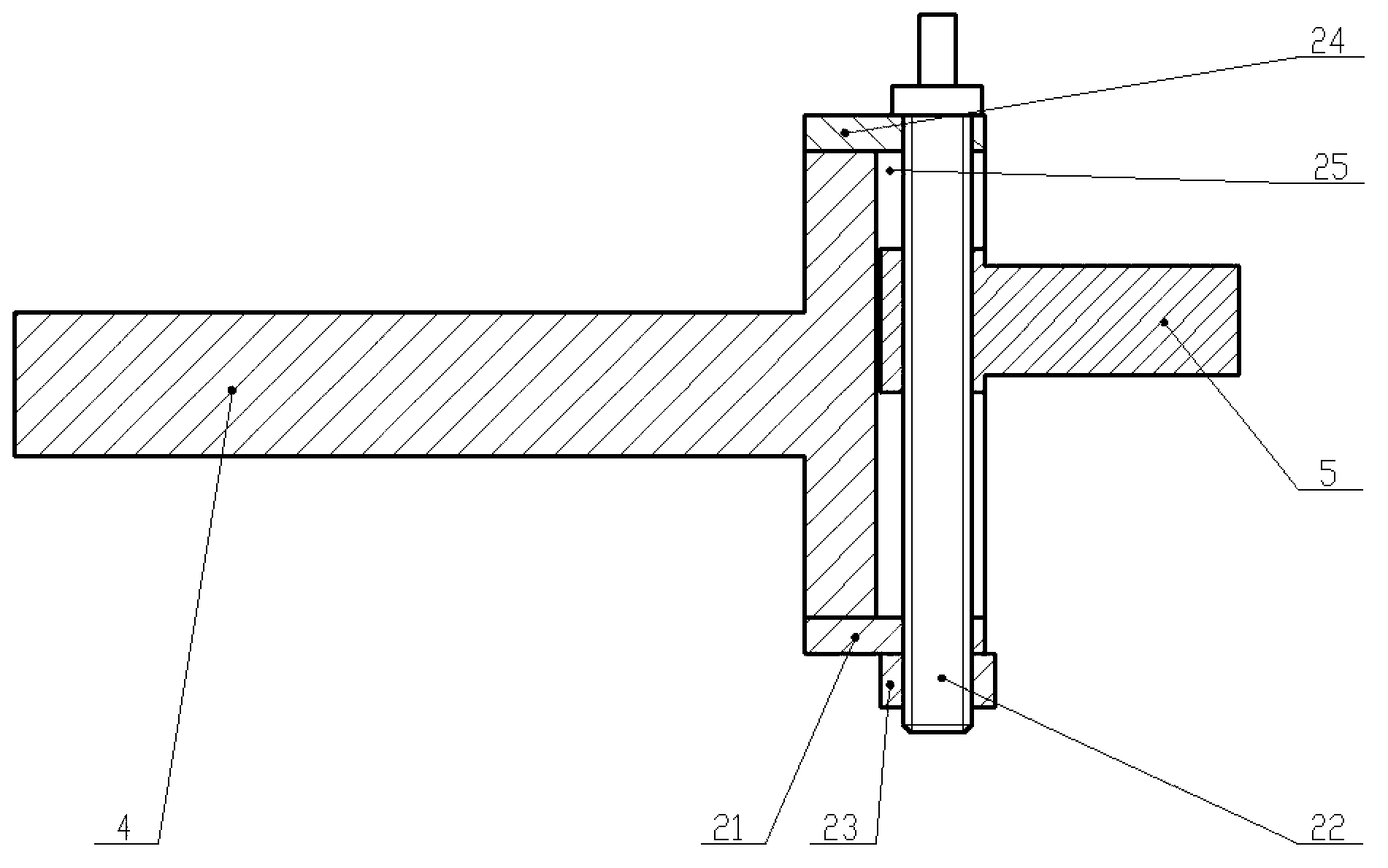

[0013] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] refer to figure 1 , figure 2 and image 3 , the measuring instrument consists of four parts: base 1, motor 2, eccentric mechanism, loading mechanism and sample clamping device. Among them, the motor 2 is fixed on the base 1, the eccentric mechanism includes an eccentric disc 4, an eccentric block 5 and a screw 22; the loading mechanism includes a front connecting rod 6, a push rod 8, a linear bearing 9, a tension pressure sensor 11, and a rear connecting rod Adapter block 12 and rear connecting rod 14; There is a through groove at the front end of the eccentric disk 4, and the lead screw 22 is installed in the through groove, and the lead screw 22 forms a threaded fit with the eccentric block 5, and the lead screw passes through the upper end cover 24 and The lower end cover 21 is installed on the ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com