Complete production equipment for laminated veneer lumbers

A technology for veneer laminates and production equipment, which is applied in the joining of wooden veneers, veneer presses, plywood presses, etc., which can solve the problem that the quality of veneer laminates cannot be guaranteed, waste of raw materials, and production efficiency. Low problems, to achieve the effect of saving equipment investment, saving labor, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

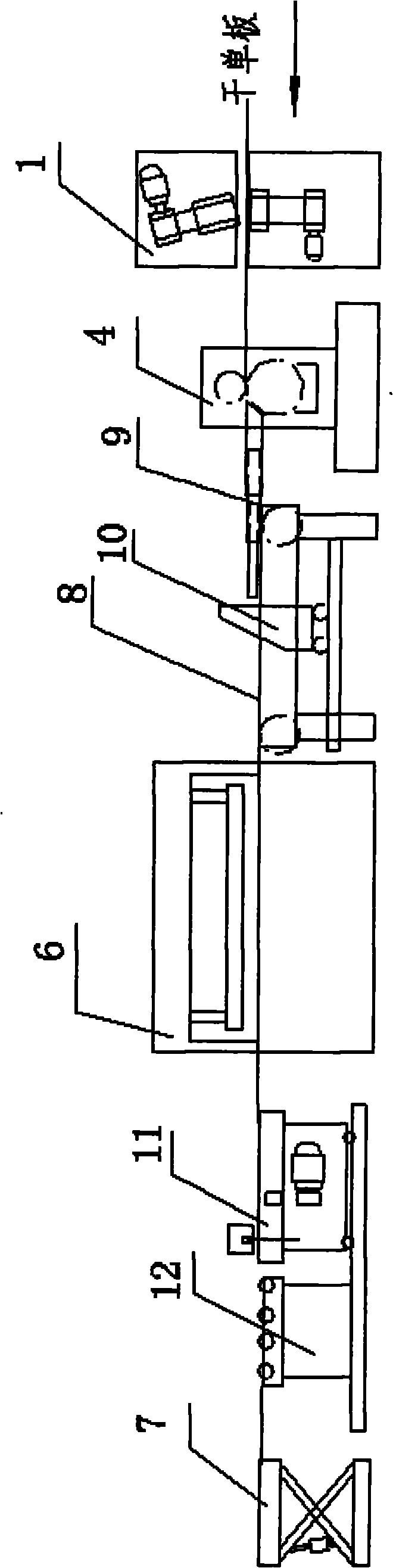

[0030] Figure 4 It is a schematic structural diagram of an embodiment of the present invention.

[0031] like Figure 4 Shown: complete set of production equipment for laminated veneer, including belt bevel milling machine 1, gluing machine 4, retractable feeder 9, CNC positioning blanking machine 10, veneer pre-pressing machine 6, mobile cutting saw 11. Conveying roller 12, material storage table 7 and multi-layer hot press (not shown in the figure), among which, abrasive belt oblique milling machine 1, gluing machine 4, retractable feeder 9, CNC positioning blanking machine 10 , a veneer pre-pressing machine 6, a mobile cutting saw 11, a conveying roller 12, a storage table 7 and a multi-layer hot-pressing machine are connected in line, and a production line is formed through the operating platform 8, and the above-mentioned retractable feeder 9 includes multiple In this embodiment, there are two telescopic plates, and one end of the telescopic feeder 9 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com