Connecting device between a friction ring and a hub of a brake disk

A connecting device and friction ring technology, applied in the direction of brake components, brake discs, brake types, etc., can solve problems such as disc failure, and achieve the effect of great flexibility and looseness avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

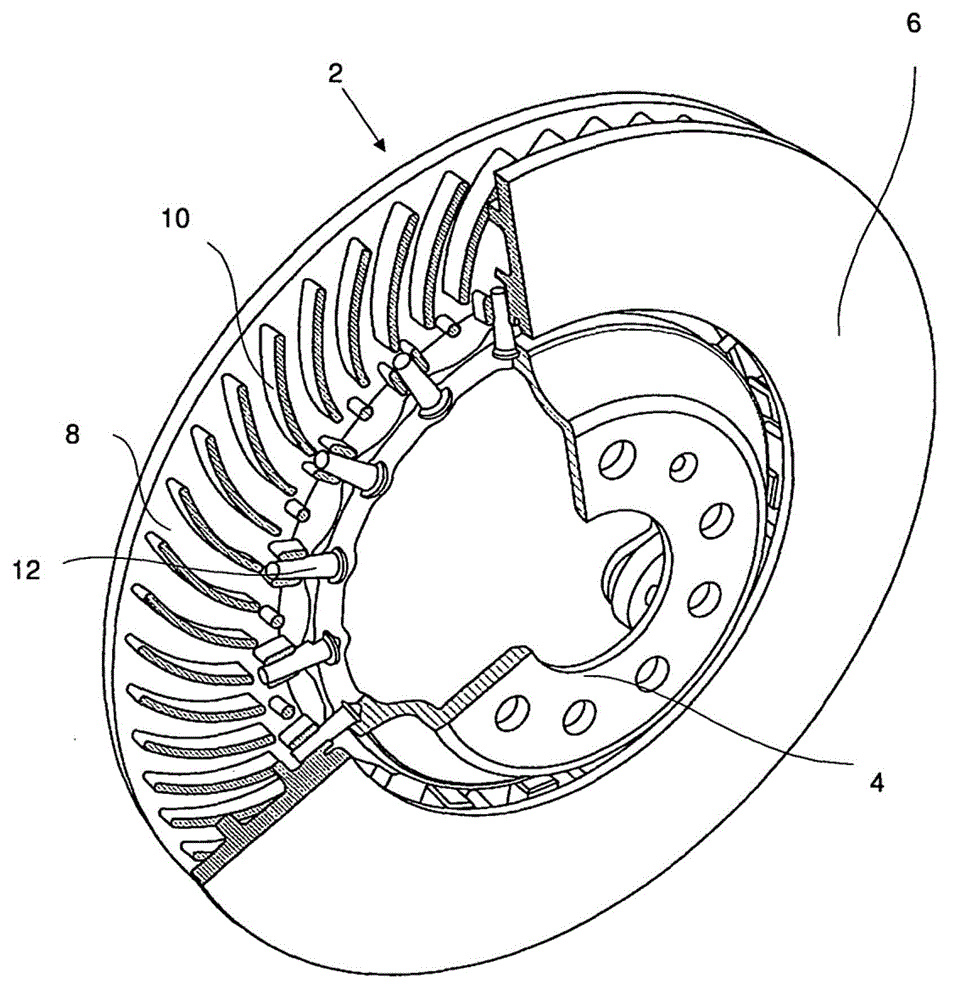

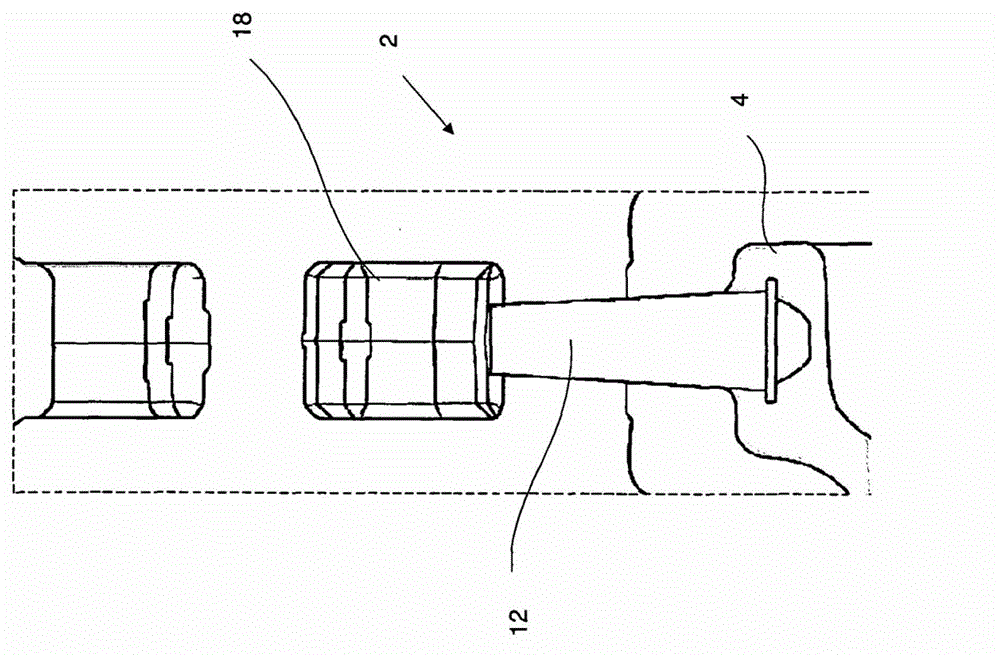

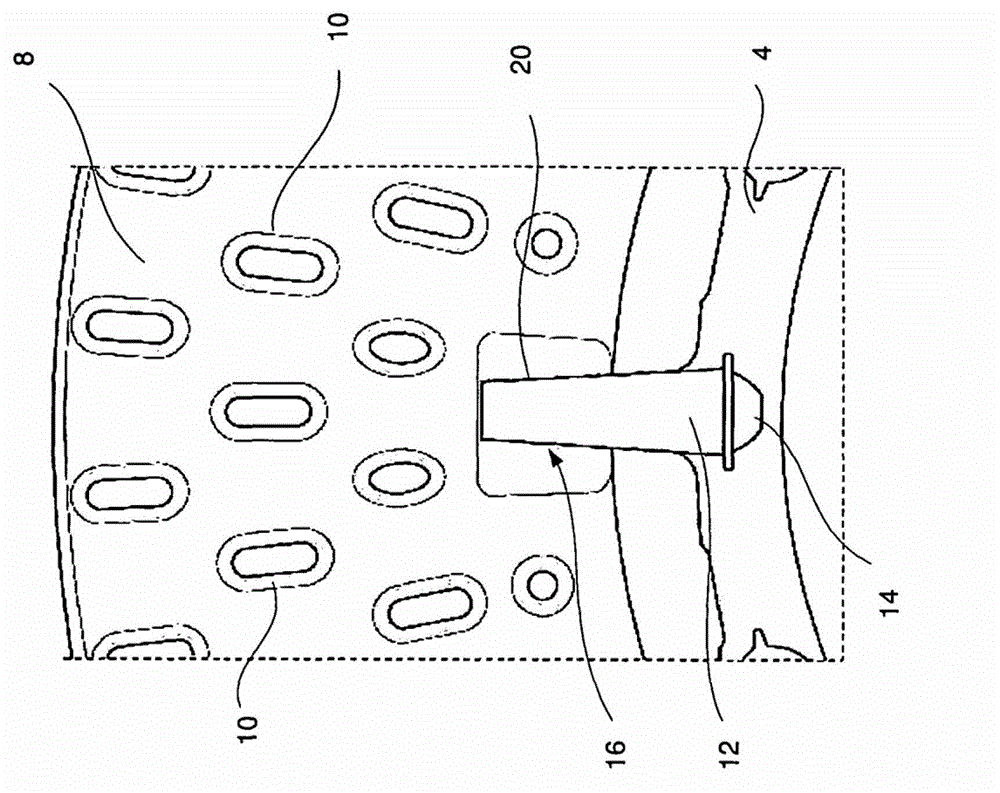

[0020] The figures show an exemplary embodiment of a connecting device according to the invention for a brake disc with a friction ring 2 and a carrier part 4 . as from figure 1 and image 3 As can be seen in , the friction ring 2 is composed of two friction ring halves, of which one friction ring half forms the outer wall 6 of the friction ring 2 and the other friction ring half forms the inner wall 8 . The two friction ring halves are connected to each other by laminations 10 which provide cooling of the brake disc during operation.

[0021] The connection between the friction ring 2 and the carrier part 4 is formed by a connecting part 12 which can be designed as a pin or as a small tube. As a result, the friction ring 2 is mounted floatingly on the carrier part 4 , whereby it can expand in the radial direction when the temperature increases. The anchoring of the connection part 12 in the carrier part 4 and the assembly of the friction disk as a whole is carried out in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com