Efficient and energy-saving concrete water reducing agent blending device

A concrete water reducer, high-efficiency and energy-saving technology, applied in the field of blending equipment, can solve the problems of increasing operating costs of enterprises, speeding up the uniform mixing of water reducing agents, and insufficient production efficiency, so as to reduce electricity costs and improve mixing uniformity , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

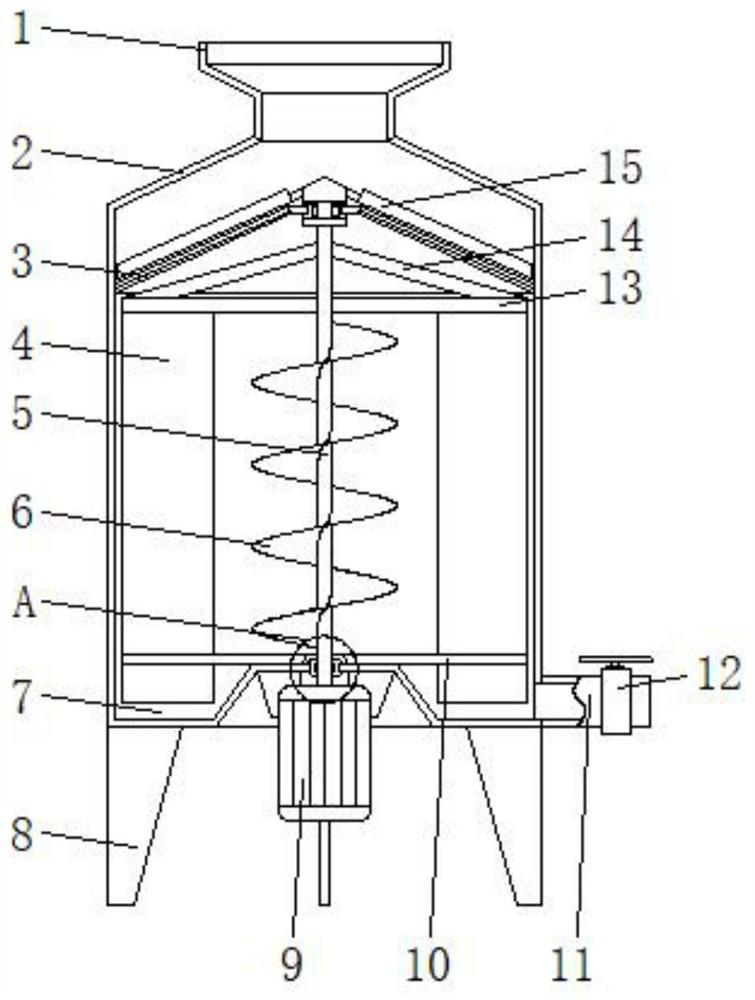

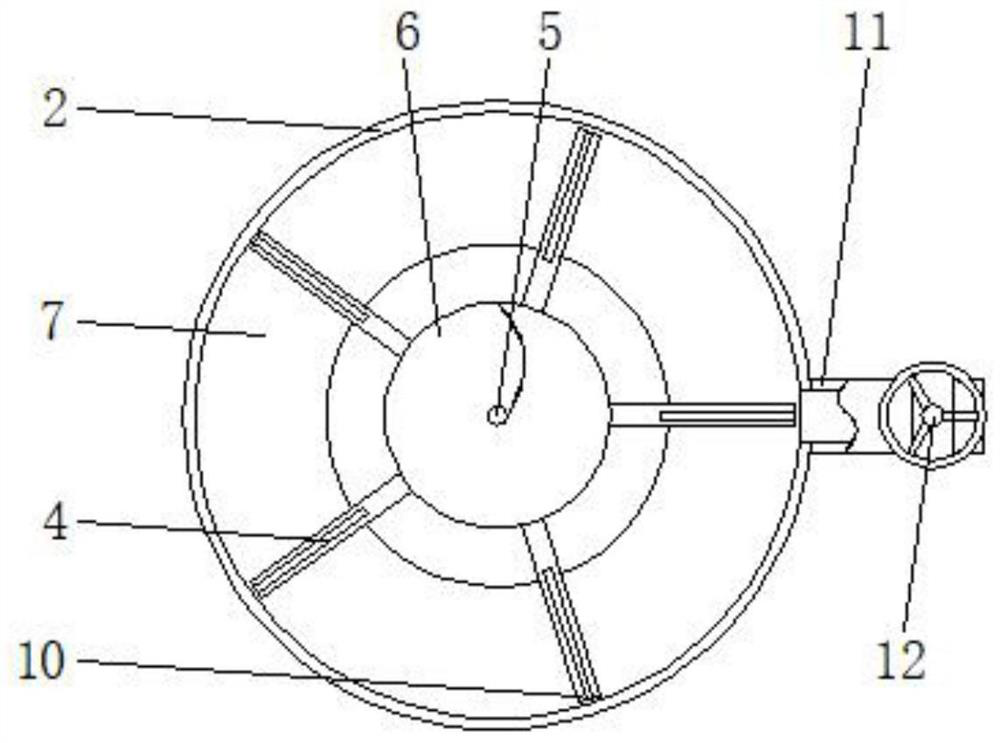

[0032] A high-efficiency and energy-saving concrete water-reducing agent mixing device, including a tank body 2, a grinding plate 3, a transmission shaft 5, a strand 6, a sedimentation tank 7, a first shaft sleeve 20 and a second shaft sleeve 23, and the upper surface of the tank body 2 A feed hopper 1 is provided, support legs 8 distributed in a circular array are welded on the lower surface of the tank body 2, a grinding plate 3 is arranged inside the upper end of the tank body 2, a sedimentation tank 7 is arranged inside the lower end of the tank body 2, and the bottom of the tank body 2 One side of the surface is provided with a discharge pipe 11, and the surface of the discharge pipe 11 is provided with a valve 12, and the discharge pipe 11 is connected with the interior of the sedimentation tank 7; the blended water reducer raw materials can be deposited in the sedimentation tank 7, and the staff The valve 12 can be opened, and the motor 9 drives the rotation of the mixin...

Embodiment 2

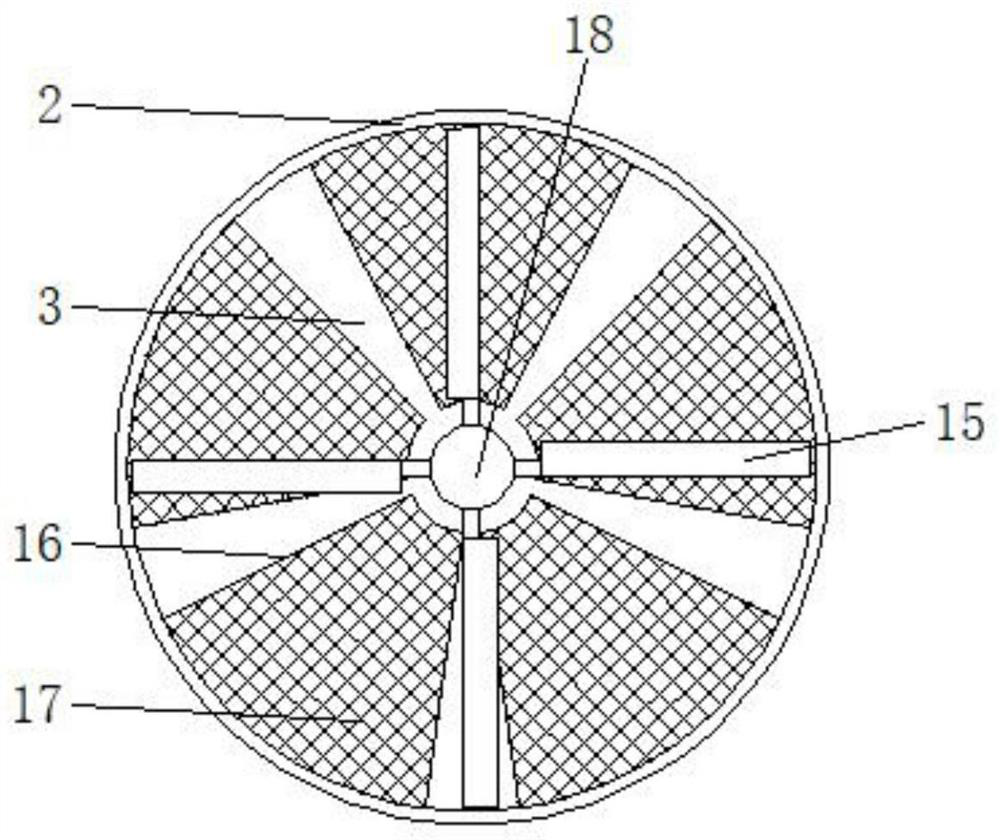

[0034] The lower surface of the tank body 2 is provided with a motor 9. As is well known to those skilled in the art, the provision of the motor 9 is commonplace, which all belong to conventional means or common knowledge, and will not be repeated here. Those skilled in the art can according to their needs or To facilitate optional matching, the upper surface of the motor 9 is provided with a drive shaft 5 that runs through the lower end of the tank body 2, and the upper end of the drive shaft 5 runs through the center of the grinding plate 3 and is connected to a first limit block 18, the outer wall of the first limit block 18 Stirring rods 15 distributed in a circular array are welded, and the surface of the transmission shaft 5 is provided with twisted pieces 6. When the transmission shaft 5 rotates, the materials around the transmission shaft 5 are transported upwards through the twisted pieces 6 and accumulated on the surface of the material layer. Therefore, the material ...

Embodiment 3

[0038] The surface of the grinding plate 3 is embedded with screens 17 distributed in a circular array, the circular position of the grinding plate 3 is embedded with a first bushing 20, the first bushing 20 is embedded with a first bearing 21, and the drive shaft 5 The upper end is rotatably inserted inside the first bushing 20 , and the outer wall of the upper end of the transmission shaft 5 is provided with a second limiting block 19 , and the first limiting block 18 and the second limiting block 19 are symmetrically distributed on both sides of the first bushing 20 . The first bearing 21 can ensure the smooth rotation of the transmission shaft 5 inside the first sleeve 20, reduce the mechanical wear of the transmission shaft 5, and the upper surface of the first limit block 18 adopts a tapered design, which can reduce the problem of material retention. And the first limit block 18 and the second limit block 19 block the gap between the transmission shaft 5 and the first sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com