Lacrosse net

a technology of lacrosse nets and lacrosse sticks, which is applied in the field of lacrosse nets, can solve the problems of increasing the feasibility of scaling-up the process, and achieve the effects of increasing the coefficient of friction, increasing the elasticity, and increasing the adheren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

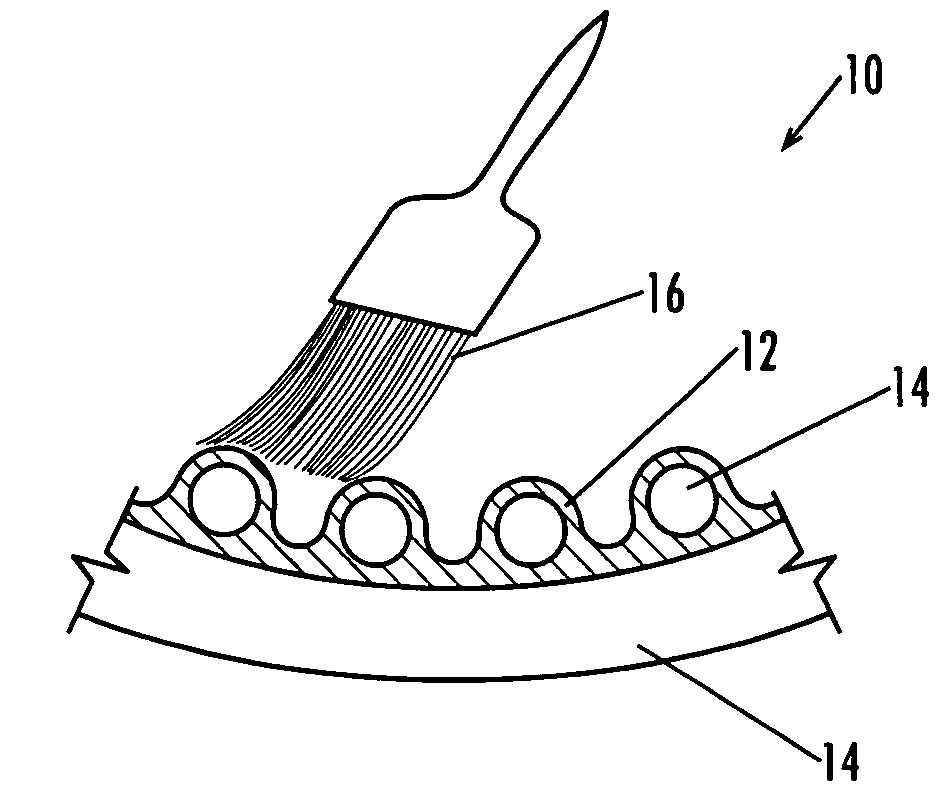

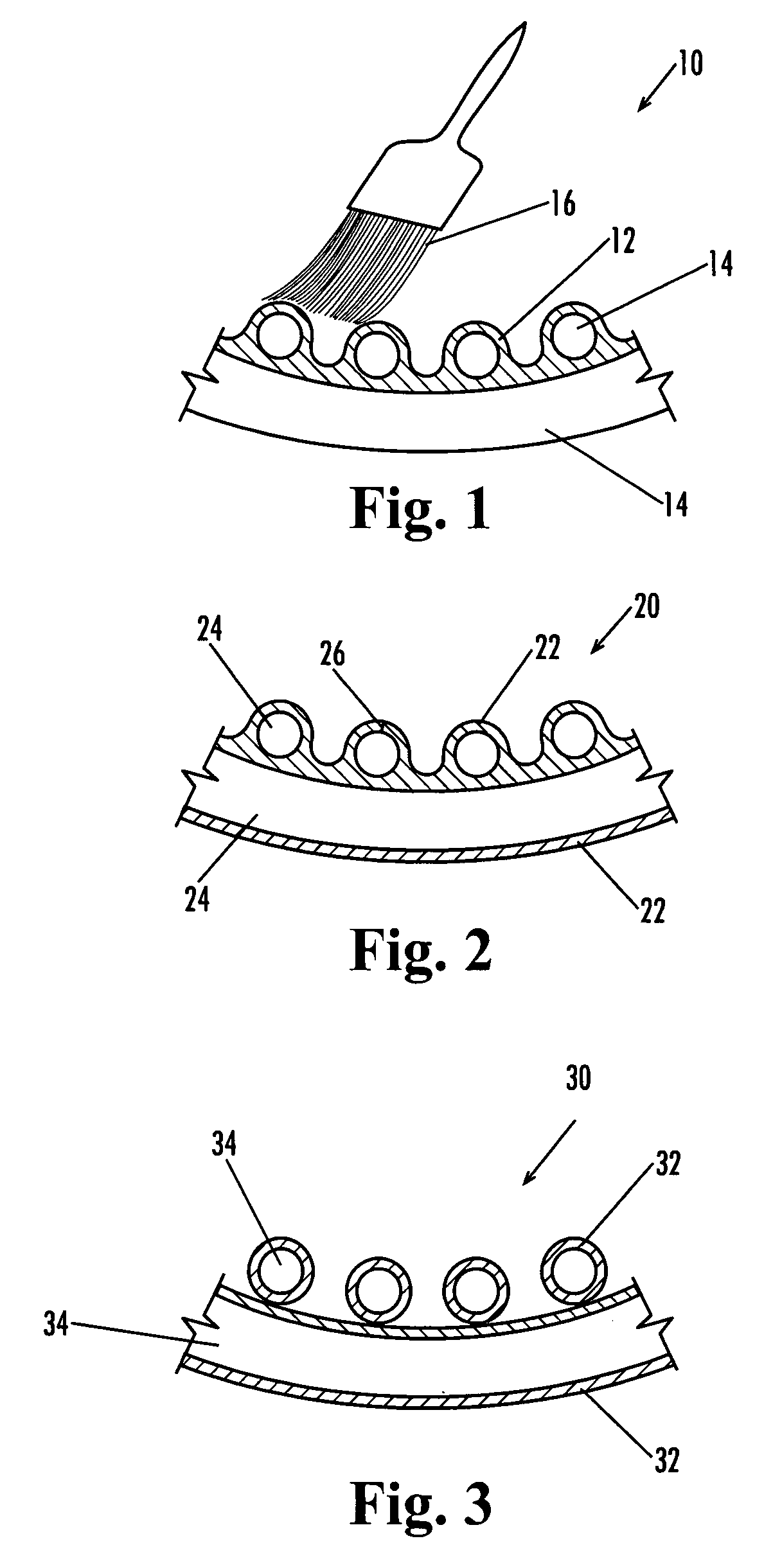

[0017]Referring now to the drawing, and in particular to FIG. 1, a modified form of a lacrosse net according to the present invention, referred to generally by reference numeral 10, provides increased adherence, integrity, and “give” as a result of a coating 12 applied to the fibers 14 on one side applied by brush 16. In one form, the fibers are manually coated by brushing them with a natural latex mixture followed by evaporation of the volatile components. Natural latex is essentially a mixture of small natural rubber particles suspended in water with the aid of a surfactant. When the aqueous media is evaporated after application, the remaining coating is composed largely of natural rubber, which in addition to providing the expected, albeit small (due to the integrity of the underlying nylon fibers), increase in elasticity, also yields a fiber finish with an increased coefficient of friction, giving rise to the “tacky” feeling that results in increased ball control. It is importan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com