Laminated board hot-pressing device

A technology of hot pressing equipment and veneer, which is used in veneer presses, plywood presses, and the joining of wooden veneers, etc. It can solve the problems of low temperature of heat transfer oil, unenvironmental protection, and unstable heating effect of heat transfer oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

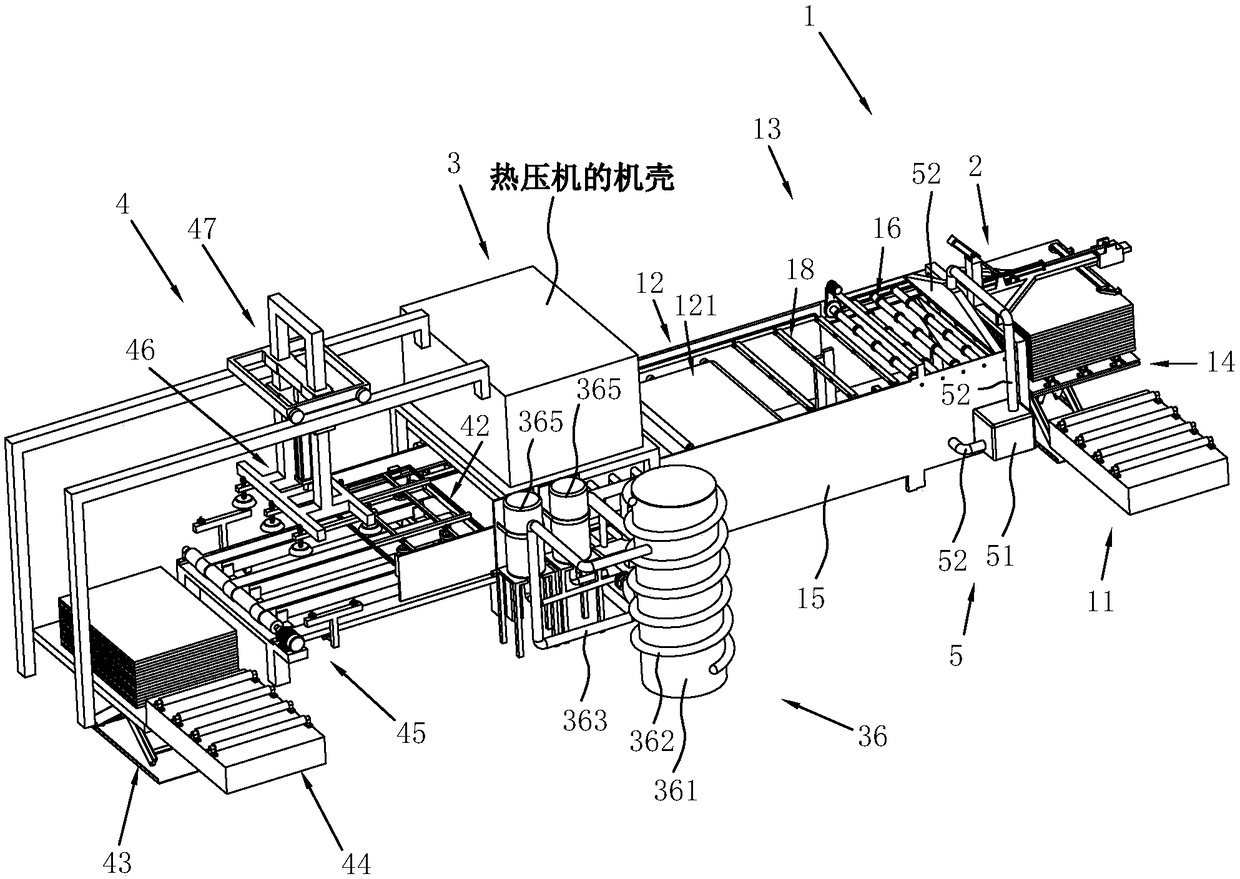

[0032] Embodiment 1: a kind of veneer hot pressing equipment, such as figure 1 Shown, comprise heat press machine 3, be used for discharging wood-based panel and decorative fabric and the feeding device 1 that discharges good wood-based panel and decorative fabric is delivered to heat press machine 3, and be used for the veneer panel that heat presses is good from The receiving device 4 delivered by the hot press 3.

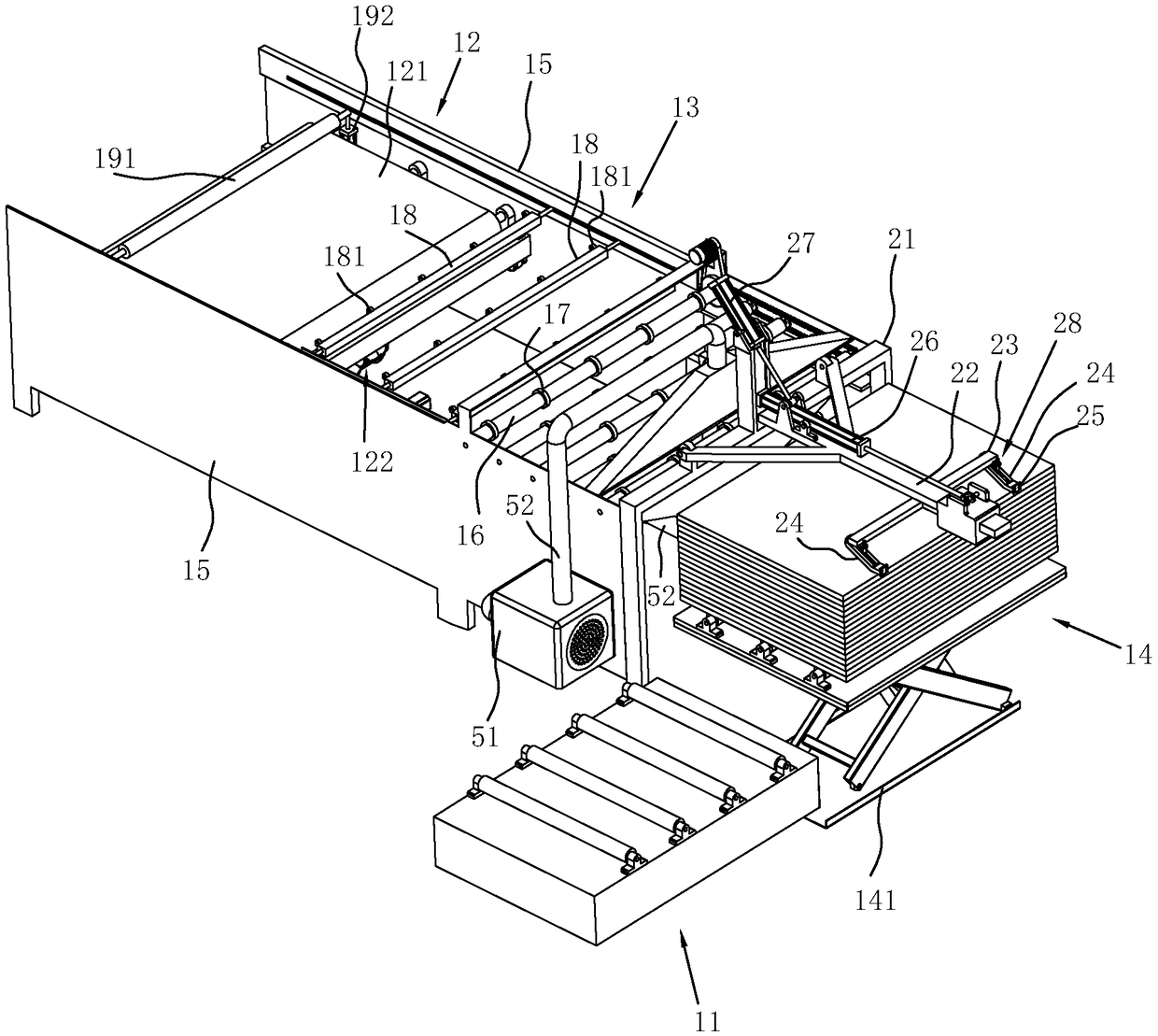

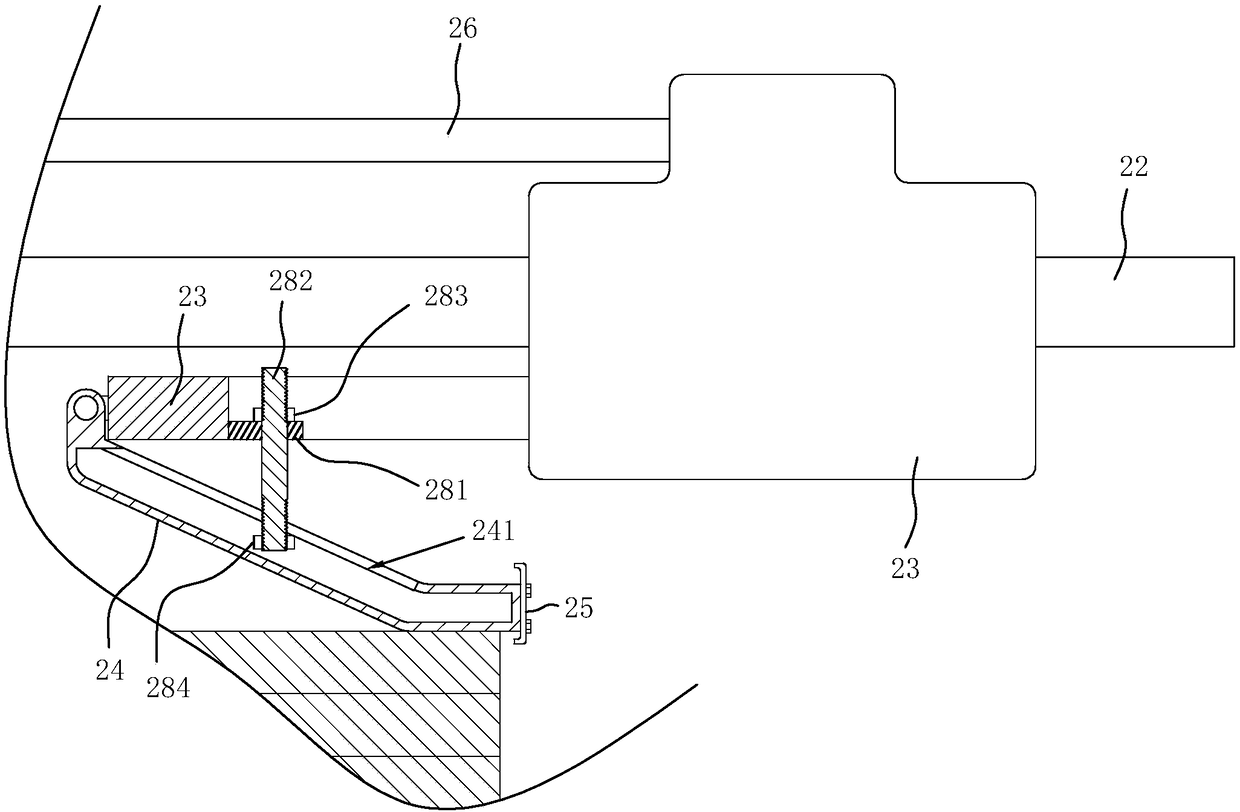

[0033] combine figure 2, the feeding device 1 includes a fixed table 11 placed on the ground and used for stacking wood-based panels, a discharge table 12 for providing operators with places for placing decorative fabrics above and below the wood-based panels, and a discharge table 12 for transferring the wood-based panels to the discharge The delivery platform 13 on the platform 12, the lifting platform 14 for raising the wood-based panel at the top to the delivery platform 13 top, and the drive mechanism 2 for driving the wood-based panel at the top of the li...

Embodiment 2

[0049] Embodiment 2: a kind of veneer hot pressing equipment, the difference with embodiment 1 is, such as Figure 6As shown, the lifting and pressing mechanism 35 used to drive the upper heat press table 32 to move up and down and apply pressure to the wood-based panel is a servo valve 352, and the model of the servo valve 352 is HVM056. Wherein the casing of the servo valve 352 is fixedly connected with the casing of the hot press machine 3 ; one end of the slide valve of the servo valve 352 is fixedly connected with the top of the upper hot pressing table 32 . The servo valve 352 has high displacement precision and fast response speed, which can improve the heat pressing effect of the heat press machine 3 .

[0050] Working process: After placing a pile of wood-based panels on the fixed platform 11, manually push the wood-based panels on the fixed platform 11 to the lifting platform 14. Then the driving mechanism 2 and the transmission platform 13 transmit the single wood-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com