Mo-contained stainless steel welding strip, preparation method thereof, sintered flux, preparation method thereof and single-layer electrode electroslag surfacing method

A technology of sintering flux and stainless steel, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as low welding efficiency, high material cost, and easy side bending and cracking of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

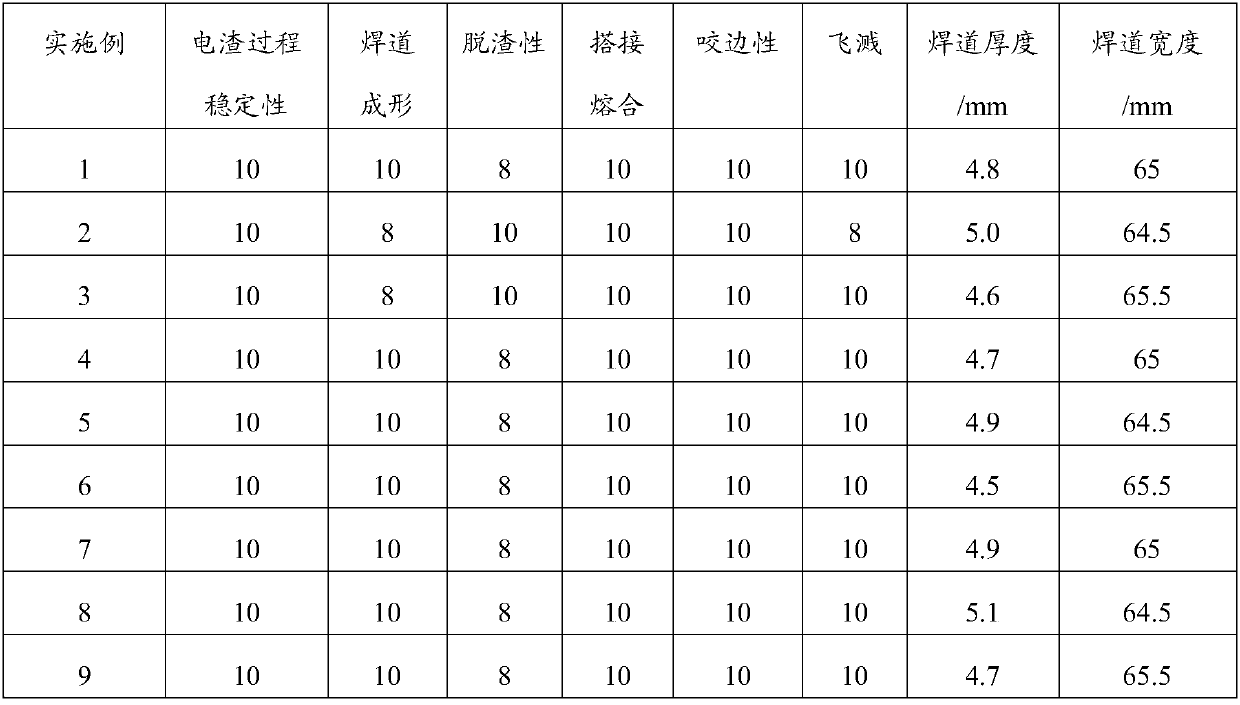

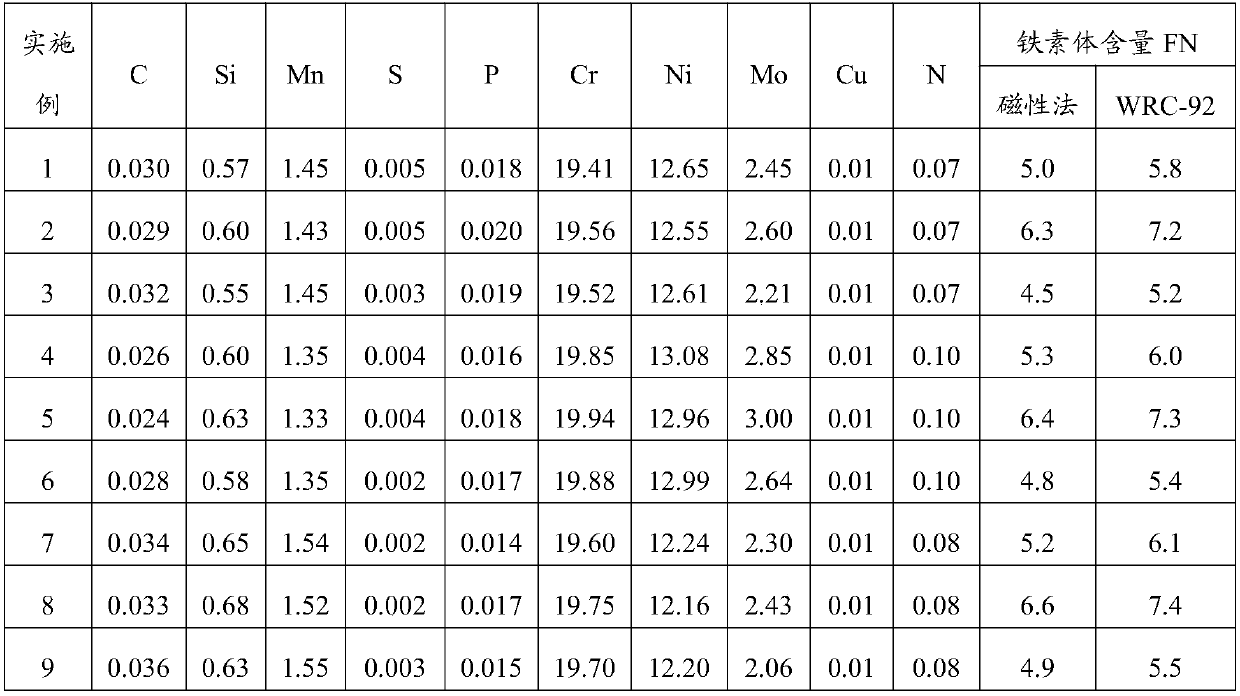

Examples

preparation example Construction

[0023] The present invention provides the preparation method of the Mo-containing stainless steel welding strip described in the above technical solution, comprising the following steps:

[0024] The raw materials corresponding to the Mo-containing stainless steel welding strip components described in the above technical solution are mixed and melted, and then the obtained molten material is sequentially cast, forged and rolled to obtain the Mo-containing stainless steel welding strip.

[0025] In the present invention, raw materials corresponding to the components of the Mo-containing stainless steel welding strip are mixed and melted to obtain molten material. In the present invention, the mixing and melting temperature is preferably 1580-1630°C, more preferably 1520-1560°C; the mixing and melting time is preferably 60-120 minutes, more preferably 65-80 minutes.

[0026] After the molten material is obtained, the present invention sequentially performs casting, forging and r...

Embodiment 1

[0044] Provide raw materials according to the component numbered H316LF-1 in Table 1, mix the raw materials and melt at 1600°C for 80 minutes, then cast the molten material at 1600°C to obtain a cast body; forge the obtained cast body at 1200°C 3000×240×95mm rough, and then rolling at 1200°C, after each rolling, the thicknesses are 3.2mm, 1.8mm, 1.1mm, 0.65mm and 0.5mm respectively, and the thicknesses are 1.8mm, 1.1mm and 0.65 mm is annealed, the annealing temperature is 1050 ℃, and the thickness is 0.5mm, and the width is 60mm.

[0045] The raw materials are provided according to the component numbered SJ15F-1 in Table 2, wherein the mass ratio of Mo and Ni in the alloy agent is 1:1.5; the raw materials are mixed, granulated, and then sintered at 800 ° C to obtain a particle size of 10 ~60 mesh sintered flux.

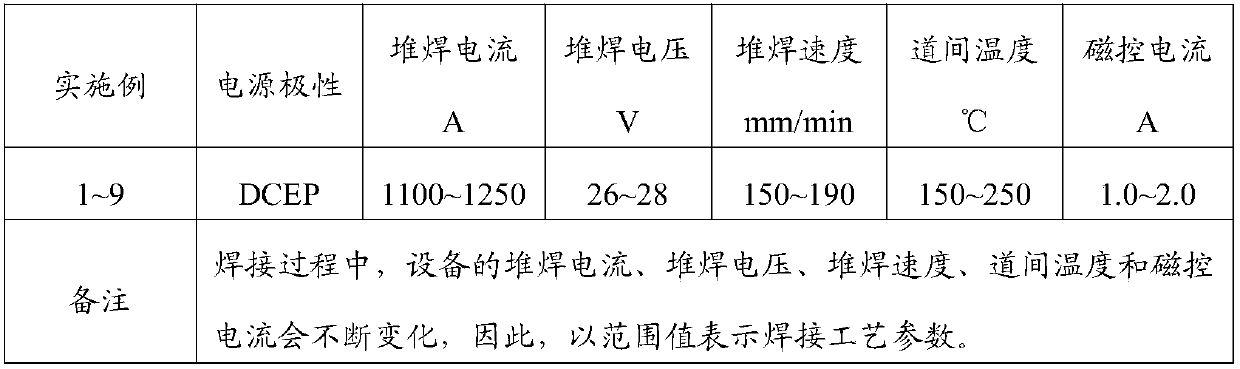

[0046] Welding is carried out according to the process parameters shown in Table 3.

Embodiment 2

[0048] The components of the welding strip and its preparation method are the same as in Example 1. The raw materials of the sintered flux are shown in Table 2 as SJ15F-2. The mass ratio of Mo and Ni in the alloy is 1:1.5, and the sintering temperature is 800°C. A sintered flux with a particle size of 10-60 meshes was obtained; the welding parameters are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com