Plunger for compressor pump body, production method thereof as well as compressor and refrigeration equipment

A compressor pump and refrigeration equipment technology, applied in the field of compressors, can solve problems such as large loss of volumetric efficiency of the whole machine, compressor operation failures, and gap changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

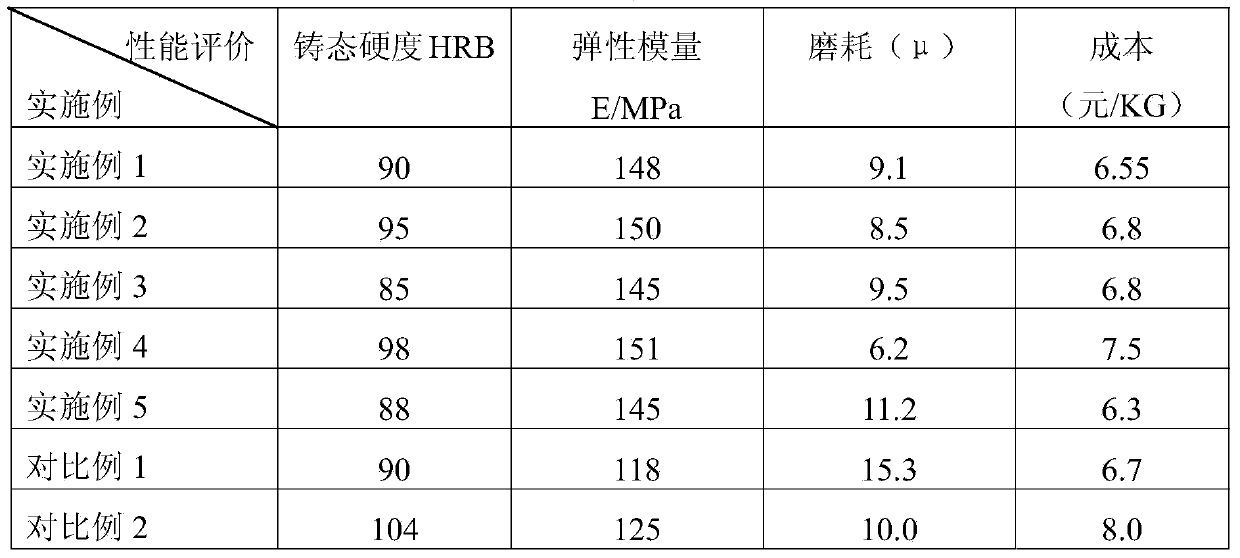

Examples

Embodiment 1

[0060] Preparation of pistons for compressor pump body, matching smelting raw materials: 1.8Kg of C; 1.3Kg of Si; 0.3Kg of Mn; 0.25Kg of Cu and 47Kg of iron, containing 0.05% by weight of P, 0.03% by weight The S. After mixing, heat in an induction furnace to melt at 1500-1520 degrees Celsius to obtain mixed molten iron; add 0.25Kg of rare earth zinc-magnesium-aluminum alloy to the mixed molten iron for vermicularization treatment; pour the vermisified mixed molten iron, In order to obtain crude pistons; the content ratio of pearlite and ferrite in the obtained crude pistons is (40-60): (60-40). The crude piston is further subjected to rough machining, heat treatment (quenching-tempering treatment) and finishing, so as to obtain a piston for a compressor pump body.

Embodiment 2

[0062] Prepare pistons for compressor pump body, select smelting raw materials: 1.6Kg of C, 1.0Kg of Si; 0.2g of Mn; 0.5Kg of Cu and 47Kg of iron, containing 0.3% by weight of P, 0.01% by weight of S . After mixing, heat to 1500-1520 degrees Celsius in an induction furnace to melt to obtain mixed molten iron; add 0.15Kg of rare earth zinc-magnesium-aluminum alloy to the mixed molten iron for vermicular treatment; cast the mixed molten iron after vermicular treatment , so as to obtain the crude piston; the content of pearlite in the obtained crude piston is 80-85%. The crude piston is further subjected to rough machining, heat treatment (quenching-tempering treatment) and finishing, so as to obtain a piston for a compressor pump body.

Embodiment 3

[0063] Example 3 Preparation of piston for compressor pump body, matching smelting raw materials: 1.9Kg of C, 1.5Kg of Si; 0.5Kg of Mn; 0.5Kg of Cu and 47Kg of iron, which contains 0.3% by weight of P, 0.06% by weight % of S. After mixing, heat in an induction furnace to melt at 1500-1520 degrees Celsius to obtain mixed molten iron; add 0.2Kg of rare earth zinc-magnesium-aluminum alloy to the mixed molten iron for vermicularization treatment; pour the vermisified mixed molten iron, In order to obtain crude pistons; the content of ferrite in the obtained crude pistons is 60-65%. The crude piston is further subjected to rough machining, heat treatment (quenching-tempering treatment) and finishing, so as to obtain a piston for a compressor pump body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com