An ultrasonic welding machine

An ultrasonic welding and ultrasonic technology, applied in the field of ultrasonic welding machines, can solve the problems of low universality of the clamping table and short life of the column cooling device, and achieve the effect of remarkable cooling effect, remarkable practicability and efficiency, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

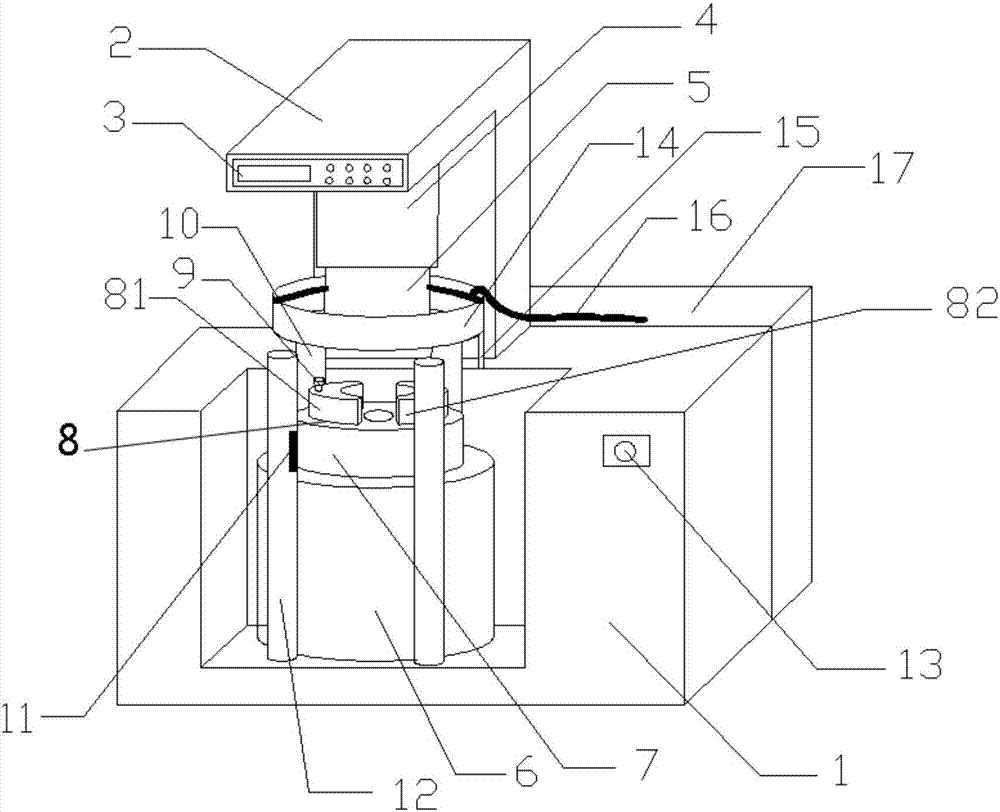

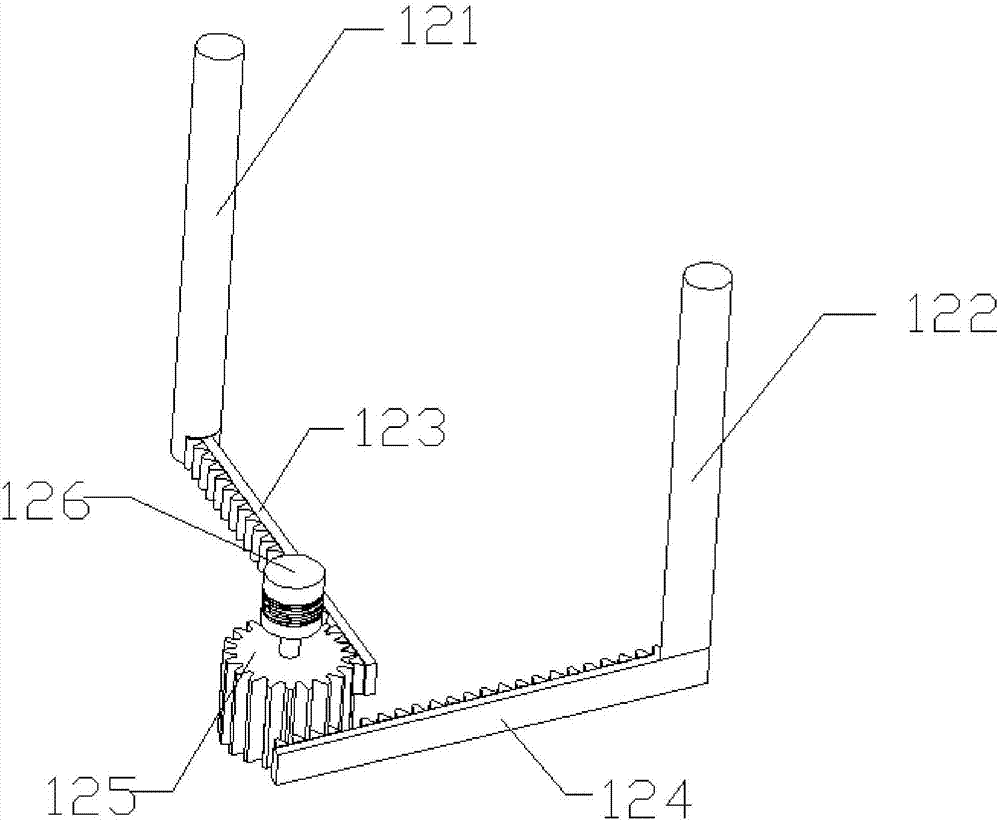

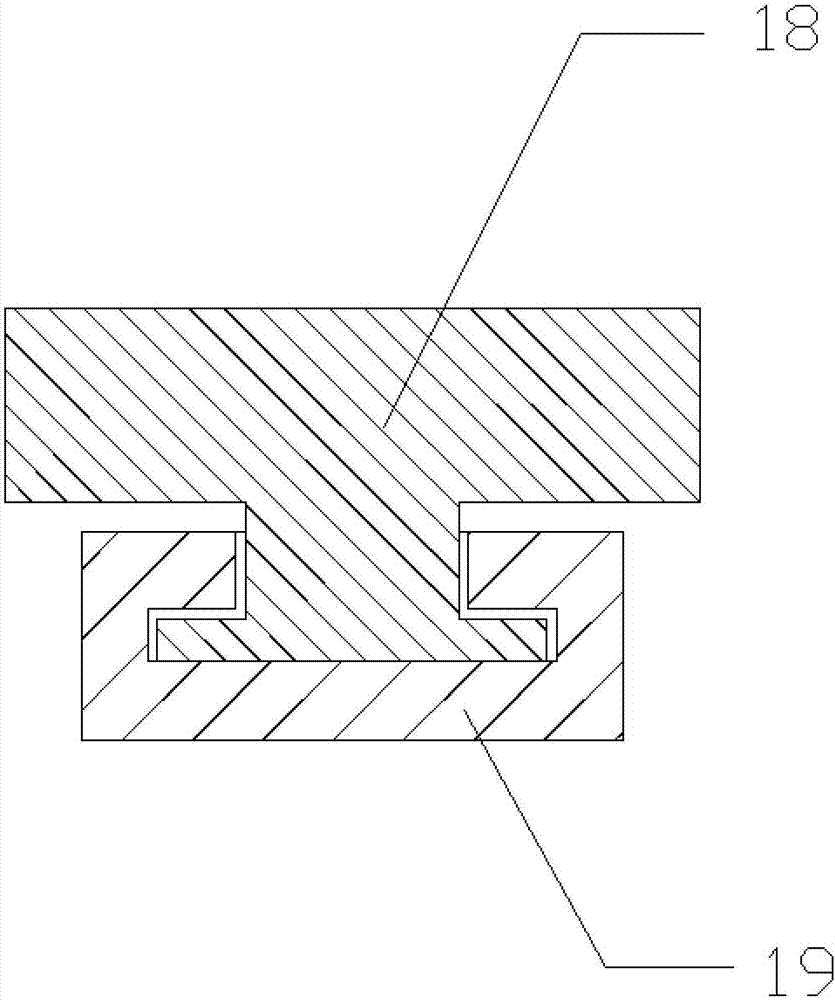

[0019] figure 1 Show the specific embodiment of the present invention: a kind of ultrasonic welding machine, comprise workbench 1, ultrasonic welding head 5, cooling device and clamping table 8, described workbench 1 upper surface is provided with welding head holder 2, welding head holder 2 The front side of the controller 3 is provided with a first cylinder 4, the lower part of the front side is slidingly connected with the ultrasonic welding head 5, the top of the ultrasonic welding head 5 is fixedly connected with the first cylinder 4, and the cooling device is arranged on the ultrasonic welding head 5 The periphery of the workbench 1 is a groove-shaped structure, the lower part of the groove-shaped structure is provided with a second cylinder 6, and the upper surface of the piston rod 7 of the second cylinder 6 is provided with a chute 19. The clamping table 8 is divided into a left clamping platform 82 and a right clamping platform 81, and the bottoms of the left clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com