High-silicon-molybdenum-chromium spheroidal graphite cast iron material for automobile turbine housings and preparation method thereof

A turbine shell and high-silicon-molybdenum technology, which is applied in the field of high-silicon-molybdenum-chromium ductile iron materials for automobile turbine shells and its preparation, can solve poor casting performance, hidden dangers in mass production of castings, and difficult control of spheroidization and inoculation links, etc. Problems, to achieve the effect of reasonable design of process conditions, good machining performance, and beneficial to casting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

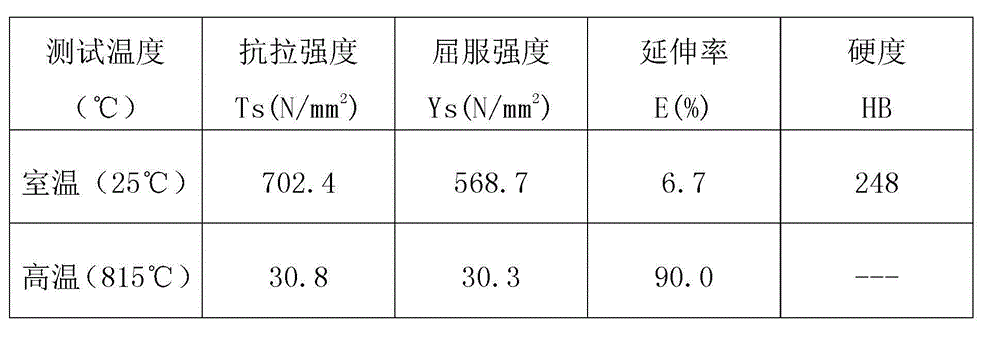

Embodiment 1

[0020] The preparation of the high silicon molybdenum chromium ductile iron material of the present invention includes the following steps:

[0021] 1. The ratio of raw materials (weight percentage) is: pig iron=14%, return material=70%, scrap steel=14.5%, silicon carbide=0.3%, low-sulfur recarburizer=0.1%, ferrosilicon=0.4%, ferromolybdenum =0.3%, ferrochrome =0.4%.

[0022] 2. The smelting equipment adopts an induction electric furnace. Put the above-mentioned weight percentages of silicon carbide, pig iron, return material, and scrap steel into the bottom of the induction furnace in order, and put the above-mentioned weight percentages of low-sulfur recarburizer, ferrosilicon, ferromolybdenum, and ferrochromium into the bottom of the induction furnace. Put it into the storage hopper for use, raise the temperature of the induction electric furnace to make the input materials begin to melt. After the materials in the induction electric furnace are completely melted, add ferrosilic...

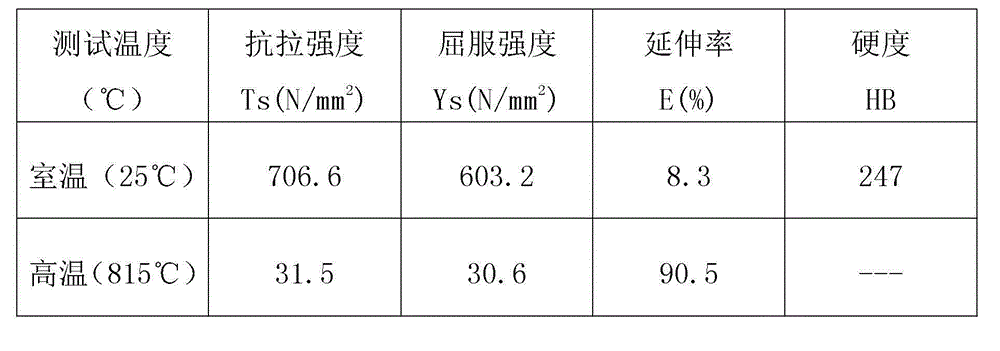

Embodiment 2

[0035] The preparation of the high silicon molybdenum chromium ductile iron material of the present invention includes the following steps:

[0036] 1. The ratio of raw materials (weight percentage) is: pig iron=16%, return material=65%, scrap steel=17%, silicon carbide=0.5%, low-sulfur recarburizer=0.2%, ferrosilicon=0.5%, ferromolybdenum =0.35%, ferrochrome =0.45%;

[0037] 2. The smelting equipment adopts an induction electric furnace. Put the above-mentioned weight percentages of silicon carbide, pig iron, return material, and scrap steel into the bottom of the induction furnace in order, and put the above-mentioned weight percentages of low-sulfur recarburizer, ferrosilicon, ferromolybdenum, and ferrochromium into the bottom of the induction furnace. Put it into the storage hopper for use, raise the temperature of the induction electric furnace, so that the input materials start to melt, and after the materials in the induction electric furnace are completely melted, add ferro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com