Silver-plated electromagnetic shielding lining cloth and production process thereof

An electromagnetic shielding and production process technology, which is applied in the field of textile and post-processing production and processing, can solve the problems of poor wearing performance, unguaranteed shielding performance, and high cost, and achieve good oxidation resistance, good electromagnetic shielding function, and good wearing performance and shielding performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

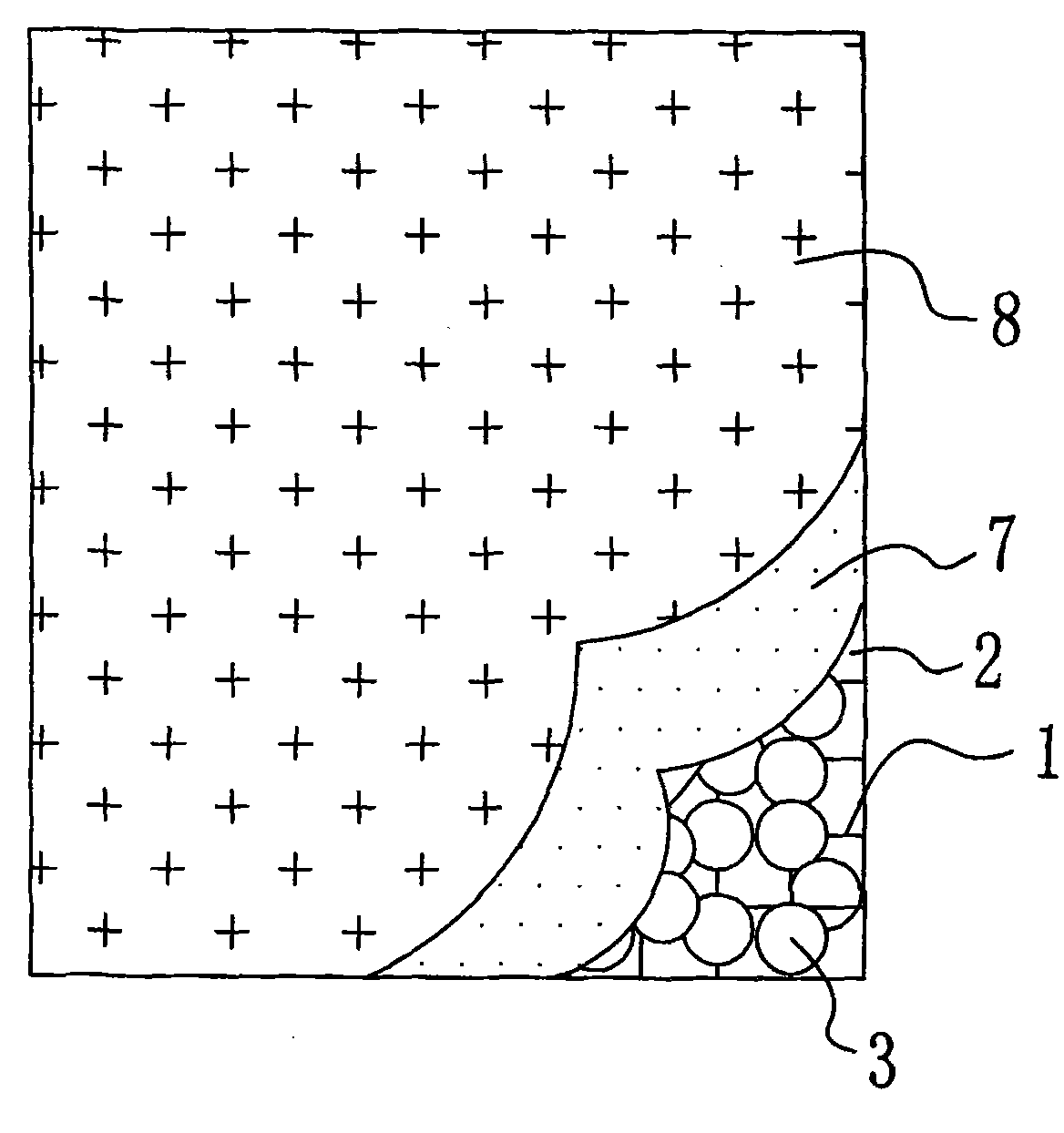

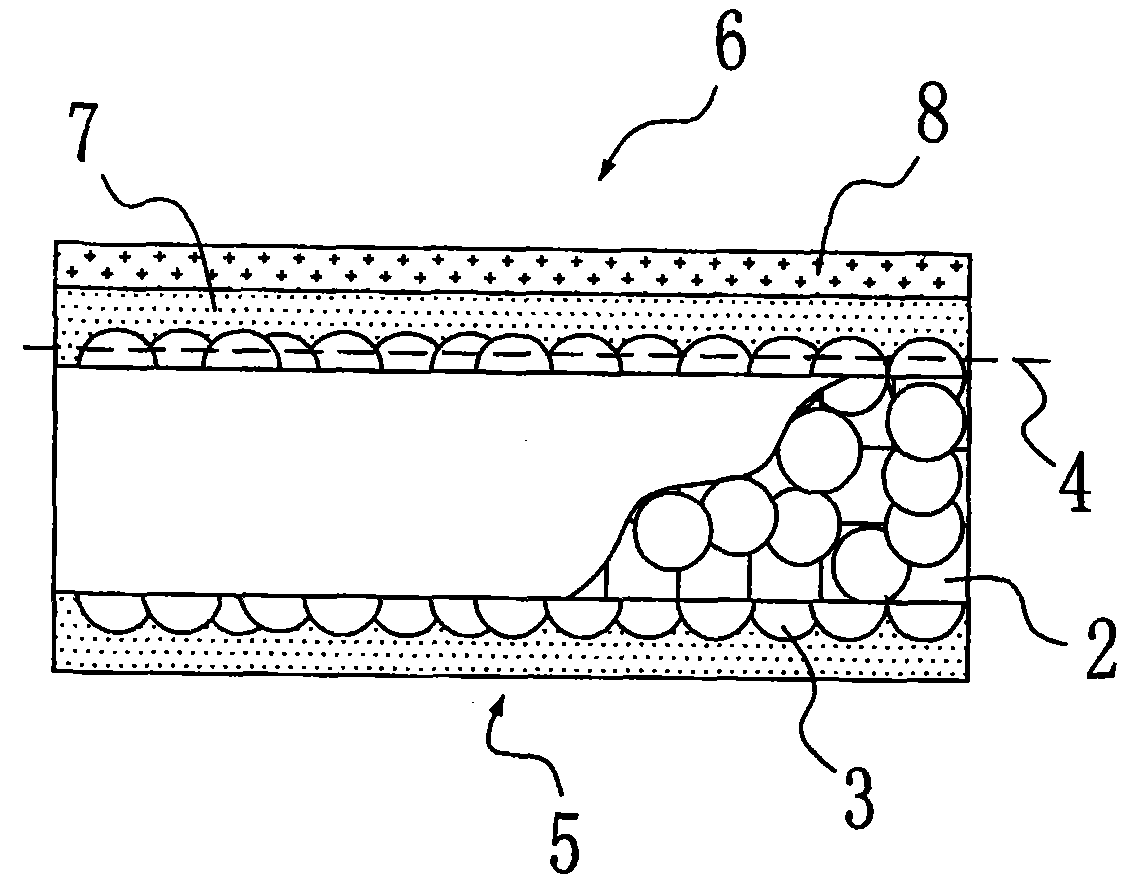

[0027] like figure 1 , 2 As shown, a silver-plated electromagnetic shielding interlining cloth includes a nylon fiber gray cloth 2 woven from a base layer nylon fiber 1, and a layer of uniform and fine silver particles 3 is plated on the nylon fiber gray cloth 2, and a plurality of silver particles 3 form a covering On the silver particle layer 4 on the nylon fiber gray cloth, the inner surface layer 5 and the outer surface layer 6 of the nylon fiber gray cloth 2 are all coated with one layer that can cover the silver particle layer 4 on the nylon fiber gray cloth 2 to prevent the silver particle layer 4 Oxidized protective layer7. The thickness of the protection layer 7 is set to be not lower than the standard of 5% of the decrease in electrical conductivity of the silver particle layer 4, and the protection layer 7 is one or more of solvent-based inorganic coating agents. At least one side of the nylon fiber gray cloth 2 is covered with a hot-melt adhesive layer 8 for bond...

Embodiment 2

[0039] Such as figure 1 , 2 As shown, a silver-plated electromagnetic shielding interlining cloth includes a nylon fiber gray cloth 2 woven from a base layer nylon fiber 1, and a layer of uniform and fine silver particles 3 is plated on the nylon fiber gray cloth 2, and a plurality of silver particles 3 form a covering On the silver particle layer 4 on the nylon fiber gray cloth, the inner surface layer 5 and the outer surface layer 6 of the nylon fiber gray cloth 2 are all coated with one layer that can cover the silver particle layer 4 on the nylon fiber gray cloth 2 to prevent the silver particle layer 4 Oxidized protective layer7. The thickness of the protective layer 7 is ≤0.01 μm. The protective layer 7 is one or several kinds of solvent-based nano-coating agents. At least one side of the nylon fiber gray cloth 2 is covered with a hot-melt adhesive layer 8 for bonding with ordinary fabrics, and the hot-melt adhesive layer 8 is covered on the surface of the protective ...

Embodiment 3

[0050] Such as figure 1 , 2 As shown, a silver-plated electromagnetic shielding interlining cloth includes a nylon fiber gray cloth 2 woven from a base layer nylon fiber 1, and a layer of uniform and fine silver particles 3 is plated on the nylon fiber gray cloth 2, and a plurality of silver particles 3 form a covering On the silver particle layer 4 on the nylon fiber gray cloth, the inner surface layer 5 and the outer surface layer 6 of the nylon fiber gray cloth 2 are all coated with one layer that can cover the silver particle layer 4 on the nylon fiber gray cloth 2 to prevent the silver particle layer 4 Oxidized protective layer7. The thickness of the protection layer 7 is set to be not lower than the standard of 5% of the decrease in electrical conductivity of the silver particle layer 4, and the protection layer 7 is one or more of solvent-based polymer coating agents. At least one side of the nylon fiber gray cloth 2 is covered with a hot-melt adhesive layer 8 for bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com