High-zinc leadless brass alloy and preparation method thereof

A zinc-lead-free brass and alloy technology, applied in the field of high-zinc lead-free brass alloy and its preparation, and environmentally friendly green metal materials, can solve the problems of difficult to obtain wide promotion and application, high cost, etc., and achieve excellent cooling and heating Processability, low cost, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

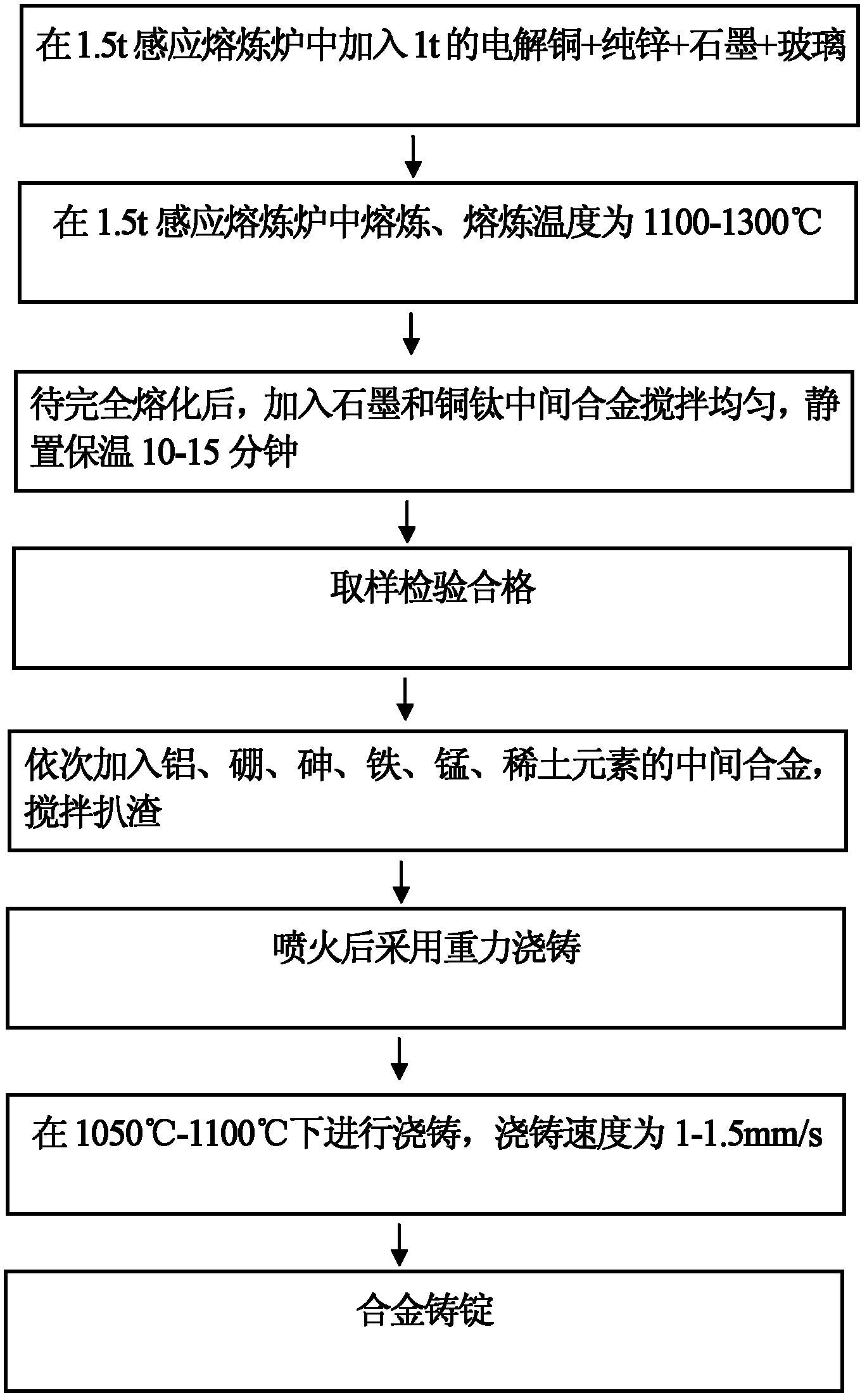

Embodiment 1

[0035] According to the alloy composition described in Table 1, the copper-zinc alloy is smelted first, and the smelting temperature is 1170 ° C. After it is completely melted, add graphite and copper-titanium intermediate alloy and stir evenly. After standing for 12 minutes, add aluminum, Master alloys of boron, arsenic, iron, manganese, and rare earth elements, wherein aluminum, arsenic, iron, and rare earth elements are added in the form of zinc master alloys, and boron and manganese are added in copper master alloys. In the master alloys, copper or zinc The mass fractions are all 80-90%. The slag is removed by stirring, and the gravity casting is adopted after spraying fire, the casting temperature is 1070°C, and the casting speed is 1mm / s to prepare alloy ingots.

[0036] During smelting, the covering agent is graphite and glass with a mixing weight ratio of 1.25:1.

[0037] Table 1 High-zinc lead-free brass alloy composition (wt%) of the present invention

[0038]

...

Embodiment 2

[0042] According to the alloy composition described in Table 2, the copper-zinc alloy is smelted first, and the smelting temperature is 1210°C. After it is completely melted, add graphite and copper-titanium intermediate alloy and stir evenly. After standing for 13 minutes, add aluminum, Master alloys of boron, arsenic, iron, manganese, and rare earth elements, wherein aluminum, arsenic, iron, and rare earth elements are added in the form of zinc master alloys, and boron and manganese are added in copper master alloys. In the master alloys, copper or zinc The mass fractions are all 80-90%. Stir and remove slag, and then use gravity casting after spraying fire, the casting temperature is 1080°C, the casting speed is 1.3mm / s, and an alloy ingot with a diameter of 170mm is prepared.

[0043] During smelting, the covering agent is graphite and glass with a mixing weight ratio of 1.50:1.

[0044] Table 2 High-zinc lead-free brass alloy composition (wt%) of the present invention

...

Embodiment 3

[0049] According to the alloy composition described in Table 3, the copper-zinc alloy is smelted first, and the smelting temperature is 1190 ° C. After it is completely melted, add graphite and copper-titanium intermediate alloy and stir evenly. After standing for 14 minutes, add aluminum, Master alloys of boron, arsenic, iron, manganese, and rare earth elements, wherein aluminum, arsenic, iron, and rare earth elements are added in the form of zinc master alloys, and boron and manganese are added in copper master alloys. In the master alloys, copper or zinc The mass fractions are all 80-90%. Stir and remove slag, and then use gravity casting after spraying fire, the casting temperature is 1100°C, and the casting speed is 1.5mm / s to prepare square ingots.

[0050] During smelting, the covering agent is graphite and glass with a mixing weight ratio of 2.2:1.5.

[0051] Table 3 High-zinc lead-free brass alloy composition (wt%) of the present invention

[0052]

[0053] In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com