Method of isolating column loading and mitigating deformation of shaped metal vessels

a technology of metal vessels and isolating columns, which is applied in the field of isolating columns and mitigating deformation of shaped metal vessels, can solve the problems of high column load, increased packaging cost, and increased packaging cost,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]A. Shaped Metal Vessel

[0028]A shaped metal vessel is used in the present invention. Details of such shaped metal vessels can be found in the co-pending patent application entitled “SHAPED METAL VESSEL”, inventor John E. Adams et al., which was filed concurrently with the present application and is incorporated herein by reference in its entirety.

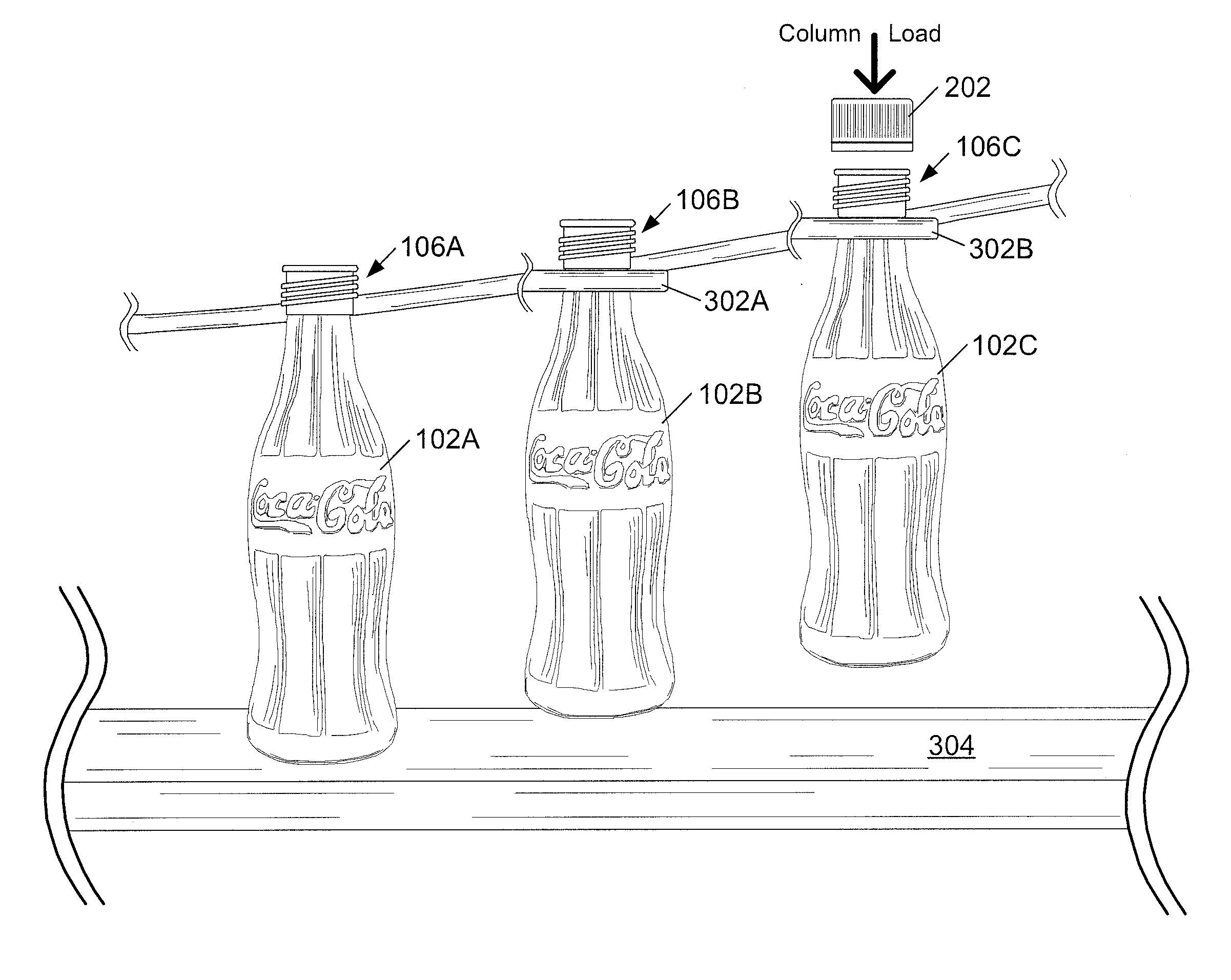

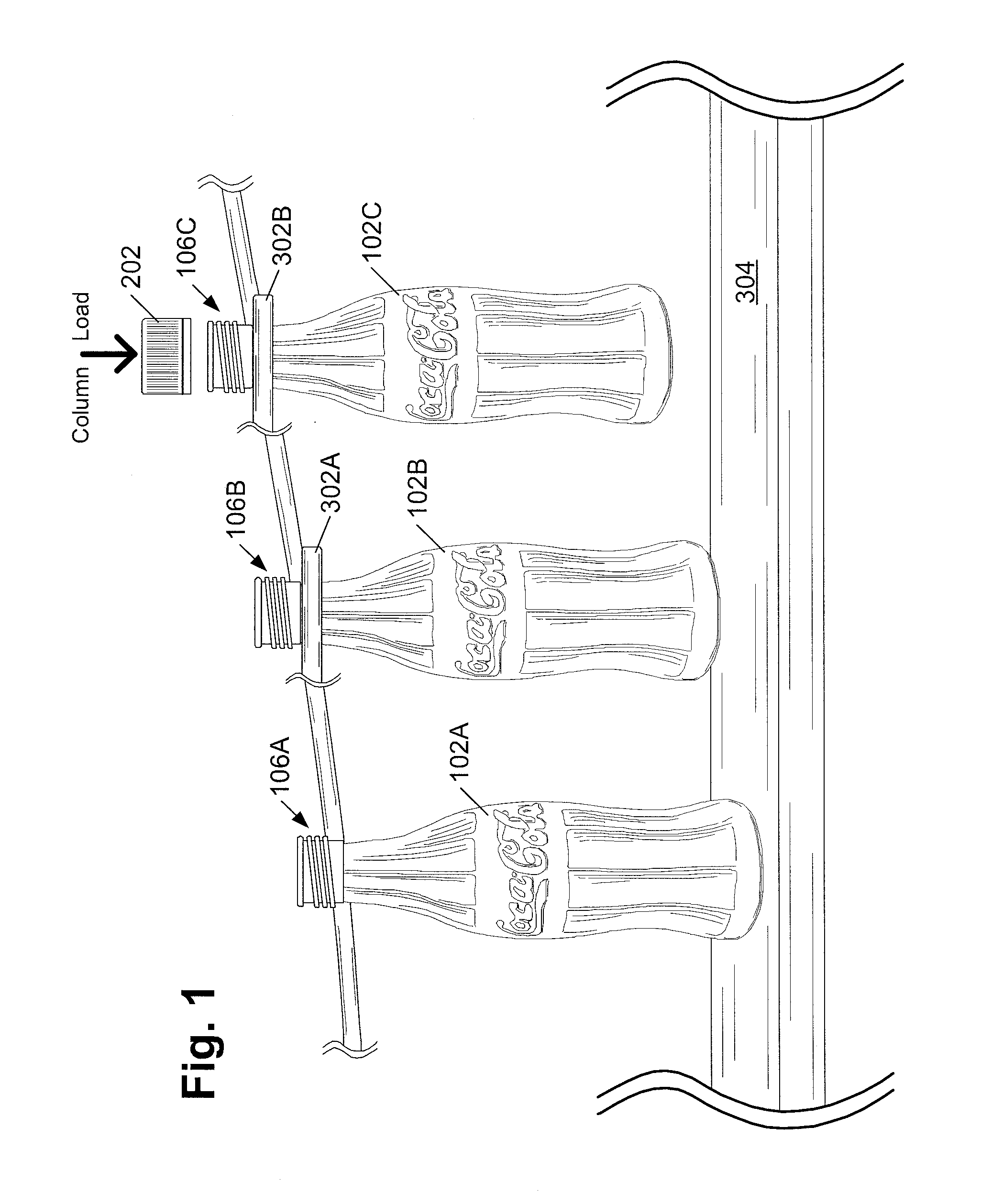

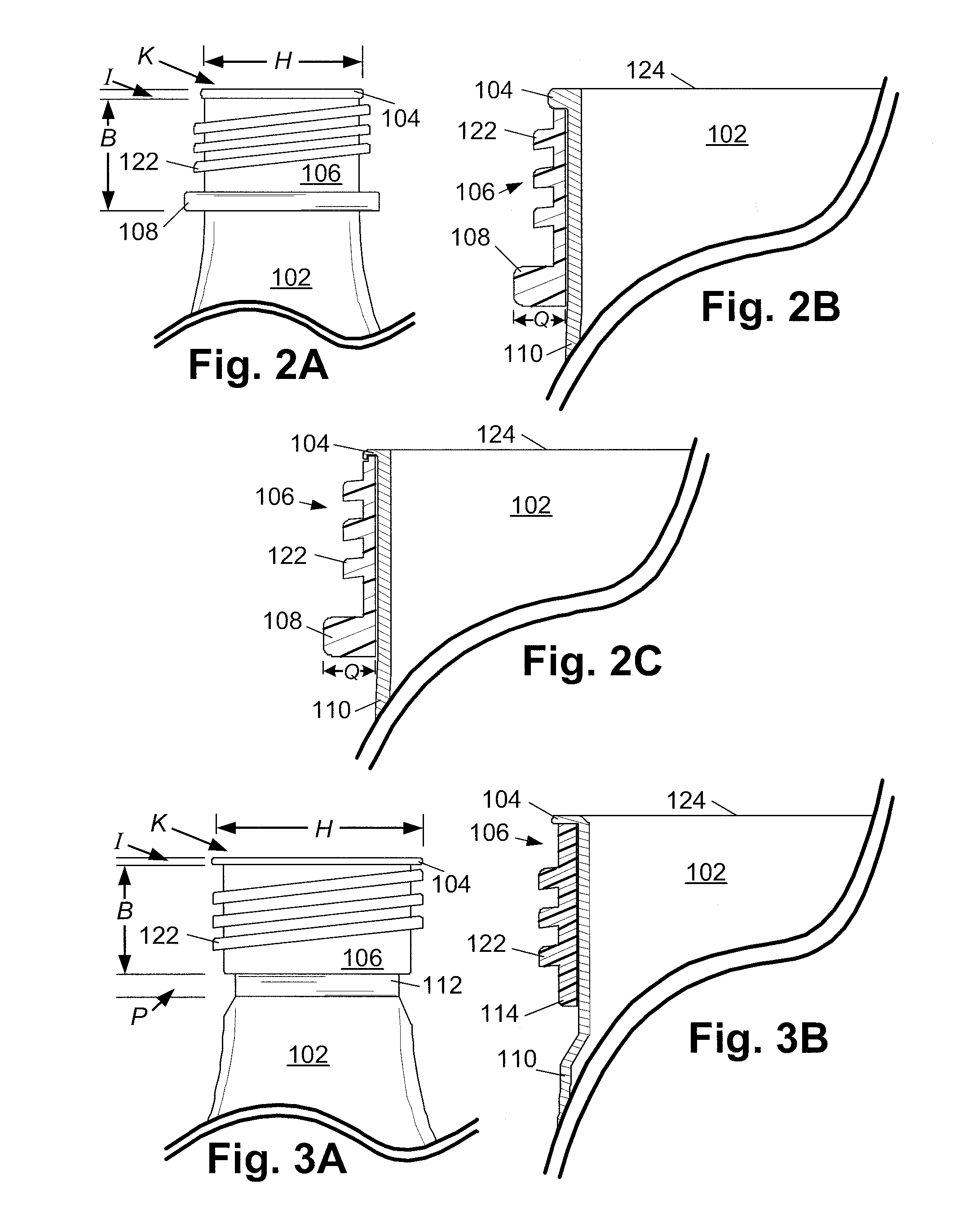

[0029]Turning now to the drawings in greater detail, it will be seen that in FIG. 1 there is illustrated one example of a system and method of isolating column loading and mitigating deformation of shaped vessels during fill and or closure application. In an exemplary embodiment, a plurality of shaped vessels 102A-C comprising outsert 106A-C can be formed by way of a plurality of cylindrical tubes and conveyed on a carrier 304. A carry ring can then be formed and or added to shaped vessel 102A-C. A carry ring support 302A-B can be used to support the shaped vessel during fill and or application of a closure 202. In this regard, a colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com