Multi-degree-of-freedom stiffness variable pneumatic operation operating arm and manufacturing method

A technology of surgical operation and manufacturing method, applied in the field of multi-degree-of-freedom variable stiffness pneumatic surgical operating arm and manufacturing, can solve problems such as insufficient rigidity, difficulty in applying operating force, and low degree of freedom of movement, so as to reduce the number and size of wounds, Reduces rigid damage and increases the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

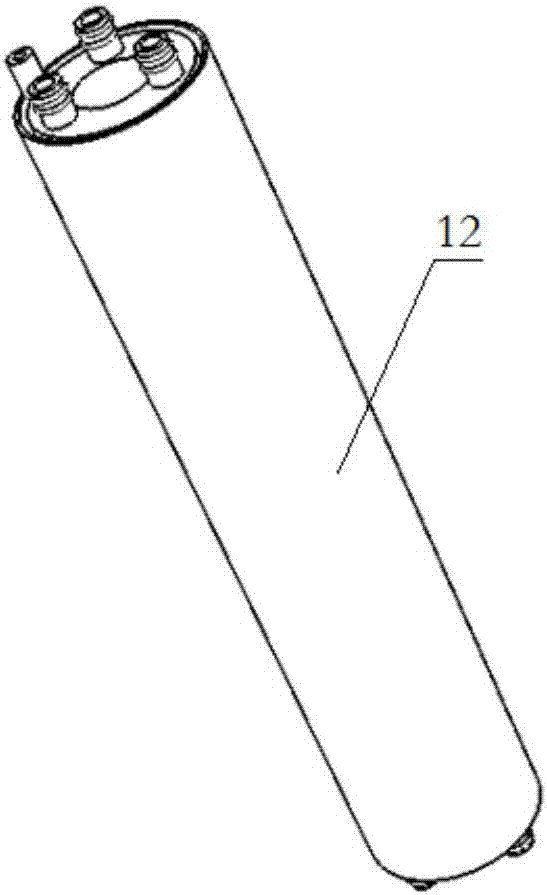

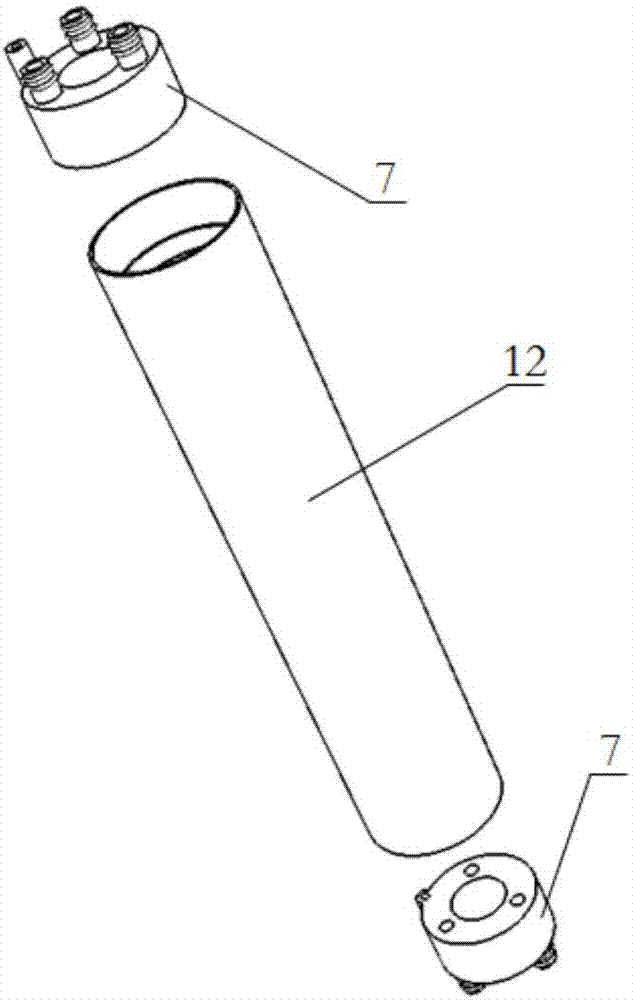

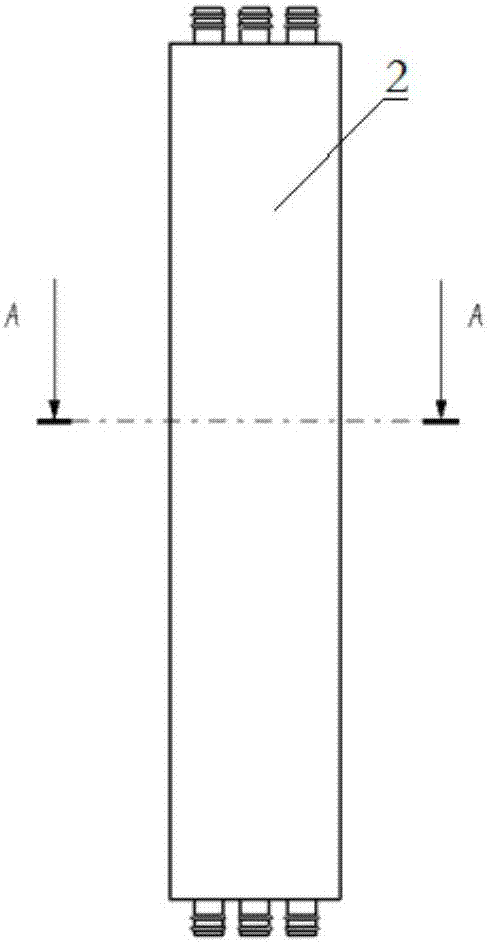

[0040] see Figures 1 to 14 , a multi-degree-of-freedom stiffness-variable pneumatic surgical manipulator, comprising several joints of the same pneumatic driver unit, the pneumatic driver unit includes a cylindrical driver, the two ends of the driver are connected with a base 7, and the driver includes an external stiffness adjustment layer 2. The stiffness adjustment layer 2 is provided with a drive layer 1 inside. The drive layer 1 includes a circular cylindrical silicone rubber layer 3 with a through hole 10. Several cavities 4 are opened on the silicone rubber layer 3. The inner surface of the silicone rubber layer 3 covers There is a PDMS layer 5, the outer surface of the silicone rubber layer 3 is covered with double-helix nylon fibers 6, the base 7 is provided with an air hole 8 corresponding to the cavity 4, and a vacuum port 13 corresponding to the stiffness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com